Abstract—

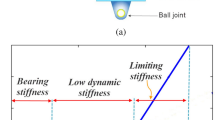

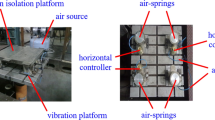

The bag-type molecular spring vibration isolator combines the characteristics of air spring and molecular spring. The molecular spring is placed in the bag-type vibration isolator. When the isolator is subjected to external load, the bag-type molecular spring vibration isolator is compressed, and the water invades and escapes from the hydrophobic micropores of the molecular spring material under external pressure, realizing the storage and release of energy. Combined with the deformation analysis of the bladder and the process of water molecules invading the hydrophobic micropores, the mechanical model of the molecular spring isolator was established and the force-displacement relationship of the isolator was deduced. The mechanical model was verified by quasi-static test and the influence factors of vibration isolator performance were analyzed by numerical simulation and experiments.Finally, the vibration isolation performance of the molecular spring isolator is measured by the vibration level drop. The results show that the theoretical and experimental results are in good agreement. The molecular spring isolator exhibits high-low-high segmental stiffness characteristics, and the stiffness in stage II is greatly reduced compared with stage I and stage III. The vibration level drop of the molecular spring isolator is more than 23 dB, and more than 93% of the vibration is isolated.

Similar content being viewed by others

REFERENCES

Li, F. and Qi, Z., China Railw., 2014, vol. 4, p. 42. https://doi.org/10.3969/j.issn.1001-683X.2014.04.010

Soulard, M., Patarin, J., Eroshenko, V., and Regis, R., Stud. Surf. Sci. Catal., 2004, vol. 154, no. 4, p. 1830. https://doi.org/10.1016/S0167-2991(04)80716-X

Yu, M., Gao, X., and Chen, Q., J. Mech., 2016, vol. 32, no. 5, p. 527. https://doi.org/10.1017/jmech.2016.52

Yu, M., Chen, Q., and Gao, X., Microsyst. Technol., 2017, vol. 23, no. 2, p. 285. https://doi.org/10.1007/s00542-014-2401-7

Tzanis, L., Trzpit, M., Soulard, M., and Patarin, J., Microporous Mesoporous Mater., 2011, vol. 146, nos. 1–3, p. 119. https://doi.org/10.1016/j.micromeso.2011.03.043

Lowe, A., Tsyrin, N., Chorążewski, M., Zajdel, P., Mierzwa, M., Leão, J.B., Bleuel, M., Feng, T., Luo, D., Li, M., Li, D., Stoudenets, V., Pawlus, S., Faik, A., and Grosu, Y., ACS Appl. Mater. Interfaces, 2019, vol. 11, no. 43, p. 40842. https://doi.org/10.1021/acsami.9b14031

Eroshenko, V., Regis, R.-Ch., Soulard, M., and Patarin, J., J. Am. Chem. Soc., 2001, vol. 123, no. 33. p. 8129. https://doi.org/10.1021/ja011011a

Soulard, M., Patarin, J., Eroshenko, V., and Regis, R., Stud. Surf. Sci. Catal., 2004, vol. 154, no. 4, p. 1830. https://doi.org/10.1016/S0167-2991(04)80716-X

Ortiz, G., Nouali, H., Marichal, C., Chaplais, G., and Patarin, J., Phys. Chem. Chem. Phys., 2013, vol. 15, p. 4888. https://doi.org/10.1039/c3cp00142c

Sun, Y., Rogge Sven, M.J., Aran, L., Steven, V., Jelle, W., Clive, S., Veronique, V.-S., and Tan, J., Nat. Mater., 2021, vol. 20, no. 7, p. 1015. https://doi.org/10.1038/s41563-021-00977-6

Grosu, Y., Mierzwa, M., Eroshenko, V., Pawlus, S., Chorążewski, M., Nedelec, J.-M., and Grolier, J.-P., ACS Appl. Mater. Interfaces, 2017, vol. 9, no. 8, p. 7044. https://doi.org/10.1021/acsami.6b14422

Fraux, G., Boutin, A., Fuchs, A.H., and Coudert, F.X., J. Phys. Chem. C, 2019, vol. 123, no. 25, p. 15589. https://doi.org/10.1021/acs.jpcc.9b02718

Jin, J., Yuan, J., and Ge, W., Theoretical Mechanics, Nanjing Southeast Univ. Press, 2019, p. 277.

He, L., Lv, Z., Zhao, Y., and Shuai, C., CN Patent CN201013822Y, 2008.

Zhang, F., Fundamentals of Molecular Interface Chemistry, Shanghai: Shanghai Scientific and Technological Literature Press, 2006.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Jin, Y., Chen, W. & Teng, H. Static and Dynamic Testing of Bag-Type Molecular Spring Vibration Isolator. Instrum Exp Tech 66, 693–701 (2023). https://doi.org/10.1134/S0020441223040073

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441223040073