Abstract

Metal-silicon junctions are crucial to the operation of semiconductor devices: aggressive scaling demands low-resistive metallic terminals to replace high-doped silicon in transistors. It suggests an efficient charge injection through a low Schottky barrier between a metal and Si. Tremendous efforts invested into engineering metal-silicon junctions reveal the major role of chemical bonding at the interface: premier contacts entail epitaxial integration of metal silicides with Si. Here we present epitaxially grown EuSi2/Si junction characterized by RHEED, XRD, transmission electron microscopy, magnetization and transport measurements. Structural perfection leads to superb conductivity and a record-low Schottky barrier with n-Si while an antiferromagnetic phase invites spin-related applications. This development opens brand-new opportunities in electronics.

Similar content being viewed by others

Introduction

Integrated-circuit scaling faces fundamental restrictions in the areas of design, manufacturing, energy and physical space1. Information technologies have entered the era of material limited device scaling2: basic materials of electronics have been extended to their performance limits. Likewise, emerging computing technologies pose further challenges to materials research. In particular, front end processes shift focus onto contacts in nanoscale devices2, thus emphasizing the importance of precise control over the structure and composition of the metal-semiconductor (MS) interface3.

Both reduced dimensionality and device scaling lead to soaring current densities raising problems of heat dissipation and electromigration. Interdiffusion and uncontrolled chemical reactions affect the properties of materials and interfaces, thus destroying device functionality. The Schottky barrier height (SBH), the most important characteristic of an MS interface, exhibits sharp dependence on the interfacial chemistry4. In particular, Si – a workhorse of modern electronics – reacts with most metals to form silicides5.

Nowadays, metal silicides are an integral part of microelectronics being used as ohmic and Schottky barrier (SB) contacts, interconnects, gate electrodes or diffusion barriers6. Compatibility with Si technology, low resistance, suppression of electromigration, good contacts to other materials ensure numerous applications of silicides. In particular, the self-aligned silicide (SALICIDE) technology free of lithographic patterning processes is commonly employed for manufacturing ultra-large-scale integration devices7. Mid-gap silicides TiSi2, CoSi2 and NiSi are most popular materials due to low resistivity but scaling to ultra-small gate lengths and junction depths is challenging: issues like phase purity and Si consumption become increasingly important5,6,8. When reduced to nanoscale, silicides make a frontier research subject: they form nanodots and nanowires with appealing properties5,6,9,10, are employed as contacts to Si nanowires11,12,13 and integrate Si technology with prospective materials like graphene14.

Rare-earth (RE) silicides make a special class of materials with a low SBH to n-Si15. This property ensures their use as source/drain terminals in the SB metal-oxide-semiconductor field-effect transistors (MOSFET) technology16 combining advantages of low parasitic resistance, small junction depth, high channel mobility, low temperature processing. The device scaling to sub-10 nm gate lengths requires atomically abrupt junctions as well as the epitaxial quality of silicide layers alleviating the problem of grain boundaries, improving thermal stability and uniformity5. Among RE silicides, crystalline YbSi2−x and ErSi2−x are leading candidates for SB-MOSFET due to their lowest values of SBH (0.27–0.28 eV, to compare with ~0.6 eV for widely used transition metal mid-gap silicides) after thermal annealing17,18,19 which can be further reduced by segregation of impurities at the silicide/Si interface20. Nevertheless, the technology demands contact materials free of manufacturing problems such as non-stoichiometry and with yet lower SBH.

Additional requirements are imposed on the contact material if it is designed to be compatible with spintronic applications. Silicon spintronics is an emerging set of energy-efficient information technologies implementing spin functionality in Si21,22. Injection of spin-polarized carriers into a semiconductor is demonstrated from magnetic semiconductors23, half-metals24 and metals through insulating tunnel barriers25,26,27,28,29 or Schottky-tunnel-barrier contacts30. Ohmic contacts are not functional without spin pumping31. Thus, SBH is a crucial parameter for metal/semiconductor spin injection32,33. Although transient femtosecond spin current can be induced in a non-magnetic material34, spin injection requires magnetic contacts. In general, any magnetic order suppresses spin scattering. Ferromagnetic silicides MnSi35 and Fe3Si36 are effective spin injectors. On the other hand, antiferromagnetic (AFM) contacts are also functional in spintronics applications as they support spin currents and better suited for using as spin detectors than ferromagnets37. AFM buffer layers may enhance spin transfer efficiency from a ferromagnet38.

Here, we propose stoichiometric europium silicide EuSi2 as a new multifunctional material for contacts with Si in nanoelectronics. We demonstrate that epitaxial EuSi2/Si junction is easy-to-manufacture and free of alien phases. The quality of the contact is confirmed by a number of techniques. In particular, transmission electron microscopy reveals the atomically sharp EuSi2/Si interface. The SBH of the EuSi2/n-Si junction (0.21 eV) is determined to be the lowest among all silicides suggesting its use in the SB-MOSFET technology. The AFM phase of EuSi2 invites its applications in spintronics.

Results and Discussion

Europium (II) compounds are famous due to a wide range of electrical, magnetic and optical properties but the Eu-Si system and, in particular, EuSi2 are far from being well-studied. EuSi2 crystallizes in the tetragonal α-ThSi2 structure type (I41/amd space group) with lattice constants 4.304, 4.304 and 13.65 Å39. Europium is highly reactive and its reaction with Si does not require high temperature: EuSi2 appears as a common side product of EuO growth on Si surfaces40,41. At the same time attempts to grow epitaxial films of EuSi2 have been unsuccessful: resulting in nanoislands and/or polycrystalline films42. Studies of the early stage of the silicide formation on Si (111) reveal that Si is the dominant diffusion species43 which is common for disilicides6. The outcome of the reaction is probably governed by the Si diffusion rate which strongly depends on the substrate temperature. Therefore, in our studies of EuSi2 growth on Si (001) substrate we pay special attention to fine tuning of temperature and Eu flux.

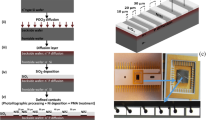

To control the state of the surface during the growth we routinely employ reflection high-energy electron diffraction (RHEED) images along the [110] azimuth of the Si substrate. The surface of the substrate is prepared by heating up to 950 °C (according to pyrometer readings) to remove the natural surface SiO2 layer. The resulting surface exhibits 2 × 1 + 1 × 2 diffraction pattern (Fig. 1a). Then, the substrate kept at a temperature of 400 °C is exposed to a constant Eu pressure of 1.5·10−8 Torr coming from a Knudsen cell kept at 470 °C. It corresponds to adsorption-controlled growth (also known as MBE distillation) with an average rate 3 Å/min. It implies that the Eu flux can be varied widely without much effect on the growth outcome as long as the growth regime remains the same. RHEED images reveal a sequence of growth stages. It is common for RE silicides to self-organize and form a number of high aspect ratio nanowires when sub-monolayer amounts of metal are deposited on the surface. Also, a number of surface phases are known for RE metals on Si, including those for Eu40,44. Three of them are observed at the beginning of the growth: successive surface superstructures 1 × 2 + 2 × 1, 1 × 5 + 5 × 1 and 1 × 3 + 3 × 1 are followed by formation of wide stripes on the RHEED image (Fig. 1b). Next, the stripes become thinner indicating improvement of the crystalline quality; the set of reflections gradually transforms to one that can be attributed to a single crystalline EuSi2 layer (Fig. 1c). Pronounced intensity modulation along the stripes at the later stages of the growth (Fig. 1d) is a fingerprint of surface roughening. However, addition of another short high-temperature (560 °C) growth stage results in smoother surface (Fig. 1e). Films with thickness up to 560 Å have been manufactured. The lateral lattice parameter determined from the distance between streaks in the RHEED pattern is equal to 4.34 ± 0.05 Å. A capping layer of SiOx with a thickness of 200 Å is deposited on top of EuSi2 to ensure its protection from the air.

RHEED images along the [110] azimuth of silicon substrate (azimuth [100] for the grown EuSi2 film): (a) Initial clean Si surface with reconstruction 2 × 1 + 1 × 2. (b) About 30 Å of EuSi2 grown on Si at 400 °C. (c) About 50 Å of EuSi2 grown on Si at 400 °C. (d) After the growth at 400 °C, about 530 Å of EuSi2 on Si. (e) After high-temperature growth at 560 °C, about 560 Å of EuSi2 on Si.

Notice that our procedure is not very different from that employed in ref. 42 but the remarkable change of the outcome (single crystal instead of polycrystalline film) originates from a meticulous optimization of the growth conditions. The stability of the EuSi2 structure probably plays a great role in the easy formation of the epitaxial silicide film: similar reaction of Sr with Si substrate results in polycrystalline SrSi2 despite Sr being an equally active metal and very similar ionic radii of Eu(II) and Sr. Since the synthesis requires relatively mild conditions a reduced thermal budget is expected for its technological implementation. Although non-stoichiometry is often observed in rare-earth disilicides the problem is significant for hexagonal and orthorhombic structures while the tetragonal phase (like EuSi2) is characterized by a composition close to stoichiometric. As for our particular system EuSi2/Si(001), a synchrotron radiation study of EuSi2 nanoislands and polycrystalline films45 shows that the product of reaction between Eu and the Si(001) substrate has the EuSi2 stoichiometry.

The epitaxial quality of the film is confirmed by X-ray diffraction (XRD) studies: Fig. 2 shows a typical θ–2θ XRD scan displaying peaks (004), (008), (0012) and (0016) from EuSi2 as well as peaks from the substrate. No other phases are detected. All EuSi2 peaks correspond to the same orientation with the c-axis orthogonal to the surface. EuSi2 crystallites with such orientation are also observed in XRD spectra of polycrystalline EuSi242 however accompanied by a number of other orientations. A lattice parameter of 13.633 ± 0.006 Å in the direction orthogonal to the EuSi2/Si interface is determined from the location of reflections in the θ–2θ scan.

θ–2θ X-ray diffraction scan of the EuSi2/Si junction (56 nm of the silicide).

The spectrum reveals allowed peaks of EuSi2, namely (004), (008), (0012) and (0016). Stars (*) denote peaks from the Si substrate. No extrinsic peaks are detected. Inset: thickness fringes around EuSi2 (004) reflection for a 20 nm film.

Thickness fringes are observed for the EuSi2 (004) reflection (see inset in Fig. 2). This characteristic feature of x-ray diffraction is a result of the wave interference due to reflections at the interfaces, both top and bottom. Taking into account the value of the x-ray wave length (1.5418 Å), the observation of the thickness fringes is a fingerprint of sharp interfaces; otherwise the reflected waves cannot maintain the coherence and thickness fringes would not show up.

The carrier injection efficiency of the structure depends on the properties of the EuSi2/Si interface rather than on the overall quality of the film. Thus, a study of the films with transmission electron microscopy (TEM) techniques becomes indispensable. A bright field TEM image of the EuSi2 film on Si (001) is shown in Fig. 3a. Even at low magnification the interface looks sharp and smooth, without any unevenness like precipitates with facets parallel to (111) Si planes. Our experiments result in a very smooth top surface of the film in strong contrast to polycrystalline EuSi2 films of previous attempts42. The selected area (electron) diffraction pattern (SADP), shown in Fig. 3b, certifies that EuSi2 adopts a tetragonal crystal lattice with lattice parameters a = 4.3 Å and c = 13.6 Å, quite close to those known in the literature39 and those determined in our RHEED and XRD studies. The orientation relationships derived from the SADP are:

Microscopic structure of the EuSi2/Si junction.

(a) Low-magnification cross-sectional bright-field TEM image of the 56 nm EuSi2 film on Si protected by SiOx viewed along the [110] zone axis of the Si substrate and showing the absence of side products. (b) Selected area electron diffraction pattern of EuSi2 superimposed with that of Si revealing their relative orientation. (c) Medium-magnification cross-sectional bright-field TEM image of the EuSi2/Si interface showing out-of-phase boundaries in the film. (d) High-resolution cross-sectional bright-field TEM image demonstrating atomic structure of the EuSi2/Si interface.

corroborating the RHEED and XRD data. It means that the lattice mismatch between EuSi2 and Si is large, approximately 12%.

The absence of any intermediate layer at the interface is found in high-resolution (HR) electron microscopy images with different magnification (Fig. 3c,d). This is quite remarkable as an amorphous interlayer is found to occur in most metal/silicon systems6. Another observation is the presence of atomic steps on the Si surface with the height varying between asi/2 and  , where

, where  is the Si unit cell constant. Inverse fast Fourier transform images (not presented here) show that the lattice mismatch between EuSi2 and Si is released through misfit dislocations. The projection of the Burgers vector on (110)Si is

is the Si unit cell constant. Inverse fast Fourier transform images (not presented here) show that the lattice mismatch between EuSi2 and Si is released through misfit dislocations. The projection of the Burgers vector on (110)Si is  . The average distance between dislocations is 20 Å – the value expected from the lattice mismatch between EuSi2 and Si. Further inspection of HR images reveals out-of-phase boundaries (OPBs) in the EuSi2 film as well as regions of 50–200 Å size with tiny misorientations. The formation of OPBs is associated with the steps at the interface: the shift between the adjacent regions is close to c/4. The density of OPBs diminishes from the EuSi2/Si interface to the EuSi2 surface. The misorientations come from misfit dislocations and related strains. The film homogeneity is established by TEM studies of 8 × 5 μm2 specimens taken from different parts of the 25 × 25 mm2 EuSi2/Si film. A remarkable quality of both the film and the interface manifests marked progress in manufacturing EuSi2/Si junction.

. The average distance between dislocations is 20 Å – the value expected from the lattice mismatch between EuSi2 and Si. Further inspection of HR images reveals out-of-phase boundaries (OPBs) in the EuSi2 film as well as regions of 50–200 Å size with tiny misorientations. The formation of OPBs is associated with the steps at the interface: the shift between the adjacent regions is close to c/4. The density of OPBs diminishes from the EuSi2/Si interface to the EuSi2 surface. The misorientations come from misfit dislocations and related strains. The film homogeneity is established by TEM studies of 8 × 5 μm2 specimens taken from different parts of the 25 × 25 mm2 EuSi2/Si film. A remarkable quality of both the film and the interface manifests marked progress in manufacturing EuSi2/Si junction.

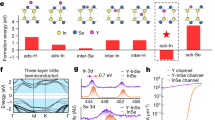

The temperature dependence of magnetic susceptibilities χ|| and χ⊥ (Fig. 4) demonstrates a typical behavior associated with the AFM transition. The observed magnetic anisotropy is consistent with the AFM magnetic easy axis normal to the film surface. The Néel temperature obtained from the cusp in χ(T) is 41 ± 2 K. This magnetic ordering temperature is the largest (along with that of GdSi2) among RE silicides46. To compare with other low-SBH silicides, YbSi2−x does not exhibit any magnetic order down to 1.8 K, while the magnetic ordering temperature of ErSi2−x is 2.8 K46. In the paramagnetic region the susceptibility follows the Curie-Weiss law (see Fig. 4). The negative Weiss constant, indicative of the AFM behavior, is −50 ± 10 K. The estimated effective moment per Eu ion is about 9 μB, which is close to the effective moment 7.9 μB associated with Eu2+ ions (spin S = 7/2). It corroborates the electron energy loss spectroscopy study which determined Eu in its silicide to be divalent47. The magnetic field dependence of the sample magnetization (inset of Fig. 4) is linear for T > 5 K and magnetic field up to 7 T. A robust antiferromagnetism of EuSi2 constitutes its additional functional advantage: AFM is accompanied by opening a spin gap which eliminates low-lying spin excitations detrimental to spin coherence. This property may enable efficient spin transport.

The temperature dependence of the magnetic susceptibility of the EuSi2/Si junction measured in magnetic field H = 1 T applied along the surface of the 56 nm film (χ||, red circles) and normal to the surface of the film (χ⊥, blue squares).

Solid black lines show Curie-Weiss law approximations of χ|| and χ⊥ above the Néel temperature. Inset: the temperature dependencies of the magnetization per Eu atom for different magnetic fields normal to the surface of the EuSi2 film.

The transport properties of the films support the results of magnetic measurements. A sharp anomaly associated with the AFM transition is observed in the vicinity of 40 K – the resistivity decreases by an order of magnitude (Fig. 5). The shift of the anomaly in a magnetic field of 9 T is −4.3 K. The resistivity of a magnetic metal is dominated by local spin fluctuations; the temperature dependence of dρ(T)/dT should follow that of the magnetic specific heat48. The form of the dρ(T)/dT curve of the EuSi2 films (Fig. 5) does correspond to that for magnetic specific heat in the Ising model for 3D antiferromagnets49. Crystalline defects usually suppress the anomaly at the Néel temperature – obviously not in this case. The dρ(T)/dT curve still stays sharp in magnetic field of up to 9 T – it just shifts towards low temperature. Such behavior is a fingerprint of a superb quality of the AFM system.

The resistivity of EuSi2 changes from 37 μOhm·cm at room temperature to 2.1 μOhm·cm at 2 K. The residual resistivity is significantly smaller than that observed for ErSi250 or ErSi1.751 thin films. Hall effect measurements of our films determine the electron concentration about 1022 cm−3. The Hall mobility increases from 5 cm2/(V·s) at room temperature to 500 cm2/(V·s) at 1.5 K. These properties make EuSi2 a very attractive metallic junction material.

In Si-based nanoelectronics the resistivity of a silicide is coupled with another major characteristic, consumption of Si in its reaction with a metal. Low silicon consumption is a most important technological requirement constraining applications of metal silicides to ultra-shallow junctions and silicon-on-insulator films. Low sheet resistance requires the silicide thickness to be maximized but correspondingly increased Si consumption leads to local junction penetration. It is a major factor that hinders applications of CoSi2 and elevates NiSi among other mid-gap silicides. Si consumption is characterized by the ratio of the resulting silicide thickness to the thickness of consumed Si, required to be as large as possible. Typical values are close to 1: 1.10 for TiSi2, 0.97 for CoSi2, 1.20 for NiSi and 1.27 for stoichiometric ErSi2. The same parameter calculated for EuSi2 is very large (1.58) making this material highly attractive for nanoscale applications. However, EuSi2 is not designed to compete with transition-metal low-resistivity silicides; instead, it is suggested as a prospective material for the SB-MOSFET technology (see below).

Injection of carriers into Si from a metal contact is governed by the SBH. The Si substrate in our experiments exhibits resistivity 3.8 kOhm·cm, electron concentration 1.5·1012 cm−3 and Hall mobility 1100 cm2V−1s−1. The current-voltage characteristic of the SBH for the grown EuSi2/n-Si contact is distinctly asymmetric in the temperature region between 160 K and 300 K (Fig. 6). With a small forward bias the I–V curve is exponential. Defects at the metal/Si interface effectively increase the SBH and hinder the injection4. The I–V curve for the EuSi2/n-Si contact follows the ideal (not influenced by surface states) classical thermionic theory52, yet another indication of the quality of the interface:

where IS is the saturation current, T – the absolute temperature, qe – the electron charge, A is the Richardson constant, S is the contact area and Φb is the SBH. According to our data the SBH of the EuSi2/n-Si junction is 0.21 ± 0.01 eV, significantly smaller than the values known for other RE silicides16. The record-low Schottky barrier height constitutes a major advantage of EuSi2 over other silicides in competition for employment as contact material in electronics.

In summary, taking into account technological advantages of metal silicides and their full compatibility with Si technology we propose europium disilicide as a prospective junction material. In the course of our work we optimized conditions for manufacturing EuSi2/Si contacts. Epitaxial films are grown by reaction of Eu with silicon substrate. The synthesis is robust, easy to implement and what is most important is free from unwanted side products. Moreover, electron microscopy shows that the EuSi2/Si interface is atomically abrupt despite a significant lattice mismatch.

Apart from the superb structural quality of the EuSi2/Si interface and EuSi2 film, europium silicide exhibits a combination of properties which respond to demands of modern electronics: At low temperature EuSi2 becomes antiferromagnetic which may assist applications employing spin-related phenomena. Rather low resistivity and very low Si consumption are among other advantages of the material. Most importantly, the EuSi2/n-Si junction exhibits the lowest among silicides Schottky barrier height. Overall, EuSi2 is the most promising material for the SB-MOSFET technology.

Methods

Synthesis

The samples are grown in Riber Compact 12 system for molecular beam epitaxy furnished with UHV system comprising Gamma Vacuum Titan Ion Pump, cryopump Cryo-Torr 8 (Brooks CTI Cryogenics), titanium sublimation pump and cryopanels cooled down by liquid nitrogen. The base pressure is less than 10−10 Torr. 4N Eu and capping material SiO are supplied from Knudsen cell effusion sources. The temperature of the substrate is controlled with PhotriX ML-AAPX/090 infrared pyrometer (LumaSense Technologies) operating at the 0.9 μm wavelength. Molecular beam intensity is measured with Bayard-Alpert ionization gauge fitted at the substrate site. The substrates are high-ohmic compensated Si (001) wafers with miscut angles not exceeding 0.5°.

Transmission Electron Microscopy

The cross-sectional samples for analytical TEM/STEM are prepared with 2 different techniques. One is a standard procedure comprising mechanical polishing of cross-sections down to a thickness of 20–25 μm followed by ion milling with Ar+ using Gatan 691 PIPS at an accelerating voltage of 3 keV until perforation; the final milling is carried out with 0.1 keV Ar+ ions. The other procedure employs Helios (FEI) scanning electron microscope (SEM)/Focus Ion Beam (FIB) dual beam system equipped with gas injectors for C and Pt deposition and a micromanipulator (Omniprobe). A 2 μm Pt layer is deposited on the surface of the sample. FIB milling (30 keV Ga+ ions) results in 2 μm thick cross-sections of approximately 8 × 5 μm2 area. Electron transparency is achieved by further thinning and final cleaning with 5 keV and 2 keV Ga+ ion beams, respectively. The cross-sections are covered by thin C layers to prevent oxidation in the Helios chamber before breaking the vacuum. The specimens are studied with a TEM/STEM Titan 80–300 (FEI) operating at 300 kV. The microscope is equipped with a spherical aberration (Cs) corrector, a HAADF detector, an atmospheric thin-window energy dispersive X-ray spectrometer (Phoenix System, EDAX) and a post-column Gatan energy filter (GIF). The images are analysed with the Digital Micrograph (Gatan) and Tecnai Imaging and Analysis (FEI) software.

Characterization

The surface of the films is controlled in situ with reflection high-energy electron diffractometer fitted with kSA 400 Analytical RHEED System (k-Space Associates, Inc.). X-ray diffraction data are obtained with Bruker D8 Advance spectrometer (CuKα X-ray source). Magnetization measurements of the films are carried out with MPMS XL-7 SQUID magnetometer (Quantum Design) using reciprocating sample option (RSO). The samples are mounted in plastic straws orienting the surface of the films parallel or perpendicular to the external magnetic field with the accuracy better than 5°. The diamagnetic moment of the Si substrate exceeds the magnetic moment of thin EuSi2 films; its subtraction from the signal generates a systematic error of about 10% in the value of magnetization. The demagnetization field is not taken into account. Transport measurements of resistivity and Hall effect in EuSi2 and I–V characteristics of the EuSi2/Si junction are carried out by the four-terminal sensing method using Lake Shore 9709A Hall effect measurement system.

Additional Information

How to cite this article: Averyanov, D. V. et al. Europium Silicide – a Prospective Material for Contacts with Silicon. Sci. Rep. 6, 25980; doi: 10.1038/srep25980 (2016).

References

Markov, I. L. Limits on fundamental limits to computation. Nature 512, 147–154 (2014).

International Technology Roadmap for Semiconductors. Emerging Research Materials. Technical Report. (2013) Available at: www.itrs2.net/2013-itrs.html. (Accessed: 8th April 2016).

Léonard, F. & Talin, A. A. Electrical contacts to one- and two-dimensional nanomaterials. Nature Nanotech. 6, 773–783 (2011).

Tung, R. T. The physics and chemistry of the Schottky barrier height. Appl. Phys. Rev. 1, 011304 (2014).

Michel, E. G. In Surface and interface science, Vol. 3 (ed. Wandelt, K. ) Ch. 14, 177–227 (Wiley, 2014).

Chen, L. J. Metal silicides: An integral part of microelectronics. JOM 57, 24–30 (2005).

Iwai, H., Ohguro, T. & Ohmi, S. NiSi salicide technology for scaled CMOS. Microel. Eng. 60, 157–169 (2002).

Lavoie, C., d’Heurle, F. M., Detavernier, C. & Cabral Jr., C. Towards implementation of a nickel silicide process for CMOS technologies. Microel. Eng. 70, 144–157 (2003).

Schmitt, A. L., Higgins, J. M., Szczech, J. R. & Jin, S. Synthesis and applications of metal silicide nanowires. J. Mater. Chem. 20, 223–235 (2010).

Pokhrel, A., DeGrave, J. P., Liang, D., Higgins, J. M. & Jin, S. In Semiconductor nanowires: From next-generation electronics to sustainable energy, (eds. Lu, W. & Xiang, J. ) Ch. 7, 312–362 (RSC, 2014).

Wu, Y., Xiang, J., Yang, C., Lu, W. & Lieber, C. M. Single-crystal metallic nanowires and metal/semiconductor nanowire heterostructures. Nature 430, 61–65 (2004).

Tang, W., Dayeh, S. A., Picraux, S. T., Huang, J. Y. & Tu, K.-N. Ultrashort channel silicon nanowire transistors with nickel silicide source/drain contacts. Nano Lett. 12, 3979–3985 (2012).

Chou, Y.-C. et al. Effect of elastic strain fluctuation on atomic layer growth of epitaxial silicide in Si nanowires by point contact reactions. Nano Lett. 15, 4121–4128 (2015).

Vilkov, O. et al. Controlled assembly of graphene-capped nickel, cobalt and iron silicides. Sci. Rep. 3, 2168 (2013).

Tu, K. N., Thompson, R. D. & Tsaur, B. Y. Low Schottky barrier of rare-earth silicide on n-Si. Appl. Phys. Lett. 38, 626–628 (1981).

Larson, J. M. & Snyder, J. P. Overview and status of metal S/D Schottky-barrier MOSFET technology. IEEE Trans. Electron Devices 53, 1048–1058 (2006).

Zhu, S. et al. N-type Schottky barrier S/D MOSFET using ytterbium silicide. IEEE Electron Device Lett. 25, 565–567 (2004).

Jang, M., Kim, Y., Shin, J., Lee, S. & Park, K. A 50-nm-gate-length erbium-silicided n-type Schottky barrier metal-oxide-semiconductor field-effect transistor. Appl. Phys. Lett. 84, 741–743 (2004).

Reckinger, N. et al. Schottky barrier lowering with the formation of crystalline Er silicide on n-Si upon thermal annealing. Appl. Phys. Lett. 94, 191913 (2009).

Reckinger, N. et al. Very low effective Schottky barrier height for erbium disilicide contacts on n-Si through arsenic segregation. Appl. Phys. Lett. 99, 012110 (2011).

Jansen, R. Silicon spintronics. Nature Mater. 11, 400–408 (2012).

Sverdlov, V. & Selberherr, S. Silicon spintronics: Progress and challenges. Phys. Rep. 585, 1–40 (2015).

Ohno, Y. et al. Electrical spin injection in a ferromagnetic semiconductor heterostructure. Nature 402, 790–792 (1999).

Farshchi, R. & Ramsteiner, M. Spin injection from Heusler alloys into semiconductors: A materials perspective. J. Appl. Phys. 113, 191101 (2013).

Jonker, B. T., Kioseoglou, G., Hanbicki, A. T., Li, C. H. & Thompson, P. E. Electrical spin-injection into silicon from a ferromagnetic metal/tunnel barrier contact. Nature Phys. 3, 542–546 (2007).

Dash, S. P., Sharma, S., Patel, R. S., de Jong, M. P. & Jansen, R. Electrical creation of spin polarization in silicon at room temperature. Nature 462, 491–494 (2009).

Le Breton, J.-C., Sharma, S., Saito, H., Yuasa, S. & Jansen, R. Thermal spin current from a ferromagnet to silicon by Seebeck spin tunneling. Nature 475, 82–85 (2011).

van‘t Erve, O. M. J. et al. Low-resistance spin injection into silicon using graphene tunnel barriers. Nature Nanotech. 7, 737–742 (2012).

van‘t Erve, O. M. J. et al. Spin transport and Hanle effect in silicon nanowires using graphene tunnel barriers. Nature Commun. 6, 7541 (2015).

Lou, X. et al. Electrical detection of spin transport in lateral ferromagnet-semiconductor devices. Nature Phys. 3, 197–202 (2007).

Ando, K. et al. Electrically tunable spin injector free from the impedance mismatch problem. Nature Mater. 10, 655–659 (2011).

Jansen, R. et al. Electrical spin injection into moderately doped silicon enabled by tailored interfaces. Phys. Rev. B 82, 241305(R) (2010).

Dankert, A., Dulal, R. S. & Dash, S. P. Efficient spin injection into silicon and the role of the Schottky barrier. Sci. Rep. 3, 3196 (2013).

Kampfrath, T. et al. Terahertz spin current pulses controlled by magnetic heterostructures. Nature Nanotech. 8, 256–260 (2013).

Lin, Y.-C., Chen, Y., Shailos, A. & Huang, Y. Detection of spin-polarized carrier in silicon nanowire with single crystal MnSi as magnetic contacts. Nano Lett. 10, 2281–2287 (2010).

Ando, Y. et al. Giant enhancement of spin pumping efficiency using Fe3Si ferromagnet. Phys. Rev. B 88, 140406(R) (2013).

Mendes, J. B. S. et al. Large inverse spin Hall effect in the antiferromagnetic metal Ir20Mn80 . Phys. Rev. B 89, 140406(R) (2014).

Wang, H., Du, C., Hammel, P. C. & Yang, F. Antiferromagnonic spin transport from Y3Fe5O12 into NiO. Phys. Rev. Lett. 113, 097202 (2014).

Evers, J., Oehlinger, G. & Weiss, A. Effect of pressure on the structures of divalent metal disilicides MSi2 (M = Ca, Eu, Sr). J. Solid State Chem. 20, 173–181 (1977).

Averyanov, D. V. et al. Direct epitaxial integration of the ferromagnetic semiconductor EuO with silicon for spintronic applications. ACS Appl. Mater. Interfaces 7, 6146–6152 (2015).

Averyanov, D. V. et al. Atomic-scale engineering of abrupt interface for direct spin contact of ferromagnetic semiconductor with silicon. Sci. Rep. 6, 22841 (2016).

Seiler, A. et al. Growth and structure characterization of EuSi2 films and nanoislands on vicinal Si(001) surface. J. Cryst. Growth 407, 74–77 (2014).

Krachino, T. V., Kuz’min. M. V., Loginov, M. V. & Mittsev, M. A. Growth of an Eu-Si(111) thin film structure: The stage of silicide formation. Phys. Solid State 46, 563–568 (2004).

Kuzmin, M., Perälä, R. E., Laukkanen, P. & Väyrynen, I. J. Atomic geometry and electronic structure of the Si (100) 2 × 3-Eu surface phase. Phys. Rev. B 72, 085343 (2005).

Ibrahimkutty, S. et al. A portable ultrahigh-vacuum system for advanced synchrotron radiation studies of thin films and nanostructures: EuSi2 nano-islands. J. Synchrotr. Rad. 22, 91–98 (2015).

Labroo, S. & Ali, N. Magnetism of rare-earth disilicides. J. Appl. Phys. 67, 4811–4813 (1990).

Matthew, J. A. D., Hofmann, R., Öfner, H. & Netzer, F. P. Silicide formation and valence switching at the Eu-Si interface monitored by electron energy loss spectroscopy in the reflection mode. J. Phys.: Condens. Matter 4, 8489–8496 (1992).

Fisher, M. E. & Langer, J. S. Resistive anomalies at magnetic critical points. Phys. Rev. Lett. 20, 665–668 (1968).

Katori, H. A., Katsumata, K. & Katori, M. Specific-heat anomaly in the Ising antiferromagnet FeBr2 in external magnetic fields. Phys. Rev. B 54, R9620–R9623 (1996).

Guizzetti, G. et al. Electrical and optical characterization of GdSi2 and ErSi2 alloy thin films. J. Appl. Phys. 67, 3393–3399 (1990).

Hogg, S. M., Vantomme, A., Wu, M. F. & Langouche, G. Electrical properties of rare earth silicides produced by channelled ion beam synthesis. Microel. Eng. 50, 211–215 (2000).

Rhoderick, E. H. & Williams, R. H. Metal-semiconductor contacts (Clarendon Press, 1988).

Acknowledgements

The work is partially supported by NRC “Kurchatov Institute”, Russian Foundation for Basic Research through grants 16-07-00204 and 16-29-03027 and Russian Science Foundation through grant 14-19-00662.

Author information

Authors and Affiliations

Contributions

D.V.A. and V.G.S. synthesized the EuSi2 films. C.G.K., I.A.K. and A.L.V. carried out T.E.M. experiments. G.V.P. performed X-ray studies. A.N.T. carried out magnetization measurements. O.E.P. performed transport experiments. A.M.T., E.F.L. and V.G.S. carried out the analysis. A.M.T. and V.G.S. wrote the paper with contributions from D.V.A., A.L.V., A.N.T. and O.E.P. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Averyanov, D., Tokmachev, A., Karateeva, C. et al. Europium Silicide – a Prospective Material for Contacts with Silicon. Sci Rep 6, 25980 (2016). https://doi.org/10.1038/srep25980

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep25980

- Springer Nature Limited

This article is cited by

-

Emerging two-dimensional ferromagnetism in silicene materials

Nature Communications (2018)

employed to determine the Schottky barrier height.

employed to determine the Schottky barrier height.