Abstract

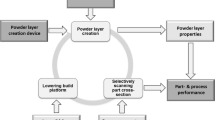

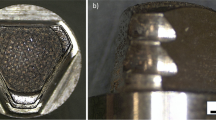

The roll wear in a hot section mill for copper is measured under industrial conditions. Fatigue and oxidative wear are found to be the main types of wear, which consist the appearance and development of a network of erosion cracks. The technique of quantitative wear measurement consists in roll remachining at a given step across the worn layer depth and fixation of the presence or absence of a network of erosion cracks on them. The finite element method is used to perform a mathematical simulation of the rolling process and to determine the main parameters, namely, the velocity, the pressure, the slip, and the full slip path on the contact surface. The obtained distributions of the parameters are compared with the results of industrial measurements. Wear localization zones are shown to correspond to the areas of intense slip and high normal pressure in roll passes. The developed recommendations point to practical importance of this work.

Similar content being viewed by others

REFERENCES

A. P. Grudev, Yu. V. Zilberg, and V. T. Tilik, Friction and Lubrication in Metal Forming: A Handbook (Metallurgiya, Moscow, 1982).

S. M. Byon, H. S. Park, and Y. Lee, “Experimental study for roll gap adjustment due to roll wear in single-stand rolling and multi-stand rolling test,” J. Mech. Sci. Technol. 22, 937–945 (2008). https://doi.org/10.1007/sl2206-008-0121-6

S. S. Rychkov, D. I. Kinzin, and A. B. Moller, “Simulation of the effect of the geometry of the nonequiaxial passes in the roughing group of stands in the 370 mill in OAO MMK on the roll wear,” Modelir. Razvit. Prots. OMD, No. 19, 16–24 (2013).

Kh. Dyya and M. Sygut, “Theoretical analysis of the pass wear in rolling of round bars,” Vestn. Magnitogorsk. Gos. Tekh. Univ., No. 3 (43), 41–47 (2013).

L. S. Bayoumi, Y. Lee, and H. J. Kim, “Effect of roll gap change of oval pass on interfacial slip of workpiece and roll pressure in round-oval-round pass rolling sequence,” KSME Int. J. 16 (4), 492–500 (2002).

Y. N. Loginov, A. Yu. Postylyakov, and Y. V. Inatovich, “Wear peculiarities of the grooves of a hot-rolling mill for electric copper,” Journal of Friction and Wear 39 (3), 215–221 (2018). https://doi.org/10.3103/S1068366618030066

Yu. N. Loginov, S. L. Demakov, A. G. Illarionov, M. A. Ivanova, and V. A. Romanov, “Structural condition of copper wire rod, obtained during the continuous Casting–Rolling process,” Tsvetn. Met., No. 8, 87 (2013).

Y. V. R. K. Prasad and S. Sasidhara, Hot Working Guide: A Compendium of Processing Maps (ASM Int., Ohio, 1997).

Yu. N. Loginov, Yu. V. Inatovich, and A. Yu. Zuev, “Contact friction during continuous hot rolling of a wire rod of electrical copper,” Proizv. Prokata, No. 2, 14–18 (2010).

S. Spuzic, K. N. Strafford, C. Subramanian, and G. Savage, “Wear of hot rolling mill rolls: an overview,” Wear 2(176), 261–271 (1994).

GOST 27674–88. Friction, Wear, and Lubrication. Terms and Definitions. Group T61. Introduction (Gosstandart, Moscow, 1996).

X. Yu, Z. Jiang, J. Zhao, D. Wei, J. Zhou, C. Zhou, and Q. Huang, “The role of oxide-scale microtexture on tribological behaviour in the nanoparticle lubrication of hot rolling,” Tribology Int., No. 93 (A), 190–201 (2016).

Funding

This work was supported by the Government of the Russian Foundation, resolution no. 211, project no. 02.A03.21.0006.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Loginov, Y.N., Postylyakov, A.Y. & Inatovich, Y.V. Effect of the Electrical Copper Rolling Parameters on the Wear of Roll Passes. Russ. Metall. 2020, 602–607 (2020). https://doi.org/10.1134/S0036029520050092

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520050092