Abstract

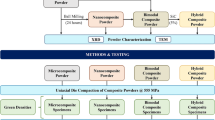

The properties and microstructure of an Al/(Al2O3 + TiB2 + ZrB2) hybrid composite made by using hot pressing of aluminum combined with different amounts of TiB2, ZrB2, and Al2O3 powders are studied. The mechanical properties of the composites are investigated on the basis of microhardness and compression tests. The results show that the microstructure of the composites is uniform and the particles are well distributed in the matrix.

Similar content being viewed by others

References

S. C. Tjong, G. S. Wang, and Y.-W. Mai, “High Cycle Fatigue Response of in situ Al-Based Composites Containing TiB2 and Al2O3 Submicron Particles,” Compos. Sci. Technol. 65 (10), 1537–1546 (2005).

M. Adamiak, “Selected Properties of the Aluminum Alloy Base Composites Reinforced with Intermetallic Particles,” J. Achievements Materials Manufactur. Eng. 14 (1/2), 43–47 (2006).

Shy-Wen Lai and D. D. L. Chung, “Superior High Temperature Resistance of Aluminium Nitride Particle Reinforced Aluminium Compared to Silicon Carbide or Alumina Particle Reinforced Aluminium,” J. Materials Sci. 29 (23), 6181–6198 (1994).

M. N. Wahab, A. R. Daud, and M. J. Ghazali, “Preparation and Characterization of Stir Cast Aluminium Nitride Reinforced Aluminium Metal Matrix Composites,” Int. J. Mech. Materials Engng. 4 (2), 115–117 (2009).

M. Chedru, J. L. Chermant, and J. Vicens, “Interfacial Reaction between Aluminium Nitride Reinforcement Particles and Aluminium Alloy in Al–AlN Metal Matrix Composite,” J. Materials Sci. Lett. 20, 1577–1583 (2001).

I. Dinaharan and N. Murugan, “Dry Sliding Wear Behavior of AA6061/ZrB2 in situ Composite,” Trans. Nonferrous Metals. Soc. China 22, 810–818 (2012).

J. B. Fogagnolo, M. H. Robert, E. M. Ruiz-Navas, and J. M. Torralba, “6061 Al Reinforced with Zirconium Diboride Particles Processed by Conventional Powder Metallurgy and Mechanical Alloying,” J. Materials Sci. 39, 127–132 (2004).

M. Singla, D. Deepak Dwivedi, L. Singh, and V. Chawla, “Development of Aluminium Based Silicon Carbide Particulate Metal Matrix Composite,” J. Minerals Materials Characteriz. Eng. 8 (6), 455–467 (2009).

E. Hong, B. Kaplin, T. You, et al., “Tribological Properties of Copper Based Composites Reinforced with Tungsten Carbide Particles,” Wear 270, 591–597 (2011).

N. P. Bansal, Handbook of Ceramic Composites. Norwell (Kluwer, 2005), pp. 198, 203.

D. Zhao, X. Liu, Y. Liu, and X. Bian, “In situ Preparation of Al Matrix Composites Reinforced by TiB2 Particles and Sub-Micron ZrB2,” J. Mater. Sci. 40 (16), 4365–4368 (2005).

C. F. Feng and L. Froyen, “In situ P/M Al/(ZrB2+Al2O3) MMCs: Processing, Microstructure and Mechanical Characterization,” Acta Mater. 47 (18), 4571–4583 (1999).

A. Wlodarczyk-Fligier, L. A. Dobrazanski, M. Kremzer, and M. Adamiak, “Manufacturing of Aluminum Matrix Composite Materials Reinforced by Al2O3 Particles,” J. Achievements Materials Manufactur. Eng. 27 (1), 99–102 (2008).

F. Farhadinia and S. Sedghi, “Fabrication of Al2O3/(ZrB2 + TiB2) Composite using MACS and Microwaves,” Metall. Materials Trans. A 45, 3125–3129 (2014).

M. Rahimian, N. Parvin, and N. Ehsani, “The Effect of Production Parameters on Microstructure and Wear Resistance of Powder Metallurgy Al–Al2O3 Composite,” Materials Design 32 (2), 1031–1038 (2011).

S. Panda, K. Dash, and B. C. Ray, “Processing and Properties of Cu Based Micro and Nano Composites,” Bull. Materials Sci. 37 (2), 227–238 (2014).

J. W. Kaczmar, K. Granat, E. Grodzka, and A. Kurzawa, “Tribological Properties of Cu Based Composite Materials Strengthened with Al2O3 Particles,” Arch. Foundry Eng. 12 (2), 33–36 (2012).

G. Abouelmagd, “Hot Deformation and Wear Resistance of P/M Aluminum Metal Matrix Composites,” Materials Proc. Technol. 155/156, 1395–1401 (2004).

A. A. Mazen and A. Y. Ahmed, “Mechanical Behavior of Al–Al2O3 MMC Manufactured by PM Techniques. 1. Scheme I Processing Parameters,” J. Materials Eng. Performance 7 (3), 393–401 (1998).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © F. Farhadinia, A. Sedghi, M.T. Nooghani.

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, Vol. 58, No. 3, pp. 90–97, May–June, 2017.

Rights and permissions

About this article

Cite this article

Farhadinia, F., Sedghi, A. & Nooghani, M.T. Properties of an Al/(Al2O3+TiB2+ZrB2) hybrid composite manufactured by powder metallurgy and hot pressing. J Appl Mech Tech Phy 58, 454–460 (2017). https://doi.org/10.1134/S0021894417030105

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894417030105