Abstract

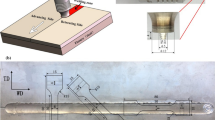

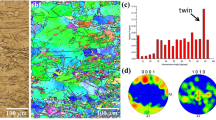

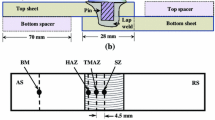

This study focuses on the microstructure evolution and mechanical properties of dissimilar magnesium alloy friction stir welded AZ61/AZ40 joints achieved at different traverse speeds (50–130 mm/min) and a constant rotation speed (1200 rpm). The surfaces of the welds are relatively smooth without any obvious surface defects except for the FSW joint at a traverse speed of 50 mm/min. The nugget zone (NZ) is bowl-shaped due to the tapered probe. The Mg-based alloys were sufficiently mixed with each other in the NZ, and the interface was irregular. In addition, the NZ exhibits fine equiaxed grains due to dynamic recrystallization (DRX), and the grain size decreases with increasing traverse speed. The welded joints show a relatively discontinuous microhardness, and the lowest microhardness occurs in the thermo-mechanically affected zone (TMAZ) on the advancing side (AS). The strength increases as the traverse speed increases from 50 to 70 mm/min and then decreases as the traverse speed increases continually. An exceptionally high tensile strength of 235 MPa was achieved at a traverse speed of 70 mm/min. The combined effects of high-density dislocations and fine second phases (η-Al8Mn5 and β-Mg17Al12 phase) promote mechanical properties.

Similar content being viewed by others

Data and code availability

All data generated or used during the study are included in the submitted article.

References

Mordike BL, Ebert T. Magnesium: properties—applications—potential. Mater Sci Eng A. 2001;302(1):37–45.

Nie JF. Precipitation and hardening in magnesium alloys. Metall Mater Trans A. 2012;43:3891–939.

Pan H, Ren Y, Fu H, Zhao H, Wang L, Meng X, Qin G. Recent developments in rare-earth free wrought magnesium alloys having high strength: a review. J Alloy Compd. 2016;663:321–31.

Singh K, Singh G, Singh H. Review on friction stir welding of magnesium alloys. J Magnes Alloys. 2018;6(4):399–416.

Li W, Niu PL, Yan SR, Patel V, Wen Q. Improving microstructural and tensile properties of AZ31B magnesium alloy joints by stationary shoulder friction stir welding. J Manuf Process. 2019;37:159–67.

Liu Z, Xin R, Wu X, Liu D, Liu Q. Improvement in the strength of friction-stir-welded ZK60 alloys via post-weld compression and aging treatment. Mater Sci Eng A. 2018;712:493–501.

Commin L, Dumont M, Masse JE, Barrallier L. Friction stir welding of AZ31 magnesium alloy rolled sheets: influence of processing parameters. Acta Mater. 2009;57(2):326–34.

Heidarzadeh A, Mironov S, Kaibyshev R, Çam G, Simar A, Gerlich A, Withers PJ. Friction stir welding/processing of metals and alloys: a comprehensive review on microstructural evolution. Prog Mater Sci. 2021;117:100752.

Wang W, Zhang W, Chen W, Yang J, Zhang L, Wang E. Homogeneity improvement of friction stir welded ZK61 alloy sheets in microstructure and mechanical properties by multi-pass lowered-temperature rolling. Mater Sci Eng A. 2017;703:17–26.

Zhang J, Liu H, Chen X, Zou Q, Huang G, Jiang B, Pan F. Deformation characterization, twinning behavior and mechanical properties of dissimilar friction-stir-welded AM60/AZ31 alloys joint during the three-point bending. Acta Metallurgica Sinica (English Letters). 2021;1–18.

Templeman Y, Hamu GB, Meshi L. Friction stir welded AM50 and AZ31 Mg alloys: microstructural evolution and improved corrosion resistance. Mater Charact. 2017;126:86–95.

He W, Zheng L, Xin R, Liu Q. Microstructure-based modeling of tensile deformation of a friction stir welded AZ31 Mg alloy. Mater Sci Eng A. 2017;687:63–72.

Luo XC, Kang LM, Liu HL, Li ZJ, Liu YF, Zhang DT, Chen DL. Enhancing mechanical properties of AZ61 magnesium alloy via friction stir processing: effect of processing parameters. Mater Sci Eng A. 2020;797: 139945.

Yang J, Ni DR, Wang D, Xiao BL, Ma ZY. Friction stir welding of as-extruded Mg–Al–Zn alloy with higher Al content. Part I: formation of banded and line structures. Mater Charact. 2014;96:142–50.

Huang Y, Wang Y, Meng X, Wan L, Cao J, Zhou L, Feng J. Dynamic recrystallization and mechanical properties of friction stir processed Mg-Zn-Y-Zr alloys. J Mater Process Technol. 2017;249:331–8.

Lee CY, Lee WB, Yeon YM, Jung SB. Friction stir welding of dissimilar formed Mg alloys (AZ31/AZ91). Mater Sci Forum. 2005;486:249–52.

Liu D, Nishio H, Nakata K. Anisotropic property of material arrangement in friction stir welding of dissimilar Mg alloys. Mater Des. 2011;32(10):4818–24.

Sunil BR, Reddy GPK, Mounika ASN, Sree PN, Pinneswari PR, Ambica I, Amarnadh P. Joining of AZ31 and AZ91 Mg alloys by friction stir welding. J Magnes Alloys. 2015;3(4):330–4.

Liu D, Xin R, Zheng X, Zhou Z, Liu Q. Microstructure and mechanical properties of friction stir welded dissimilar Mg alloys of ZK60–AZ31. Mater Sci Eng A. 2013;561:419–26.

Luo C, Li X, Song D, Zhou N, Li Y, Qi W. Microstructure evolution and mechanical properties of friction stir welded dissimilar joints of Mg–Zn–Gd and Mg–Al–Zn alloys. Mater Sci Eng A. 2016;664:103–13.

Klenam DEP, Ogunwande GS, Omotosho T, Ozah B, Maledi NB, Hango SI, Bodunrin MO. Welding of magnesium and its alloys: an overview of methods and process parameters and their effects on mechanical behaviour and structural integrity of the welds. Manuf Rev. 2021;8:29.

Huetsch LL, Herzberg K, Dos Santos JF, Huber N. A study on local thermal and strain phenomena of high-speed friction stir-processed Mg AZ31. Weld World. 2013;57(4):515–21.

Shang Q, Ni DR, Xue P, Xiao BL, Ma ZY. Evolution of local texture and its effect on mechanical properties and fracture behavior of friction stir welded joint of extruded Mg-3Al-1Zn alloy. Mater Charact. 2017;128:14–22.

Xie L, Zhu X, Sun W, Jiang C, Wang P, Yang S, Song Y. Investigations on the material flow and the influence of the resulting texture on the tensile properties of dissimilar friction stir welded ZK60/Mg–Al–Sn–Zn joints. J Mater Res Technol. 2022;17:1716–30.

Zhang H, Wang HY, Wang JG, Rong J, Zha M, Wang C, Jiang QC. The synergy effect of fine and coarse grains on enhanced ductility of bimodal-structured Mg alloys. J Alloys Compds. 2019;780:312–7.

Lu S, Qi F, Chen J, Jia XD. Numerical simulation and experiment of temperature field on Mg alloy weld processed by friction-stir welding. J Comput Theor Nanosci. 2012;9(9):1231–5.

Zhou Z, Yue Y, Ji S, Li Z, Zhang L. Effect of rotating speed on joint morphology and lap shear properties of stationary shoulder friction stir lap welded 6061–T6 aluminum alloy. Int J Adv Manuf Technol. 2017;88:2135–41.

Guerra M, Schmidt C, McClure JC, Murr LE, Nunes AC. Flow patterns during friction stir welding. Mater Charact. 2002;49(2):95–101.

Kumar Singh U, Kumar Dubey A. Study of joining performance of dissimilar Mg alloys in friction stir welding. Proc Inst Mech Eng C J Mech Eng Sci. 2021;235(18):3554–62.

Esparza JA, Davis WC, Trillo EA, Murr LE. Friction-stir welding of magnesium alloy AZ31B. J Mater Sci Lett. 2002;21:917–20.

Afrin N, Chen DL, Cao X, Jahazi M. Microstructure and tensile properties of friction stir welded AZ31B magnesium alloy. Mater Sci Eng A. 2008;472(1–2):179–86.

Liu D, Xin R, Zhao L, Hu Y. Effect of textural variation and twinning activity on fracture behavior of friction stir welded AZ31 Mg alloy in bending tests. J Alloy Compd. 2017;693:808–15.

Hamilton C, Sommers A, Dymek S. A thermal model of friction stir welding applied to Sc-modified Al–Zn–Mg–Cu alloy extrusions. Int J Mach Tools Manuf. 2009;49(3–4):230–8.

Yang J, Xiao BL, Wang D, Ma ZY. Effects of heat input on tensile properties and fracture behavior of friction stir welded Mg–3Al–1Zn alloy. Mater Sci Eng A. 2010;527(3):708–14.

Suhuddin UFHR, Mironov S, Sato YS, Kokawa H, Lee CW. Grain structure evolution during friction-stir welding of AZ31 magnesium alloy. Acta Mater. 2009;57(18):5406–18.

Acknowledgements

This work was financially supported by the Technology Project of Nanchong and Southwest Petroleum University (SWPU) Cooperation (No. 23XNSYSX0003).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Wang, J., Cui, C. et al. Improving microstructural and mechanical properties of dissimilar friction stir welded AZ61/AZ40 joint. Archiv.Civ.Mech.Eng 24, 66 (2024). https://doi.org/10.1007/s43452-024-00876-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00876-y