Abstract

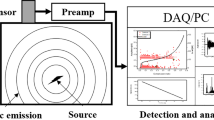

Deviations during forging processes lead to workpiece failure when the forming limits of the material are exceeded. In production processes an early detection of manufacturing faults is preferred. The acoustic emission (AE) technique is examined with respect to its ability to detect deviations in lubrication conditions and in the structural integrity of different aluminum part geometries and alloys during forming. In a first step, an upsetting of varying specimen shapes was performedinordertostudy correlationsofoccurring defectsaswell as changing friction conditions with acoustic emission response. Afterwards, a cross joint was forged and AE was analyzed. The results suggest that crack detection during forging is feasible but limited by material ductility. In addition, it is shown that the characteristics of the acoustic emission during forming strongly depend on the respective alloy. With respect to faultless warm forging it is found that different stages are reflected in the AE signal, facilitating the detection of process deviations.

Similar content being viewed by others

References

B.-A. Behrens, R. Nickel, S. Müller, Flashless precision forging of a two-cylinder-crankshaft, Production Engineering 3 (4-5) (2009) 381–389. https://doi.org/10.1007/s11740-009-0185-x.

A. Forcellese, F. Gabrielli, Warm forging of aluminium alloys: a new approach for time compression of the forging sequence, International Journal of Machine Tools and Manufacture 40 (9) (2000) 1285–1297. https://doi.org/10.1016/S0890-6955(99)00127-3.

H. Yoshimura, Examples of precision forging by enclosed-die forging, in: 10th International Cold Forging Congress 2000, VDI Berichte, vol. 1555, VDI Verlag, Düsseldorf, 2000, pp. 151–161.

M. Kleiner, M. Geiger, A. Klaus, Manufacturing of lightweight components by metal forming, CIRP Annals - Manufacturing Technology 52 (2) (2003) 521–542. https://doi.org/10.1016/S0007-8506(07)60202-9.

K. Ono, Current understanding of mechanisms of acoustic emission, The Journal of Strain Analysis for Engineering Design 40 (1) (2005) 1–15. https://doi.org/10.1243/030932405X7674.

V.A. Baranov, Acoustic Emission in Friction, Tribology and Interface Engineering Series, 53, Elsevier, Amsterdam, 2006.

C.R. Heiple, S.H. Carpenter, Acoustic emission produced by deformation of metals and alloys. Pt. 1. A review, Journal of Acoustic Emission 6 (3) (1987) 177–204.

C. Scruby, H. Wadley, J.E. Sinclair, The origin of acoustic emission during deformation of aluminium and an aluminium-magnesium alloy, Philosophical Magazine A 44 (2) (1981) 249–274. https://doi.org/10.1080/01418618108239532.

H.N. Wadley, C.B. Scruby, J.H. Speake, Acoustic emission for physical examination of metals, International Metals Reviews 25 (1) (1980) 41–64.

C. Hellier, Acoustic emission testing, in: Handbook of Nondestructive Evaluation, McGraw-Hill, New York, 2001 (chapter 10).

D.G. Aggelis, E.Z. Kordatos, T.E. Matikas, Monitoring of metal fatigue damage using acoustic emission and thermography, Journal of Acoustic Emission 29 (2011) 113–122.

H.S. Benabdallah, D.A. Aguilar, Acoustic emission and its relationship with friction and wear for sliding contact, Tribology Transactions 51 (6) (2008) 738–747. https://doi.org/10.1080/10402000802044324.

C.L. Jiaa, D.A. Dornfeld, Experimental studies of sliding friction and wear via acoustic emission signal analysis, Wear 139 (2) (1990) 403–424.

B.-A. Behrens, A. Santangelo, C. Buse, Acoustic emission technique for online monitoring during cold forging of steel components: a promising approach for online crack detection in metal forming processes, Production Engineering 7 (4) (2013) 423–432. http://dx.doi.org/10.1007/s11740-013-0452-8.

B.-A. Behrens, I. El-Galy, T. Huinink, C. Buse, Online Monitoring of Deep Drawing Process by Application of Acoustic Emission, in: G. Hirt (Ed.), 10th International Conference on Technology of Plasticity, ICTP 2011, Steel research international Special edition, Verl. Stahleisen GmbH, Düsseldorf, (2011) 385–389.

B.-A. Behrens, T. Hagen, J. Knigge, I. Elgaly, T. Hadifi, A. Bouguecha, New trends in forging technologies, AIP Conference Proceedings 1353 (1) (2011) 380–385. https://doi.org/10.1063/1.3589545.

B.-A. Behrens, T. Hagen, A. Klassen, J. Knigge, J. Mielke, I. Pfeiffer, Forging of aluminium components under a superimposed hydrostatic pressure to induce local strain hardening, Advanced Material Research 137 (2010) 191–217. https://doi.org/10.4028/www.scientific.net/AMR.137.191.

C.K. Mukhopadhyay, S. Venugopal, T. Jayakumar, S.L. Mannan, B. Raj, B. Chatterji, R. Srinivasan, V. Gopalakrishnan, G. Madhusudan, R.S. Tripathi, Acoustic emission (AE) monitoring of open die and closed die forging processes of Al alloy, Materials and Manufacturing Processes 22 (7) (2007) 887–892. https://doi.org/10.1080/10426910701448974.

K.P. Rao, K. Sivaram, A review of ring-compression testing and applicability of the calibration curves, Journal of Materials Processing Technology 37 (1) (1993) 295–318.

M. Lugo, J.B. Jordon, M.F. Horstemeyer, M.A. Tschopp, J. Harris, A.M. Gokhale, Quantification of damage evolution in a 7075 aluminum alloy using an acoustic emission technique, Materials Science and Engineering A 528 (22-23) (2011) 6708–6714. https://doi.org/10.1016/j.msea.2011.05.017.

A. Yilmaz, The Portevin-Le Châtelier effect: a review of experimental findings, Science and Technology of Advanced Materials 12 (6) (2011) 63001 https://doi.org/10.1088/1468-6996/12/6/063001.

F. Chmelík, A. Ziegenbein, H. Neuhäuser, P. Lukáč, Investigating the Portevin-Le Châtelier effect by the acoustic emission and laser extensometry techniques, Materials Science and Engineering A 324 (1-2) (2002) 200–207. https://doi.org/10.1016/S0921-5093(01)01312-0.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Behrens, BA., Bouguecha, A., Buse, C. et al. Potentials of in situ monitoring of aluminum alloy forging by acoustic emission. Archiv.Civ.Mech.Eng 16, 724–733 (2016). https://doi.org/10.1016/j.acme.2016.04.012

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.acme.2016.04.012