Abstract

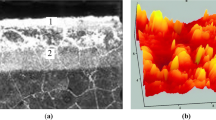

The macro- and microstructures and the distribution of microhardness over the height and width of the remelted and heat-affected zones in structural low-carbon grade 20 steel (1020 AISI) are investigated after laser processing under various conditions, including the application of an electric arc.

Similar content being viewed by others

References

A. G. Grigor’yants and I. N. Shiganov, Laser Equipment and Technology. Laser Welding of Metals (Vysshaya shkola, Moscow, 1988), Vol. 5.

W. W. Duley, Laser Processing and Analysis of Materials (Plenum Press, New York, 1983).

Chen Yanbin, Chen Jie, Li Liqun, and Wu Lin, “Properties of arc and weld in laser-TIG hybrid process,” Trans. China Weld. Inst., 24(1), 55–57 (2003).

Zhao Fucheng and A. V. Baranov, “Character of transition of drops in molten metal at hybrid CO2-laser + MIG welding,” Vopr. Materialoved. 2(66), 111–116 (2011).

N. B. Pugacheva, E. B. Trushina, and E. I. Pugacheva, “Laser welding of Ti-5Al-2.5Sn titanium alloy,” Vopr. Materialoved. 2(74) 83–92 (2013).

N. B. Pugacheva, E. B. Trushina, E. I. Pugacheva, et al., “Welded seams’ structure of Cr18Ni10Ti steel and VT1-0 titanic alloy with an intermediate copper plate after laser melting,” Vopr. Materialoved. 1(73) 166–174 (2013).

Yu. V. Afonin, A. P. Golyshev, A. I. Ivanchenko, et al., “High-quality beam generation in a 8-kW cw CO2 laser”, Kvant. electron. 34(4), 307–309 (2004).

N. B. Pugacheva, C. V. Smirnov, D. I. Vichuzhanin, et al., “Strength and structure of permanent joints of titanium and austenitic steel obtained by laser welding with intermediate layers,” Deform. Razrushenie Mater., No. 7, 26–33 (2012).

Database of Steels and Alloys, Ed. by V. G. Sorokin and M. A. Gervas’ev (Intermet Inzhiniring, Moscow, 2003).

M. Kh. Shorshorov, Metallography of Titanium Steels and Alloys (Nauka, Moscow, 1965).

N. B. Pugacheva, C. V. Smirnov, G. E. Ermolaev, et al., “Microstructure of the surface and peculiarities of physical and chemical simulation of oxygen laser cutting of mild steel,” Fiz. Khim. Obrab. Mater., No. 1, 15–22 (2010).

V. D. Sadovskii, I. L. Yakovleva, V. M. Schastlivtsev, and T. I. Tabatchikova, Laser Heating and Steel Structure (UrO AN SSSR, Sverdlovsk, 1989).

I. L. Yakovleva, V. M. Schastlivtsev, T. I. Tabatchikova, et al., “Martensite-like diffusion-less shear formation mechanism of austenite during laser-induced heating of pearlitic steel,” Fiz. Met. Metalloved., 79(5), 152–159 (1995).

V. M. Schastlivtsev, D. A. Mirzaev, I. L. Yakovleva, et al., Pearlite in Carbon Steels (UrO RAN, Yekaterinburg, 2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.B. Pugacheva, E.B. Trushina, N.P. Antenorova, 2014, published in Metally, 2014, No. 4, pp. 77–85.

Rights and permissions

About this article

Cite this article

Pugacheva, N.B., Trushina, E.B. & Antenorova, N.P. Effect of laser processing on the microstructure of a structural low-carbon steel. Russ. Metall. 2014, 569–575 (2014). https://doi.org/10.1134/S0036029514070118

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029514070118