Abstract

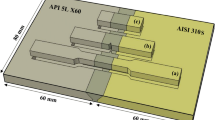

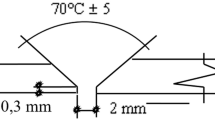

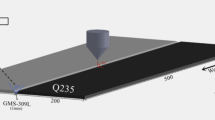

The microstructure and mechanical properties of dissimilar joints of AISI 316L austenitic stainless steel and API X70 high-strength low-alloy steel were investigated. For this purpose, gas tungsten arc welding (GTAW) was used in three different heat inputs, including 0.73, 0.84, and 0.97 kJ/mm. The micro-structural investigations of different zones including base metals, weld metal, heat-affected zones and interfaces were performed by optical microscopy and scanning electron microscopy. The mechanical properties were measured by microhardness, tensile and impact tests. It was found that with increasing heat input, the dendrite size and inter-dendritic spacing in the weld metal increased. Also, the amount of delta ferrite in the weld metal was reduced. Therefore, tensile strength and hardness were reduced and impact test energy was increased. The investigation of the interface between AISI 316L base metal and ER316L filler metal showed that increasing the heat input increases the size of austenite grains in the fusion boundary. A transition region was formed at the interface between API X70 steel and filler metals.

Similar content being viewed by others

References

J. C. Lipoid, D. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley, New York, 2005.

P. D. Teidra, O. Martin, Mater. Des. 49 (2013) 103–110.

S. H. Hashemi, D. Mohammadyani, M. Pouranvari, S. M. Mousavizadeh, Eng. Mater. 32 (2009) 33–39.

L. Zhongqiu, F. Jian, Z. Yong, Y. Zexi, Energy Proc. 16 (2012) 444–450.

M. K. Samal, M. Seidenfuss, E. Roos, K. Balani, Eng. Fail. Anal. 18 (2011) 993–999.

G. Phanikumar, K. Chattopadhyay, P. Dutta, Sci. Technol. Weld. Join. 16 (2011) 306–313.

H. Naffakh, M. Shamanian, F. Ashrafizadeh, J. Mater. Process. Technol. 209 (2009) 3623–3628.

M. M. A. Khana, L. Romolia, M. Fiaschib, G. Dinia, F. Sarri, J. Mater. Process. Technol. 212 (2012) 856–862.

S. Wang, Q. Ma, Y. Li, Mater. Des. 32 (2011) 831–839.

C. H. Lee, K. H. Chang, J. Mater. Sci. 42 (2007) 6607–6614.

P. Sedeka, J. Brozda, L. Wang, P. J. Withers, Int. J. Press. Vessels Pip. 80 (2003) 705–711.

E. Ranjbarnodeh, S. Serajzadeh, A. H. Kokabi, S. Hanke, A. Fischer, Int. J. Adv. Manuf. Technol. 55 (2011) 649–656.

D. Y. Lin, C. C. Hsieh, Met. Mater. Int. 15 (2009) 507–514.

N. Arivazhagan, S. Singh, S. Prakash, G. M. Reddy, Mater. Des. 32 (2011) 3036–3042.

M. Sadeghian, M. Shamanian, A. Shafyei, Mater. Des. 60 (2014) 678–684.

K. D. Ramkumar, A. Bajpai, S. Raghuvanshi, Mater. Sci. Eng. A 638 (2015) 60–66.

B. Mvola, P. Kah, J. Martikainen, R. Suoranta, Rev. Adv. Mater. Sci. 44 (2016) 146–159.

M. Al Hajri, A. U. Malik, A. Meroufel, F. Al Muaili, Case Studies in Engineering Failure Analysis 3 (2015) 96–103.

R. Saluja, K. M. Moeed, Int. J. Eng. Sci. Technol. 4 (2012) 2206–2212.

E. J. Barnhouse, J. C. Lippold, Weld. J. 77 (1998) 477–484.

S. Kumar, A. S. Shahi, Mater. Des. 32 (2011) 3617–3624.

R. Yilmaz, H. Uzun, Journal of Marmara of Pure and Applied Sciences 18 (2002) 97.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mortazavi, E., Najafabadi, R.A. & Meysami, A. Effect of heat input on microstructure and mechanical properties of dissimilar joints of AISI 316L steel and API X70 high-strength low-alloy steel. J. Iron Steel Res. Int. 24, 1248–1253 (2017). https://doi.org/10.1016/S1006-706X(18)30024-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(18)30024-4