Abstract

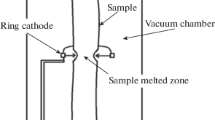

The elemental, phase, and structural state of Nb–Mo–C alloys with equiatomic metal contents and 15, 20, 25, and 30 at % C are studied after electron-beam zone melting. In the alloy containing 15 at %, a fine microstructure, which is typical of eutectic alloys, forms; as the carbon content increases, primary carbide crystals appear in the alloy structure. The main carbide phase in all alloys is found to be an NbC-based carbide rather than an Nb2C-based carbide. The component distribution between the phases is studied as a function of the average alloy composition. The results of short-time strength tests of alloy specimens at room temperature and at 1500°C and also their high-temperature bending creep tests are presented. The 100-h creep strength maximum for the alloys is shown to be 200–300 MPa at 1500°C (\(\sigma _{{100}}^{{1500}}\) = 200–300 MPa).

Similar content being viewed by others

REFERENCES

S. J. Balsone, B. P. Bewlay, M. R. Jackson, P. R. Subramanian, J. C. Zhao, A. Chatterjee, and T. M. Heffernan, “Materials beyond superalloy-exploiting high-temperature composites,” in Structural Intermetallics (Miner., Metals Mater. Soc. AIME, 2001), pp. 99–108.

T. M. Pollock, “Alloy design for aircraft engines,” Nat. Mater. 15 (8), 809–815 (2016).

I. L. Svetlov, M. I. Karpov, T. S. Stroganova, D. V. Zaitsev, and Yu. Artemenko, “High-temperature creep in situ Nb–Si composites,” Deform. Razrushenie Mater., No. 11, 2–6 (2019).

I. L. Svetlov, M. I. Karpov, A. V. Neuman, and T. S. Stroganova, “Temperature dependence of the ultimate strength of in situ multicomponent Mb–Si–X (X = Ti, Hf, W, Cr, Al, and Mo) composites,” Deform. Razrushenie Mater., No. 10, 17–22 (2017).

S. Miura, M. Aoki, Y. Saeki, K. Ohkubo, T. Mohri, and Y. Mishima, “Effects of Zr on the eutectoid decomposition behavior of Nb3Si into (Nb)/Nb5Si3,” Met. Mater. Trans. A 36 (3), 489–496 (2005).

K. Chattopadhyay, R. Sinha, R. Mitra, and K. K. Ray, “Effect of Mo and Si on morphology and volume fraction of eutectic in Nb–Si–Mo alloys,” Mater. Sci. Eng. A 456 (1–2), 358–363 (2007).

K. S. Chan and D. L. Davidson, “Improving the fracture toughness of constituent phases and Nb-based in situ composites by a computational alloy design approach,” Met. Mater. Trans. A 34 (9), 1833–1849 (2003).

J. Sha, H. Hirai, T. Tabaru, A. Kitahara, H. Ueno, and S. Hanada, “High-temperature strength and room-temperature toughness of Nb–W–Si–B alloys prepared by arc melting,” Mater. Sci. Eng. A 364 (1–2), 151–158 (2004).

C. L. Ma, J. G. Li, Y. Tan, R. Tanaka, and S. Hanada, “Microstructure and mechanical properties of Nb/Nb5Si3 in situ composites in Nb–Mo–Si and Nb–W–Si systems,” Mater. Sci. Eng. A 386 (1–2), 375–383 (2004).

Q. Wang, C. Zhou, and S. Wang, “Effect of Zr and Hf additions on microstructure and mechanical properties of Nb–Si based ultrahigh-temperature alloys,” J. Mater. Res. Technol. 9 (6), 15585–15592 (2020).

R. Ma and X. P. Guo, “Effects of V addition on the microstructure and properties of multielemental Nb–Si based ultrahigh-temperature alloys,” J. Alloys Compd. 845, 156254 (2020).

R. Ma and X. P. Guo, “Influence of molybdenum content on the microstructure, mechanical properties, and oxidation behavior of multi-elemental Nb–Si based ultrahigh-temperature alloys,” Intermetallics 129, 107053 (2021).

J. Geng and P. Tsakiropoulos, “A study of the microstructures and oxidation of Nb–Si–Cr–Al–Mo in situ composites alloyed with Ti, Hf, and Sn,” Intermetallics 15 (3), 382–395 (2007).

R. Ding, I. P. Jones, and H. Jiao, “Effect of Mo and Hf on the mechanical properties and microstructure of Nb–Ti–C alloys,” Mater. Sci. Eng. A 458 (1–2), 126–135 (2007).

R. Ding, H. Jiao, and I. P. Jones, “Effect of Mo on mechanical properties and microstructure of Nb–Ti–C alloys,” Mater. Sci. Eng. A 483–484 (1–2), 199–202 (2008).

X. Zhang, X. He, C. Fan, Y. Li, G. Song, Y. Sun, and J. Huang, “Microstructural and mechanical characterization of multiphase Nb-based composites from Nb–Ti–C–B system,” Intern. J. Refract. Metals Hard Mater. 41, 185–190 (2013).

Y. Tan, C. L. Ma, A. Kasama, R. Tanaka, Y. Mishima, S. Hanada, and J. M. Jang, “Effect of alloy composition on microstructure and high-temperature properties of Nb–Zr–C ternary alloys,” Mater. Sci. Eng. A 341 (1–2), 282–288 (2003).

Z. W. Shi, J. L. Liu, and H. Wei, “Investigation on the microstructure and mechanical behaviors of a laser formed Nb–Ti–Al alloy,” Mater. Char. 162, 110193 (2020).

W. Wei, J. Sun, S. Zhang, B. liu, K. Yan, J. Qi, and H. Zhang, “Phase precipitation behavior and mechanical properties of multiphase Nb–Ti–C and Nb–Ti–Al—C,” Mater. Sci. Eng. A 815, 141218 (2021).

Q. Wei, G. Luo, J. Zhang, S. Jiang, P. Chen, Q. Shen, and L. Zhang, “Designing high-entropy alloy–ceramic eutectic composites of MoNbRe0.5TaW(TiC)x with high compressive strength,” J. Alloys Compd. 818, 152846 (2020).

S. Y. Kamata, D. Kanekon, Y. Lu, N. Sekido, K. Maruyama, G. Eggeler, and K. Yoshimi, “Ultrahigh-temperature tensile creep of TiC-reinforced Mo–Si–B–based alloy,” Sci. Rep. 8 (1), 1–14 (2018).

T. S. Stroganova, M. I. Karpov, V. P. Korzhov, V. I. Vnukov, D. V. Prokhorov, I. S. Zheltyakova, I. B. Gnesin, and I. L. Svetlov, “Influence of titanium and molybdenum on the structure and mechanical properties of in situ niobium–silicon-based composite,” Izv. Ross. Akad. Nauk, Ser. Fiz. 79 (9), 1300–1304 (2015).

X. Zhang, Y. Li, X. He, X. Liu, Q. Jiang, and Y. Sun, “Microstructural characterization and mechanical properties of Nb–Ti–C–B in situ composites with W addition,” Mater. Sci. Eng. A 646, 332–340 (2015).

M. Fujikura, A. Kasama, R. Tanaka, and S. Hanada, “Effect of alloy chemistry on the high-temperature strength and room-temperature fracture toughness of advanced Nb-based alloys,” Mater. Trans. 45 (2), 493–501 (2004).

I. L. Svetlov, O. G. Ospennikova, M. I. Karpov, and Yu. V. Artemenko, “High-temperature borosilicate molybdenum alloys strengthened by titanium carbides. Mo–Si–B–TiC (Review),” Materialovedenie, No. 9, 16–33 (2020).

M. I. Karpov, D. V. Prokhorov, V. I. Vnukov, T. S. Stroganova, B. A. Gnesin, I. B. Gnesin, I. S. Zheltyakova, and I. L. Svetlov, “Structure and high-temperature mechanical properties of high-carbon niobium-based alloys,” Deform. Razrushenie Mater., No. 5, 12–18 (2019).

S. A. Saltykov, Stereometric Metallography, Metallurgiya, Moscow, 1976).

J. Schindelin, I. Arganda-Carreras, E. Frise, et al., “An open-source platform for biological-image analysis,” Nature Methods 9 (7), 676–682 (2012).

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 19-02-00434.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by Yu. Ryzhkov

Rights and permissions

About this article

Cite this article

Gnesin, I.B., Karpov, M.I., Prokhorov, D.V. et al. Effect of the Carbon Content on the Structure and Mechanical Properties of a High-Temperature Carbide-Hardening Niobium–Molybdenum Alloy. Russ. Metall. 2022, 520–527 (2022). https://doi.org/10.1134/S0036029522050044

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029522050044