Abstract

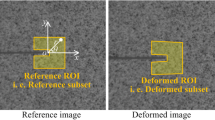

Aluminum alloy V-1167RDTV specimens 1 mm thick with a central crack are used to determine the position of the tip of a mode I crack from a strain field distribution during cyclic loading in the course of fatigue crack growth rate tests and during static loading in determining the force characteristics of fracture toughness. When analyzing the displacement and strain distributions at the crack tip, we proposed a technique to measure the length of a statically growing crack to determine critical stress intensity factor Kc for a mode I crack in plane-stress state.

Similar content being viewed by others

REFERENCES

E. N. Kablov, “Strategic trends in the development of materials and technologies of their processing up to 2030,” Aviats. Mater. Tekhnol., No. S, 7–17 (2012).

E. N. Kablov, “Innovative solutions of FGUP VIAM GNTs RF for ‘Strategic Directions of Designing Materials and Technologies of Their Processing up to 2030,’” Aviats. Mater. Tekhnol., No. 1, 3–33 (2015). https://doi.org/10.18577/2071-9140-2015-0-1-3-33

H. D. Bui, Fracture Mechanics: Inverse Problems and Solutions (Fizmatlit, Moscow, 2011).

M. A. Shtremel’, Fracture. Book 1. Fracture of Material (Izd. Dom MISiS, Moscow, 2014).

Surface Layers and Internal Interfaces in Heterogeneous Materials, Ed. by V. E. Panin (Izd. SO RAN, Novosibirsk, 2006).

N. I. Prigorovskii, Methods and Means for Determining Strain and Stress Fields (Mashinostroenie, Moscow, 1983).

R. Jones and C. Wykes, Holographic and Speckle Interferometry (Cambridge Univ. Press., Cambridge, 1983).

Experimental Mechanics, Ed. by A. Kobayasi (Mir, Moscow, 1990).

A. P. Vladimirov, I. S. Kamantsev, A. V. Ishchenko, V. E. Veselova, E. S. Gorkunov, and S. M. Zadvorkin, “Study of the nucleation of a fatigue crack using a change in the specimen surface relief and speckle images,” Deform. Razr. Mater., No. 1, 21–26 (2015).

A. P. Lutsenko, I. N. Odintsev, A. V. Grinevich, P. B. Severov, and T. P. Plugatar’, “Optical-correlation investigation of material deformation,” Aviats. Mater. Tekhnol., No. S4, 70–86 (2014). https://doi.org/10.18577/2071-9140-2014-0-s4-7086

M. A. Sutton, J.-J. Orteu, and H. W. Schreier, Image Correlation for Shape, Motion and Deformation Measurements (University of South Carolina, Columbia, 2009).

A. V. Il’ichev and A. E. Raskutin, “Digital image correlation study of the influence of a stress concentrator on the state of stress in carbon fiber reinforced plastic,” Aviats. Mater. Tekhnol., No. 3, 62–66 (2014). https://doi.org/10.18577/2071-9140-2014-0-3-62-66

A. V. Grinevich, V. S. Erasov, V. V. Avtaev, and S. M. Shvets, “Determination of the fracture toughness of aluminum alloy sheets,” Aviats. Mater. Tekhnol., No. S4, 40–44 (2014). https://doi.org/10.18577/2071-9140-2014-0-s4-40-44

M. Sonka, V. Hlavac, and R. Boyle, Image Processing, Analysis and Machine Vision (Chapman and Hall International, 1993). https://doi.org/10.1007/978-1-4899-3216-7

P. Lopez-Crespo, A. Shterenlikht, E. A. Patterson, J. R. Yates, and P. J. Withers, “The stress intensity of mixed mode cracks determined by digital image correlation,” J. Strain Analysis 43 (8), 769–780 (2008).

Y. Du, F. A. Diaz, R. L. Burguete, and E. A. Patterson, “Evaluation using digital image correlation of stress intensity factors in an aerospace panel,” Exp. Mechan. 51, 45–57 (2011).

ACKNOWLEDGMENTS

This work was performed in terms of problem 2.2 Certification and Study of Materials in Strategic Directions of Designing Materials and Technologies of Their Processing up to 2030.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Avtaev, V.V., Yakovlev, N.O., Erasov, V.S. et al. Determination of the Crack Tip Position by Digital Image Correlation during Static and Cyclic Fracture Toughness Tests of Aluminum Alloys. Russ. Metall. 2019, 458–465 (2019). https://doi.org/10.1134/S0036029519040025

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029519040025