Abstract

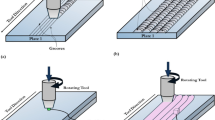

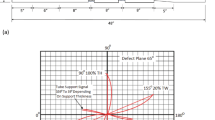

To make further exploration on the deformation behavior of tube under double-sided pressures, the thick-walled 6063 aluminum alloy tubes with an outer diameter of 65 mm and an average thickness of 7.86 mm have been used to be bulged under the combined action of internal and external pressures. In the experiment, two ends of the thick-walled tubes were fixed using the tooth and groove match. Three levels of external pressure (0 MPa, 40 MPa, and 80 MPa), in conjunction with the internal pressure, were applied on the tube outside and inside simultaneously. The effect of external pressure on the bulging behavior of the thick-walled tubes, such as the limiting expansion ratio, the bulging zone profile, and the thickness distribution, has been investigated. It is shown that the limiting expansion ratio, the bulging zone profile, and the thickness distribution in the homogeneous bulging area are all insensitive to the external pressure. However, the external pressure can make the thick-walled tube achieve a thinner wall at the fracture area. It reveals that the external pressure can only improve the fracture limit of the thick-walled 6063 tubes, but it has very little effect on their homogeneous bulging behavior. It might be because the external pressure can only increase the magnitude of the hydrostatic pressure for the tube but has no effect on the Lode parameter.

Similar content being viewed by others

References

B. Constantine, R. Roth, and J.P. Clark, JOM 53, 33 (2001).

A.I. Taub, P.E. Krajewski, A.A. Luo, and J.N. Owens, JOM 59, 48 (2007).

M. Koç and T. Altan, J. Mater. Process Technol. 108, 384 (2001).

A. Alaswad, K.Y. Benyounis, and A.G. Olabi, Mater. Des. 33, 328 (2012).

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge, Mater. Sci. Eng. A-Struct. 280, 37 (2000).

J. Hirsch and T. Al-Samman, Acta Mater. 61, 818 (2013).

F.J. Fuchs, W. Electric, and N.J. Princeton, Mech. Eng. 88, 34 (1966).

L.M. Smith, S. Ganeshmurthy, and K. Alladi, J. Mater. Process Technol. 142, 599 (2003).

N. Jain and J. Wang, Int. J. Mater. Prod. Technol. 21, 200 (2004).

N. Jain, J. Wang, and R. Alexander, J. Mater. Process Technol. 145, 59 (2004).

N. Jain and J. Wang, Int. J. Mech. Sci. 47, 1827 (2005).

U. Guven, P. I. Mech. Eng. B.-J. Eng. 223, 1361 (2009).

M. Gotoh, T. Chung, and N. Iwata, JSME Int. J. A-Solid Mech. 38, 123 (1995).

L.M. Smith, R.C. Averill, J.P. Lucas, T.B. Stoughton, and P.H. Matin, Int. J. Plast. 19, 1567 (2003).

P.H. Matin and L.M. Smith, Int. J. Plast. 21, 671 (2005).

D. Banabic and S. Soare, Paper presented at Numisheet 2008 (Interlaken, Switzerland, 2008), pp. 199–204.

J.M. Allwood and D.R. Shouler, Int. J. Plast. 25, 1207 (2009).

A. Assempour, H.K. Nejadkhaki, and R. Hashemi, Comp. Mater. Sci. 48, 504 (2010).

M. Nurcheshmeh and D.E. Green, Int. J. Mater. Form. 5, 213 (2012).

M. Nurcheshmeh and D.E. Green, Int. J. Mech. Sci. 82, 131 (2014).

J. Liu, Z. Wang, and Q. Meng, J. Mater. Eng. Perform. 21, 429 (2012).

X.L. Cui, X.S. Wang, and S.J. Yuan, J. Mater. Process Technol. 214, 1341 (2014).

X.L. Cui, X.S. Wang, and S.J. Yuan, Int. J. Mech. Sci. 88, 232 (2014).

J.J. Lewandowski and P. Lowhaphandu, Int. Mater. Rev. 43, 145 (1998).

Acknowledgements

This study was financially supported by the Program for Changjiang Scholars and Innovative Research Team in University (No. IRT1229), the National Natural Science Foundation of China (No. 50975061) and the Fundamental Research Funds for the Central Universities (HIT.NSRIF.201134). The authors would like to express their gratitude to the funding.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cui, XL., Wang, XS. & Yuan, SJ. The Bulging Behavior of Thick-Walled 6063 Aluminum Alloy Tubes Under Double-Sided Pressures. JOM 67, 909–915 (2015). https://doi.org/10.1007/s11837-015-1291-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1291-1