Abstract

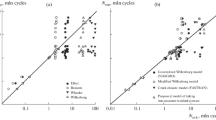

The results of overload and underload tests on aluminum specimens in the near-threshold crack growth rate region are discussed. These tests are performed to choose a model for predicting the fatigue life. The influence of the character and the magnitude of overload and underload on the fatigue crack growth time is analyzed. The obtained crack growth curves and the fatigue lives cannot be explained in terms of classical models, which makes it necessary to develop a new model.

Similar content being viewed by others

REFERENCES

O. E. Wheeler, “Spectrum loading and crack growth,” J. Basic Eng. 94, 181–186 (1972).

J. Willenborg, R. H. Engle, and H. A. Wood, A Crack Growth Retardation Model Based on Effective Stress Concepts Report No. AFFDL-TM-71-1 FBR (Wright-Patterson Air Force Base, Ohio, 1971).

D. V. Nelson, “Review of fatigue crack-growth prediction under irregular loading,” in Spring Meeting Society for Experimental Stress Analysis (Chicago, 1975), pp. 6–11.

W. Elber, “The significance of fatigue crack closure,” in Damage Tolerance in Aircraft Structures (ASTM STP 486, 1971), pp. 230–242.

H. Führing and T. Seeger, “Structural memory of cracked components under irregular loading,” in Fracture Mechanics, Ed. by C. W. Smith (ASTM STP 677, 1979), pp. 1144–1167.

J. Shijve, Fatigue of Structures and Materials (Springer, Delft, 2009).

P. I. Kudryavtsev, Nonpropagating Fatigue Cracks (Mashinostroenie, Moscow, 1982).

R. Sunder, “Engineering application of threshold stress intensity,” in Proceedings of Annual Symposium on Fracture Mechanics (ASTM- ESIS, USA, 2013), pp. 24–48.

R. Sunder, “Fatigue as a process of brittle micro-fracture,” Fatig. Fract. Eng. Mater. Struct. 28 (3), 289–300 (2005).

BiSS Nano Servohydraulic Testing Machine. http:// biss.in/cms/v2/index.php?option=com_content&view= article&id=69&Itemid=111.

Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM E647-13ael (ASTM Int., West Conshohocken, 2013).

S. Bekal, Calculation Growth on Variable Amplitude Loading: Master Thesis (Institute of Technology, Manipal, India, 2013).

A. N. Savkin, A. V. Andronik, and K. A. Badikov, Program of Cycle-by-Cycle Calculation of the Crack Length in a C(T) Specimen by the Compliance Method Using the Crack Opening Sensor Data from a Microsoft Excel File (VolgGTU, Volgograd, 2015).

Fracture Mechanics and Strength of Materials: A Handbook. Vol. 4. Fatigue and Cyclic Fracture Toughness of Structural Materials, Ed. by V. V. Panasyuk (Naukova Dumka, Kiev, 1990).

ACKNOWLEDGMENTS

This work was supported by the Russian Foundation for Basic Research, project no. 17-08-01648 A and grant MK-943.2017.8 of the President of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Savkin, A.N., Sunder, R., Andronik, A.V. et al. Effect of Overload on the Near-Threshold Fatigue Crack Growth Rate in a 2024-T3 Aluminum Alloy: I. Effect of the Character, the Magnitude, and the Sequence of Overload on the Fatigue Crack Growth Rate. Russ. Metall. 2018, 1094–1099 (2018). https://doi.org/10.1134/S0036029518110113

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029518110113