Abstract

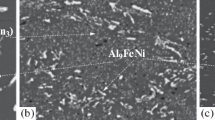

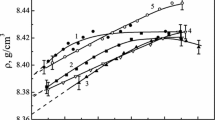

Parameters of superplasticity of the Al–7.6% Mg–0.6% Mn–0.25% Cr alloy have been studied in the range of 490–520°C, and the optimum temperature of deformation has been determined. The evolution of the grain structure in the bulk and on the surface of samples during the superplastic deformation at a temperature of 510°C has been analyzed. The contribution of grain-boundary sliding has been estimated in the strain-rate regime of superplastic deformation according to the results of the analysis of changes in the structure of the surface with preliminarily applied marker scratches. The contribution of grain-boundary sliding to the total deformation is 20–30%; the contribution of diffusion creep decreases from 40 to 20% with an increase in the deformation rate by an order of magnitude, from 1 × 10–3 to 1 × 10–2 s–1. The intragranular deformation is localized in the peripheral regions of grains and in the region of striated zones.

Similar content being viewed by others

REFERENCES

S. Kalpakjian, Manufacturing engineering and technology, 3rd ed. (Addison-Wesley Publishing Company, Massachusetts, 1995).

T. G. Nieh, J. Wadsworth, and O. D. Sherby, Superplasticity in Metals and Ceramics (Cambridge University Press, New York, 2005).

K. Sotoudeh and P. S. Bate, “Diffusion creep and superplasticity in aluminium alloys,” Acta Mater. 58, 1909–1920 (2010).

I. I. Novikov and V. K. Portnoi, “Superplasticity of alloys with ultrafine grain,” (Metallurgiya, Moscow, 1981) [in Russian].

H. Masuda, T. Kanazawa, H. Tobe, and E. Sato, “Dynamic anisotropic grain growth during superplasticity in Al–Mg–Mn alloy,” Scr. Mater. 149, 84–87 (2018).

R. W. Cahn, P. Haasen, and E. J. Kramer, Mater. Sci. Technology (VCH, New York, 1993), Vol. 6.

R. M. Cleveland, A. K. Ghosh, and J. R. Bradley, “Comparison of superplastic behavior in two 5083 aluminum alloys,” Mater. Sci. Eng., A 351, 228–236 (2003).

K. Zhang and H. Yan, “Deformation behavior of fine-grained 5083 Al alloy at elevated temperature,” Trans. Nonferrous Met. Soc. China 19, 307–311 (2009).

R. Verma, A. K. Ghosh, S. Kim, and C. Kim, “Grain refinement and superplasticity in 5083 Al,” Mater. Sci., Eng. A 191, 143–150 (1995).

S. S. Woo, Y. R. Kim, D. H. Shin, and W. J. Kim, “Effects of Mg concentration on the quasi-superplasticity of coarse-grained Al–Mg alloys,” Scr. Mater. 37, 1351–1358 (1997).

A. A. Kishchik, A. V. Mikhailovskaya, V. S. Levchenko, and V. K. Portnoi, “Formation of microstructure and superplasticity of magnalics,” Phys. Met. Metallogr. 118, 96–103 (2017).

D. Y. Maeng, J. H. Lee, S. I. Hong, and B. S. Chun, “Microstructure and mechanical properties of rapidly solidified Al–7 wt % Mg–X (X = Cr, Zr or Mn) alloys,” Mater. Sci. Eng., A 311, 128–134 (2001).

A. D. Kotov, A. V. Mikhaylovskaya, and V. K. Portnoy, “Effect of the solid-solution composition on the superplasticity characteristics of Al–Zn–Mg–Cu–Ni–Zr alloys,” Phys. Met. Metallogr. 115, 730–735 (2014).

V. K. Portnoy, D. S. Rylov, V. S. Levchenko, and A. V. Mikhaylovskaya, “The influence of chromium on the structure and superplasticity of Al–Mg–Mn alloys,” J. Alloys Compd. 581, 313–317 (2013).

G. T. Langdon, “Grain boundary sliding revisited: Developments in sliding over four decades,” J. Mater. Sci. 41, 597–609 (2006).

E. Alabort, P. Kontis, D. Barba, K. Dragnevski, and R. C. Reed, “On the mechanisms of superplasticity in Ti–6Al–4V,” Acta Mater. 105, 449–463 (2016).

M. A. Rust and R. I. Todd, “Surface studies of Region II superplasticity of AA5083 in shear: Confirmation of diffusion creep, grain neighbor switching and absence of dislocation activity,” Acta Mater. 59, 5159–5170 (2011).

C. M. Cepeda-Jiménez, J. M. García-Infanta, O. A. Ruano, and F. Carreno, “High strain rate superplasticity at intermediate temperatures of the Al7075 alloy severely processed by equal channel angular pressing,” J. Alloys Compd. 509, 9589–9597 (2011).

H. E. Adabbo, G. Gonzalez-Doncel, O. A. Ruano, J. M. Belzunce, and O. D. Sherby, “Strain hardening during superplastic deformation of Al-7475 alloy,” Mater. Res. Soc. 3, 587–594 (1989).

A. V. Mikhaylovskaya, O. A. Yakovtseva, M. N. Sitkina, A. D. Kotov, A. V. Irzhak, S. V. Krymskiy, and V. K. Portnoy, “Comparison between superplastic deformation mechanisms at primary and steady stages of the fine grain AA7475 aluminium alloy,” Mater. Sci. Eng., A 718, 277–286 (2018).

J. R. Spingarn and W. D. Nix, “Diffusion creep and diffusionally accommodated grain rearrangement,” Acta Metall. 26, 1389–1398 (1978).

I. I. Novikov, V. K. Portnoy, and V. S. Levchenko, “Investigation of structural changes during superplastic deformation of Zn–22%Al alloy by replica locating technique,” Acta Metall. 29, 1077–1090 (1981).

O. A. Yakovtseva, A. V. Mikhaylovskaya, A. V. Pozdniakov, A. D. Kotov, and V. K. Portnoy, “Superplastic deformation behaviour of aluminium containing brasses,” Mater. Sci. Eng., A 674, 135–143 (2016).

W. Wang, M. Yang, D. Yan, P. Jiang, F. Yuan, and X. Wu, “Deformation mechanisms for superplastic behaviors in a dual-phase high specific strength steel with ultrafine grains,” Mater. Sci. Eng., A 702, 133–141 (2017).

O. A. Yakovtseva, A. V. Mikhailovskaya, A. D. Kotov, and V. K. Portnoi, “Effect of alloying on superplasticity of two-phase brasses,” Phys. Met. Metallogr. 117, 742–748 (2016).

C. W. Humpries and N. Ridley, “Cavitation during the superplastic deformation of an α/β brasses,” J. Mater. Sci. 13, 2477–2482 (1978).

O. A. Yakovtseva, A. V. Mikhaylovskaya, A. G. Mochugovskiy, V. V. Cheverikin, and V. K. Portnoy, “Superplastic deformation mechanisms in high magnesium containing aluminum alloy,” Mater. Sci. Forum 838–839, 66–71 (2016).

D. H. Bae and A. K. Ghosh, “Cavity growth during superplastic flow in an Al−Mg alloy: I. Experimental study,” Acta Mater. 50, 993−1009 (2002).

R. Verma, P. A. Friedman, A. K. Ghosh, S. Kim, and C. Kim, “Characterization of superplastic deformation behavior of a fine grain 5083 Al alloy sheet,” Metall. Mater. Trans. A 27, 1889–1898 (1996).

J. J. Blandin, B. Hong, A. Varloteaux, M. Suery, and G. L’esperance, “Effect of the nature of grain boundary regions on cavitation of a superplastically deformed aluminium,” Acta Mater. 44, 2317–2326 (1996).

Determination of Superplasticity Indicators: Methodical Recommendation MR 252-31-86 (VILS, Moscow, 1986) [in Russian].

V. K. Portnoy and I. I. Novikov, “Evaluation of grain boundary sliding contribution to the total strain during superplastic deformation,” Scr. Mater. 40, 39–43 (1999).

ACKNOWLEDGMENTS

The work was supported by the Ministry of Education and Science of the Russia Federation in the framework of the Federal task no. 11.7172.2017/8.9 for 2017–2020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Gorin

Rights and permissions

About this article

Cite this article

Yakovtseva, O.A., Mikhaylovskaya, A.V., Kotov, A.D. et al. Effect of the Strain and Strain Rate on Microstructure Evolution and Superplastic Deformation Mechanisms. Phys. Metals Metallogr. 120, 87–94 (2019). https://doi.org/10.1134/S0031918X18110224

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18110224