Abstract

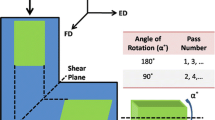

The effect of the fraction and the direction of deformation on the structure and the hardness of commercial-purity titanium severely deformed in a Bridgman cell at room temperature is studied. The direction of rotation of a movable anvil considerably affects the conditions under which the ω phase precipitates and the structural parameters of dynamically recrystallized grains and deformation-induced fragments formed upon severe plastic deformation.

Similar content being viewed by others

REFERENCES

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials Produced by Severe Plastic Deformation (Logos, Moscow, 2000).

V. V. Rybin, Severe Plastic Deformation and Fracture of Metals (Metallurgiya, Moscow, 1986).

V. A. Pozdnyakov and A. M. Glezer, “Possible evolution of a defect structure during severe plastic deformations: the role of relaxation mechanisms,” Izv. Ross. Akad. Nauk, Ser. Fiz. 68 (10) 1449–1455 (2004).

E. Estrin and A. Vinogradov, “Extreme grain refinement by severe plastic deformation: a wealth of challenging science,” Acta Mater. 61 (3) 782–817 (2013).

Y. Beygelzimer, “Grain refinement versus voids accumulation during severe plastic deformation of polycrystals: mathematical simulation,” Mech. Mater. 37, 753–767 (2005).

Y. Todaka, J. Sasaki, T. Moto, and M. Umemoto, “Bulk submicrocrystalline ω-Ti produced by high-pressure torsion straining,” Scr. Mater. 59 (6), 615–618 (2008).

A. P. Zhilyaev, F. Galvez, A. Sharafutdinov, and M. T. Perez-Prado, “Influence of the high pressure torsion die geometry on the allotropic phase transformations in pure Zr,” Mater. Sci. Eng. A 527 (16–17), 3918–3928 (2010).

Zhang J., Zhao Y., Pantea C., Qian J., J. Zhang, Y. Zhao, C. Pantea, J. Qian, L. L. Daemen, P. A. Rigg, R. S. Hixson, and C. W. Greeff, “Experimental constraints on the phase diagram of elemental zirconium,” Phys. Chem. Solids 66 (7), 1213–1219 (2005).

J. C. Jamieson, “Crystal structures of titanium, zirconium, and hafnium at high pressures,” Science 140, 72–80 (1963).

M. Tane, Y. Okuda, Y. Todaka, H. Ogi, and A. Nagakubo, “Elastic properties of single-crystalline ω phase in titanium,” Acta Materialia 61 (20), 7543–7554 (2013).

N. Adachi, Y. Todaka, H. Suzuki, and M. Umemoto, “Evolution of deformation texture of high-pressure ω‑phases in pure Ti and Zr during high-pressure torsion straining,” Mater. Sci. Eng. 82, 0120201–01202031 (2015).

Yu. Ivanisenko, A. Kilmametov, H. Rusner, and R. Z. Valiev, “Evidence of α → ω phase transition in titanium after high pressure torsion,” Int. J. Mater. Res. 99, 1–8 (2008).

A. M. Glezer, A. A. Tomchuk, R. V. Sundeev, and M.V. Gorshenkov, “Two-phase model of the structure formed upon sever plastic deformation in α-Fe and FeNi alloy,” Mater. Lett. 161, 360–366 (2015).

F. Z. Utyashev, Deformation Techniques for the Manufacturing and Processing of Ultrafine-Grained Materials (Gilem, Ufa, 2013).

N. A. Shurygina, A. O. Cheretaeva, A. M. Glezer, D. L. D’yakonov, I. V. Chshetinin, R. V. Sundeev, A. A. Tomchuk, and L. F. Muradimova, “Effect of the temperature of megaplastic deformation in a Bridgman chamber on the formation of structures and the physicochemical properties of titanium (VT1-0),” Bull. Rus. Acad. Nauk: Fiz. 82 (9), 1113–1124 (2018).

A. M. Glezer, A. A. Tomchuk, and T. V. Rassadina, “Effect of reversible torsion on the structure and mechanical properties of iron under severe plastic deformations in a Bridgman camera,” Dokl. Phys. 61 (2), 61–63 (2016).

A. M. Glezer and L. S. Metlov, “Physics of megaplastic (severe) deformation in solids,” Phys. Solid State 52 (6), 1162–1169 (2010).

Funding

This work was supported in part by the Russian Foundation for Basic Research (project no. 18-08-00640a) and the Ministry of Education and Science of the Russian Federation (project no. 2017/113 (2097)).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Shurygina, N.A., Glezer, A.M., D’yakonov, D.L. et al. Effect of the Fractionality and Direction of Severe Plastic Deformation on the Structure and Properties of Commercial-Purity Titanium. Russ. Metall. 2019, 1051–1056 (2019). https://doi.org/10.1134/S0036029519100264

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029519100264