Abstract

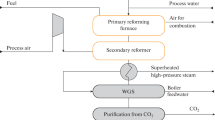

The Russian Federation has large gas resources, and an increase in the share of their chemical processing is a topical problem, solution of which involves many scientific teams. This paper describes innovative achievements of the author and his colleagues in developing highly efficient catalysts for methane conversion into ethylene and synthesis gas—key large-tonnage semiproducts of the chemical industry. The prospects of creating corresponding technologies and their practical implementation are discussed. In particular, for the most active catalysts of ethylene production, technical conditions and a production technology have been developed and introduced at the Baltic Enterprise (Baltiiskaya Manufaktura) research and production company. Within the framework of cooperation with the Gazprom public joint-stock company, technical conditions for catalysts for synthesis gas production have been developed and approved, mathematical modeling has been conducted, and options of reactor units and a process flowsheet have been proposed.

Similar content being viewed by others

References

P. G. Tsybul’skii, Report at the Gubkin Russian State Oil and Gas University (presentation) (Moscow, 2011) [in Russian].

BP Statistical Review of World Energy 2012.

BP Statistical Review of World Energy 2015.

http://www.interfax.ru/russia/416576. Cited March 25, 2016.

S. Cornot-Gandolphe, The Impact of the Development of Shale Gas in the United States on Europe’s Petrochemical Industries (IFRI Centre Energie, 2013).

T. Khazova, “Oil and gas chemistry: A strategic kick,” Neftegaz.ru, No. 4, 34 (2013). http://www.allianceanalytics.ru/upload/iblock/fc7/aliyans.pdf. Cited March 25, 2016.

E.A.Golysheva, http://www.alliance-analytics.ru/upload/iblock/2de/3.%20Golysheva%20E.A.pdf. Cited March 25, 2016.

E. Atepaeva, “US and Chinese capacities to produce ethylene,” Neftegazovaya Vertikal’, No. 23, 24 (2014). http://www.ngv.ru/news/globaldata_moshchnosti_po_proizvodstvu_etilena_ssha_i_kitaya/?sphrase_id=294671. Cited March 25, 2016.

A.G.Dedov, V.A.Ketsko, T.N.Kol’tsova, et al., RF Patent no. 2341507, Byull. Izobret., no. 35 (2008).

A. G. Dedov, G. D. Nipan, A. S. Loktev, et al., “Oxidative coupling of methane: Influence of the phase composition of silica-based catalysts,” Applied Catalysis A: General 406, 1 (2011).

G. D. Nipan, A. G. Dedov, A. S. Loktev, et al., “SiO2based composites in the catalysis of methane oxidative coupling: Role of phase composition,” Dokl. Phys. Chem. 419 (2), 73 (2008).

B. Vora, J. Q. Chen, A. Bozzano, et al., “Various routes to methane utilization—SAPO-34 catalysis offers the best option,” Catalysis Today 141, 77 (2009).

A. G. Dedov, V. A. Makhlin, M. V. Podlesnaya, et al., “Kinetics, mathematical modeling, and optimization of the oxidative coupling of methane over a LiMnW/SiO2 catalyst,” Theor. Found. Chem. Eng. 44 (1), 1 (2010).

A. A. Tyunyaev, G. D. Nipan, T. N. Kol’tsova, et al., “Polymorphic Mn/W/Na(K,Rb,Cs)/SiO2 catalysts for oxidative coupling of methane,” Russ. J. Inorg. Chem. 54 (5), 664 (2009).

A. G. Dedov, A. S. Loktev, G. D. Nipan, et al., “Oxidative coupling of methane to form ethylene: Effect of the preparation method on the phase composition and catalytic properties of Li–W–Mn–O–SiO2 composite materials,” Pet. Chem. 55 (2), 163 (2015).

http://blog.propurchaser.com/2015/ethylene-december-low.Cited March 25, 2016.

A.Larionova, http://www.mrcplast.ru/newsnews_open-301084.html. Cited March 25, 2016.

http://expert.ru/2014/07/10/vzglyad-v-buduschee. Cited March 25, 2016.

A. G. Dedov, A. S. Loktev, D. A. Komissarenko, et al., “Partial oxidation of methane to produce syngas over a neodymium-calcium cobaltate-based catalyst,” Applied Catalysis A: General 489, 140 (2015).

A. G. Dedov, A. S. Loktev, D. A. Komissarenko, et al., “New selective catalysts of oxidative conversion of methane to synthesis gas,” Dokl. Phys. Chem. 441 (2), 233 (2011).

A. G. Dedov, A. S. Loktev, G. N. Mazo, et al., “Highperformance catalytic materials for dry reforming of methane,” Dokl. Phys. Chem. 462 (1), 99 (2015).

G. N. Mazo, L. M. Kolchina, N. V. Lyskov, et al., “Features of high-temperature behavior in NdCaCoO4—the catalyst of the partial oxidation of methane to syngas,” Russ. J. Phys. Chem. 87 (12), 1976 (2013).

A. G. Dedov, A. S. Loktev, I. E. Mukhin, et al., “Selective oxidation of methane to synthesis gas: Cobaltand nickel-based catalysts,” Dokl. Phys. Chem. 461 (2), 73 (2015).

T. N. Gartman, F. S. Sovetin, E. A. Borovkova, et al., “Producing synthesis gas by oxidative coupling of methane in the presence of a NdCaCoO4-based catalyst: Kinetic modeling of an autothermal process,” Neftekhimiya 55 (4), 302 (2015).

A. G. Dedov, E. S. Lobakova, P. B. Kashcheeva, et al., “New biocomposite materials based on fibrous polymeric matrices,” Dokl. Akad. Nauk 462 (4), 435 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.G. Dedov, 2016, published in Vestnik Rossiiskoi Akademii Nauk, 2016, Vol. 86, No. 5, pp. 396–405.

RAS Corresponding Member Aleksey Georgievich Dedov is Chairman of the Department of General and Inorganic Chemistry at the Gubkin Russian State Oil and Gas University.

Rights and permissions

About this article

Cite this article

Dedov, A.G. Materials and technologies for gas feedstock processing: Challenges, prospects, and solutions. Her. Russ. Acad. Sci. 86, 234–241 (2016). https://doi.org/10.1134/S1019331616030023

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1019331616030023