Abstract

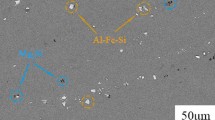

In this report, the pitting corrosion behavior of the 5083 aluminum alloy under 3.5% NaCl solution and microbial corrosion environment was studied. The microstructure of the 5083 alloy before and after sulfate-reducing bacteria (SRB) influenced corrosion was characterized by optical microscopy (OM), scanning electron microscopy (SEM), and energy dispersive spectrometry (EDS) analysis. The result showed the pitting corrosion rate of the alloy was increased by nearly 7 times from 3.5 wt % NaCl solution to SRB-containing environment, which was indicated by a surface corrosion pit size of 1.06 microns for aluminum alloy in 3.5 wt % NaCl solution environment, and a surface corrosion pit size of 7.02 microns in SRB-containing environment. To enhance the properties of corrosion resistance, a superhydrophobic fluoro silane coating was prepared on 5083 aluminum alloy. The prepared alloy with coating was analyzed by contact angle measurement, X-ray diffraction (XRD) analysis and electrochemistry methods. The superhydrophobic coating, mainly composed of amorphous phase, exhibited good corrosion resistance. The modification of aluminum alloy with superhydrophobic coating increased the AC impedance significantly and shifted the corrosion potential to the positive direction, suggesting the coating has a good protective effect against the aluminum alloy corrosion.

Similar content being viewed by others

REFERENCES

A. O. Ayhan and M. F. Yaren, “Effects of microstructural through-thickness non-uniformity and crack size on fatigue crack propagation and fracture of rolled Al-7075 alloy,” Fatigue Fract. Eng. Mater. Struct. 43 (9), 2071–2084 (2020).

L. Stemper, et al., “Giant hardening response in AlMgZn(Cu) alloys,” Acta Mater. 206, 116617 (2021).

J. Hirsch, “Recent development in aluminum for automotive applications,” Trans. Nonferrous Met. Soc. China 24 (7), 1995–2002 (2014).

J. Hirsch, “Aluminum in innovative light-weight car design,” Mater. Trans. 52 (5), 818–824 (2011).

C. Punckt, et al., “Sudden onset of pitting corrosion on stainless steel as a critical phenomenon,” Science 305 (5687), 1133–1136 (2004).

S. Dhanish, G. Yoganandan, and J.N. Balaraju, “Development of TSA anodized/MnVO sealed coating using a statistical approach for Al 7075 alloy and a study of its corrosion behavior,” Surf. Coat. Technol. 402, 126316 (2020).

J. Bi, et al., “Microstructure and mechanical properties of a novel Sc and Zr modified 7075 aluminum alloy prepared by selective laser melting,” Mater. Sci. Eng., A 768, 9 (2019).

G. Zhang, et al., “Effect of micro-arc oxidation coatings formed at different voltages on the in situ growth of layered double hydroxides and their corrosion protection,” J. Electrochem. Soc. 165 (7), C317–C327 (2018).

K. K. Ma, et al., “Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy,” Acta Mater. 62, 141–155 (2014.

J. H. Martin, et al., “3D printing of high-strength aluminium alloys,” Nature 549 (7672), 365–369 (2017).

Y. B. Yan, et al., “Microstructure and properties of magnesium AZ31B-aluminum 7075 explosively welded composite plate,” Mater. Sci. Eng., A 527 (9), 2241–2245 (2010).

J. F. Ou, et al., “Superhydrophobic surfaces on light alloy substrates fabricated by a versatile process and their corrosion protection,” ACS Appl. Mater. Interfaces 5 (8), 3101–3107 (2013).

P. Liu, et al., “Improved anticorrosion of magnesium alloy via layer-by-layer self-assembly technique combined with micro-arc oxidation,” Mater. Lett. 75, 118–121 (2012).

H. R. Wang, et al., “Preparation and properties of titanium oxide film on NiTi alloy by micro-arc oxidation,” Appl. Surf. Sci. 257 (13), 5576–5580 (2011).

T. Ishizaki, Y. Masuda, and M. Sakamoto, “Corrosion resistance and durability of superhydrophobic surface formed on magnesium alloy coated with nanostructured cerium oxide film and fluoroalkylsilane molecules in corrosive NaCl aqueous solution,” Langmuir 27 (8), 4780–4788 (2011).

S. Khorsand, et al., “Corrosion behavior of super-hydrophobic electrodeposited nickel-cobalt alloy film,” Appl. Surf. Sci. 364, 349–357 (2016).

F. Zhang, et al., “Preparation of superhydrophobic films on titanium as effective corrosion barriers,” Appl. Surf. Sci. 257 (7), 2587–2591 (2011).

T. Liu, et al., “Corrosion behavior of super-hydrophobic surface on copper in seawater. Electrochim. Acta 52 (28), 8003–8007 (2007).

C. Huang, et al., “Mechanical properties of AA5083 in different tempers at low temperatures,” IOP Conf. Ser.: Mater. Sci. Eng. 279, 012002 (2017).

J. Shi, et al., “Effect of the addition of Zn on the microstructure and mechanical properties of 5083 alloy,” J. Mater. Eng. Perform. 26 (6), 2912–2918 (2017).

Y. Li, et al., “The effect of homogenization on the corrosion behavior of Al–Mg alloy,” Phys. Met. Metallogr. 119 (4), 339–346 (2018).

F. Liu, et al., “The corrosion of two aluminium sacrificial anode alloys in SRB-containing sea mud,” Corros. Sci. 83, 375–381 (2014).

H. Liu, et al., “Effect of sulfate-reducing bacteria and iron-oxidizing bacteria on the rate of corrosion of an aluminum alloy in a central air-conditioning cooling water system,” Ind. Eng. Chem. Res. 53 (19), 7840–7846 (2014).

H. W. Liu, et al., “Effect of iron oxidizing bacteria biofilm on corrosion inhibition of imidazoline derivative in CO2-containing oilfield produced water with organic carbon source starvation,” J. Electrochem. Soc. 165 (7), C354–C361 (2018).

M. Siva Surya and G. Prasanthi, “Physical and mechanical characterization of Al7075/SiC functionally graded materials fabricated by powder metallurgy route,” Adv. Mater. Process. Technol., (2020).

Z. Zhao, et al., “Corrosion resistance of as-rolled Mg–Li–AlSi alloys,” Int. J. Electrochem. Sci. 13 (5), 4338–4349 (2018).

Z. Zhao, et al., “Influence of Al and Si additions on the microstructure and mechanical properties of Mg–4Li alloys,” Mater. Sci. Eng., A 702, 206–217 (2017).

Y. Han, et al., “Self-adhesive lubricated coating for enhanced bacterial resistance,” Bioactive Mater. 6 (8), 2535–2545 (2021).

D. Liu, et al., “Superior antiwear biomimetic artificial joint based on high-entropy alloy coating on porous Ti6Al4V,” Tribol. Int. 158, 106937 (2021).

ACKNOWLEDGMENTS

This work was supported by the Natural Science Foundation of China (nos. 51773106, 51701029 and 51778088), Guangdong Basic and Applied Basic Research Foundation (no. 2020A1515011274), the Fundamental Research Funds for the Central Universities, Sun Yat-sen University (no. 2021qntd13).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Zilong Zhao, Xiang, J., Tan, Y. et al. Preparation of Superhydrophobic Coating on 5083 Aluminum Alloy for Corrosion Protection in Simulated Marine Environment Containing SRB. Phys. Metals Metallogr. 122, 1581–1587 (2021). https://doi.org/10.1134/S0031918X2114026X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2114026X