Abstract

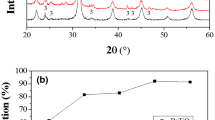

BaTi1–x Nb x O3 compounds (with x = 0.00, 0.01, 0.03, 0.06, and 0.09) are synthesized by the microwavehydrothermal (MH) method. The donor concentration effect on the structural properties is investigated. The new MH method is used instead of the previous solid state reaction for the BaTiO3+Nb2O3 system. In the MH process, as the niobium incorporation rate increases, the particle growth substantially slows down. The synthesis of Nb-doped BaTiO3 is investigated under the MH conditions subjected to 150°C for only 2 h using C16H36O4Ti (tetra-n-butyl orthotitanate), Ba(OH)2∙8H2O, and NbCl5 as Ba, Ti, and Nb sources respectively. For the phase evolution studies, X-ray diffraction patterns are analyzed and Raman spectroscopy is performed. The transmission electron microscope and the field emission scanning electron microscope images are taken for the detailed analysis of the grain size, surface, and morphology of the compound.

Similar content being viewed by others

References

V. V. Kharton, A. A. Yaremchenko, and E. N. Naumovich, J. Solid State Electrochem., 3, No. 6, 303–326 (2000).

Z. Bi, M. Cheng, Y. Dong, H. Wu, Y. She, and B. Yi, Solid State Ionics, 176, Nos. 7/8, 655–661 (2005).

H. Takamura, K. Enomoto, Y. Aizumi, A. Kamegawa, and M. Okada, Solid State Ionics, 175, Nos. 1-4, 379 (2004).

J. Holc, J. Slunecko, and M. Hrovat, Sens. Actuators, B, 26, Nos. 1-3, 99–102 (1995).

L. B. Kong and Y. S. Shen, Sens. Actuators, B, 30, No. 3, 217–221 (1996).

J. P. Lukaszewicz, N. Miura, and N. Yamazoe, Sens. Actuators, B, 1, Nos. 1-6, 195–198 (1990).

E. L. Brosha, R. Mukundan, D. R. Brown, F. H. Garzon, J. H. Visser, M. Zanini, Z. Zhou, and E. M. Logothetis, Sens. Actuators, B, 69, No. 1, 171–182 (2000).

E. Traversa, S. Matsushima, G. Okada, Y. Sadaoka, Y. Sakai, and K. Watanabe, Sens. Actuators, B, 25, No. 1, 661–664 (1995).

M. M. Vijatovic, J. D. Bobic, and B. D. Stojanovic, Sci. Sintering, 40, 155–165 (2008).

O. I. V’yunov, L. L. Kovalenko, and A. G. Belous, Inorg. Mater., 42, No. 12, 1363–1368 (2006).

B. D. Stojanovic, C. R. Foschini, M. A. Zaghete, F. O. S. Veira, K. A. Peron, M. Cilense, and J. A. Varela, J. Mater. Process. Technol., 143/144, 802–806 (2003).

J. Nowotny and M. Rakas, Ceram. Int., 20, 265–275 (1994).

E. Brzozowski and M. S. Castro, J. Mater. Process. Technol., 168, 464–470 (2005).

Y. Yuan, S. R. Zhang, X. H. Zhou, and B. Tang, J. Mater. Sci., 44, 3751–3757 (2009).

L. Liu, H. Guo, H. Lü, S. Dai, B. Cheng, and Z. Chen, J. Appl. Phys., 97, 054102 (2005).

E. Brzozowski, M. S. Castro, C. R. Foschini, and B. Stojanovic, Ceram. Int., 28, 773–777 (2002).

C. Chen, Y. Wei, X. Jiao, and D. Chen, Mater. Chem. Phys., 110, 186–191 (2008).

H. Xu and L. Gao, Mater. Lett., 58, 1582–1586 (2004).

W. Sun, C. Li, J. Li, and W. Liu, Mater. Chem. Phys., 97, 481–487 (2006).

H. Yaseen, S. Baltianski, and Y. Tsur, J. Am. Ceram. Soc., 89, No. 5, 1584–1589 (2006).

H.-J. Noh and S.-G. Lee, Trans. Electr. Electron. Mater., 10, No. 2, 121–125 (2009).

L. Liu, H. Guo, H. Lü, S. Dai, B. Cheng, and Z. Chen, J. Appl. Phys., 97, 054102 (2005).

L. Szymczak, Z. Ujma, M. Adamczyk, and M. Pawelczyk, Ceram. Int., 34, 1993–2000 (2008).

B. L. Newalkar, S. Komarneni, and H. Katsuki, Mater. Res. Bull., 36, 2347–2355 (2001).

V. D. Mote, Y. Purushotham, B. N. Dole, et al., J. Theor. Appl. Phys., 6, 6 (2012).

E. Purushotham and N. G. Krishna, Bull. Mater. Sci. (2009).

M. Herrmann, W. Engel, and H. Giibel, JCPDS Int. Cent. Diffr., Adv. X-Ray Anal., 45, 212–217 (2002).

M. Weier, J. Chem. Eng.–Calif. Univ. (2005).

H. A. A’vila, L. A. Ramajo, M. M. Reboredo, M. S. Castro, and R. Parra, Ceram. Int. (2011).

B. Min, S.-M. Moon, and N.-H. Cho, Curr. Appl. Phys., 1–4 (2011).

Z. Lazarevi, N. R. Cevi, M. Vijatovi, N. Paunovi, M. R. Cevi, B. Stojanovi, and Z. D. Cevi-Mitrovi, Acta Phys. Polonica A, 115, No. 4 (2009).

S. H. Jhung, J.-H. Lee, J. W. Yoon, Y. K. Hwang, J.-S. Hwang, S.-E. Park, and J.-S. Chang, Mater. Lett., 58, 3161–3165 (2004).

Y. Hotta, K. Tsunekawa, C. Duran, K. Sato, T. Nagaoka, and K. Watari, Mater. Sci. Eng. A, 475, 57–61 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © 2016 A. Khanfekr, M. Tamizifar, R. Naghizadeh.

Rights and permissions

About this article

Cite this article

Khanfekr, A., Tamizifar, M. & Naghizadeh, R. Effects of a donor concentration on the structure of Nb-doped nano-sized BaTiO3 powders prepared by microwave-hydrothermal synthesis methods. J Struct Chem 57, 181–187 (2016). https://doi.org/10.1134/S0022476616010224

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0022476616010224