Abstract

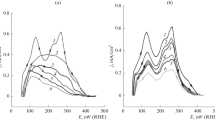

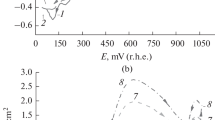

Some features of processes occurring during the polarization of smooth platinum electrode in 10.0 M methanesulfonic acid (CH3SO3H) solution at high anodic potentials are studied by the cyclic voltammetry method. On cyclic voltammograms of smooth platinum electrode in concentrated methanesulfonic acid solution, well-pronounced oxidation waves are observed at potentials E = 2.0–2.5 V and E = 2.9–3.7 V. The electrochemical processes occurring in 10 M CH3SO3H solution within the E = 2.0–2.5 V potential range are shown to be associated with discharge of water molecules; the broad oxidation wave within the potential range of E = 2.9–3.7 V is related to the formation of peroxide compounds. Based on the electrochemical measurements and analysis of products of preparative electrooxidative electrolysis, the formation of a complex organosulfur peroxide compound, bis(methanesulfonyl) peroxide CH3S(O)2OOS(O)2CH3 (other names: dimethyl disulfoperoxide, or dimethanesulfonyl peroxide, or dimesylate peroxide) is established. Anodic oxidation mechanism in concentrated CH3SO3H solutions is proposed. It is supposed that the formation of the peroxide compound is associated with the participation of mesylate-radicals that dimerize at the smooth platinum anode and then are desorbed into the solution bulk.

Similar content being viewed by others

REFERENCES

Gernon, M.D., Wu, M., Buszta, T., and Jaimey, P., Environmental benefits of methane sulfonic acid. Comparative properties and advantages, Green Chem., 1999, vol. 1, no. 3, p. 127.https://doi.org/10.1039/a900157c

Danilov, F.I., Sknar, I.V., and Sknar, Yu.E., Kinetics of nickel electroplating from methanesulfonate electrolyte, Russ. J. Electrochem., 2011, vol. 47, no. 9, p. 1035. https://doi.org/10.1134/S1023193511090114

Danilov, F.I., Butyrina, T.E., Protsenko, V.S., and Vasil’eva, E.A., Oxidation of Sn(II) in methanesulfonate electrolytes in presence of antioxidants, Russ. J. Appl. Chem., 2010, vol. 83, no.4, p. 752. https://doi.org/10.1134/S1070427210040348

Bengoa, L.N., Pary, P., Conconi, M.S., and Egli, W.A., Electrodeposition of Cu-Sn alloys from a methanesulfonic acid electrolyte containing benzyl alcohol, Electrochim. Acta, 2017. vol. 256. p. 211. https://doi.org/10.1016/j.electacta.2017.10.027

Velichenlco, A.B., Gruzdeva, E.V., Lukyanenko, T.V., Danilov, F.I., and Amadelli, R., Electrodeposition of lead dioxide from methanesulfonate solutions, J. Power Sources, 2009, vol. 191, no. 1, p. 103.https://doi.org/10.1016/j.jpowsour.2008.10.054

Comisso, N., Cattarin, S., Guerriero, P., Mattarozzi, L., Musiani, M., and Verlato, E., Electrochemical behavior of porous Pb02 layers prepared by oxygen bubble templated anodic deposition, Electrochim. Acta, 2016, vol. 200, p. 259. https://doi.org/10.1016/j.electacta.2016.03.184

Protsenko, V.S., Kityk, A.A., and Danilov, F.I., Kinetics and mechanism of chromium electrodeposition from methanesulfonate solutions of Cr (III) salts, Surf. Eng. Appl Electrochem., 2014, vol. 50, no. 5, p. 384. https://doi.org/10.3103/S106837551405007X

Walsh, F.C. and Ponce de Leon, C., Versatile electrochemical coatings and surface layers from aqueous methanesulfonic acid, Surf. Coat. Technol. 2014, vol. 259, p. 676. https://doi.org/10.1016/j.surfcoat.2014.10.010

Hasan, M. and Rohan, J.F., Cu Electrodeposition from Methanesulfonate Electrolytes for ULSI and MEMS Applications, J. Electrochem. Soc., 2010, vol. 157, no. 5, p. 278. https://doi.org/10.1149/1.3332729

Shahin, G.E., Electroless nickel plating solutions. Pat. US20030232148A1 (USA). 2002.

Srinivasan, K.N. and John, S., Electroless nickel deposition from methane sulfonate bath, J. Alloys Compd. 2009, vol.486, no. 3, p.447. https://doi.org/10.1016/j.jallcom.2009.06.178

Huttunen-Saarivirta, E., Observations on the uniformity of immersion tin coatings on copper Surf. Coat. Technol., 2002, vol. 160, no. 3, p. 288. https://doi.org/10.1016/S0257-8972(02)00412-7

Bengoa, L.N., Tuckart, W.R., Zabala, N., Prieto, G., and Egli, W.A., Tin Coatings Electrodeposited from Sulfonic Acid-Based Electrolytes: Tribological Behavior, J. Mater. Eng. Perform., 2015, vol. 24, no. 6, p.2274. https://doi.org/10.1007/s11665-015-1503-4

Low, C.T.J. and Walsh, F.C., The influence of a perfluorinated cationic surfactant on the electrodeposition of tin from a methanesulfonic acid bath, J. Electroanal. Chem., 2008, vol. 615, p. 91. https://doi.org/10.1016/j.jelechem.2007.11.031

Walsh, F.C. and Ponce de Leon, C., A review of the electrodeposition of metal matrix composite coatings by inclusion of particles in a metal layer: an established and diversifying technology, Trans. IMF, 2014, vol. 92, no. 2, p. 83. https://doi.org/10.1179/0020296713Z.000000000161

Low, C.T.J., Kerr, C., Ponce-de-Leon, C., and Walsh, F.C., Electrodeposition: Properties, Processes and Applications, New York: Nova Publishers, 2012, p. 283–296.

Mollamahaleh, Y.B., Hosseini, D. Mazaheri, M., and Sadrnezhaad, S.K., Surfactant-Free Production of Ni-Based Nanostructures, Mater. Sci. Appl., 2011, vol. 2, p. 444. https://doi.org/10.4236/msa.2011.25059

Li, Q., Feng, Z., Liu, L., Sun, J., Qu, Li, Y.F., and An, M., Research on the tribological behavior of a nanocrystalline zinc coating prepared by pulse reverse electrodeposition, RSC Adv., 2015, vol. 5, p. 12025. https://doi.org/10.1039/c4ra13691h

Tsunoda, K. and Tamura, T., Tetravalent tin salt of metastaimic acid and a trivalent indium salt of an organosulfonic acid, chelating agent, a caustic alkali; cyanide free smootlmess. Pat. US6331240B1 (USA), 2001.

Zanella, C., Xing, S., and Deflorian F., Effect of electrodeposition parameters on chemical and morphological characteristics of Cu-Sn coatings from a methanesulfonic acid electrolyte, Surf. Coat. Technol., 2013, vol. 236, p. 394. https://doi.org/10.1016/j.surfcoat.2013.10.020

Low, C.T.J., Kerr, C., and Walsh, F.C., Electrodeposition of tin, copper and tin-copper alloys from a methanesulfonic acid electrolyte containing a perfluorinated cationic surfactant, Surf. Coat. Technol., 2008, vol. 202, no. 8, p. 1339. https://doi.org/10.1016/j.surfcoat.2007.06.032

Pewnim, N. and Roy, S., Electrodeposition of tin-rich Cu-Sn alloys from a methanesulfonic acid electrolyte, Electrochim. Acta, 2013, vol. 90, p. 498. https://doi.org/10.1016/j.electacta.2012.12.053

Konetzki, R.A., Chang, Y.A. and Marcotte, V.C., Oxidation kinetics of Pb-Sn alloys, J. Mater. Res., 2011, vol. 4, no. 6, p. 1421. https://doi.org/10.1557/JMR.1989.1421

Goh, Y., Flaseeb, A.S.M.A., Faizul, M., and Sabri, M., Effects of hydroquinone and gelatin on the electrodeposition of Sn-Bi low temperature Pb-free solder, Electrochim. Acta, 2013, vol. 90, p. 265. https://doi.org/10.1016/j.electacta.2012.12.036

Yalcymovych, A. and Ipser, H., Synthesis and characterization of pure Ni and Ni-Sn intermetallic nanoparticles, Nanoscale Res. Lett., 2017, vol. 12, no. 1, p. 142. https://doi.org/10.1186/s11671-017-1894-2

Zhang, Z., Nenoff, T.M., Leung, K., Ferreira, S.-R., et al., Room-temperature synthesis of Ag–Ni and Pd–Ni Alloy Nanoparticles, J. Phys. Chem. C, 2010, vol. 114, no. 34, p. 14309.https://doi.org/10.1021/jp911947v

Danilov, F.I., Protsenko, V.S., Vasil’eva, E.A., and Kabat, O.S., Antifriction coatings of Pb- Sn-Cu alloy electro-deposited from methanesulphonate bath, Trans. IMF, 2011, vol. 89, no. 3, p. 151. https://doi.org/10.1179/174591911X12977017699347

Nogita, K., Gourlay, C.M., and Nishimura, T., Cracking and phase stability in reaction layers between Sn-Cu–Ni solders and Cu substrates, JOM, 2009, vol. 61, no. 6, p. 45. https://doi.org/10.1007/s11837-009-0087-6

Walsh, F.C. and Ponce de Leon, C., A review of the electrodeposition of metal matrix composite coatings by inclusion of particles in a metal layer: An established and diversifying technology, Trans. IMF, 2014, vol. 92, no. 2, p. 83. https://doi.org/10.1179/0020296713Z.000000000161

Sun, X.J. and Li, J.G., Friction and wear properties of electrodeposited nickel-titania nanocomposite coatings, Tribol. Lett., 2007, vol. 28, p. 223. https://doi.org/10.1007/s11249-007-9254-5

Caramia, V., Walsh, F.C. Ponce de Leon, C., and Low, C.T.J., Anodic deposition of compact, freely-standing or microporons polypyrroie films from aqueons methanesuiphonic acid, Trans. IMF, 2015, vol. 93, no. 3, p. 139. https://doi.org/10.1179/0020296714Z.000000000203

Sanglee, K., Chuangchote, S., Chaiwiwatworakul, P., and Kumnorkaew, P., PEDOT:PSS Nanofilms Fabricated by a Nonconventional Coating Method for Uses as Transparent Conducting Electrodes in Flexible Electrochromic Devices, J. Nanomater., 2017, vol. 4, p. l. https://doi.org/10.1155/2017/5176481

Tan, L.S., Simlco, S.R., Bal, S.J., Vaia, R.A., et al., Phase of separated, conducting composites from polyaniline and benzobisthiazole rigid of rod polymer, J. Polym. Sci. B Polym. Phys., 2001, vol. 39, p. 2539. https://doi.org/10.1002/polb.1224

Yasushi, A.K., Suzuki, T. T., and Kobata, T.S. Electrolytic liquid for electrolytic polishing and electrolytic polishing method. Patent US20080067077A1 (USA). 2008.

Jing, N., Riddle, J. A., Yu, Z., Xiong, M., Wang, Z., Chu, Y., Pan, R., Tiers, G.V.D., and Brown, K.A., Coating composition and method of making and using the same, Pat. 9944822B2 (USA), 2013.

Helle, K. and Walsh, F.C., Electrodeposition of composite layers consisting of inert inclusions in a metal matrix, Trans. IMF, 1997, vol. 75, p. 53. https://doi.org/10.1080/00202967.1997.11871143

Bicelli, L.P., Bozzini, Mele, B.C., and D’Urzo, L., A review of nanostructural aspects of metal electrodeposition, Int. J. Electrochem. Soc., 2008, vol. 3, no. 4, p. 356.

Vasil’eva, E.A., Semenova, I.V., Protsenko, V.S., Konstantinova, T.E., and Danilov, F.I., Electrodeposition of hard iron-zirconia dioxide composite coatings from a methanesulfonate electrolyte, Russ. J. Appl. Chem., 2013, vol. 86, no. 11, p. l735. https://doi.org/10.1134/S1070427213110177

Low, C.T.J., de la Toba Corral, M., and Walsh, F.C. Anodising of titanium in methanesulphonic acid to form titanium dioxide nanotube arrays, Trans. IMF, 2011, vol. 89, no. l, p. 44. https://doi.org/10.1179/174591911X12953503084903

Lee, K., Kim, D., Berger, S., Kirchgeorg, R., and Schmuki, P., Anodically formed transparent mesoporous TiO2 electrodes for high electrochromic contrast, J. Mater. Chem., 2012, vol. 22, no. 19, p. 9821. https://doi.org/10.1039/c2jm31244a

Couper, A.M., Pletcher, D., and Walsh, F.C., Electrode materials for electrosynthesis, Chem. Rev., 1990, vol. 90, no. 5, p. 837. https://doi.org/10.1021/cr00103a010

Li, X., Pletcher, D., and Walsh, F.C., Electrodeposited lead dioxide coatings, Chem. Soc. Rev. 2011, vol. 40, no. 7, p. 3879. https://doi.org/10.1039/c0cs00213e

Ambika, C., Flirankumar, G., Thanikaikarasan, S., Lee, K.K., Valenzuela, E., and Sebastian, P.J., Influence of TiO2 as filler on the discharge characteristics of a proton battery. J. New Mater. Electrochem. Syst., 2015, vol. 18, no. 4, p. 219.https://doi.org/10.14447/jnmes.v18i4.351

Arenas, L.F., Walsh, F.C., and Ponce de Leon, C., The Importance of Cell Geometry and Electrolyte Properties to the Cell Potential of Zn-Ce Hybrid Flow Batteries, J. Electrochem. Soc., 2016, vol. 163, no. 1, p. A5170. https://doi.org/10.1149/2.0261601jes

Dong, J, Wu, X., Chen, Y., Brandon, N., Li, X., Yang, J., et al., A study on Pb2+/Pb electrodes for soluble lead redox flow cells prepared with methanesulfonic acid and recycled lead, J. Appl. Electrochem., 2016, vol. 46, no. 8, p. 861. https://doi.org/10.1007/s10800-016-0980-y

Govindan, M., He, K., and Moon, I.S., Evaluation of dual electrochemical cell design for cerium-vanadium redox flow battery to use different combination of electrodes, Int. J. Electrochem. Sci., 2013, vol. 8, no. 6, p. 10265.

Kulova, T.L. and Skundin, A.M., High-voltage materials for positive electrodes of lithium ion batteries (review), Russ. J. Electrochem., 2016, vol. 52, no. 6, p. 501.https://doi.org/10.1134/S1023193516060070

Lutropur methanesulfonic acid—the friendly acid. The purest form of methanesulfonic acid methanesulfonic acid made by BASF, BASF report, 2011. https://goo-gl.ru/5jUq

Akmedov, M.A. and Khidirov, Sh.Sh., Voltametric determination of the composition and properties of methane sulfonic acid, J. Struct. Chem., 2014, vol. 55, no. 6, p. 1148. https://doi.org/10.1134/S0022476614060249

O’Reilly, M.E., Kim, R.S., Oh, S., and Surendranath, Y., Catalytic Methane Monofunctionalization by an Electrogenerated High-Valent Pd Intermediate, ACS Cent. Sci., 2017, vol. 3, no. 11, p. 1174. https://doi.org/10.1021/acscentsci.7b00342

Akhmedov, M.A., Khidirov, Sh. Sh., Koparova, M.Y., and Kliibiev, Kh. S., Electrochemical synthesis of methanesulfonic acid from aqueous solutions of dimethylsulfone, Izv. Vyssh. Uchebn. Zaved. Khim. Khim. Tekhnol., 2016, vol. 59, no. 12, p. 100. https://doi.org/10.6060/tcct.20165912.5345

Khidirov, Sh.Sh., Akhmedov, M.A., Kliibiev, Kli.S., and Akhmedov, Sh.V., Electrochemical modification of cellulose, Bulletin DSU (in Russian), 2015, no. 6, p. 191.

Khidirov, Sh.Sh., Kliibiev, K.S., and Akhmedov, M.A., Electrochemical Synthesis of Cellulose Mesylates, Pharmaceutical Chem. J., 2017, vol. 50, no. 12, p. 817. https://doi.org/10.1007/s11094-017-1539-x

Petrii, O.A., Zero charge potentials of platinum metals and electron work functions (Review), Russ. J. Electrochem., 2013, vol. 49, no. 5, p. 401. https://doi.org/10.1134/S1023193513050145

Damaskin, B.B., Petrii, O.A., and Tsirlina, G.A., Electrochemistry (in Russian), Moscow: Lan, 2008.

Komarova, N.V. and Kamentsev, Ya.S., A Practical Guide to the Use of Capillary Electrophoresis Systems “Kapel” (in Russian), St. Petersburg: Veda, 2006, 212 p.

P 4.2.2643-10 The Methods for laboratory testing and testing of disinfectants for their effectiveness and safety: Management (in Russian), Moscow: FCH and E. Rospotrebnadzor, 2010, p. 34, 35.

Tomilov, A.P., Mayranovskii, S.G., Fioshin, M.Ya., and Smirnov, V.A., Elecirochemistiy of Organic Compounds (in Russian), Moscow: Khimiya, 1968, p. 54.

Zhuravlev, A. I. and Trostnikov, V.N., Glow of Living Tissues (in Russian), Moscow: Nauka, 1966.

Chackalackal, S.M. and Stafford, F.E., Infrared Spectra of Methane-, Fluoro-, and Chlorosulfonic Acids, JACS, 1966, vol. 88, no. 21, p. 4815–1819. https://doi.org/10.1021/ja00973a010

Pentin, Yu.A. and Kuramshina, G.M., The fundamentals of molecular spectroscopy (in Russian), Moscow: Mir, 2008.

Zeng, X., Beckers, H., Willner, FI., and Lehmann, C.W., Bis(methanesulfonyl) Peroxide, CH3S(O)2OOS(O)2CH3: Spectroscopic, Structural, and Thermal Properties, Z. Anorg. Allg. Chem., 2010, vol. 636, no. 13–14, p. 2447. https://doi.org/10.1002/zaac.201000184

Zhu, B., Zeng, X., Beckers, FI., Francisco, J.S., and Willner, H., The Methylsulfonyloxyl Radical, CH3SO3, Angew. Chem. Int. Ed., 2015, vol. 54, no. 39, p. 11404. https://doi.org/10.1002/anie.201503776

Korth, H.G., Neville, A.G., and Lusztyk, J., Direct spectroscopic detection of sulfonyloxyl radicals and first measurements of their absolute reactivities, J. Phys. Chem., 1990, vol. 94, no. 25, p. 8835. https://doi.org/10.1021/j100388a017

Haszeldine, R.N., Heslop, R.B., and Lethbridge, J.W., The properties and reactions of dimethanesulphonyl peroxide, J. Chem. Soc., 1964, p. 4901. https://doi.org/10.1039/jr9640004901

Applied Electrochemistry, (in Russian), 2nd Edition, Moscow: Khimiya, 1975.

Hawkins, E.G.E., Organic Peroxides: Their Formation and Reactions, London: Spon, 1961.

Yablonsky, O.P., Belyaev, V.A., and Vinogradov, A.N. Association of Hydroperoxides of Hydrocarbons, Russ. Chem. Rev., 1972, vol. 61, no. 7, p. 1260.

Antonovskii, V.L. and Khursan, S.L., Physical Chemistry of Organic Peroxides (in Russian), Moscow: Akademkniga, 2003.

Carlos, G., Comiran, E., de Oliveira, M.H., Limberger, R.P., Bergold, A.M., and Froehlich, P.E., Development, validation and comparison of two stability-indicating RP-LC methods using charged aerosol and UV detectors for analysis of lisdexamfetamine dimesylate in capsules, Arab. J. Chem., 2016, vol. 9, no. 12, p. 1905. https://doi.org/10.1016/j.arabjc.2015.06.001

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Yu. Pleskov

Based on the paper presented at the XIV Meeting “Fundamental Problems of Solid State Ionics,” Chernogolovka (Russia), September 9–13, 2018.

Supplementary materials are available for this article https://doi.org/10.1134/S1023193519060028 and are accessible for authorized users.

Rights and permissions

About this article

Cite this article

Akhmedov, M.A., Khidirov, S.S. Anodic Processes at Smooth Platinum Electrode in Concentrated Solution of Methanesulfonic Acid. Russ J Electrochem 55, 579–589 (2019). https://doi.org/10.1134/S1023193519060028

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193519060028