Abstract

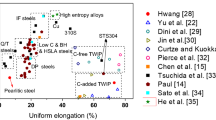

The sequential twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP) effects were induced in a commercial AISI 304L stainless steel by tailoring the average austenite grain size (via thermomechanical processing of cold rolling and reversion/recrystallization annealing), leading to a combination of high yield stress and total elongation as well as a remarkable strength-ductility synergy similar to advanced high-strength steels (AHSS) for automotive industry. In fact, the refinement of grains promoted the TWIP effect at the expense of the TRIP effect due to its effect on increasing the apparent stacking fault energy; while the coarsening/growth of grains led to a pronounced TRIP effect via deformation-induced martensitic phase transformation during straining. Moreover, the TRIP/TWIP effects were characterized by the simple work-hardening analysis such as slope change and appearance of extremum points on the curves of work-hardening rate, logarithmic and parabolic segments on the curves of instantaneous work-hardening exponent, and deviations from the strain-hardening Hollomon lines. The results were supported by the interrupted tensile tests and detailed electron backscattered diffraction (EBSD) analysis, where the merit of the TWIP-TRIP steels was shown in the case of a commercial austenitic stainless steel.

Similar content being viewed by others

Acknowledgments

Saeed Sadeghpour would like to thank Jane and Aatos Erkon säätiö (JAES) and Tiina ja Antti Herlinin säätiö (TAHS) for their financial supports on Advanced Steels for Green Planet Project. The authors would also like to greatly thank the members of the “Formability Laboratory” and “Advanced Steels and Thermomechanically Processed Engineering Materials Laboratory” for their help and support.

References

Järvenpää A, Ghosh S, Khosravifard A, Jaskari M, Hamada A. A new processing route to develop nano-grained structure of a TRIP-aided austenitic stainless-steel using double reversion fast-heating annealing. Mater Sci Eng, A. 2021;808: 140917.

Pradhan SK, Bhuyan P, Bairi LR, Mandal S. Comprehending the role of individual microstructural features on electrochemical response and passive film behaviour in type 304 austenitic stainless steel. Corros Sci. 2021;180: 109187.

Sun G, Du L, Hu J, Zhang B, Misra RDK. On the influence of deformation mechanism during cold and warm rolling on annealing behavior of a 304 stainless steel. Mater Sci Eng, A. 2019;746:341–55.

Sohrabi MJ, Naghizadeh M, Mirzadeh H. Deformation-induced martensite in austenitic stainless steels: a review. Arch Civil Mech Eng. 2020;20:124.

Dong FY, Zhang P, Pang JC, Chen DM, Yang K, Zhang ZF. Optimizing strength and ductility of austenitic stainless steels through equal-channel angular pressing and adding nitrogen element. Mater Sci Eng, A. 2013;587:185–91.

Zhang M, Chen H, Wang Y, Wang S, Li R, Li S, Wang YD. Deformation-induced martensitic transformation kinetics and correlative micromechanical behavior of medium-Mn transformation-induced plasticity steel. J Mater Sci Technol. 2019;35(8):1779–86.

Cios G, Tokarski T, Żywczak A, Dziurka R, Stępień M, Gondek Ł, Marciszko M, Pawłowski B, Wieczerzak K, Bała P. The investigation of strain-induced martensite reverse transformation in AISI 304 austenitic stainless steel. Metall Mater Trans A. 2017;48:4999–5008.

Hamada AS, Karjalainen LP, Misra RDK, Talonen J. Contribution of deformation mechanisms to strength and ductility in two Cr–Mn grade austenitic stainless steels. Mater Sci Eng, A. 2013;559:336–44.

Weiß A, Gutte H, Scheller PR. Deformation induced martensite formation and its effect on transformation induced plasticity (TRIP). Steel Res Int. 2006;77(9–10):727–32.

Järvenpää A, Jaskari M, Kisko A, Karjalainen P. Processing and properties of reversion-treated austenitic stainless steels. Metals. 2020;10(2):281.

Qin W, Li J, Liu Y, Kang J, Zhu L, Shu D, Peng P, She D, Meng D, Li Y. Effects of grain size on tensile property and fracture morphology of 316L stainless steel. Mater Lett. 2019;254:116–9.

Masumura T, Fujino K, Tsuchiyama T, Takaki S, Kimura K. Effect of carbon and nitrogen on Md30 in metastable austenitic stainless steel. ISIJ Int. 2021;61:546–55.

Sohrabi MJ, Mirzadeh H, Sadeghpour S, Mahmudi R. Grain size dependent mechanical behavior and TRIP effect in a metastable austenitic stainless steel. Int J Plast. 2023;160: 103502.

Byun TS, Hashimoto N, Farrell K. Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels. Acta Mater. 2004;52:3889–99.

Talonen J, Hänninen H, Nenonen P, Pape G. Effect of strain rate on the strain-induced γ→ α′-martensite transformation and mechanical properties of austenitic stainless steels. Metall Mater Trans A. 2005;36(2):421–32.

Ahmedabadi PM, Kain V. Kinetics parameters for deformation-induced martensitic transformation in austenitic stainless steels. Philos Mag Lett. 2020;100:555–60.

De AK, Murdock DC, Mataya MC, Speer JG, Matlock DK. Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scripta Mater. 2004;50:1445–9.

De Cooman BC, Estrin Y, Kim SK. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018;142:283–362.

Grässel O, Frommeyer G. Effect of martensitic phase transformation and deformation twinning on mechanical properties of Fe–Mn–Si–AI steels. Mater Sci Technol. 1998;14(12):1213–7.

Grässel O, Krüger L, Frommeyer G, Meyer LW. High strength Fe–Mn–(Al, Si) TRIP/TWIP steels development—properties—application. Int J Plast. 2000;16:1391–409.

Curtze S, Kuokkala VT. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010;58(15):5129–41.

Shterner V, Timokhina IB, Beladi H. On the work-hardening behaviour of a high manganese TWIP steel at different deformation temperatures. Mater Sci Eng, A. 2016;669:437–46.

Jabłońska MB. Effect of the conversion of the plastic deformation work to heat on the behaviour of TWIP steels: a review. Arch Civil Mech Eng. 2023;23(2):135.

Jabłońska MB, Jasiak K, Kowalczyk K, Bednarczyk I, Skwarski M, Tkocz M, Gronostajski Z. Deformation behaviour of high-manganese steel with addition of niobium under quasi-static tensile loading. Mater Sci-Pol. 2022;40(3):1–11.

Jabłońska MB, Jasiak K, Kowalczyk K, Skwarski M, Rodak K, Gronostajski Z. The influence of the heat generation during deformation on the mechanical properties and microstructure of the selected TWIP steels. IntJ Mater Form. 2023;16(3):1–17.

Molnár D, Sun X, Lu S, Li W, Engberg G, Vitos L. Effect of temperature on the stacking fault energy and deformation behaviour in 316L austenitic stainless steel. Mater Sci Eng, A. 2019;759:490–7.

Lee CY, Jeong J, Han J, Lee SJ, Lee S, Lee YK. Coupled strengthening in a medium manganese lightweight steel with an inhomogeneously grained structure of austenite. Acta Mater. 2015;84:1–8.

Wang MM, Tasan CC, Ponge D, Kostka A, Raabe D. Smaller is less stable: size effects on twinning vs. transformation of reverted austenite in TRIP-maraging steels. Acta Mater. 2014;79:268–81.

Wang T, Shukla S, Gwalani B, Sinha S, Thapliyal S, Frank M, Mishra RS. Co-introduction of precipitate hardening and TRIP in a TWIP high-entropy alloy using friction stir alloying. Sci Rep. 2021;11(1):1–10.

Benzing JT, Liu Y, Zhang X, Luecke WE, Ponge D, Dutta A, Oskay C, Raabe D, Wittig JE. Experimental and numerical study of mechanical properties of multi-phase medium-Mn TWIP-TRIP steel: influences of strain rate and phase constituents. Acta Mater. 2019;177:250–65.

Kalsar R, Sanamar S, Schell N, Brokmeier HG, Saha R, Ghosh P, Suwas S. In-situ study of tensile deformation behaviour of medium Mn TWIP/TRIP steel using synchrotron radiation. Mater Sci Eng, A. 2022;857: 144013.

Dobrzański LA, Borek W. Thermo-mechanical treatment of Fe-Mn-(Al, Si) TRIP/TWIP steels. Arch Civil Mech Eng. 2012;12:299–304.

Grajcar A, Borek W. Thermo-mechanical processing of high-manganese austenitic TWIP-type steels. Arch Civil Mech Eng. 2008;8(4):29–38.

Zamani MR, Mirzadeh H, Malekan M, Weißensteiner I, Roostaei M. Unveiling the strengthening mechanisms of as-cast micro-alloyed CrMnFeCoNi high-entropy alloys. J Alloy Compd. 2023;957: 170443.

Lu J, Hultman L, Holmström E, Antonsson KH, Grehk M, Li W, Vitos L, Golpayegani A. Stacking fault energies in austenitic stainless steels. Acta Mater. 2016;111:39–46.

Zambrano OA (2016) Stacking fault energy maps of Fe–Mn–Al–C–Si steels: effect of temperature, grain size, and variations in compositions. J Eng Mater Technol, 138(4)

Jun JH, Choi CS. Variation of stacking fault energy with austenite grain size and its effect on the MS temperature of γ→ ε martensitic transformation in Fe–Mn alloy. Mater Sci Eng, A. 1998;257(2):353–6.

Huang M, Wang C, Wang L, Wang J, Mogucheva A, Xu W. Influence of DIMT on impact toughness: relationship between crack propagation and the α′-martensite morphology in austenitic steel. Mater Sci Eng, A. 2022;844: 143191.

Polatidis E, Čapek J, Arabi-Hashemi A, Leinenbach C, Strobl M. High ductility and transformation-induced-plasticity in metastable stainless steel processed by selective laser melting with low power. Scripta Mater. 2020;176:53–7.

Rahman KM, Vorontsov VA, Dye D. The effect of grain size on the twin initiation stress in a TWIP steel. Acta Mater. 2015;89:247–57.

Meyers MA, Andrade UR, Chokshi AH. The effect of grain size on the high-strain, high-strain-rate behavior of copper. Metall and Mater Trans A. 1995;26:2881–93.

Shahmir H, Mehranpour MS, Shams SAA, Lee CS, Langdon TG (2022) Grain Size Tailoring to Control Strain Hardening and Improve the Mechanical Properties of a CoCrFeNiMn High-Entropy Alloy. High Entropy Alloys Mater, 1–12

Razzaghi M, Mirzadeh H, Emamy M. Unraveling the effects of Zn addition and hot extrusion process on the microstructure and mechanical properties of as-cast Mg–2Al magnesium alloy. Vacuum. 2019;167:214–22.

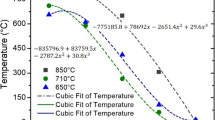

Zergani A, Mirzadeh H, Mahmudi R. Unraveling the effect of deformation temperature on the mechanical behavior and transformation-induced plasticity of the SUS304L stainless steel. Steel Res Int. 2020;91(9):2000114.

Dieter GE, Bacon D. Mechanical Metallurgy. 3rd ed. New York: McGraw-Hill; 1988.

Deng Q, Zhang Y, Liu Z, Chang Z, Su N, Wu Y, Hao L, Peng L, Ding W. Laser powder bed fusion of an age-hardenable Mg-10Gd-0.2 Zr alloy with excellent strength-ductility synergy. J Alloys Compounds. 2022;910:164863.

Deng Q, Wu Y, Zhu W, Chen K, Liu D, Peng L, Ding W. Effect of heat treatment on microstructure evolution and mechanical properties of selective laser melted Mg-11Gd-2Zn-0.4 Zr alloy. Mater Sci Eng: A. 2022;829:142139.

Gutiérrez-Urrutia I, Raabe D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 2012;60:5791–802.

Soleimani M, Kalhor A, Mirzadeh H. Transformation-induced plasticity (TRIP) in advanced steels: a review. Mater Sci Eng, A. 2020;795: 140023.

Xiong RG, Fu RY, Yu SU, Qian LI, Wei XC, Lin LI. Tensile properties of TWIP steel at high strain rate. J Iron Steel Res Int. 2009;16:81–21.

Lee YK, Choi C. Driving force for γ→ ε martensitic transformation and stacking fault energy of γ in Fe-Mn binary system. Metall Mater Trans A. 2000;31:355–60.

Li X, Chen L, Zhao Y, Yuan X, Misra RDK. Influence of original austenite grain size on tensile properties of a high-manganese transformation-induced plasticity (TRIP) steel. Mater Sci Eng, A. 2018;715:257–65.

Huang M, Wang L, Wang C, Mogucheva A, Xu W. Characterization of deformation-induced martensite with various AGSs upon charpy impact loading and correlation with transformation mechanisms. Mater Charact. 2022;184: 111704.

Mosecker L, Saeed-Akbari A. Nitrogen in chromium–manganese stainless steels: a review on the evaluation of stacking fault energy by computational thermodynamics. Sci Technol Adv Mater. 2013;14: 033001.

Feng Z, Zecevic M, Knezevic M. Stress-assisted (γ→α′) and strain-induced (γ→ ε→ α′) phase transformation kinetics laws implemented in a crystal plasticity model for predicting strain path sensitive deformation of austenitic steels. Int J Plast. 2021;136: 102807.

Kocks UF, Mecking H. Physics and phenomenology of strain hardening: the FCC case. Prog Mater Sci. 2003;48:171–273.

Karthik GM, Kim ES, Sathiyamoorthi P, Zargaran A, Jeong SG, Xiong R, Kang SH, Cho JW, Kim HS. Delayed deformation-induced martensite transformation and enhanced cryogenic tensile properties in laser additive manufactured 316L austenitic stainless steel. Addit Manuf. 2021;47: 102314.

Nabizada A, Zarei-Hanzaki A, Abedi HR, Barati MH, Asghari-Rad P, Kim HS. The high temperature mechanical properties and the correlated microstructure/texture evolutions of a TWIP high entropy alloy. Mater Sci Eng, A. 2021;802: 140600.

Luo ZC, Huang MX. Revisit the role of deformation twins on the work-hardening behaviour of twinning-induced plasticity steels. Scripta Mater. 2018;142:28–31.

Meyers MA, Chawla KK. Mechanical behavior of materials. Cambridge University Press; 2008.

Dini G, Najafizadeh A, Ueji R, Monir-Vaghefi SM. Tensile deformation behavior of high manganese austenitic steel: the role of grain size. Mater Des. 2010;31:3395–402.

Mahato B, Shee SK, Sahu T, Chowdhury SG, Sahu P, Porter DA, Karjalainen LP. An effective stacking fault energy viewpoint on the formation of extended defects and their contribution to strain hardening in a Fe–Mn–Si–Al twinning-induced plasticity steel. Acta Mater. 2015;86:69–79.

Kang S, Jung JG, Kang M, Woo W, Lee YK. The effects of grain size on yielding, strain hardening, and mechanical twinning in Fe–18Mn–0.6 C–1.5 Al twinning-induced plasticity steel. Mater Sci Eng, A. 2016;652:212–20.

Renard K, Jacques PJ. On the relationship between work hardening and twinning rate in TWIP steels. Mater Sci Eng, A. 2012;542:8–14.

Sohrabi MJ, Mirzadeh H, Sadeghpour S, Mahmudi R. Dependency of work-hardening behavior of a metastable austenitic stainless steel on the nucleation site of deformation-induced martensite. Mater Sci Eng, A. 2023;868: 144600.

Sohrabi MJ, Mirzadeh H, Sadeghpour S, Mahmudi R. Explaining the drop of work-hardening rate and limitation of transformation-induced plasticity effect in metastable stainless steels during tensile deformation. Scripta Mater. 2023;231: 115465.

Shen YF, Li XX, Sun X, Wang YD, Zuo L. Twinning and martensite in a 304 austenitic stainless steel. Mater Sci Eng, A. 2012;552:514–22.

Tian Y, Gorbatov OI, Borgenstam A, Ruban AV, Hedström P. Deformation microstructure and deformation-induced martensite in austenitic Fe-Cr-Ni alloys depending on stacking fault energy. Metall and Mater Trans A. 2017;48:1–7.

Naghizadeh M, Mirzadeh H. Effects of grain size on mechanical properties and work-hardening behavior of AISI 304 austenitic stainless steel. Steel Res Int. 2019;90:1900153.

Varma SK, Kalyanam J, Murk LE, Srinivas V. Effect of grain size on deformation-induced martensite formation in 304 and 316 stainless steels during room temperature tensile testing. J Mater Sci Lett. 1994;13:107–11.

Nohara K, Ono Y, Ohashi N. Composition and grain size dependencies of strain-induced martensitic transformation in metastable austenitic stainless steels. Tetsu-to-Hagané. 1977;63(5):772–82.

Sohrabi MJ, Mirzadeh H, Dehghanian C. Significance of martensite reversion and austenite stability to the mechanical properties and transformation-induced plasticity effect of austenitic stainless steels. J Mater Eng Perform. 2020;29:3233–42.

Zhou Z, Wang S, Li J, Li Y, Wu X, Zhu Y. Hardening after annealing in nanostructured 316L stainless steel. Nano Mater Sci. 2020;2:80–2.

Hong Y, Zhou C, Zheng Y, Zhang L, Zheng J, Chen X, An B. Formation of strain-induced martensite in selective laser melting austenitic stainless steel. Mater Sci Eng, A. 2019;740:420–6.

Grajcar A, Kuziak R, Zalecki W. Third generation of AHSS with increased fraction of retained austenite for the automotive industry. Arch civil Mech Eng. 2012;12:334–41.

Funding

This work received no funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

The manuscript has been prepared by the contribution of all authors, it is the original authors work, it has not been published before, it has been solely submitted to this journal, and if accepted, it will not be submitted to any other journal in any language.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sohrabi, M.J., Mirzadeh, H., Sadeghpour, S. et al. Tailoring the strength-ductility balance of a commercial austenitic stainless steel with combined TWIP and TRIP effects. Archiv.Civ.Mech.Eng 23, 170 (2023). https://doi.org/10.1007/s43452-023-00718-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00718-3