Abstract

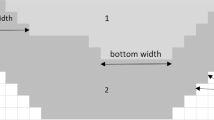

As a type of general layout problems, dig-limits optimization focuses on generating the ore–waste boundaries of a bench sector in an open-pit mining operation. Typically, blast holes are dense; therefore, selective mining units (SMUs) are small, which is not compatible with loading equipment. Loader cannot select ore-waste boundaries of SMUs because the arm of the excavator is generally longer than SMU sizes. Therefore, clusters of SMUs being compatible with loader movements need to be formed. In this paper, the dig-limits optimization problem is shown to be NP-hard and formulated to maximize profit to be obtained from a mining sector such that ore and waste clusters corresponding to mine excavator movements are considered and solved by mixed-integer linear programming. To see the efficiency of the proposed approach, a case study is conducted on seven sectors of a bench in a gold mine. The results showed that the approach is practical and has potential to increase the value of operation. The resulting average economic value of seven sectors is $129,060. Additionally, optimal design of one bench solved by the model is compared to a manual design of a mining engineer and a deviation of 6.4% has been observed.

Similar content being viewed by others

References

Allard D, Armstrong M and Kleingeld W (1994). The Need for a Connectivity Index in Mining Geostatistics Geostatistics for the Next Century (pp. 293–302). Springer.

Assibey-Bonsu W and Krige D (1999). Use of direct and indirect distributions of selective mining units for estimation of recoverable resource/reserves for new mining projects. In: Paper Presented at the Proceedings, APCOM’99 Symposium. Colorado School of Mines.

Bakirli B, Gencer C and Aydoğan E (2014). A combined approach for fuzzy multi-objective multiple knapsack problems for defence project selection. Journal of the Operational Research Society 65(7):1001–1016.

Bernardi S and Anjos MF (2013). A two-stage mathematical-programming method for the multi-floor facility layout problem. Journal of the Operational Research Society 64(3):352–364.

Frimpong S, Asa E and Szymanski J (1998). MULSOPS: multivariate optimized pit shells simulator for tactical mine planning. International Journal of Surface Mining, Reclamation and Environment 12(4):163–171.

Isaaks E, Treloar I and Elenbaas T (2014). Optimum dig lines for open pit grade control. In: Paper presented at the 9th International Mining Geology Conference, Adelaide, South Australia.

Jara R, Couble A, Emery X, Magri E and Ortiz J (2006). Block size selection and its impact on open-pit design and mine planning. Journal of the South African Institute of Mining and Metallurgy 106(3):205–212.

Kawalec W (2004). Short-term scheduling and blending in a lignite open pit mine with BWEs. In: Hardygora M, Paszkowska G and Sikora M (eds). Mine Planning and Equipment Selection (pp. 53–59).

Kear R (2006). Strategic and tactical mine planning components. Journal of the South African Institute of Mining and Metallurgy 106(2):93.

Kumral M (2013). Optimizing ore-waste discrimination and block sequencing through simulated annealing. Applied Soft Computing 13(8):3737–3744.

Kumral M (2015). Grade control in multi-variable ore deposits as a quality management problem under uncertainty. International Journal of Quality & Reliability Management 32(4):334–345.

Norrena K and Deutsch C (2000). Automatic Determination of Dig Limits Subject to Geostatistical, Economical and Equipment Constraints. Center for Computational Geostatistics (CCG), University of Alberta, Edmonton, Alberta, Canada.

Norrena K and Deutsch C (2002). Optimal determination of dig limits for improved grade control. In: Paper Presented at the APCOM 2002: 30 th International Symposium on the Application of Computers and Operations Research in the Mineral Industry.

Osanloo M, Gholamnejad J and Karimi B (2008). Long-term open pit mine production planning: a review of models and algorithms. International Journal of Mining, Reclamation and Environment 22(1):3–35.

Richmond A (2002). Applying four different risk models in local ore selection. Natural Resources Research 11(4):299–314.

Richmond A (2004). Integrating multiple simulations and mining dilution in open pit optimisation algorithms. In: Paper Presented at the Orebody Modelling and Strategic Mine Planning Conference.

Richmond A and Beasley J (2004). Financially efficient dig-line delineation incorporating equipment constraints and grade uncertainty. International Journal of Surface Mining 18(2):99–121.

Ruiseco JR and Kumral M (2017). A practical approach to mine equipment sizing in relation to dig-limit optimization in complex orebodies: multi-rock type, multi-process, and multi-metal case. Natural Resources Research 26(1):23–35.

Ruiseco JR, Williams J and Kumral M (2016). optimizing ore-waste dig-limits as part of operational mine planning through genetic algorithms. Natural Resources Research 25(4):473–485.

Silva E, Alvelos F and de Carvalho JV (2014). Integrating two-dimensional cutting stock and lot-sizing problems. Journal of the Operational Research Society 65(1):108–123.

Smith ML (1998). Optimizing short-term production schedules in surface mining: integrating mine modeling software with AMPL/CPLEX. International Journal of Surface Mining, Reclamation and Environment 12(4):149–155.

Song X and Bennell JA (2014). Column generation and sequential heuristic procedure for solving an irregular shape cutting stock problem. Journal of the Operational Research Society 65(7):1037–1052.

Souza MJ, Coelho IM, Ribas S, Santos HG and Merschmann LHDC (2010). A hybrid heuristic algorithm for the open-pit-mining operational planning problem. European Journal of Operational Research 207(2):1041–1051.

Tabesh M and Askari-Nasab H (2013). Automatic creation of mining polygons using hierarchical clustering techniques. Journal of Mining Science 49(3):426–440.

van Laarhoven PJM, Aarts EHL (1987). Simulated annealing Simulated Annealing: Theory and Applications (pp. 17–38). Dordrecht: Springer.

Wilde B and Deutsch CV (2015). A Short Note Comparing Feasibility Grade Control with Dig Limit Grade Control. Retrieved May 10, 2015.

Acknowledgements

The authors thank the Natural Sciences and Engineering Research Council of Canada (NSERC) for supporting this research (Fund No.: 236482).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sari, Y.A., Kumral, M. Dig-limits optimization through mixed-integer linear programming in open-pit mines. J Oper Res Soc (2017). https://doi.org/10.1057/s41274-017-0201-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1057/s41274-017-0201-z