Abstract—

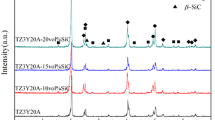

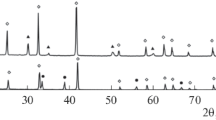

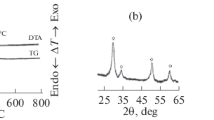

We have prepared powders and ceramic composite materials in the ZrO2–Al2O3 system containing 10 and 20 wt % Al2O3 and examined the effect of ferric oxide additions on the linear shrinkage, phase composition, porosity, microstructure, and mechanical properties of the ZrO2–Al2O3 ceramic materials. The results demonstrate that the addition of ferric oxide leads to a considerable increase in linear shrinkage and ensures porosity as low as under 1% even at a sintering temperature of 1450°C in both composite materials. Moreover, small amounts of the additive stabilize the tetragonal phase of ZrO2, whereas increasing the Fe content to 3 mol % leads to an increase in the amount of the monoclinic phase. We have obtained densely sintered ZrO2–10% Al2O3 and ZrO2–20% Al2O3 ceramic materials at 1450°C, with a bending strength of up to 760 and 475 MPa, respectively.

Similar content being viewed by others

REFERENCES

Balagopal, N., Warrier, K.G.K., and Damodaran, A.D., Alumina–ceria composite powders through a flash combustion technique, J. Mater. Sci. Lett., 1991, vol. 10, no. 19, pp. 1116–1118.

Deshmukh, R.M. and Kulkarni, S.S., A review on biomaterials in orthopedic bone plate application, Int. J. Current Eng. Technol., 2015, vol. 5, no. 4, pp. 2587–2591.

Nevarez-Rascon, A., Gonzalez-Lopez, S., Acosta-Torres, L.S., Nevarez-Rascon, M.M., and Orrantia-Borunda, E., Synthesis, biocompatibility and mechanical properties of ZrO2–Al2O3 ceramics composites, Dental Mater. J., 2016, vol. 35, no. 3, pp. 392–398.

Smirnov, V.V., Krylov, A.I., Smirnov, S.V., Goldberg, M.A., Antonova, O.S., Kochanov, G.P., and Barinov, S.M., Sintering and microstructure of materials based on the fluorohydroxyapatite–ZrO2–Al2O3 system, Inorg. Mater., 2016, vol. 52, no. 10, pp. 1025–1030.

Matsui, K., Ohmichi, N., Ohgai, M., Yoshida, H., and Ikuhara, Y., Effect of alumina-doping on grain boundary segregation-induced phase transformation in yttria-stabilized tetragonal zirconia polycrystal, J. Mater. Res., 2006, vol. 21, no. 9, pp. 2278–2289.

Jayaseelan, D., Nishikawa, T., Awaji, H., and Gnanam, F.D., Pressureless sintering of sol–gel derived alumina–zirconia composites, Mater. Sci. Eng., A, 1998, vol. 256, nos. 1–2, pp. 265–270.

Akin, I., Yilmaz, E., Sahin, F., Yucel, O., and Goller, G., Effect of CeO2 addition on densification and microstructure of Al2O3–YSZ composites, Ceram. Int., 2011, vol. 37, no. 8, pp. 3273–3280.

Xu, X., Xu, X., Liu, J., Hong, W., and Hou, F., Low-temperature fabrication of Al2O3–ZrO2 (Y2O3) nanocomposites through hot pressing of amorphous powders, Ceram. Int., 2016, vol. 42, no. 13, pp. 15 065–15 071.

Flegler, A.J., Burye, T.E., Yang, Q., and Nicholas, J.D., Cubic yttria stabilized zirconia sintering additive impacts: a comparative study, Ceram. Int., 2014, vol. 40, no. 10, pp. 16 323–16 335.

Foschini, C.R., Souza, D.P.F., Paulin Filho, P.I., and Varela, J.A., AC impedance study of Ni, Fe, Cu, Mn doped ceria stabilized zirconia ceramics, J. Eur. Ceram. Soc., 2001, vol. 21, no. 9, pp. 1143–1150.

Guo, F. and Xiao, P., Effect of Fe2O3 doping on sintering of yttria-stabilized zirconia, J. Eur. Ceram. Soc., 2012, vol. 32, no. 16, pp. 4157–4164.

Smirnov, V.V., Obolkina, T.O., Krylov, A.I., Smirnov, S.V., Goldberg, M.A., Antonova, O.S., and Barinov, S.M., Agglomeration and properties of ceramics based on partially stabilized zirconium dioxide containing oxides of aluminum and iron, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 1, pp. 121–124.

Ye, Y., Li, J., Zhou, H., and Chen, J., Microstructure and mechanical properties of yttria-stabilized ZrO2/Al2O3 nanocomposite ceramics, Ceram. Int., 2008, vol. 34, no. 8, pp. 1797–1803.

Funding

This work was supported by the Russian Federation President’s Grant no. MK-5661.2018.8 and the Russian Federation President’s Scholarship no. SP-3724.2018.4.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Obolkina, T.O., Goldberg, M.A., Smirnov, V.V. et al. Increasing the Sintering Rate and Strength of ZrO2–Al2O3 Ceramic Materials by Iron Oxide Additions. Inorg Mater 56, 182–189 (2020). https://doi.org/10.1134/S0020168520020156

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520020156