Abstract—

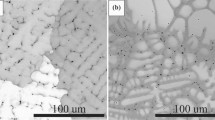

We have studied how the key parameters of a deformation process under the conditions of a bulk exothermic reaction of the formation of the Ni3Al intermetallic compound influence its grain size. The results demonstrate that the grain size of the intermetallic compound synthesized under pressure decreases with an increase in the time delay of exposure to pressure and an increase in deformation rate.

Similar content being viewed by others

REFERENCES

Stoloff, N.S., Liu, C.T., and Deevi, S.C., Emerging applications of intermetallics, Intermetallics, 2000, no. 8 (9–11), pp. 1313–1320.

Sikka, V.K., Deevi, S.C., Viswanathan, S., Swindeman, R.W., and Santella, M.L., Advances in processing of Ni3Al-based intermetallics and applications, Intermetallics, 2000, no. 8 (9–11), pp. 1329–1337.

Jozwik, P., Polkowski, W., and Bojar, Z., Review – applications of Ni3Al based intermetallic alloys—current stage and potential perceptivities, Materials, 2015, no. 8, pp. 2537–2568.https://doi.org/10.3390/ma8052537

Schulson, E.M., Weihs, T.P., Viens, D.V., and Baker, I., The effect of grain size on the yield strength of Ni3Al, Acta Metall., 1985, no. 33, pp. 1587–1591.

Jozwik, P. and Bojar, Z., Analysis of grain size effect on tensile properties of Ni3Al-based intermetallic strips, Arch. Metall. Mater., 2007, vol. 52, no. 2, pp. 321–327.

Aoki, K. and Izumi, O., Improvement in room temperature ductility of the L12 type intermetallic compound Ni3Al by boron addition, J. Jpn. Inst. Met., 1979, no. 43, pp. 1190–1196.https://doi.org/10.2320/jinstmet1952.43.12_1190

Kim, M.S., Hanada, S., Watanabe, S., and Izumi, O., Effect of grain size on strength, ductility and fracture in recrystallized Ni3Al doped with boron, Trans. Jpn. Inst. Met., 1988, vol. 29, no. 4, pp. 274–283.

Feng, T., Li, S.P., and Luo, H.L., Microstructure and properties of modified cast Ni3Al base MX246 alloys, Acta Metall. Sin., 2002, no. 31, pp. 547–551.

Giamei, A.F. and Anton, D.L., Rhenium additions to a Ni-base superalloy: effect on microstructure, Metall. Trans. A, 1985, vol. 16, no. 11, pp. 1997–2005.

Reed, R.C., Tao, T., and Warnken, N., Alloys-by-design: application to nickel-based single crystal superalloys, Acta Mater., 2009, no. 57, pp. 5898–5913.

Chan, K.S., Theoretical analysis of grain size effects on tensile ductility, Scr. Metall. Mater., 1990, vol. 24, pp. 1725–1750.https://doi.org/10.1016/0956-716X(90)90536-P

Jozwik, P. and Bojar, Z., Analysis of grain size effect on tensile properties of Ni3Al-based intermetallic strips, Arc. Metall. Mater., 2007, vol. 52, no. 2, pp. 322–327.

Polkowski, W., Jozwik, P., and Bojar, Z., Differential speed rolling of Ni3Al based intermetallic alloy—analysis of the deformation process, Mater. Lett., 2015, no. 139, pp. 46–49. https://doi.org/10.1016/j.matlet.2014.09.129

Bazhin, P.M., Stolin, A.M., and Alymov, M.I., Preparation of nanostructured composite ceramic materials and products under conditions of a combination of combustion and high-temperature deformation (SHS extrusion), Nanotechnol. Russ., 2014, vol. 9, nos. 11–12, pp. 583–600.

Stolin, A.M. and Bazhin, P.M., Manufacture of multipurpose composite and ceramic materials in the combustion regime and high-temperature deformation (SHS extrusion), Theor. Found. Chem. Eng., 2014, vol. 48, no. 6, pp. 751–763.

Ovcharenko, V.E., Akimov, K.O., and Boyangin, E.N., Influence of preloading and deformation on the grain structure and strength of the Ni3Al intermetallic compound synthesized under pressure, Inorg. Mater., 2019, vol. 55, no. 10, pp. 989–993.https://doi.org/10.1134/S0020168519080120

Ovcharenko, V.E., Boyangin, E.N., Akimov, K.O., and Ivanov, K.V., Formation of grain structure in Ni3Al intermetallic compound synthesized by thermal explosion, Combust., Explos. Shock Waves, 2019, vol. 55, no. 2, pp. 191–196.https://doi.org/10.1134/S0010508219020084

Funding

This work was supported by the Russian Academy of Sciences through the Basic Research Program, 2013–2020, project no. 23.2.2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Ovcharenko, V.E., Akimov, K.O. Effect of Deformation on the Grain Size of the Ni3Al Intermetallic Compound Synthesized under Pressure. Inorg Mater 56, 1122–1126 (2020). https://doi.org/10.1134/S0020168520110114

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520110114