Abstract

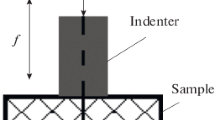

Previous studies have shown the possibility of eddy current monitoring of fatigue degradation during contact loading of austenitic AISI 321 steel. However, AISI 321 steel has insufficiently high contact endurance under cyclic impact loading conditions. Therefore, the application of physical methods for nondestructive testing of fatigue degradation of surface-hardened austenitic AISI 321 steel, which has an increased contact endurance, is of considerable interest. The aim of this work is to investigate the possibility of eddy current testing of fatigue degradation during contact loading of austenitic AISI 321 steel subjected to surface hardening frictional treatment. Mechanical tests for contact gigacycle fatigue were carried out according to the scheme of pulsating impact “plane–plane” contact with ultrasonic loading frequency. It is shown that eddy current monitoring of fatigue degradation during contact loading of surface-hardened AISI 321 steel is possible but has certain limitations due to nonmonotonic changes in the readings \(\alpha \) of the eddy current device depending on the number of loading cycles. At the same time, it is possible to control the development of intensive destruction of the surface layer of steel that is observed under these loading conditions in the range of the number of cycles \(3 \times {{10}^{8}}~\)–\(5 \times {{10}^{8}}\) taking into account the ambiguous nature of the dependences of the eddy current readings on the number of loading cycles in the testing method. The testing can be carried out by measuring the readings of the eddy current device at the eddy-current transducer excitation frequencies \(f = 96- 124\) kHz. In this case, we largely analyze surface layers in which fatigue degradation processes are intensively developing and affecting the physical characteristics of steel. The greatest influence on the value of \(\alpha \) is exerted by plastic deformation and destruction of the steel surface.

Similar content being viewed by others

REFERENCES

Bakunov, A.S., Muzitskii, V.F., and Shubochkin, S.E., A modern solution to problems of eddy-current structuroscopy, Russ. J. Nondestr. Test., 2004, vol. 40, no. 5, pp. 346–349.

Savrai, R.A. and Kogan, L.H., Eddy current testing of fatigue degradation of metastable austenitic steel under gigacycle contact-fatigue loading, Russ. J. Nondestr. Test., 2021, vol. 57, no. 5, pp. 393–400.

Savrai, R.A., Makarov, A.V., Osintseva, A.L., and Malygina, I.Yu., Estimating the contact endurance of the AISI 321 stainless steel under contact gigacycle fatigue tests, J. Mater. Eng. Perform., 2018, vol. 27, no. 2, pp. 601–611.

Tsay, L.W., Liu, Y.C., Lin, D.-Y., and Young, M.C., The use of laser surface-annealed treatment to retard fatigue crack growth of austenitic stainless steel, Mater. Sci. Eng. A, 2004, vol. 384, nos. 1–2, pp. 177–183.

Tokaji, K., Kohyama, K., and Akita, M., Fatigue behaviour and fracture mechanism of a 316 stainless steel hardened by carburizing, Int. J. Fatigue, 2004, vol. 26, pp. 543–551.

Ceschini, L. and Minak, G., Fatigue behaviour of low temperature carburized AISI 316L austenitic stainless steel, Surf. Coat. Technol., 2008, vol. 202, no. 9, pp. 1778–1784.

Stinville, J.C., Villechaise, P., Templier, C., Riviere, J.P., and Drouet, M., Plasma nitriding of 316L austenitic stainless steel: Experimental investigation of fatigue life and surface evolution, Surf. Coat. Technol., 2010, vol. 204, nos. 12–13, pp. 1947–1951.

Kikuchi, S., Nakahara, Y., and Komotori, J., Fatigue properties of gas nitrided austenitic stainless steel pre-treated with fine particle peening, Int. J. Fatigue, 2010, vol. 32, pp. 403–410.

Celik, O., Baydogan, M., Atar, E., Sabri Kayali, E., and Cimenoglu, H., Fatigue performance of low temperature nitrided AISI 321 grade austenitic stainless steel, Mater. Sci. Eng. A, 2013, vol. 565, pp. 38–43.

Hsu, J.-P., Wang, D., Kahn, H., Ernst, F., Michal, G.M., and Heuer, A.H., Fatigue crack growth in interstitially hardened AISI 316L stainless steel, Int. J. Fatigue, 2013, vol. 47, pp. 100–105.

Peng, Y., Liu, Z., Chen, C., Gong, J., and Somers, M.A.J., Effect of low-temperature surface hardening by carburization on the fatigue behavior of AISI 316L austenitic stainless steel, Mater. Sci. Eng. A, 2020, vol. 769, p. 138524.

Muñoz-Cubillos, J., Coronado, J.J., and Rodríguez, S.A., Deep rolling effect on fatigue behavior of austenitic stainless steels, Int. J. Fatigue, 2017, vol. 95, pp. 120–131.

Lei, Y.B., Wang, Z.B., Xu, J.L., and Lu, K., Simultaneous enhancement of stress- and strain-controlled fatigue properties in 316L stainless steel with gradient nanostructure, Acta Mater, 2019, vol. 168, pp. 133–142.

Spadaro, L., Hereñú, S., Strubbia, R., Gómez Rosas, G., Bolmaro, R., and Rubio González, C., Effects of laser shock processing and shot peening on 253 MA austenitic stainless steel and their consequences on fatigue properties, Opt. Laser Technol., 2020, vol. 122, p. 105892.

Carneiro, L., Wang, X., and Jiang, Y., Cyclic deformation and fatigue behavior of 316L stainless steel processed by surface mechanical rolling treatment, Int. J. Fatigue, 2020, vol. 134, p. 105469.

Ho, H.S., Zhou, W.L., Li, Y., Liu, K.K., and Zhang, E., Low-cycle fatigue behavior of austenitic stainless steels with gradient structured surface layer, Int. J. Fatigue, 2020, vol. 134, p. 105481.

Yang, S., Zeng, W., and Yang, J., Characterization of shot peening properties and modelling on the fatigue performance of 304 austenitic stainless steel, Int. J. Fatigue, 2020, vol. 137, p. 105621.

Walvekar, A.A. and Sadeghi, F., Rolling contact fatigue of case carburized steels, Int. J. Fatigue, 2017, vol. 95, pp. 264–281.

Li, W. and Liu, B., Experimental investigation on the effect of shot peening on contact fatigue strength for carburized and quenched gears, Int. J. Fatigue, 2018, vol. 106, pp. 103–113.

Cao, Z., Liu, T., Yu, F., Cao, W., Zhang, X., and Weng, Y., Carburization induced extra-long rolling contact fatigue life of high carbon bearing steel, Int. J. Fatigue, 2020, vol. 131, p. 105351.

Paladugu, M. and Scott Hyde, R., Material composition and heat treatment related influences in resisting rolling contact fatigue under WEC damage conditions, Int. J. Fatigue, 2020, vol. 134, p. 105476.

Savrai, R.A. and Osintseva, A.L., Effect of hardened surface layer obtained by frictional treatment on the contact endurance of the AISI 321 stainless steel under contact gigacycle fatigue tests, Mater. Sci. Eng. A, 2021, vol. 802, p. 140679.

Savrai, R.A., Makarov, A.V., Malygina, I.Yu., Rogovaya, S.A., and Osintseva, A.L., Improving the strength of the AISI 321 austenitic stainless steel by frictional treatment, Diagn. Res. Mech. Mater. Struct., 2017, no. 5, pp. 43–62. https://doi.org/10.17804/2410-9908.2017.5.043-062

Deng, S.Q., Godfrey, A., Liu, W., and Zhang, C.L., Microstructural evolution of pure copper subjected to friction sliding deformation at room temperature, Mater. Sci. Eng. A, 2015, vol. 639, pp. 448–455.

Narkevich, N.A., Shulepov, I.A., and Mironov, Yu.P., Structure, mechanical, and tribotechnical properties of an austenitic nitrogen steel after frictional treatment, Phys. Metal. Metal., 2017, vol. 118, no. 4, pp. 399–406.

Savrai, R.A., Makarov, A.V., Malygina, I.Yu., and Volkova, E.G., Effect of nanostructuring frictional treatment on the properties of high-carbon pearlitic steel. Part I: microstructure and surface properties, Mater. Sci. Eng. A, 2018, vol. 734, pp. 506–512.

Savrai, R.A. and Makarov, A.V., RF Patent no. 162959, 2016.

Dorofeev, A.L., Induktsionnaya strukturoskopiya (Induction Structroscopy), Moscow: Energiya, 1973.

Makarov, A.V., Savrai, R.A., Gorkunov, E.S., Malygina, I.Y., Pozdejeva, N.A., Kolobylin, Y.M., and Kogan, L.K., Effect of friction-induced hardening on the features of magnetic and eddy-current behavior of an annealed structural steel under cyclic loading conditions, Russ. J. Nondestr. Test., 2008, vol. 44, no. 7, pp. 496–508.

Dyakin, V.V. and Sandovskii, V.A., Teoriya i raschet vikhretokovykh preobrazovatelei (Theory and Calculation of Attached Eddy Current Transducers), Moscow: Nauka, 1981.

Mikheev, M.N. and Gorkunov, E.S., Magnitnye metody strukturnogo analiza i nerazrushayushchego kontrolya (Magnetic Methods of Structural Analysis and Nondestructive Testing), Moscow: Nauka, 1993.

Jiles, D.C., The effect of compressive plastic deformation on the magnetic properties of AISI 4130 steels with various microstructures, J. Phys. D, 1988, vol. 21, no. 7, pp. 1196–1204.

Makarov, A.V., Gorkunov, E.S., Savrai, R.A., Kolobylin, Y.M., Malygina, I.Y., Davydova, N.A., Kogan, L.K., and Yurovskikh, A.S., The influence of a combined strain-heat treatment on the features of electromagnetic testing of fatigue degradation of quenched constructional steel, Russ. J. Nondestr. Test., 2013, vol. 49, no. 12, pp. 690–704.

ACKNOWLEDGMENTS

The authors express their gratitude to Yu.M. Kolobylin for his participation in experimental studies.

Funding

The work was carried out within the framework of the state tasks for the Institute of Engineering Science of the Ural Branch of the Russian Academy of Sciences (IES UB RAS) on topic no. AAAA18-118020790147-4 and Mikheev Institute of Metal Physics of the Ural Branch of the Russian Academy of Sciences on the topic “Diagnostics,” no. AAAA18-118020690196-3. Electronic scanning microscopy and mechanical tests were performed at the Common Use “Plastometry” at the IES UB RAS.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Savrai, R.A., Kogan, L.K. Effect of Hardening Frictional Treatment on Features of Eddy Current Testing of Fatigue Degradation of Metastable Austenitic Steel under Gigacycle Contact Fatigue Loading. Russ J Nondestruct Test 58, 722–731 (2022). https://doi.org/10.1134/S1061830922080095

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830922080095