Abstract

Wearable enzyme-based biosensors enable advanced healthcare diagnostics through the monitoring of biomarkers and physiological states. The integration of materials engineering and enzyme conjugation has established the groundwork for advancements in modern analytical chemistry, poised to extend the frontiers of wearable biosensing further. Recent advancements in enzymatic biofuel cells have also enhanced devices by harnessing biofuels, such as glucose and lactate in biofluids. Importantly, biofuel cells offer the potential for self-powered biosensors. Here, we present an overview of the principles and considerations associated with engineering materials and integrating enzymes with electrodes to achieve effective wearable biosensing and self-sustaining biofuel cell-based energy systems. Furthermore, we discuss challenges encountered by enzymatic sensors and biofuel cells. Representative applications of wearable devices in healthcare settings are highlighted, along with a summary of real sample analyses, emphasizing the concentration ranges of analytes present in actual sweat samples to underscore their relevance in real-world scenarios. Finally, the discussion explores the anticipated impact of future material innovations and integrations on the development of next-generation wearable biodevices.

Similar content being viewed by others

Introduction

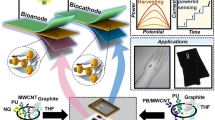

Wearable sensors, integrated analytical devices for analyzing biological fluids, have garnered significant interest in recent years due to their unique capability for real-time and continuous monitoring of biomarkers in a noninvasive or minimally invasive manner1,2. These sensing devices have been developed in diverse forms, such as temporary tattoos3,4, wristbands5,6, bandages7,8, textiles9,10, face masks11,12, eyeglasses13,14, contact lenses15,16, mouthguard17,18 and microneedles19, enabling access to biofluids for on-body analysis. In addition, recent advances in wearable sensors have demonstrated the effectiveness of real-time wireless monitoring20. The concept of wearable sensors enabling a digital diagnosis system is shown in Fig. 1a. Historically, traditional biosensors were constructed by immobilizing biorecognition elements on sensing interfaces. For instance, a glucose biosensor could be created by immobilizing glucose oxidase (GOx) on a carbon-based electrode to provide a selective recognition layer that specifically catalyzes glucose and converts biochemical concentration into a measurable signal on the electrode transducer21,22. This review focuses on enzymes for wearable healthcare sensing applications, prioritizing their widespread utility and significance, despite the presence of various other biorecognition approaches, e.g., antigen-antibody interactions23,24 and aptamer recognitions25,26. Various engineered materials have also played a role in enhancing sensing performances by controlling properties such as conductivity, surface area, and catalytic activity of electrodes27,28,29. However, materials for traditional off-body sensors were primarily designed to enhance analytical performance without considering crucial features such as biocompatibility, flexibility, wearability, and comfort. Furthermore, the operation of traditional analysis often entailed system complexity, reliance on external energy sources, pH value adjustments, and pre-treatment of biofluid samples. These representative aspects must be considered when developing materials and enzymatic electrodes for practical applications.

a Wearable sensors enabling digital diagnosis system. b Illustration demonstrating integration of functional materials with enzymes for biorecognition to detect biomolecule targets, e.g., glucose and lactic acid. c A typical amperogram from a biosensor, accompanied by the calibration curve utilizing amperometric current as a signal. d Illustration showing the working principle of a wearable biofuel cell-based self-powered biosensor. e Power-voltage curve obtained from the biofuel cell-based device, accompanied by the calibration curve utilizing self-generated power or current as a signal.

Alongside the advancement of biosensing layers via the coupling of biorecognition elements with transducing materials, another essential consideration pertains to the provision of energy for the entire functional wearable system. This is particularly crucial for wearable devices aiming for a compact and standalone platform for uninterrupted monitoring. Therefore, strategies for achieving self-sustaining energy systems to integrate with wearable sensors are being explored30,31,32. Among many energy-harvesting alternatives from the human body, enzymatic biofuel cells (EBFCs) hold promise for harnessing energy from sweat fuel sources containing metabolites (such as glucose and lactate)33,34. EBFCs also offer the unique capability to act as self-powered biosensor units, simplifying the system by merging the sensing unit with the energy unit35. To achieve desirable wearable biosensing and self-sustaining systems through enzyme-material integration, optimizing engineering materials is crucial. This optimization should tackle challenges such as the rigidity and bulkiness of traditional devices, poor stability, slow electron transfer, biofouling and interfering effects from complex samples, and limitations in surface area and enzyme immobilization, substrate availability, and oxygen concentration.

Several recent review articles have explored various topics, including wearable devices36, point-of-care biosensors37, biofuel cells38, and advanced materials for electrochemical biosensors39,40. For example, one published review discusses the fabrication of wearable biofuel cells, exploring the materials and strategies applicable to their construction41. Additionally, it explores the diverse applications of these biofuel cells, summarizes and compares the materials and energy performances of various wearable biofuel cells, and suggests strategies for enhancing their performance. Similarly, other reviews have addressed the fabrication and applications of wearable biofuel cells42,43. The published reviews also cover self-powered wearable sensors, energy harvesters, energy storage, and power supply strategies44. Our review, however, focuses on biosensing applications for health monitoring using wearable enzyme-based and self-powered devices. We also aim to contribute additional thought-provoking perspectives and further assimilate information pertaining to updated trends in these emerging areas. Our review delves into approaches to engineering materials and enzyme-material integration to achieve high-performance wearable biosensing and self-sustaining biosensing devices. Key strategies to address challenges posed by engineering materials for enzyme conjugation in biorecognition for wearable biosensing and self-sustaining energy systems are explored. Aspects regarding biocompatibility to preserve enzymatic activity, ensuring rapid communication between immobilized enzymes and electrodes, and providing mechanical flexibility to conform to the body in wearable devices are addressed. Moreover, durability considerations address the need for sustained performance in real-world scenarios. Representative settings are highlighted, along with an overview of real sample analyses, emphasizing the concentration ranges of analytes, including sweat glucose and lactate. It emphasizes the importance of on-body settings for obtaining comprehensive results, particularly utilizing multiplex sensors to analyze actual analyte concentrations in real sweat samples. This review explores wearable systems capable of simultaneously analyzing various significant biomarkers, including glucose, lactate, uric acid, Na+, K+, NH4+, pH, and physiological signals such as temperature, electrocardiogram (ECG), electroencephalogram (EEG), and electromyography (EMG), to provide insights into health conditions. In addition to discussing diagnostic systems, this review also presents representative examples of integrated drug-releasing systems. This integration illustrates the advancement of closed-loop biomedical systems that incorporate diagnosis and therapy. Additionally, the outlook section discusses the potential impact of future material integrations and strategies on the development of next-generation wearable biodevices.

Underpinning the use of advanced functional materials for enzyme conjugation in biorecognition for biosensing applications

Advanced functional materials are crucial in enzyme-based biosensors. Engineering features such as surface functionality, shape, surface area, and composition enable the tailoring of characteristics to enhance performance in supporting sensor development45. Enzymes have been immobilized within nanostructured materials, such as nanoparticles and nanotubes, through covalent binding, adsorption, and entrapment techniques46,47, thereby facilitating the development of sensitive biosensors. Materials, such as carbon nanomaterials, metal nanomaterials, and conductive polymers, have been conjugated with enzymes to ensure the high performance of point-of-care sensors due to their high electrical conductivity and high surface area-to-volume ratio. They offer advantages in facilitating rapid electron transfer between enzyme active sites and electrode surfaces, as well as enhancing catalytic properties and sensing responses48.

Optimizing wearable enzyme-based electrodes requires careful consideration of various factors related to the structural and chemical design of materials. Key considerations encompass the selection of materials and structures to manage surface characteristics, biocompatibility, porosity, and surface functionalization. For example, nanomaterials with high surface area enhance enzyme immobilization by maximizing active sites and promoting close enzyme-electrode proximity for efficient electron transfer49,50. Moreover, fabricating nanostructures, such as porous architectures, can facilitate efficient mass transport of analytes to enzyme active sites, promoting rapid diffusion of target molecules to the sensor surface and improving response time51,52. Additionally, nanocomposite materials comprising carbon materials and precious metal nanoparticles can enhance both electron transfer and catalytic activity53,54. Furthermore, stability and activity can be tuned through engineering nanomaterials and enzyme-material integration strategies to improve immobilization efficiency, thereby expanding the long-term and analytical performances of on-body sensors.

Incorporating energy management aspects into wearable devices is also crucial for their functionality. The combination of energy harvesting and storage elements within wearable biosensor platforms facilitates self-sustained monitoring44. A self-sustaining system primarily comprises various energy devices, including energy-harvesting and energy-storage components such as self-charging biosupercapacitors12, alongside biosensors capable of harnessing power from biofluids by energy-harvesting devices (such as EBFCs). These devices are designed to ensure the full system is self-sustaining, thereby provisioning a continuous power source for the sustained operation of wearable biosensors. The synergistic interplay between sensing and energy device functionalities yields autonomous devices ideal for practical platforms.

Principles of wearable enzyme-based biosensors and self-powered biosensors

Enzymes play a role in biosensors due to their specificity and catalytic activity, enabling the selective and sensitive detection of analytes55,56. Immobilizing enzymes onto wearable electrodes allows biosensors to convert biochemical reactions into measurable electrical signals, facilitating real-time monitoring of chemicals57. Various electrochemical techniques, such as amperometry, capitalize on this enzyme-immobilized electrode setup to translate biochemical concentrations into corresponding electrical parameters58. For example, one of the most widely used principles relies on amperometry coupled with immobilized oxidase enzymes on functional electrodes. These enzymes catalyze the oxidation of analytes, such as glucose59,60. The resulting oxidation event or the indirect measurement of the catalytic reaction product, such as H2O2, can be detected by the electrochemical transducer using the amperometric technique (Fig. 1b). Consequently, the concentration of analyte can be detected by the current increment observed in current-time curves (Fig. 1c). Other techniques beyond amperometry are also viable. Impedance techniques assess changes in electrode surface properties caused by enzyme-substrate interactions61, while voltammetry applies varying potentials to the wearable electrode to induce redox reactions, offering analytical insights into analyte concentrations62. Potentiometry measures the potential difference generated during enzymatic reactions63. These examples provide versatile tools for wearable biosensing applications. Nanomaterial-based biosensors on wearable electrodes have garnered attention for enhancing electrochemical signals and effectively tethering enzymes64. Nanomaterials generally improve the surface area, conductivity, and electron-transfer ability of the sensing interface.

Energy efficiency is particularly crucial for wearable monitoring, necessitating standalone and compact biosensors capable of continuous signal detection65,66. Integrating energy harvesting and storage devices with wearable biosensors is essential, making EBFCs appealing for self-powered bioelectronics33,35. As shown in Fig. 1d, these cells utilize enzymes as electrocatalysts to catalyze reactions converting fuel (analyte) into electricity, similar to conventional fuel cells. In an EBFC, an enzyme facilitates the oxidation of fuel at the bioanode, liberating electrons that flow to the cathode via an external circuit. Meanwhile, at the cathode, oxygen (O2) is reduced, completing the circuit cycle and thus generating an electrical current67. EBFCs boast advantages such as renewable biocatalysts and compatibility with various fuels, including sugar and alcohol.

This working principle can be leveraged to create wearable EBFCs to harness biochemical energy from bodily fluids, thereby facilitating the development of power-harvesting devices for self-sustainable in vivo applications and miniaturized sensors. EBFCs are instrumental in powering self-sustaining devices, lessening dependence on conventional batteries, and ensuring uninterrupted analysis68. By enzymatically oxidizing biofuels at the bioanode and accepting electrons at the cathode, EBFCs produce power corresponding to the biofuel (or analyte) concentration (Fig. 1e)69. This self-sustaining energy model enhances the sustainability and convenience of biosensing devices.

Engineering materials and designs for wearable enzyme-based biosensors and self-powered enzyme-based biosensors

Transitioning to biosensors for detecting biochemicals requires integrating materials and enzymes, posing significant challenges due to the numerous interfaces involved. These interfaces include those between electrodes and enzymes, as well as between immobilized enzymes and biofluid samples in dynamic environments. Challenges encompass material flexibility, electrode nanostructure, stability of enzyme and mediator immobilization, electron transport efficiency, substrate and O2 availability, and biocompatibility. One major challenge often results in low or fluctuating current outputs, such as low amperometric currents in enzymatic biosensors or low power outputs in EBFCs. Despite efforts, wearable enzymatic sensors and EBFCs still face performance issues, including lower current or power densities, reduced volumetric catalytic activity, low energy density, or open circuit voltage. Several designs have been proposed for long-term monitoring devices with a focus on operational duration. Monitoring results must be reliable and promptly delivered, while sensors should be universally accessible and user-friendly with a high frequency of readings. There is a demand for user-friendly long-term monitoring devices that prioritize miniaturization, biocompatibility, and minimal interference with daily activities. Wearable sensors are particularly valued for such applications70. An example is a small sweat sensor with a dimension of approximately 1.5 cm × 1.5 cm, which demonstrates size reduction and enhanced wearing comfort71. Hence, it is crucial to consider multiple strategies to mitigate these challenges and meet the requirements for achieving high performance in wearable enzymatic biosensors and EBFC-based self-powered sensors.

Exploring mechanical properties considerations

Wearable devices require flexibility to withstand dynamic deformations caused by human body movements. Engineering materials to mitigate rigidity, which does not align with the softness of human tissues, present considerable challenges while preserving essential functions such as high conductivity and efficient electron transfer. Employing soft materials facilitates the creation of comfortable devices that adapt to the body’s movements. Moreover, opting for inexpensive and lightweight materials for miniaturized flexible sensors is necessary to address the need for practical fabrication and wearer comfort.

Polymers, e.g., polyurethane (PU), Ecoflex®, and polydimethylsiloxane (PDMS), are extensively utilized as substrates for sensors or as the polymer matrix in nanocomposites. Apart from their high elasticity, these materials exhibit biological compatibility72. The integration of polymers with conducting materials such as carbon materials73,74, metal nanoparticles75,76, or conductive polymers77,78 produces flexible electrodes. Stretchability can be realized by employing nanomaterial-based stretchable inks, blending carbon (e.g., CNTs) with the elastomer. For instance, a wearable textile-based sensor was fabricated by printing CNT ink electrodes on layers of Ecoflex® and PU to enhance the flexibility of the printed electrodes (Fig. 2a)79. This self-powered biosensor exhibited resilience against repeated mechanical deformations. Another example is a diabetes patch (Fig. 2b)80. This patch features a sensing array printed onto a silicone film, allowing for conformal contact with human skin.

a Textile-based EBFCs integrated with socks for self-powered lactate sensors, subjected to mechanical resilience tests during twisting deformations. Adapted with permission from ref. 79 © 2016, Royal Society of Chemistry. b Wearable diabetes monitoring utilizing silicon film attached to human skin. Adapted with permission from ref. 80 © 2016, Springer Nature Limited. c Printed devices for electrochemical sensors and EBFCs based on stretchable CNT-based ink. Adapted with permission from ref. 81. © 2016, American Chemical Society. d Skin-mountable wearable EBFC device with an “island-bridge” design capable of harvesting sweat energy to power a light-emitting diode (LED). Adapted with permission from ref. 82. © 2019, WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim.

Mechanical engineering designs also enable the effective distribution of strain within the electrode structure. A printed biosensing device, featuring a stretchable CNT-based ink, exemplifies this concept (Fig. 2c)81. The use of a free-standing serpentine electrode enables substantial strain levels (up to 500%) to be achieved. The freestanding nature of bridges allows for more independent movement, thereby boosting stretchability.

Island-bridge electrode devices with freestanding serpentine bridges offer effective strain distribution. The inclusion of a serpentine pattern in the bridges allows for stretching deformation without excessively concentrating stress. Additionally, integrating a stretchable ink formula with an “island-bridge” design enhances the resilience of device. An example includes a skin-mountable wearable biofuel cell for lactate level monitoring, utilizing a layer of Ecoflex® (Fig. 2d)82. This design features carbon-based electrode “islands” connected by conductive silver “bridges” in a serpentine shape. Mechanical stability is ensured by incorporating a polystyrene (PS) “skeleton” and styrene-ethylene-butylene-styrene (SEBS) beneath the carbon islands.

Optimizing nanostructures for efficient enzyme-material integration

The electrical output of enzymatic sensors and EBFCs is often constrained by slow electron transfer, enzyme catalytic inefficiency, and limited mass transport. A key strategy to address such limitations involves engineering materials to achieve high surface area, such as porous electrodes. These materials enhance current density, facilitate mass transport, and increase enzyme loadings. For instance, a nanoporous carbon-encapsulated 3D porous graphene electrode boosts electrochemical surface area and electrocatalytic activity (Fig. 3a)83. The structure of the pore is important when dealing with enzymes. For example, pore mouths that are too small (< 3.5 nm) make GOx adsorption difficult84. Laser-induced graphene, produced by directing a CO2 IR laser at a polyimide film is another way to achieve a large surface area85. Nanoporous gold electrode (NPG) also provides similar advantages; for example, NPG (with pores around 21 nm) enables high enzyme loadings and enhanced current density (Fig. 3b)86. The fabrication starts with magnetron sputtering gold/silver alloy. Subsequently, electrochemical dealloying of silver was conducted in solutions (NaF and sulfuric acid) to achieve NPG.

a Porous carbon-reinforced 3D graphene electrode showcasing enhanced surface area and electrocatalytic activity. Adapted with permission from ref. 83. © 2022, Elsevier B.V. b Porous gold-based EBFCs integrated onto contact lenses. Adapted with permission from ref. 86. © 2018, American Chemical Society. c Wearable epidermal biofuel cells utilizing 3D coralloid nitrogen-doped hierarchical-micromesoporous carbon aerogels. Adapted with permission from ref. 87. © 2021, Elsevier Ltd.

In EBFCs, both the anode and cathode should be optimized to maximize fuel transport to the enzyme’s redox-active site. By employing porous nanostructured materials in EBFCs, power densities can be elevated from μW cm−2 to mW cm−2. An example is the 3D coralloid nitrogen-doped carbon aerogels (with pore sizes ranging from 0.5 to 4 nm) exhibiting a high specific surface area of ~ 500 m2 g−1 (Fig. 3c)87. These aerogels improve bioelectrode performance.

The high electrocatalytic NPG electrode can be used for ethanol and glucose biosensors to reduce the detection potential88. NPG with a pore size of ∼ 40 nm was also demonstrated to be a good carrier for biomacromolecules. The high density of edge-plane-like defective sites and large specific surface area of NPG also exhibited enhanced electrocatalysis toward reduced nicotinamide adenine dinucleotide (NADH) and H2O2.

Improving enzyme immobilization for controlling stability and electron transfer kinetics

The immobilization of enzymes on wearable electrode surfaces while preserving their activity presents a significant challenge. Example challenges include the low power density and limited lifetime in EBFCs. These limitations can hinder their application as self-powered biosensors due to reduced sensitivity. Moreover, enzyme deactivation and mass transfer barriers further impede enzyme activity, necessitating careful consideration during the design of immobilization strategies.

Common immobilization strategies include physical adsorption89 covalent binding90, entrapment91, or cross-linking92. Crosslinking in hydrogels is an example to enhance enzyme loading and analyte/biofuel transport efficiency93. Ensuring rapid electron transfer between enzymes and the electrode surface is also needed for optimizing the performance. This involves designing scaffolds for enzyme immobilization and developing effective enzymes or enzyme cascades with improved catalytic activity to fully harness the potential of enzymatic reactions94,95. Employing enzyme cascades can enhance the sequential oxidation of fuel, improving communication between consecutive enzymes, thereby increasing sensitivity or energy conversion96.

Using electron mediators enables rapid rates of electron transfer. Additionally, immobilizing enzymes on conductive materials with high specific surface areas can address challenges about low power density and short lifetimes. For example, a structure combining lactate oxidase and 1,4-naphthoquinone mediator into an MXene/single-walled carbon nanotube composite has been developed to harvest energy from sweat (Fig. 4a)97.

a MXene-based bioanode for wearable biosupercapacitor. Adapted with permission from ref. 97. © 2023, Wiley‐VCH GmbH. b EBFCs using layer-by-layer assembled GOx-coated metallic cotton fibers. Adapted under the terms and conditions of CC-BY 4.098, © 2018, Cheong Hoon Kwon et al., published by Springer Nature. c A glucose EBFC based 3D bioelectrodes. Adapted with permission from ref. 99. © 2013, Royal Society of Chemistry.

Another example is the fabrication of a porous metallic cotton fiber (MCF)-based EBFC using a layer-by-layer assembly method. This approach enhances the direct electron transfer (DET) rate between enzymes and conductive supports (Fig. 4b)98. In this setup, MCFs serve not only as a conductive host for depositing anodic enzyme materials but also as electrocatalytic cathodes for oxygen reduction reactions (ORR). Multilayers composed of GOx and tris-(2-aminoethyl)amine facilitate electron transfer through the enzyme layers.

Combining DET and mediated electron transfer (MET) offers another avenue to boost electron transfer rates in EBFCs. For instance, a glucose EBFC utilizing naphthoquinone-mediated glucose oxidation by GOx and direct oxygen reduction by laccase was demonstrated. This configuration achieves a high open-circuit voltage of 0.76 V, current densities of approximately 4.5 mA cm−2, and a maximum power output of about 1.6 mW cm−2 (Fig. 4c)99.

Considering enzyme orientation is crucial when integrating enzymes with materials. Regulating enzyme orientation and electron transfer on functional electrodes can be achieved by designing a redox mediator including an aromatic site for enzyme orientation, an anchoring site intended for immobilization, and a redox mediator for electron transfer100. This is realized through the development of a redox mediator containing a pyrene group to regulate enzyme orientation, an electron-carrier redox mediator (2,2’-azino-bis(3-ethylbenzthiazoline-6-sulfonic acid) (ABTS)), and an electropolymerizable pyrrole. The bioelectrode modified with pyrrole–ABTS–pyrene groups demonstrates favorable performance in constructing an EBFC.

Maintaining enzyme stability is crucial. Enzymes are vulnerable to environmental factors such as temperature and pH, posing challenges in finding materials that can preserve enzyme activity over time. Reactive oxygen species (ROS), like O2‧−, generated during incomplete O2 reduction, can impact enzyme activity101. Additionally, instability may stem from enzyme or cofactor use. In addition to enzyme stability, the materials utilized for enzyme conjugation are crucial. Factors such as low stability of mediators, electrode contamination, or toxicity can also impose limitations on wearable operation. Combining biotechnology (through extremophilic enzymes102 and enzyme engineering103,104 with materials engineering strategies can enhance the chemical microenvironment for enzymes at electrode surfaces, thereby improving stability. For example, a porous membrane composed of emulsion-based agarose, glycerol, and aluminum oxide nanoparticles demonstrated enhanced sensing stability and reliable long-term monitoring for up to 20 h105.

Mitigating effects of interferences and biofouling

Analyzing complex biofluids poses a significant challenge. For instance, in glucose analysis, interference effects such as the co-oxidation of unwanted compounds (e.g., ascorbic acid, acetaminophen, and uric acid) can distort glucose concentration results. Biofluids also contain substantial molecules that impede electrochemical signals. This challenge is notable in on-body applications, where biofluids contain the target analyte and potential interfering and biofouling substances.

Enzymes facilitate reactions with precision, catalyzing specific transformations. Selecting the high specificity of enzymes, such as GOx, which catalyzes the oxidation of β-d-glucose to d-glucono-δ-lactone and H2O2 in the presence of O2, is essential for improving accuracy. Additionally, developing materials such as interference rejection membranes can further refine analytical performance within such complex environments. Various approaches can be employed to eliminate interferences106. One approach uses permselective membranes, such as negatively-charged perfluorinated ionomers (e.g., Nafion)107 and cellulose acetate18, to repel anionic interferents (e.g., ascorbic acid). Another approach is using mediators, such as ferrocene, methylene blue, and tetrathiafulvalene-tetracyanoquinodimethane, to lower the detection potential108. Catalysts (e.g., Prussian blue or horseradish peroxidase) can also facilitate the reduction of H2O2, thereby minimizing the detection potential to avoid overvoltage and false signals from interfering species109. Moreover, cross-linked poly(2-hydroxyethyl methacrylate) and cellulose acetate permselective membranes have been shown to eliminate interferences, such as ascorbic acid, uric acid, and acetaminophen18,110. Furthermore, electrostatic repulsion between graphene oxide and interferences, coupled with the electrocatalytic properties of the silver nanoparticles@multi-walled carbon nanotubes nanocomposite (AgNPs@MWCNTs), can eliminate ascorbic acid and uric acid interferences111.

To mitigate the biofouling effect, zwitterionic polymers based on methacryloyloxyethyl phosphoryl-choline polymer can be used for coatings to prevent protein adsorption and cell adhesion112. This is attributed to the formation of a strong hydration sphere113. Additionally, enzyme electrodes coated with poly(2-methacryloyloxyethyl phosphorylcholine-co-glycidyl methacrylate) exhibit higher glucose sensitivity compared to those using Lipidure, Nafion, and poly(ethylene glycol) polymers112. Moreover, the use of a chitosan film as a protective layer can mitigate the effects of proteins, thus extending the lifetime of the wearable electrode114.

Managing fluctuations in substrate availability and controlling fluids

In real-life scenarios, the secretion of biofluids can vary in both volume and concentration of metabolites. Passive sweat sampling platforms may experience saturation or dilution over time, making them unsuitable for prolonged operation. Utilizing fluidic configurations is a strategy to address substrate depletion effectively.

Designing fluidics using wicking materials115 or structured microchannels116 enables the sequential tracking of target flow from the sweat gland through the detection zone, eventually reaching the outlet. The fluctuating availability of metabolites is particularly critical for self-powered biosensors. For instance, a nanofiber-based microfluidic analysis system exemplifies this approach117. This system is comprised of hydrophilic and porous polyimide/sodium dodecyl sulfate nanofiber films. This architectural design mitigates the potential for chemical-induced skin damage caused by the release of soluble chemical reagents from microfluidic networks with hollow structures. Moreover, the utilization of this microfluidic system based on nanofibers assures complete sweat penetration into the sensing chambers, while simultaneously keeping the sensing arrays against impurities released by the skin. Additionally, an osmotic sweat extraction hydrogel coupled with a paper microfluidic channel was demonstrated to facilitate sweat transport, addressing the challenge of fuel availability (Fig. 5a)118. The collected sample undergoes processing and analysis via a paper microfluidic channel, featuring an extended site for evaporation at the end, allowing for long-term sensing from fresh sweat. Another fluidics platform for sample management is a stretchable cotton thread-embedded microfluidic system, enabling a constant absorption rate under various mechanical deformations (Fig. 5b)119. Additionally, silicone elastomer-based microfluidic channels can be constructed and assembled on the sensing interface for high-throughput sweat sampling120,121,122,123,124. Furthermore, studying fluid dynamics simulation is essential for understanding the flow behavior of the microfluidic system.

a Wearable sensor featuring an osmotic hydrogel and a paper microfluidic channel for sweat extraction and management. Adapted with permission from ref. 118. © 2022, American Chemical Society. b Stretchable microfluidic-integrated glucose biofuel cell-based sensor utilizing a cotton thread-embedded microfluidic device. Adapted with permission from ref. 119. © 2022, Wiley‐VCH GmbH. c Air-breathing biocathode employing a superhydrophobic-based design to create an air-solid-liquid triphase for wearable lactate biofuel cells. Adapted with permission from ref. 145. © 2023, Elsevier B.V. d Breathable and woven electrode designed for lactate biofuel cells. Adapted with permission from ref. 146. © 2023, Elsevier Ltd. e Polychlorotrifluoroethylene (PCTFE) based oxygen-rich cathode serving as an internal oxygen supply. Adapted with permission from ref. 147. © 2018, Elsevier B.V.

Microfluidic valve technologies are important for precisely manipulating fluid flow within wearable systems125,126,127,128. This capability is essential for directing fluids to specific areas or chambers within a microfluidic device, facilitating controlled flows and reactions129. Important considerations in designing microfluidic valves include valve type, materials compatibility, actuation method, flow rate, and microchannel dimensions. Factors influencing flow rate modulation, such as channel geometry, fluid viscosity, and system design, must be carefully addressed. Flow rate variations within microfluidic systems can affect fluid handling efficiency, mixing, and reaction kinetics. Accurate mixing is crucial for achieving uniform reactions and reliable assay results. Challenges in achieving precise control include fluid dynamics constraints, valve reliability, and the complexity of system integration. Overcoming these challenges requires interdisciplinary approaches and optimization strategies to ensure accurate fluid handling in microfluidic applications.

One useful example is the utilization of capillary bursting valves for passive sweat management in on-body detection, facilitating the analysis of multiple analytes in sweat such as chloride, glucose, lactate, pH, temperature, urea, creatinine, sweat volume, and sweat rate123,124. Additionally, active biofluid management can be achieved using a programmable microfluidic valving system capable of sampling biofluids chronologically, routing them, and compartmentalizing them for biomarker analysis. One such example involves fabricating a programmable microfluidic valving system for on-skin biofluid management and contextual biomarker analysis130. In this example, electronically programmable microfluidic valving is achieved through microheater-controlled thermo-responsive poly(N-isopropylacrylamide) (PNIPAM) hydrogel valves. The thermo-responsive PNIPAM-based hydrogel undergoes expansion or contraction in response to temperature changes above or below its lower critical solution temperature (LCST), induced by activating or deactivating the microheater. When the hydrogel’s temperature is below its LCST, dominant hydrogen-bonding interactions with water molecules lead to hydration and structural expansion. Conversely, when the temperature exceeds the LCST, weakened hydrogen bonds and dominant hydrophobic interactions cause water release and hydrogel shrinkage upon heating the valve area. This active biofluid control strategy addresses challenges posed by flow rate variability on electrochemical sensor response.

An alternative approach to designing a microfluidic patch that allows users to initiate the timing of analysis was achieved through the development of finger-actuated pumps and valves for sweat sensing of multiple analytes131. The integration of finger-actuated pumps, valves, and sensing chambers in this device enables on-demand and electronics-free monitoring of various sweat analytes. To facilitate on-demand assessment of sweat analytes, a mechanism was designed with a system that allows the user to pull a thin tab to initiate the pump, enabling the sample to flow through the channel towards the analysis chamber.

A dual-valved microfluidic device represents another example of programmed time-control sweat collection132. The integration of passive and active valves on soft microfluidics has facilitated precise fluid control. Passive valves establish automatically controlled microfluidic pathways, while active valves, which require external actuation or triggering to open or close, operate on a specific time schedule to isolate captured sweat in a chamber from incoming sweat. Passive capillary burst valves integrated into the soft microfluidic channel were utilized to collect sweat in separate chambers in a sequential manner. Importantly, a thermal expansion valve, employing heat-expandable microspheres and polydimethylsiloxane (PDMS), was used to programmatically control sweat accumulation. The instantaneous activation of the thermal expansion valve hinders the microfluidic pathway, minimizing sample contamination and molecular diffusion. Studies involving humans demonstrated that the sweat analyte data obtained from this time-programmed sweat collection device are more comprehensive than those obtained from conventional methods, which lack specific data on temporal variations in sweat composition, such as volume, pH, lactate, and cortisol.

The typically low concentration of O2 in most solutions, often less than 1 mM133,134, poses another challenge for on-body enzymatic reactions. For example, glucose oxidase-based amperometric sensors may suffer from reduced performance due to insufficient O2 availability. GOx, immobilized on typical glucose biosensors, relies on O2 as a co-substrate for its enzymatic reaction. This limitation can lead to decreased sensitivity and errors in GOx amperometric sensors, as well as limited power output in EBFCs due to the low amount of O2 supplied to the cathode during the O2 reduction reaction.

To tackle this challenge, one strategy involves the development of air-breathing materials to enhance the solubility and mass transfer of O2. A superhydrophobic electrode facilitates an efficient air-liquid-solid three-phase interface, enhancing O2 diffusion compared to a solid-liquid two-phase interface. This is due to the higher diffusion coefficient of O2 in air than in liquid135. The superhydrophobic substrate is achieved through a combination of composite surface structures and low surface energy materials, trapping air pockets beneath the electrode when immersed in solution136. Breathable electrodes should possess high porosity, gas permeability, lightweight, biocompatibility, and flexibility, enabling easy access of oxygen from the air to the sensing interface. Various structures, such as nanomesh137, porous138, textile139, and nanofiber network140, have been incorporated to create air-breathable electrodes. Common materials used include fabric141, nanofiber-based polytetrafluoroethylene/silver nanowires/silk fibroin nanofibers142, polyamide nanofibers with silver nanowires140, fibrous polyimide143, fibrous PDMS144. An example of this approach is the fabrication of a superhydrophobic base electrode, which is utilized to create an “air-sac” layer at the air-solid-liquid triphase interface, thereby enabling air-breathing capability. This process effectively increases the accessibility of O2 from the air to the liquid phase (Fig. 5c)145. The “air-sac” layer exhibited an approximately 120% increase in the rate of O2 reduction. Another example of enhancing breathability in devices is demonstrated by a woven hybrid energy harvester (Fig. 5d)146.

Another approach to address this oxygen limitation uses an oxygen-rich cathode binder material based on polychlorotrifluoroethylene (PCTFE). This material can provide an internal O2 supply for the EBFC reduction reaction even under O2-deficit conditions (Fig. 5e)147, owing to the high O2 solubility in the PCTFE binder. The use of an O2-rich cathode can improve bioenergy conversion systems when O2 levels are low or fluctuating. This principle applies to both traditional enzyme-based amperometric sensors148 and EBFCs147.

Considering biocompatible and ‘green’ materials

In wearable technology, prioritizing biocompatible and environmentally friendly “green” materials is essential for user safety and environmental sustainability. Examples include incorporating egg white proteins (Fig. 6a)149 and silk fibroin (SF)150 to develop sustainable electrodes for bioelectronics, utilizing their 3D network structure for enzyme entrapment and biodegradability. Additionally, food-based edible EBFCs, which utilize plant and fruit extracts alongside edible charcoal, offer further “green” alternatives151.

a A glucose amperometric biosensor and a bioanode for a BFC and self-powered biosensor using redox-mediated AuNPs, glucose oxidase, and egg white proteins. Adapted under the terms and conditions of CC-BY 4.0149, © 2023, Natcha Rasitanon et al., published by MDPI. b A bio-active porous enzymatic nanofiber membrane composed of silk fibroin nanofibrils (SFNFs) and enzymes for enzymatic biosensor with long-term stability. Adapted with permission from ref. 150. © 2021, Wiley‐VCH GmbH.

SF is a material to form a scaffold to anchor enzymes152. Additionally, silk proteins offer a biodegradable character. A fibroin substrate derived from the silk fibroin was used in glucose biosensors, degrading after 10 days153. A bio-active porous enzymatic nanofiber (PEN) membrane based on silk fibroin nanofibrils (SFNFs) effectively retains enzymes in 3D functional scaffolds (Fig. 6b)150. Glutaraldehyde was added to cross-link SFNFs, transforming the protein bulk structures into three-dimensional skeletons and enabling the formation of the enzymatic membrane. This process provides a large surface area for biochemical reactions when the analyte reaches the immobilized enzyme membrane. These features reduce enzyme escape, promote enzyme-analyte reactions, and ensure stability. In addition, there is reported that GOx entrapped in SF can remain stable for up to 10 months154. Platinum nanoparticles-graphene (Pt-graphene) nanocomposite attaches the PEN membrane, facilitating electron transfer between enzymes and electrodes, resulting in long-term stability and effective glucose and lactate sensing for a duration of up to 25 hours. Pt-graphene film also enhances catalytic activity against H2O2 and reduces its potential to oxidize H2O2. Furthermore, Pt-G film interacts with enzymes and SFNFs, reducing enzyme loss during prolonged sensor operation.

Accessing biofluids

Sweat analysis provides convenient access to biofluids from the human body; however, exploring alternative biofluids such as interstitial fluid (ISF) offers opportunities to gather additional valuable information. In addition to passive sweat sampling, using ISF, which exists in extracellular spaces and directly emanates from blood vessels, holds promise for biomedical diagnosis155. ISF offers advantages such as abundance, minimal bio-interference, and high clinical relevance. Given the wealth of information within ISF, on-skin biosensors have been developed for minimally invasive analysis to extract data from ISF156. Key methods used to access ISF include microneedles157 and iontophoresis158.

Microneedles are employed for ISF extraction by penetrating the skin and can be either solid or hydrogel-based materials159,160. Typically, these microneedles are shaped as small pyramids or cones with sharp tips161. The material properties of microneedle electrodes influence the performance and stability of biosensors integrated with microneedle arrays. Conductive polymers, such as poly(3,4-ethylenedioxythiophene)-poly(styrene sulfonate) (PEDOT: PSS)162, offer high conductivity and compatibility with enzyme immobilization, providing a miniaturized platform for enzyme attachment and signal transduction. Gold electrodes, owing to their conductivity, biocompatibility, and stability, are also viable options163. Gold surfaces can be functionalized with self-assembled monolayers (SAMs) to facilitate enzyme binding. Challenges in achieving effective electron communication between enzymes and microneedle electrodes include the distance between the enzyme active site and the microneedle surface, electron transfer rate, loss of enzyme activity, and biofouling. Additionally, designing microneedle geometries for on-body biosensor applications targeting ISF sampling involves several key considerations for effective performance, including needle length and diameter, material type, microneedle tip design, biocompatibility, skin interaction, and user-friendliness. The length of microneedles should be sufficient to penetrate the outer layer of the skin (epidermis) and reach the dermal layer where ISF resides, typically ranging from 150 to 1500 μm164,165. The diameter of microneedles should be small enough to minimize pain and tissue damage but large enough to allow access to biofluid. The geometry of microneedle tips significantly influences skin penetration efficiency and pain reduction, with shapes such as conical162, pyramidal166,167, or beveled168 designs. It is crucial to utilize biocompatible materials and surface coatings to minimize the risks of skin irritation, inflammation, or infection. Conical or tapered tip geometries are preferred for facilitating skin penetration and reducing discomfort, with tip angles typically ranging from 15° to 60°; sharper angles generally require less insertion force169. Microneedle diameters typically range from 30 μm to 200 μm, with larger diameters allowing for higher fluid flow rates and sensor integration, albeit potentially causing tissue damage and discomfort170,171,172.

An example of fabricating a microneedle-based electrochemical biosensor for glucose and lactic acid detection involves using a hydrogel that can change its form at room temperature in the presence of a photoinitiator and light173. Photolithography was employed to produce polymeric microneedles, which were constructed from photocurable materials including vinylferrocene, enzymes, polyethylene glycol diacrylate (PEGDA), and a photoinitiator. Vinylferrocene, with a redox potential around 0.2 to 0.3 V, served as a redox mediator. The biosensing principle relied on the oxidation of analytes (glucose or lactic acid) catalyzed by enzymes (GOx or lactate oxidase), mediated by the redox mediator molecule, which carried produced electrons from the redox center of the enzyme to the electrode surface. Glucose and lactate levels were determined using amperometry at an applied potential of 0.30 V. These biosensors hold promise for continuously monitoring glucose levels in diabetic patients’ blood or detecting lactic acid levels in athletes.

Another example involves the use of composites of gold and multi-walled carbon nanotubes (MWCNTs) to fabricate a microneedle for monitoring lactate and glucose174. The microneedle array base structures were fabricated using polycarbonate, with pyramid dimensions of 0.06 cm base and 0.1 cm height, covering a 4 × 4 array area of 0.2 cm2. Subsequently, the microneedle array was coated with gold to create the conductive electrode. The working electrode was then coated with Au-MWCNTs to enhance its electrochemical characteristics. Polymethylene blue was layered onto the electrode surface to serve as a redox mediator. FAD-glucose dehydrogenase (FADGDH) and lactate oxidase were immobilized using a drop-casting procedure to obtain the biorecognition layers for detecting glucose and lactate concentrations, which could be determined through amperometric analysis at an applied potential of 0.15 V. This device effectively monitored lactate and glucose concentrations in an artificial skin model.

In addition to using needles to pierce the skin, iontophoresis offers an alternative method for accessing ISF in wearable devices175. This technique employs an electric voltage with a small current to drive the movement of charged ions, inducing an electroosmotic flow that facilitates the extraction of substances from the skin176. The use of electric current enhances the rate of substance transport beyond their passive permeabilities, mainly facilitated by electromigration and electroosmosis mechanisms. Both iontophoresis and reverse iontophoresis use controlled electrical currents to transport ions, molecules, and drugs across biological membranes, such as the skin, in a non-invasive manner. In iontophoresis, a small current drives charged ions or drugs through the skin, overcoming its natural barrier properties for transdermal delivery177. Conversely, reverse iontophoresis reverses the ion movement direction to extract molecules from the body through the skin178. The contribution of each mechanism depends on the physicochemical properties of the substances involved.

The choice of electrode material is crucial in both iontophoresis and reverse iontophoresis applications, directly impacting the efficiency and safety of the device. Silver-based or carbon-based electrodes are commonly used in iontophoresis179,180. In reverse iontophoresis, the electrical current typically ranges from about 0.1 to 4 mA, with the specific current level depending on device design, target molecules, and skin properties181,182. The size of iontophoretic electrodes is similar to sensing electrodes, typically in the millimeter range. Materials commonly used for iontophoretic electrodes include silver-based183, carbon-based184 materials, stainless steel185, and certain polymeric materials186. The properties of these materials directly impact the efficiency and safety of iontophoretic applications. For example, high electrical conductivity ensures efficient ion transport and reliable current distribution across the skin, enhancing effectiveness for drug delivery or sample collection. Electrode materials should also be biocompatible to minimize the risk of skin irritation or allergic reactions during prolonged use.

In addition to the electrode material, a critical parameter governing iontophoretic systems includes the magnitude of electrical current applied, determining the rate and extent of ion or molecule transport across skin. Typically, low currents ranging from 0.1 mA to a few mA are used for safe and controlled delivery or extraction of substances182,187. The duration of the current application also influences the amount of substance delivered or extracted. While longer application times can enhance molecule transport, care must be taken to avoid excessive exposure that could lead to adverse effects.

Examples of reverse iontophoretic ISF extraction in biosensing systems were developed using a pair of screen-printed Ag/AgCl electrodes158,188. To extract ISF, a current density of about 0.2 to 0.3 mA cm−2 was applied to the skin through cathode and anode iontophoresis electrodes for 5 min. These wearable biosensor platforms demonstrated potential for alcohol and glucose monitoring.

Advancements in material and system designs are driving improvements in the effectiveness and safety of iontophoretic techniques, particularly in drug delivery and noninvasive biomarker sampling from biofluids extracted from the skin. Designing effective iontophoretic electrodes involves addressing challenges such as optimizing electrode size for targeted sampling areas, ensuring uniform current distribution, maximizing skin contact and comfort, and enhancing electrode biocompatibility. However, employing the iontophoresis approach presents challenges, such as limitations in fluid extraction volume and the impracticality of prolonged extraction times for biosensing applications. Researchers are tackling these challenges through approaches such as the use of electrode materials such as carbon-based materials and conductive polymers, employing microfabrication techniques to create customized electrode shapes, developing electrode arrays for improved current distribution, integrating real-time monitoring systems for feedback control, and incorporating human factors and user-centered design principles. These endeavors aim to enhance the effectiveness, reliability, and safety of iontophoretic techniques in applications such as drug delivery and noninvasive biomarker sampling, ultimately improving user outcomes and the usability of wearable devices.

Powering biosensing systems with enzyme-based energy devices

EBFCs function as power sources by converting biochemicals from human biofluids into electricity. They offer the advantage of ensuring a continuous energy supply for wearable electronic devices189. Compared with conventional energy sources such as batteries, EBFCs have garnered significant attention due to their high efficiency and environmental friendliness. These bioenergy devices provide a power solution for small-scale, on-demand electronics190. EBFCs typically yield power ranging from μW cm−2 to mW cm−2, making them well-suited for wearable sensors. Their portability and eco-friendly operation make them ideal for supporting wearable biomedical and miniaturized electronic devices. Harnessing EBFCs addresses energy needs in sensors and small personal bioelectronics, offering sustainable solutions while reducing environmental impact and decreasing reliance on traditional energy sources191.

While progress has been made in developing a biobattery-based patch that can operate on the skin, achieving shape conformability on the skin and rapid on-site activation remains a challenge. During storage, enzymatic batteries should be dried to preserve the activity of enzymes. Before use, they must be moistened to initiate enzymatic reactions on the electrodes. An example is a water-activated electric skin patch capable of producing transdermal current promptly, which integrates a built-in flexible glucose/O2 biobattery capable of generating current192. The main components of this integrated patch include a flexible biobattery and water-absorbent sponge tanks for storing the buffer electrolyte and fuel. Dehydrated fuel and electrolytes can be stored in the sponge, which can also rapidly absorb water and retain the resulting solution. Rapid activation of the patch components through the addition of water deep within the patch is achieved by employing a flexible sponge saturated with buffer electrolyte and glucose (the primary source of biofuel). In this device, CNT-modified carbon fabric was used as the electrode substrate to enhance surface area and conductivity. Glucose dehydrogenase was immobilized on the electrode to fabricate the anode, while iron(II) phthalocyanine was used to construct the cathode to catalyze the O2 reduction reaction. The wet cotton sheet containing the electrolyte solution exhibited a current of approximately 80 μA, while human skin displayed a current of approximately 10 μA. A maximum power density of 6 W cm−2 was achieved by the biobattery on a cotton sheet saturated with a buffer solution containing 200 mM glucose at 0.2 V. A stable patch current of about 10 μA was observed for over 12 h in the soft spongy container containing 200 mM glucose biofuel and electrolyte, confirming the stability of the output current during prolonged measurements.

Utilizing the principle of EBFCs could be beneficial for fabricating a wearable sensing device operated entirely on self-generated power, eliminating the requirement for an extra power source193. EBFCs, which convert glucose in urine into electrical energy, were utilized to power the diaper system. Carbon nanotubes/gold nanoparticles (CNTs/AuNPs) hybrids were employed on the glucose oxidase-based bioanode to enhance the output performance of EBFCs. Enzyme immobilization was achieved using glutaraldehyde to cross-link GOx with CNTs/AuNPs hybrids before coating on the electrode. MnO2-CNTs were used as the cathode to accept electrons from the bioanode. The hybrid material composed of CNTs/AuNPs is a promising candidate for facilitating efficient electron transfer between the electrode surface and the immobilized enzyme due to its small size and high electronic conductivity. When the EBFC operates in a 5 mM glucose solution, its power density can reach 220 μW cm−2. The EBFC was integrated into the diaper and connected to a power management system equipped with a capacitor for energy storage. The power management system, including a capacitor for energy storage, was linked to the EBFC integrated into the diaper. The light-emitting diode (LED) flashed in response to the stored energy, which was subsequently used to display the observable signal. The power generated by the EBFC regulated the charging rate of the capacitor, which was reflected in the frequency of LED flickering. As a result, the flashing LED provided a direct indication of the glucose concentration in the urine.

Several biomolecules other than glucose can also serve as energetic sources for the biofuel system. One notably important biofuel is lactate. An example of this was demonstrated in a hybrid EBFC, which was designed to supply electricity for powering wearable devices194. These EBFCs, utilizing poly(vinyl alcohol)-based (PVA-based) hydrogel electrolytes, were integrated with lactate oxidase/tetrathiafulvalene-MWCNTs/reduced graphene oxide/porous Ni substrate bioanodes, and Ag/Ag2O cathodes. The hydrogel exhibited significant capacity for absorbing lactate-containing PBS electrolyte solutions. The integrated PVA-based hybrid biofuel cell demonstrated a maximum power density of ~ 129 μW cm−2 and an open circuit voltage of 0.50 V when operating in a 20 mM lactate solution. When human sweat was utilized as the biofuel, the hybrid biofuel cell had the potential to achieve a maximum power density of ~ 85 μW cm−2. Furthermore, when coupled with a DC-DC converter, the PVA-based hybrid biofuel cells exhibit the capability to supply power to a watch.

To realize integrated wearable systems, researchers are striving to create standalone devices by merging various functional platforms. These platforms should encompass not only EBFCs but also extend to other biosensors and energy storage units (e.g., supercapacitors). An example includes the demonstration of hybrid energy devices that integrate supercapacitors with EBFCs195. These devices incorporate anodes and cathodes based on buckypaper@polydimethylsiloxane electrodes that incorporate enzymes reacting with respective fuels and mediators facilitating the transfer and storage of electrons. On the anode side, FADGDH, an enzyme facilitating glucose oxidation, was employed, accompanied by the utilization of 1,10-phenanthroline-5,6-dione as a mediator. On the cathode, bilirubin oxidase, an enzyme facilitating oxygen reduction, was utilized, with 2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) serving as the mediator. The hybrid energy devices exhibited a power output of 0.93 mW cm−2 and a capacitive storage capacity of 307 mF cm−2. The performance of this hybrid device, using electrodes comprising both enzymes and mediators, was attributed to their self-charging capability. In addition, after two charge–discharge cycles in the presence of a glucose solution, the open circuit voltage (OCV) remained stable for up to 800 s at 0.675 V, even in the absence of fuel, enabling the discharge of the hybrid energy device. It was confirmed that the integrated energy devices exhibited performance characteristics of both a fuel cell and a supercapacitor.

Advancing on-body analysis settings for real sweat analysis

Researchers have extensively studied various biomarkers in real biofluids, with glucose and lactic acid emerging as popular choices. The concentration ranges of glucose and lactate from electrochemical sensors between 2016 and 2024 are summarized in Fig. 7. Glucose and lactate levels in real sweat were found to range from approximately 2.0 × 10−5 to 1.5 × 10−3 M and 2.0 × 10−4 to 6.8 × 10−2 M, respectively. These values vary depending on the human subject and testing conditions, influenced by factors e.g., physiological conditions and hydration levels196,197. Physical activity, particularly intense or prolonged exertion, can elevate sweat lactate levels198. Additionally, stress, diet, and overall health can contribute to metabolic variations. Lactate production increases during anaerobic metabolism in exercise, leading to a high lactate concentration in sweat. Dehydration may also result in elevated lactate levels199. During intense exercise, e.g., field track running, treadmill running, and ergometer cycling, lactate concentrations can reach up to 68 mM200. Notably, health issues (e.g., diabetes) can alter sweat compositions, impacting glucose levels. In sensor development, it is crucial to account for both lower and upper limits of analyte concentration, ensuring the sensor’s capability to detect trace levels while also accommodating high concentrations. Achieving high sensitivity is essential to detect analytes at trace levels, while maintaining the sensor’s ability to detect high concentrations without saturation effects ensures its practical utility across a wide range of expected situations.

The reported concentration ranges of a glucose and b lactate in real sweat collected from electrochemical sensors. Data sourced from refs. 60,61,71,79,85,105,117,118,120,150,198,200,201,202,203,205,240,241,242,243,244,245,246,247,248,249,250,251,252,253,254,255,256,257,258,259 for glucose and lactate.

We first highlight representative cases displaying the two lowest concentration levels of sweat glucose and lactate, as depicted in the bottom positions on the bar charts within the literature’s data. These enzyme-based biosensors can determine sweat glucose at concentrations as low as 20 and 30 µM, achieved through different materials: one utilizing an enzyme-based Au electrode with CNTs and Prussian blue201, and the other employing a laser-induced porous graphene electrode with platinum nanoparticles (PtNPs)85. The GOx was entrapped in chitosan and CNT matrix for Au electrode and Prussian blue. The Prussian blue was used as a mediator to catalyze H2O2 reduction. On the other hand, the GOx immobilized on laser-induced graphene electrode by using coupling agent (EDC/NHS) to activate the carboxylate groups on the electrode surface. This electrode can directly detect H2O2 with the aid of PtNPs. The sensor’s capabilities are attributed to the following features; for instance, the Au electrode demonstrates electrocatalytic activity and conductivity, thereby enhancing electron transfer. Additionally, the PtNPs-modified porous graphene electrode offers a surface for enzyme immobilization and facilitates efficient communication between the electrode and enzyme active sites.

Regarding lactate detection, textile-based self-powered sensors achieved low concentrations of around 0.2–1.0 mM. One sensor utilized stretchable CNT ink with a 1,4-naphthoquinone mediator bioanode and silver oxide/silver (Ag2O/Ag) cathode79, while the other employed flexible screen-printed Prussian blue-based ink with a graphene and enzyme mixture layer118. These platforms detected such low lactate concentrations due to mediators (1,4-naphthoquinone and Prussian blue) and nanomaterial-based inks (stretchable CNT and Prussian blue-based carbon materials), along with enzyme immobilization techniques such as Nafion and chitosan coatings. We also highlight examples exhibiting the two highest concentration levels of sweat glucose and lactate, represented by the rightmost positions on the bar chart. The high glucose concentrations observed in sweat were 0.31 and 1.5 mM, detected using screen-printed platinum-decorated graphite bioelectrode202 and Prussian blue-graphite bioelectrode203. These bioelectrodes were prepared by coating GOx with Nafion, and the detections relied on catalytic reaction of H2O2 on the platinum and Prussian blue surface. The sensor’s ability to cover a wide concentration range was attributed to the high surface area and electrocatalytic activity of the supporting materials for enzyme immobilization.

The high concentration of lactate detected in real sweat was achieved by enzymatic sensors using ZnO nanoflakes coated on Au electrodes61, and surface-modified, screen-printed carbon electrodes200, reaching concentrations of 50.7 mM and 68 mM, respectively. Enzyme immobilization was accomplished through electrostatic physical adsorption and covalent bonding using EDC–NHS, respectively. Lactate detection in the former relied on H2O2 oxidation, while in the latter, it relied on changes in charge transfer resistance on the enzyme electrodes.

Multiplex biosensing systems and diagnostic-therapeutic integration

Wearable technology has enabled the effective study of predominant biofluid analytes such as glucose, lactate, K+, and Na+. Innovations in wearable devices have focused on enhancing reliability in on-body analysis settings. In biomedical applications, key challenges related to on-body settings need to be considered. Ensuring the practicality of wearable biosensors and bioelectronics in real analysis settings is essential. The variability in sample matrix among individuals can affect sensor accuracy, requiring thorough validation. Challenges in on-body settings include managing unstable signals and noise induced by human movement, as well as ensuring the mechanical stability of wearable devices to closely adhere to body movements for practicality. Finding suitable device placement locations that remain steady and comfortable for users while providing access to valuable information from biofluids poses another significant challenge. Advancements in wearable biosensors and bioelectronics have addressed many limitations of traditional on-body analysis settings. Lightweight, miniaturized, and flexible platforms enable seamless integration with daily activities. Additionally, self-powered sensing platforms eliminate the need for bulky batteries, ensuring long-term analysis capability while reducing device size. Following the development of materials and integration with relevant enzymes for building desired sensors, some representative ideas for integrating devices in on-body studies are briefly highlighted.

Introducing a wearable chemical-electrophysiological hybrid biosensing system highlights its capability for simultaneous real-time monitoring of biochemical and electrophysiological signals, showcasing its potential for personalized diagnostic applications. Another example of on-body healthcare diagnostic settings was seen with the development of a wearable chemical-electrophysiological hybrid biosensing system for real-time health and fitness monitoring204. This skin-worn wearable hybrid sensing system offers simultaneous real-time monitoring of a biochemical signal (lactate) and an electrophysiological signal (electrocardiogram). Additionally, an integrated wearable sensor array was developed for multiplexed perspiration analysis, covering glucose, lactate, K+, Na+, and skin temperature201. The wearable sensor was worn on various body parts, including the forehead, wrists, and arms, and successfully applied for on-body analysis. This platform enables multiplexed perspiration analysis in personalized diagnostic and physiological monitoring applications.

The integration of enzymatic biosensors with physical sensors, such as electrocardiogram (ECG), electromyogram (EMG), and electroencephalogram (EEG), represents another approach with significant implications for healthcare. This synergistic fusion enables the simultaneous measurement of biochemical markers alongside physiological signals, offering a comprehensive understanding of health status. One representative system hybridizes epidermal sensors to monitor glucose, pH, temperature, ECG, EMG, and EEG (Fig. 8a)205. The patch was fabricated using microelectromechanical systems (MEMS) technology on a thin, flexible polyethylene terephthalate (PET) film to ensure suitable skin contact. MEMS-patterned Au electrodes on PET support were utilized to directly record electrophysiological signals such as ECG, EMG, EEG, and temperature. PtNPs/nanoporous carbon@MXene-based sensors and polyaniline-based sensors were employed for glucose and pH detection, respectively. This wearable device, paired with a miniaturized printed circuit board (PCB), could assess glucose and ECG levels of the wearer by attaching it to the subject’s chest during stationary cycling. Real-time on-body monitoring was demonstrated by attaching the sensor directly to the subject’s chest. Prior to wearing the sensors, all sensors were calibrated, and the subjects’ chests were cleansed with alcohol swabs. Through the integration of pH and temperature sensors, the responses of the biosensing patch for glucose were internally calibrated to account for changes in pH and sweat temperature during on-body perspiration monitoring. This biosensing patch exhibited selectivity against interfering and biofouling effects, attributed to the catalytic properties of PtNPs in reducing the detection potential of H2O2 and the permselective protective layer of Nafion.

a An electronic skin for stress response monitoring. Adapted with permission from ref. 206. © 2024, The Author(s), under exclusive license to Springer Nature Limited. b A biosensing patch for biopotentials and sweat glucose monitoring. Adapted with permission from ref. 205. © 2022, Wiley‐VCH GmbH. c The battery-free and wireless wound dressing for wound infection monitoring and electrically controlled on-demand drug delivery. Adapted with permission from ref. 215. © 2021, Wiley‐VCH GmbH. d Multifunctional conducting polymer-based theragnostic bandage for multiplex sensing and drug delivery capabilities. Adapted under the terms and conditions of CC-BY 4.0216, © 2024, Lingyin Meng et al., published by Springer Nature.

A soft sensor was developed for monitoring stress responses, capable of classifying different stressor types (cold pressor test, virtual reality challenge, intense exercise) and predicting state anxiety levels with high accuracy and reliability using a machine learning pipeline (Fig. 8b)206. The device is capable of evaluating three essential indicators of health—pulse waveform, galvanic skin response, and skin temperature—and monitoring six specific substances found in sweat: glucose, lactate, uric acid, sodium ions, potassium ions, and ammonium. It was affixed to the subject’s wrist for on-body analysis, utilizing a microfluidic module to access sweat. The incorporation of a miniaturized iontophoresis component enabled the self-sustaining stimulation of sweat production while at rest, eliminating the necessity for strenuous physical activity. Various on-body locations such as the forehead, forearm, chest, and shoulder could be considered for attachment, ensuring comfort and minimal movement for reliable sample collection. Enzymatic sensors based on Prussian blue with a nickel hexacyanoferrate coating exhibited the ability to eliminate interfering effects, operating at a detection potential of 0 V. This biosensor provided long-term sweat biomarker analysis for over ~ 4 days in untreated human sweat samples, attributed to the catalytically inactive nickel hexacyanoferrate forming a stabilized solid solution composite, thereby protecting the Prussian blue.

Ultimately, wearable devices aim not only to detect biochemical information for diagnostic purposes but also to utilize it for dynamically adjusting treatment regimens. The objective is to unlock the potential for optimizing therapeutic interventions by providing timely drug delivery tailored to individual needs. One of the most beneficial integrations is incorporating on-body sensors for wound monitoring and drug delivery applications. Therefore, researchers aim to further design integrated systems for real-time, noninvasive monitoring of biochemical markers, enabling the assessment of wound healing progress and early detection of complications.

Effective wound management is an essential component of healthcare. Effective management of individual wounds is essential for facilitating wound healing, frequently necessitating the utilization of wound bandages or dressings. Various physiological parameters present in wound exudate, such as temperature, pH, uric acid, glucose, and total protein, can be monitored using multiplex sensors and biosensors207,208,209. Continuous and prolonged monitoring of these biomarkers in real-time can offer valuable insights into the healing progress and the conditions of the wound environment, specifically regarding the potential for infection.

For instance, the normal pH of skin or healing wounds typically falls between 5.5 and 6.5, whereas chronic or infected wounds with a high bacterial load often exhibit a basic pH above 7.3210,211. Furthermore, there is a significant correlation between the severity of wounds and the concentration of uric acid in wound exudate, which is linked to the colonization of bacteria such as Staphylococcus aureus or Pseudomonas aeruginosa and the generation of reactive superoxide radicals212,213. Consequently, the ability to determine the difference between the severity and infection of a wound is facilitated by the simultaneous detection of pH and uric acid concentrations. Furthermore, in accordance with the paradigm of timely and individualized treatment, investigations need to integrate a therapeutic system into bandages for wounds.

An example illustrating the design of a wearable bioelectronic system demonstrated its efficacy in monitoring the physiological conditions of wounds through multimodal wound biomarker analysis, while concurrently facilitating combination therapy via electro-responsive controlled drug delivery214. The system comprised sensors for glucose, lactate, uric acid, temperature, pH, and NH4+. The wearable patch collected multiplexed biomarker data, which provided insights into temporal and spatial variations in the wound microenvironment and the inflammatory condition of the infected wound at various stages of the healing process. In addition, the integration of electrical stimulation on the wearable technology together with electrically modulated antibiotic delivery significantly expedited the closure of chronic wounds.

The development of fully integrated wound-dressing-based devices represents a significant advancement in wearable platforms, enabling continuous wound monitoring alongside on-demand drug delivery. Extensive research efforts have focused on integrating responsive drug delivery systems into smart wound dressings, improving drug dosage precision and enabling tailored therapy for enhanced patient outcomes. One development reported an integrated, battery-free, and wireless smart wound dressing for wound infection monitoring and drug delivery (Fig. 8c)215. The wearable electronics were fabricated based on a polyimide substrate to achieve a flexible platform. The multiplex sensor was developed for the simultaneous detection of temperature, pH, and uric acid to assess wound conditions. The uric acid sensor was based on a nonenzymatic sensor using reductive graphene oxide and gold nanoparticles on the electrode. A polyaniline-coated AuNPs sensor was adapted for pH measurement, while temperature was monitored using a temperature sensor chip. In addition to the sensing module, the drug delivery electrode contained cefazolin antibiotics coated in a polypyrrole (PPy) layer, providing on-demand infection treatment through electrically controlled delivery. The cefazolin antibiotic was utilized to treat wounds infected by Staphylococcus aureus. This wound dressing was applied to infected wounds on rats. The decision criteria for initiating drug delivery were based on temperature, pH, and uric acid concentration, serving as indicators signaling the need for drug administration to the subject’s skin. The determination of drug delivery initiation thresholds relied on precedent clinical investigations and pharmacokinetic evaluations, with thresholds set at approximately 35 °C, 8.3, and 358 µM for temperature, pH, and uric acid, respectively. Additionally, observations of uninfected wounds revealed lower values for temperature (approximately 32 °C), pH (approximately 7.6), and uric acid (approximately 269 µM), falling below the established cutoff levels. These settings ensured timely and precise delivery of the therapeutic agent, optimizing its efficacy while minimizing the risk of under- or over-dosing for the user. By integrating these decision criteria into the drug delivery system, it could autonomously respond to the user’s physiological needs, providing personalized and targeted therapy safely and efficiently. The wound of the rat subject was treated with electronically controlled drug delivery by applying a potential of −0.5 V for 90 s. In this process, the PPy film was reduced, releasing the negatively charged molecules of the doped drug into the wound exudate under electrical repulsion and diffusional force. A decrease in the levels of temperature, pH, and uric acid was observed after treatment, indicating that wounds treated with medications showed improved recovery. By capitalizing on the advantages afforded by flexible electronics and wireless communication, this system represents a closed-loop biomedical system that integrates therapeutic interventions with diagnosis.