Abstract

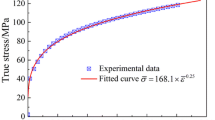

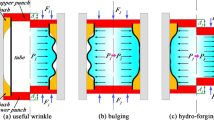

Finite element analysis and scanning electron microscope were conducted to investigate the bulging deformation and fracture of tubes in double-sided hydroforming. The effect of the external pressure imposed on the tube, which determines the magnitude of superimposed hydrostatic pressure, on the stress state, yield locus, fracture surface formation, and fracture strain was evaluated. The simulation results revealed that sufficiently high external pressure can change the stress state of the tube in double-sided hydroforming from an in-plane biaxial tensile stress state to a three-dimensional stress state, and it can increase its hydrostatic pressure in a superimposed manner. Moreover, double-sided free bulging and corner filling experiments were conducted on 5A02 aluminum alloy and 2A12 aluminum alloy tubes. It was found that the external pressure has a significant impact on the fracture behavior of these tubes. The increasing external pressure could change the type, number, size, and proportion of the dimples on the fractured surface, and transform the fracture mode from a void accumulation fracture to a pure shear fracture, which significantly improves the fracture limit of the tubes. These results are significant for the consolidation of the theoretical and numerical simulation prediction of the superimposed hydrostatic pressure effect in the hydroforming process.

Similar content being viewed by others

References

R. Bihamta, Q.-H. Bui, M. Guillot, G. D’Amours, A. Rahem, M. Fafard, Global optimisation of the production of complex aluminium tubes by the hydroforming process, CIRP J. Manuf. Sci. Technol. 9 (2015) 1–11. http://dx.doi.org/10.1016/j.cirpj.2015.02.001.

H.Y. Li, X.S. Wang, S.J. Yuan, Q.B. Miao, Z.R. Wang, Typical stress states of tube hydroforming and their distribution on the yield ellipse, J. Mater. Process. Technol. 151 (2004) 345–349. http://dx.doi.org/10.1016/j.jmatprotec.2004.04.085.

E. Chu, Y. Xu, Hydroforming of aluminum extrusion tubes for automotive applications. Part I: buckling, wrinkling and bursting analyses of aluminum tubes, Int. J. Mech. Sci. 46 (2004) 263–283. http://dx.doi.org/10.1016/j.ijmecsci.2004.02.014.

Y.P. Korkolis, S. Kyriakides, Inflation and burst of anisotropic aluminum tubes for hydroforming applications, Int. J. Plast. 24 (2008) 509–543. http://dx.doi.org/10.1016/j.ijplas.2007.07.010.

M. Liewald, R. Pop, Magnesium tube hydroforming, Materwiss. Werksttech. 39 (2008) 343–348. http://dx.doi.org/10.1002/mawe.200800303.

A.A. Luo, A.K. Sachdev, 11 – Bending and hydroforming of aluminum and magnesium alloy tubes, in: M. Koç (Ed.), Hydroforming Adv. Manuf., Woodhead Publishing, 2008 238–266. http://dx.doi.org/10.1533/9781845694418.2.238.

X. Guo, F. Ma, Q. Guo, X. Luo, N. Kim, K. Jin, A calculating method of tube constants of ductile fracture criteria in tube free bulging process based on M-K theory, Int. J. Mech. Sci. (2017), http://dx.doi.org/10.1016/j.ijmecsci.2017.04.012.

Y. Lou, H. Huh, Extension of a shear-controlled ductile fracture model considering the stress triaxiality and the Lode parameter, Int. J. Solids Struct. 50 (2013) 447–455. http://dx.doi.org/10.1016/j.ijsolstr.2012.10.007.

P.W. Bridgman, Studies in Large Plastic Flow and Fracture, With Special Emphasis on the Effects of Hydrostatic Pressure, McGraw-Hill, New York, 1952, http://dx.doi.org/10.4159/harvard.9780674731349.

J.J. Lewandowski, P. Lowhaphandu, Effects of hydrostatic pressure on mechanical behaviour and deformation processing of materials, Int. Mater. Rev. 43 (1998) 145–187. http://dx.doi.org/10.1179/imr.1998.43.4.145.

J.A. Sauer, D.R. Mears, K.D. Pae, Effects of hydrostatic pressure on the mechanical behaviour of polytetrafluoroethylene and polycarbonate, Eur. Polym. J. 6 (1970) 1015–1032. http://dx.doi.org/10.1016/0014-3057(70)90034-0.

I.E. French, P.F. Weinrich, C.W. Weaver, Tensile fracture of free machining brass as a function of hydrostatic pressure, Acta Metall. 21 (1973) 1045–1049. http://dx.doi.org/10.1016/0001-6160(73)90020-5.

I.E. French, P.F. Weinrich, The influence of hydrostatic pressure on the tensile deformation and fracture of copper, Metall. Trans. A 6 (1975) 785, http://dx.doi.org/10.1007/BF02672300.

A. Brownrigg, W.A. Spitzig, O. Richmond, D. Teirlinck, J.D. Embury, The influence of hydrostatic pressure on the flow stress and ductility of a spherodized 1045 steel, Acta Metall. 31 (1983) 1141–1150. http://dx.doi.org/10.1016/0001-6160(83)90176-1.

D.S. Liu, J.J. Lewandowski, The effects of superimposed hydrostatic pressure on deformation and fracture: Part I. Monolithic 6061 aluminum, Metall. Trans. A 24 (1993) 601–608. http://dx.doi.org/10.1007/BF02656629.

J. Peng, P.D. Wu, Y. Huang, X.X. Chen, D.J. Lloyd, J.D. Embury, K.W. Neale, Effects of superimposed hydrostatic pressure on fracture in round bars under tension, Int. J. Solids Struct. 46 (2009) 3741–3749. http://dx.doi.org/10.1016/j.ijsolstr.2009.07.001.

P.D. Wu, X.X. Chen, D.J. Lloyd, J.D. Embury, Effects of superimposed hydrostatic pressure on fracture in sheet metals under tension, Int. J. Mech. Sci. 52 (2010) 236–244. http://dx.doi.org/10.1016/j.ijmecsci.2009.09.14.

F.J. Fuchs, Hydrostatic pressure: its role in metal forming, Mech. Eng. (1966) 34–40.

L.M. Smith, S. Ganeshmurthy, K. Alladi, Double-sided high-pressure tubular hydroforming, J. Mater. Process. Technol. 142 (2003) 599–608. http://dx.doi.org/10.1016/S0924-0136(02)01041-5.

F. Zhang, J. Chen, J. Chen, X. Zhu, Forming limit model evaluation for anisotropic sheet metals under through-thickness normal stress, Int. J. Mech. Sci. 89 (2014) 40–46. http://dx.doi.org/10.1016/j.ijmecsci.2014.08.016.

J.M. Allwood, D.R. Shouler, Generalised forming limit diagrams showing increased forming limits with non-planar stress states, Int. J. Plast. 25 (2009) 1207–1230. http://dx.doi.org/10.1016/j.ijplas.2008.11.001.

X.-L. Cui, X.-S. Wang, S.-J. Yuan, Deformation analysis of double-sided tube hydroforming in square-section die, J. Mater. Process. Technol. 214 (2014), http://dx.doi.org/10.1016/j.jmatprotec.2014.02.005.

X.-L. Cui, X.-S. Wang, S.-J. Yuan, The bulging behavior of thick-walled 6063 aluminum alloy tubes under double-sided pressures, JOM 67 (2015), http://dx.doi.org/10.1007/s11837-015-1291-1.

X.L. Cui, X.S. Wang, S.J. Yuan, Experimental verification of the influence of normal stress on the formability of thin-walled 5A02 aluminum alloy tubes, Int. J. Mech. Sci. 88 (2014) 232–243. http://dx.doi.org/10.1016/j.ijmecsci.2014.07.011.

Y. Shi, H. Jin, P.D. Wu, D.J. Lloyd, Effects of superimposed hydrostatic pressure on necking and fracture of tube under hydroforming, Int. J. Solids Struct. (2017), http://dx.doi.org/10.1016/j.ijsolstr.2017.02.027.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, XL., Yuan, SJ. Effects of superimposed hydrostatic pressure on bulging deformation and fracture of tubes in double-sided hydroforming. Archiv.Civ.Mech.Eng 19, 569–583 (2019). https://doi.org/10.1016/j.acme.2018.12.012

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.acme.2018.12.012