Abstract

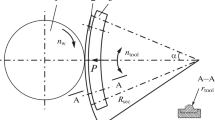

The formation of temperature fields and tempering zones during electric pulse hardening of thin-walled parts is studied. A mechanism is developed to supply a filler wire for semiautomatic vibrational arc facing. The influence of the pulsed arcing parameters on the surface hardness of the part to be hardened is experimentally studied.

Similar content being viewed by others

REFERENCES

V. I. Ivanov and F. Kh. Burumkulov, “Hardening and increasing the resource of objects by electric spark: classification, technological features,” Elektron. Obrab. Mater., No. 5, 27–36 (2010).

V. V. Bulychev, A. I. Ponomarev, and S. A. Golubina, “Improvement of the technologies of hardening facing of plow parts using vibrational arc processes,” Traktory Sel’khoz. Mashiny, No. 4, 54–56 (2010).

G. R. Latypova, V. V. Bulychev, and E. V. Ageev, “Application of the T15K6 powder produced from the wastes of a hard alloy for the hardening of disk operating parts by electric contact welding,” Izv. Yugo-Zapad. gos. Univ., No. 6(63), 39–43 (2015).

R. A. Latypov, V. V. Bulychev, and I. N. Zybin, “Metallurgical features of formation of solid-phase joint of metals by electric current heating,” Elektrtometallurgiya, No. 8, 8–15 (2016).

Theory of Welding Processes (Izd. MGTU, Moscow, 2007).

L. S. Livshits, Physcial Metallurgy for Welders: Welding of Steels (Mashinostroenie, Moscow, 1979).

A. P. Gulyaev, Physical Metallurgy (Metallurgiya, Moscow, 1986).

V. V. Bulychev, V. A. Dubrovskii, and S. A. Golubina, “Method of vibrational arc welding with a core wire and a device for its feed,” RF Patent 2301728, Byul. Izobret., No. 18 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Bulychev, V.V., Golubina, S.A. & Latypova, G.R. Experimental-Calculation Estimation of the Temperature Field Distribution during the Hardening of Thin-Walled Parts by Electric Pulse Facing. Russ. Metall. 2018, 1134–1137 (2018). https://doi.org/10.1134/S0036029518120054

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029518120054