Abstract—

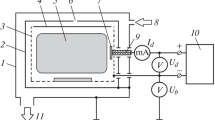

The dependence of the sputtering efficiency for a Mo mirror mock-up on the discharge power and the pressure of the working gas (Ar) has been investigated for three options of grounding of the discharge-cell elements in the plasma cleaning system. A gas discharge with a direct current or medium-frequency pulsed current is expected to be used to clean the entrance mirror of CXRS-edge (Active Spectroscopy) diagnostics of ITER. By selecting the electrode-grounding scheme it is possible to obtain different degrees of deceleration of ions that leave the discharge cell and are able to sputter the walls of the diagnostic port. The location of the diagnostic-port walls in close vicinity to the discharge cell and the absence of a working-gas flow through the region of the cleaning discharge are the specific features of the mirror cleaning systems in ITER. These conditions have been simulated by placing a full-scale functional model of the discharge cell into a leaky gas-dynamic fairing, which was made of stainless steel, like the walls of ITER diagnostic port. It is shown that the highest cleaning efficiency is attained when the cathode elements of the discharge cell and the entrance mirror in particular are electrically isolated from the diagnostic-port walls. These results can be used to develop plasma cleaning systems for other optical diagnostics of ITER.

Similar content being viewed by others

REFERENCES

Moser, L., Marot, L., Steiner, R., Reichle, R., Leipold, F., Vorpahl, C., Le Guern, F., Walach, U., Alberti, S., Furno, I., Yan, R., Peng, J., Ben Yaala, M., and Meyer, E., Phys. Scr., 2017, vol. 2017, no. T170, p. 014047. https://doi.org/10.1088/1402-4896/aa8f30

Dmitriev, A.M., Babinov, N.A., Bazhenov, A.N., Bukreev, I.M., Kochergin, M.M., Koval, A.N., Kurskiev, G.S., Litvinov, A.E., Masyukevich, S.V., Mukhin, E.E., Razdobarin, A.G., Samsonov, D.S., Solokha, V.V., Tolstyakov, S.Yu., Andrew, P., et al., Phys. Scr., 2017, vol. 2017, no. T170, p. 014072. https://doi.org/10.1088/1402-4896/aa95e5

Rogov, A.V. and Kapustin, Yu.V., Usp. Prikl. Fiz., 2016, vol. 4, no. 3, p. 240.

Vetoshkin, V.M., Kobziev, V.F., and Romanov, E.A., Tekhnologiya tonkikh plenok. Uchebno-metodicheskoe posobie (Technology of Thin Films. Educational and Methodological Manual), Izhevsk: Udmurt State Univ., 2013.

Kersten, H., Steffen, H., and Behnke, J.F., Surf. Coat. Technol., 1996, vols. 86–87, p. 762. https://doi.org/10.1016/S0257-8972(96)03030-7

Welzel, T. and Ellmer, K., J. Phys. D: Appl. Phys., 2013, vol. 46, no. 31, p. 315202. https://doi.org/10.1088/0022-3727/46/31/315202

Kagantsov, S.M., Frolov, I.Yu., and Solov’ev, A.V., in Mezhvuzovskii sbornik nauchnykh trudov “Metody i ustroistva peredachi i obrabotki informatsii” (Inter-University Collection of Scientific Works “Methods and Devices for Transferring and Processing of Information”), St. Petersburg: Gidrometeoizdat, 2003, p. 34.

Upadhyay, J., Peshl, J., Popović, S., Valente-Feliciano, A.-M., and Vušković, L., AIP Adv., 2018, vol. 8, p. 085008. https://doi.org/10.1063/1.5045692

Yamamura, Y. and Tawara, H., Energy Dependence of Ion-Induced Sputtering Yields from Monoatomic Solids at Normal Incidence, Research Report NIFS-DATA-23, Nagoya, 1995.

Dmitriev, A.M., Babinov, N.A., Bazhenov, A.N., Bukreev, I.M., Elets, D.I., Filimonov, V.V., Koval, A.N., Kueskiev, G.S., Litvinov, A.E., Mikhin, E.E., Razdobarin, A.G., Samsonov, D.S., Senitchenkov, V.A., Solovei, V.A., Terechenko, I.B., et al., Fusion Eng. Des., 2019, vol. 146, part A, p. 1390. https://doi.org/10.1016/j.fusengdes.2019.02.090

Vol'pyan, O.D. and Kuz’michev, A.I., Prikl. Fiz., 2008, no. 3, p. 34.

Berlin, E.V. and Seidman, L.A., Ionno-plazmennye protsessy v tonkoplenochnoi tekhnologii (Ion-Plasma Processes for Thin-Film Technology), Moscow: Tekhnosfera, 2010.

Klyuchnikov, L.A., Krupin, V.A., Korobov, K.V., Nurgaliev, M.R., Nemets, A.R., Dnestrovskii, A.Yu., Naumenko, N.N., Tugarinova, S.N., Serov, S.V., and Den’shchikov, D.S., Vopr. At. Nauki Tekh., Ser.: Termoyad. Sint., 2016, vol. 39, no. 1, pp. 95–104.

Orlovskiy, I., Alekseev, A., Andreenko, E., Asadulin, G., and Gorshkov, A., Fusion Eng. Des., 2017, vol. 123, p. 1011. https://doi.org/10.1016/j.fusengdes.2017.02.057

Giurlani, W., Berretti, E., Innocenti, M., and Lavacchi, A., Coatings, 2019, vol. 9, no. 2, p. 79. https://doi.org/10.3390/coatings9020079

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Goryacheva

Rights and permissions

About this article

Cite this article

Rogov, A.V., Kapustin, Y.V. Development of the Plasma Cleaning System for the Entrance Mirror of the CXRS-edge Diagnostics of ITER on the Basis of a Discharge with a Mesh Hollow Cathode. Instrum Exp Tech 64, 393–400 (2021). https://doi.org/10.1134/S0020441221030313

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441221030313