Abstract

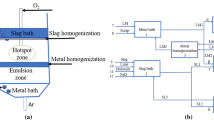

Based on the similarity principles, a 1: 7 scale physical model was established to study the behavior of molten steel flow and inclusion removal in a 145 t Rheinsahl-Heraeus (RH) degasser. On the basis of the quantitative measurements of the circulation flow rate and inclusion removal under various lifting gas flow rates, the effect of circulation flow rate on inclusion removal was investigated in the RH degasser. The inclusion removal rate shows the trend of first increase and then decrease twice with increasing the circulation flow rate when the circulation flow rates are smaller than 104.7 L/min. Whereas, the inclusion removal rate increases again with the further increase in circulation flow rate when the circulation flow rate is larger than 104.7 L/min. At lower circulation flow rates, inclusions are mainly removed by Stokes flotation to the slag/steel interface after inclusions are transferred near the slag/steel interface by the circulation flow. At higher circulation flow rates, the collision and aggregation of inclusions improves the inclusion removal efficiency. With the further increase in the circulation flow rate, inclusions are mainly removed by following the turbulent fluctuation (turbulent diffusion) to the slag/steel interface after inclusions are transferred near the slag/steel interface by the circulation flow.

Similar content being viewed by others

References

D. Q. Geng, H. Lei, J. C. He, Metall. Mater. Trans. B 41 (2010) 234–247.

L. Lin, Y. P. Bao, F. Yue, L. Q. Zhang, H. L. Ou, Int. J. Miner. Metall. Mater. 19 (2012) 483–489.

X. G. Ai, Y. P. Bao, H. J. Wu, X. Ma, N. Jia, Special Steel 30 (2009) No. 3, 1–3.

P. A. Kishan, S. K. Dash, ISIJ Int. 49 (2009) 495–504.

J. H. Wei, H. T. Hu, Ironmak. Steelmak. 32 (2005) 427–434.

M. Y. Zhu, Y. L. Wu, C. W. Du, Z. Z. Huang, J. Iron Steel Res. Int. 12 (2005) No. 2, 20–24.

K. Nakanishi, T. Fujii, J. Szekely, Ironmak. Steelmak. 2 (1975) 193–197.

T. Kuwabara, K. Umezawa, K. Mori, H. Watanabe, Trans. ISIJ 28 (1988) 305–314.

D. Q. Geng, H. Lei, J. C. He, Ironmak. Steelmak. 39 (2012) 431–438.

S. Inoue, Y. Furuno, T. Usui, S. Miyahara, ISIJ Int. 32 (1992) 120–125.

M. Takahashi, H. Matsumoto, T. Saito, ISIJ Int. 35 (1995) 1452–1458.

M. A. Van Ende, Y. M. Kim, M. K. Cho, J. Choi, I. H. Jung, Metall. Mater. Trans. B 42 (2011) 477–489.

C. W. Li, G. G. Cheng, X. H. Wang, G. S. Zhu, A. M. Cui, J. Iron Steel Res. Int. 19 (2012) No. 5, 23–28.

S. K. Ajmani, S. K. Dash, S. Chandra, C. Bhanu, ISIJ Int. 44 (2004) 82–90.

C. A. da Silva, I. A. da Silva, E. M. de Castro Martins, V. Seshadri, C. A. Perim, G. A. Vargas Filho, Ironmak. Steelmak. 31 (2004) 37–42.

F. Ahrenhold, W. Pluschkell, Steel Res. Int. 70 (1999) 314–318.

Y. Miki, B. G. Thomas, A. Denissov, Y. Shimada, Iron and Steelmaker 24 (1997) No. 8, 31–38.

C. J. Treadgold, Ironmak. Steelmak. 30 (2003) 120–124.

V. Tusset, C. Marique, H. Mathy, B. Gommers, N. Van Poeck, Ironmak. Steelmak. 30 (2003) 142–145.

X. G. Ai, Y. P. Bao, H. J. Wu, F. Yue, H. Cui, Iron and Steel 44 (2009) No. 7, 43–46.

H. F. Shu, L. Liu, X. H. Liu, X. F. Zhang, J. Iron Steel Res. Int. 18 (2011) Suppl. 2, 347–351.

S. G. Zheng, M. Y. Zhu, S. S. Pan, Acta Metall. Sin. 42 (2006) 657–661.

Y. G. Chi, Q. Z. Shen, Z. H. Wu, M. Y. Peng, Z. H. Xiao, Special Steel 32 (2011) No. 4, 10–13.

S. G. Zheng, M. Y. Zhu, Steel Res. Int. 79 (2008) 685–690.

S. G. Zheng, M. Y. Zhu, Y. Wang, J. Northeast. Univ. 31 (2010) 677–680.

W. Zheng, X. Shen, Y. C. Yang, G. Q. Li, K. Lu, H. Tu, C. Y. Zhu, Steelmaking 29 (2013) No. 5, 38–42.

T. Qu, M. Jiang, C. Liu, Y. Komizo, Steel Res. Int. 81 (2010) 434–445.

M. Y. Zhu, Z. Q. Xiao, Maths-physical Modeling of Steel Refining Process, Metallurgical Industry Press, Beijing, 1998.

Y. Sahai, T. Emi, ISIJ Int. 36 (1996) 1166–1173.

D. Q. Geng, H. Lei, J. C. He, J. Iron Steel Res. 21 (2009) No. 12, 10–13.

T. Murai, H. Matsuno, E. Sakurai, H. Kawashima, Tetsuto-Hagané 84 (1998) 13–18.

P. G. Saffman, J. S. Turner, J. Fluid Mech. 1 (1956) 16–30.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51474059, 51204042); Program for Liaoning Excellent Talents in University of China (LJQ2014031); Fundamental Research Funds for the Central Universities of China (N140205003)

Rights and permissions

About this article

Cite this article

Zheng, Sg., Zhu, My. Modelling Effect of Circulation Flow Rate on Inclusion Removal in RH Degasser. J. Iron Steel Res. Int. 23, 1243–1248 (2016). https://doi.org/10.1016/S1006-706X(16)30183-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(16)30183-2