Abstract

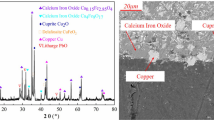

As a direct-to-blister copper flash smelting slag contains important levels of copper (14%) and lead (2–4%) it is subjected to a process of high temperature reduction. To recover copper as well as lead the slag is subjected then to a process of decopperization by reducing the oxide metal compounds in an electric furnace. This study presents an alternative to the above process by recovering Pb and Cu from the slag by a hydrometallurgical route using citric acid solutions. The objective of this study was to determine process parameters at which the effectiveness of the lead leaching process is greatest with the minimum transfer of copper to the solution. This paper presents the results of laboratory tests on flash smelting slag leaching with citric acid solutions. Process parameters (time, temperature, citric acid concentration, l/s ratio) at which the Pb concentration decreases from the initial value (3.05%) to the value of 0.41–0.6% in the post-leaching sediment were determined. Analogous values for copper were 12.44% (before leaching) and 11.5–11.8% (after). The lead and copper content was determined by atomic absorption spectrometry (AAS). The hydrometallurgical method could successfully replace the existing treatment of slag in an electric furnace and converter.

Similar content being viewed by others

References

W.G. Davenport, D.M. Jones, M.J. King, E.H. Partelpoeg, Flash Smelting, Analysis Control and Optimization, 2nd ed., Wiley, New York, USA, 2010.

A.W. Bydalek, P. Migas, W. Wolczynski, S. Biernat, A. Bydalek, K. Jasinska, P. Kwapisinski, Determining the degree of removal of copper from slag, Arch. Foundry Eng. 16 (4) (2016).

M. Kucharski, Effect of thermodynamic and physical properties of flash smelting slags on copper losses during slag cleaning in an electric furnace, Arch. Metall. 32 (1987) 307–323.

N. Habbache, N. Alane, S. Djerad, L. Tifouti, Leaching of copper oxide with different acid solutions, Chem. Eng. J. 152 (2009) 503.

F. Demir, B. Dönmez, Optimization of the dissolution of magnesite in citric acid solutions, Int. J. Miner. Process 87 (2008) 60.

R. Zárate-Gutiérrez, L. Gregorio-Vázquez, G.T. Lapidus, Selective leaching of lead from a lead–silver–zinc concentrate with hydrogen peroxide in citrate solutions, Can. Metall. Quart. 54 (3) (2015) 305–309.

M.A. Shabani, M. Irannajad, A.R. Azadmehr, Investigation on leaching of malachite by citric acid, Int. J. Miner. Metall. Mater. 19 (9) (2012) 782.

U.U. Jadhav, H. Hocheng, A review of recovery of metals from industrial waste, J. Achieve Mater. Manufact. Eng. 54 (2) (2012) 159–167.

J.-H. Chen, C.-E. Huang, Selective separation of Cu and Zn in the citric acid leachate of industrial printed wiring board sludge by D2EHPA-modified amberlite XAD-4 resin, Ind. Eng. Chem. Res. 46 (2007) 7231–7238.

V. Ettler, M. Komarkova, J. Jehlicka, P. Coufal, D. Hradil, V. Machovic, F. Delorme, Leaching of lead metallurgical slag in citric solutions –implications for disposal and weathering in soil environments, Chemosphere 57 (2004) 567–577.

P. Meshram, L. Bhagat, U. Prakash, B.D. Pandey, Abhilash, Organic acid leaching of base metals from copper granulated slag and evaluation of mechanism, Can. Metall. Quart. (2017), https://doi.org/10.1080/00084433.2017.1293900.

M.S. Sonmez, R.V. Kumar, Leaching of waste battery paste components. Part 1: lead citrate synthesis from PbO and PbO2, Hydrometallurgy 95 (2009) 53–60.

M.S. Sonmez, R.V. Kumar, Leaching of waste battery paste components Part 2: leaching and desulphurisation of PbSO4 by citric acid and sodium citrate solution, Hydrometallurgy 95 (2009) 82–86.

C.-H. Wu, C.-Y. Kuo, S.-L. Lo, Removal of metals from industrial sludge by extraction with different acids, J. Environ. Sci. Health Part A - Toxic/Hazard. Subst. Environ. Eng. A39 (8) (2004) 2205–2219.

M. Gergoric, C. Ravaux, B.-M. Steenari, F. Espegren, T. Retegan, Leaching and recovery of rare-earth elements from neodymium magnet waste using organic acids, Metals 8 (2018) 721.

S. Srecko, Träger Thomas, Friedrich Bernd, Synthesis and thermal decomposition of lead citrate, in: Proc. EMC, 2015.

D. del Mundo Dacera, S. Babel, Use of citric acid for heavy metals extraction from contaminated sewage sludge for land application, Water Sci. Technol. 54 (9) (2006) 129–135.

H. Park, K. Jung, R. Diaz Alorro, K. Yoo, Leaching behavior of copper, zinc and lead from contaminated soil with citric acid, Mater. Trans. 54 (7) (2013) 1220–1223.

R. Bassi, S.O. Prosher, Extraction of metals from a contaminated sandy soil using citric acid, Environ. Prog. 19 (4) (2000) 275–282.

K. Huang, K. Inoue, H. Harada, H. Kawakita, K. Ohto, Leaching of heavy metals by citric acid from fly ash generated in municipal waste incineration plants, J. Mater. Cycles Waste Manage. 13 (2011) 118–126.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gargul, K., Boryczko, B., Bukowska, A. et al. Leaching of lead and copper from flash smelting slag by citric acid. Archiv.Civ.Mech.Eng 19, 648–656 (2019). https://doi.org/10.1016/j.acme.2019.02.001

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.acme.2019.02.001