Abstract

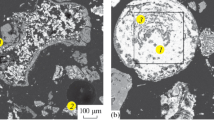

The reactions of reduction of chromium and iron from chromospinelide and the reactions of carbide formation from the reduced metals are separated in space in experiments performed on ore grains with an artificially applied silicate shell. It is found that the silicate layer that isolates spinelide fro direct contact with carbon takes part in the reactions of both reduction and carbide formation. Free carbon extracts oxygen anions from the layer at the contact surface with the formation of CO, and the forming anion vacancies transfer “excess” electrons to the iron and chromium cations in the spinelide lattice and reduce them. Free and carbide-fixed carbon extracts iron and chromium cations from the silicate layer, and carbides form on the surface. The cation vacancies and electron holes (high-charge cations) that form in the silicate phase under these conditions are involved in the oxidation of the metal reduced in spinelide and cause its dissolution in the silicate phase and the precipitation of lower carbides on the surface of the silicate phase. The structure that is characterized of carbon ferrochrome forms on the surface of the silicate phase. Carbide formation is slower than reduction because of higher energy consumed for the formation of high-charge cations and the transfer of cations from the spinelide volume to the outer surface of the silicate phase. In the absence of a silicate layer, a carbide shell blocks the contact of carbon with oxides, which leads to the stop of reduction and, then, carbide formation. In the presence of a silicate (slag) shell around a spinelide grain, the following two concentration galvanic cells operate in parallel: an oxygen (reduction) cell and a metal (oxidation) cell. The parallel operation of the two galvanic cells with a common electrolyte (silicate phase) results in a decrease in the electric potentials between spinelide inside the silicate phase and carbon and carbides on its surface, and each of the processes is significantly facilitated and accelerated. In other words, the production of carbon ferrochrome is accelerated.

Similar content being viewed by others

References

I. A. Bespal’yakova, V. S. Ignat’ev, A. N. Alybina, and C. B. Kuvelich, “Phase composition of silicon, manganese, and chromium ferroalloys,” in Physicochemical Studies of the Low-Waste Technologies in Electrothermy (Nauka, Moscow, 1985), pp. 137–139.

M. I. Gasik and B. I. Emlin, Electrometallurgy of Ferroalloys: A Textbook (Vishcha Shkola, Donetsk, 1983).

M. I. Gasik and N. P. Lyakishev, Metallurgy of Chromium (ELIZ, Moscow, 1999).

N. P. Lyakishev and M. I. Gasik, Physical Chemistry and Technology of Electroferroalloys: A Textbook (ELIZ, Moscow, 2005).

V. P. Chernobrovin, I. Yu. Pashkeev, G. G. Mikhailov, et al., Theoretical Fundamentals of the Production of Carbon Ferrochrome from the Urals Ores (YuzhUrGU, Chelyabinsk, 2004).

V. E. Roshchin, A. V. Roshchin, and K. T. Akhmetov, “Mechanism and sequence of the metal reduction in the lattice of chromospinelides,” Russian Metallurgy (Metally), No. 3, 173–178 (2014).

V. E. Roshchin, Yu. N. Goikhenberg, and D. M. Galimov, “Native metal of the Chelyabinsk meteorite,” Russian Metallurgy (Metally), No. 5, 419–425 (2014).

V. E. Roshchin and A. V. Roshchin, “Selective reduction of metals in the lattice of a complex oxide,” Russian Metallurgy (Metally), No. 3, 169–175 (2013).

V. E. Roshchin and A. V. Roshchin, “Physics of the solid phase oxidation and reduction of metals,” Russian Metallurgy (Metally), No. 5, 354–359 (2015).

P. Kofstad, Nonstoichiometry, Diffusion, and Electrical Conductivity in Binary Metal Oxides (Wiley, New York, 1972).

G. V. Samsonov, Refractory Compounds (Metallurgizdat, Moscow, 1963).

V. I. Fistul’, Physics and Chemistry of Solids: A Textbook (Metallurgiya, Moscow, 1995), Vol. 1.

A. V. Roshchin and V. E. Roshchin, “Diffusion of anions and cations in oxide crystal lattices during the reduction and oxidation of metals,” Russian Metallurgy (Metally), No. 1, 2–7 (2003).

Power Diffraction File International Centre for Diffraction Data (PDF–2, ICPDS, 5-720).

Power Diffraction File International Centre for Diffraction Data (PDF–2, ICPDS, 78-1502).

E. Ringdalen, M. Rocha, J. R. Neto, and T. Malvik, “Properties of chromite ores from Ferbasa and their effect on Cr-losses to slag during HCFeCr production at Ferbasa,” in Proceedings of 13th International Ferroalloys Congress INFACON on Efficient Technologies in Ferroalloy Industry (2013), pp. 115–125.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.E. Roshchin, A.V. Roshchin, K.T. Akhmetov, S.P. Salikhov, 2016, published in Metally, 2016, No. 5, pp. 11–21.

Rights and permissions

About this article

Cite this article

Roshchin, V.E., Roshchin, A.V., Akhmetov, K.T. et al. Role of a silicate phase in the reduction of iron and chromium and their oxidation with carbide formation during the manufacture of carbon ferrochrome. Russ. Metall. 2016, 1092–1099 (2016). https://doi.org/10.1134/S0036029516090123

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029516090123