Abstract

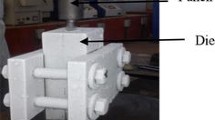

Equal channel angular pressing (ECAP) is an efficient metal forming tool, generally used to improve the mechanical properties by refining the grain structure in metals and alloys. In the present work, both experimental and simulation approaches have been utilized to investigate the deformation behavior of EN AW 7075 alloy during ECAP. The formation and homogeneity of the Von-Mises stress and plastic strain of the samples during ECAP with different outer corner angles (OCAs) have been investigated by the finite element method (FEM). The results revealed that the effective strain was higher and uniform for 10°, 20°, and 30° OCAs die compared to other OCAs. Beyond 30°, the magnitude of strain was found lower with a less homogenous distribution of strain. A sharp plastic deformation zone (PDZ) was noticed for 10° and 20° OCAs, although broadened gradually over an OCA value of 20°. Moreover, lower and uniform Von-Mises stress was generated along the diameter of the sample for the OCA of 20° compared to other OCAs. A gradual reduction of plastic strain has been documented with the enhancement of OCAs along with the sample diameter. The sharpest damage, however, was noticed for the OCA of 90° due to the higher gap between the sample and both die surfaces. Interestingly, the most uniform severe plastic deformation and highest strain homogeneity in terms of inhomogeneity index and coefficient of variance were achieved for 20° and 30° OCAs. Electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) analysis illustrated the formation of ultra-fine grain structures containing very fine η´ and η precipitates during the post-ECAP process. An improvement in the hardness, yield strength, and ultimate strength by 22%, 18%, and 14%, respectively, after ECAP has been recorded in comparison to the initial artificially aged condition. The improvements in mechanical properties were improvised primarily due to grain refinement combined with precipitate hardening.

Graphic abstract

Similar content being viewed by others

Data availability statement

The raw/processed data required to reproduce these findings can be shared upon request.

References

Tański RS, Snopiński P, Pakieła W, Borek W, Prusik K. Structure and properties of AlMg alloy after combination of ECAP and post-ECAP ageing. Arch Civ Mech Eng. 2016;16:325–34.

Duan Y, Tang L, Xu G, Deng Y, Yin Z. Microstructure and mechanical properties of 7005 aluminum alloy processed by room temperature ECAP and subsequent annealing. J Alloys Compd. 2016;664:518–29. https://doi.org/10.1016/j.jallcom.2016.01.022.

Jafarlou DM, Zalnezhad E, Hassan MA, Ezazi MA, Mardi NA, Hamouda AMS. Severe plastic deformation of tubular AA 6061 via equal channel angular pressing. Mater Des. 2016;90:1124–35. https://doi.org/10.1016/j.matdes.2015.11.026.

Jabłońska MB, Kowalczyk K, Tkocz M, Bulzak T, Bednarczyk I, Rusz S. Dual rolls equal channel extrusion as unconventional SPD process of the ultralow-carbon steel: finite element simulation, experimental investigations and microstructural analysis. Arch Civ Mech Eng. 2021;21:25. https://doi.org/10.1007/s43452-020-00166-3.

Ghosh A, Ghosh M, Gudimetla K, Kalsar R, Kestens L, Balasubramanian R. Development of ultrafine grained Al–Zn–Mg–Cu alloy by equal channel angular pressing: microstructure, texture and mechanical properties. Arch Civ Mech Eng. 2020. https://doi.org/10.1007/s43452-019-0003-y.

Zhang Y, Jin S, Trimby PW, Liao X, Murashkin MY, Valiev RZ, Liu J, Cairney JM, Ringer SP. Dynamic precipitation, segregation and strengthening of an Al–Zn–Mg–Cu alloy (AA7075) processed by high-pressure torsion. Acta Mater. 2019;162:19–32. https://doi.org/10.1016/j.actamat.2018.09.060.

Khelfa T, Bolaños JAM, Cabrera FLJM, Khitouni MM. Microstructure and mechanical properties of AA6082-T6 by ECAP under warm processing. Met Mater Int. 2019. https://doi.org/10.1007/s12540-019-00388-y.

Elhefnawey M, Shuai GL, Li Z, Nemat-alla M, Zhang DT, Li L. On achieving superior strength for Al–Mg–Zn alloy adopting cold ECAP. Vacuum. 2020. https://doi.org/10.1016/j.vacuum.2020.109191.

Xue K, Wang B, Yan S, Bo D, Li P. Strain-induced dissolution and precipitation of secondary phases and synergetic stengthening mechanisms of Al–Zn–Mg–Cu alloy during ECAP. Adv Eng Mater. 2019;1801182:1–9. https://doi.org/10.1002/adem.201801182.

Jabłońska MB, Kowalczyk K, Tkocz M, Chulist R, Rodak K, Bednarczyk I, Cichański A. The effect of severe plastic deformation on the IF steel properties, evolution of structure and crystallographic texture after dual rolls equal channel extrusion deformation. Arch Civ Mech Eng. 2021;21:153. https://doi.org/10.1007/s43452-021-00303-6.

Jia H, Li Y. Texture evolution of an Al-8Zn alloy during ECAP and post-ECAP isothermal annealing. Mater Charact. 2019;155:109794. https://doi.org/10.1016/j.matchar.2019.109794.

Agwa MA, Ali MN, Al-shorbagy AE. Optimum processing parameters for equal channel angular pressing. Mech Mater. 2016;100:1–11. https://doi.org/10.1016/j.mechmat.2016.06.003.

Djavanroodi F, Ebrahimi M. Effect of die channel angle, friction and back pressure in the equal channel angular pressing using 3D finite element simulation. Mater Sci Eng, A. 2010;527:1230–5. https://doi.org/10.1016/j.msea.2009.09.052.

Eivani AR, Taheri AK. A new method for estimating strain in equal channel angular extrusion. J Mater Process Technol. 2007;183:148–53. https://doi.org/10.1016/j.jmatprotec.2006.09.020.

Nagasekhar AV, Kim HS. Analysis of T-shaped equal channel angular pressing using the finite element method. Met Mater Int. 2008;14:565–8. https://doi.org/10.3365/met.mat.2008.10.565.

Nemati J, Sulaiman S, Majzoobi GH, Baharudin BTHT. Finite element study of deformation behaviour of Al- 6063 alloy developed by equal channel angular extrusion. Adv Mat Res. 2014;1043:119–23. https://doi.org/10.4028/www.scientific.net/AMR.1043.119.

Ghosh A, Ghosh M. 3D FEM simulation of Al-Zn-Mg-Cu alloy during multi-pass ECAP with varying processing routes. Mater Today Commun. 2021;26:102112. https://doi.org/10.1016/j.mtcomm.2021.102112.

Ebrahimi M, Attarilar S, Gode C, Djavanroodi F. Damage prediction of 7025 aluminum alloy during equal-channel angular pressing. Int J Miner Metall Mater. 2014;21:990–8. https://doi.org/10.1007/s12613-014-1000-z.

Karpuz P, Simsir C, Gür CH. Investigating the effects of hardening of aluminium alloys on equal-channel angular pressing—a finite-element study. Mater Sci Eng, A. 2009;503:148–51. https://doi.org/10.1016/j.msea.2008.01.095.

Oruganti JSMRK, Subramanian PR, Michael SA, Gigliotti F. Effect of friction, backpressure and strain rate sensitivity on material flow during equal channel angular extrusion. Mater Sci Eng: A. 2005;406:102–9. https://doi.org/10.1016/j.msea.2005.06.031.

Wang J, Horita Z, Furukawa M, Nemoto M. An investigation of ductility and microstructural evolution in an Al-3 % Mg alloy with submicron grain size. J Mater Res. 1993;8:2810–8.

Nakashima K, Horita Z, Nemoto M. Influence of channel angle on the development of ultrafine grains in equal-channel angular pressing. Acta Mater. 1998;46:1589–99.

Yoon SC, Kim HS. Finite element analysis of the effect of the inner corner angle in equal channel angular pressing. Mater Sci Eng, A. 2008;490:438–44. https://doi.org/10.1016/j.msea.2008.01.066.

Nagasekhar A, Tick-hon Y. Optimal tool angles for equal channel angular extrusion of strain hardening materials by finite element analysis. Comput Mater Sci. 2004;30:489–95. https://doi.org/10.1016/j.commatsci.2004.02.041.

Deng G, Lu C, Su L, Kiet A, Li J, Liu M, Zhu H. Influence of outer corner angle (OCA) on the plastic deformation and texture evolution in equal channel angular pressing. Comput Mater Sci. 2014;81:79–88. https://doi.org/10.1016/j.commatsci.2013.07.006.

Kim HS. Finite element analysis of equal channel angular pressing using a round corner die. Mater Sci Eng, A. 2001;315:122–8.

Yoon SC, Quang P, Hong SI, Kim HS. Die design for homogeneous plastic deformation during equal channel angular pressing. J Mater Process Technol. 2007;188:46–50. https://doi.org/10.1016/j.jmatprotec.2006.11.117.

Xu C, Langdon TG. Influence of a round corner die on flow homogeneity in ECA pressing. Scr Mater. 2003;48:1–4.

Ghosh A, Ghosh M, Seikh A, Alharti N. Phase transformation and dispersoid evolution for Al–Zn–Mg–Cu alloy containing Sn during homogenisation. J Market Res. 2019;9:1–12. https://doi.org/10.1016/j.jmrt.2019.08.055.

Esmaeili A, Shaeri MH, Tala M, Razaghian A. Fatigue behavior of AA7075 aluminium alloy severely deformed by equal channel angular pressing. J Alloys Compd. 2018;757:324–32. https://doi.org/10.1016/j.jallcom.2018.05.085.

Jia H, Bjørge R, Cao L, Song H, Marthinsen K, Li Y. Quantifying the grain boundary segregation strengthening induced by post-ECAP aging in an Al-5Cu alloy. Acta Mater. 2018;155:199–213. https://doi.org/10.1016/j.actamat.2018.05.075.

Ghosh A, Ghosh M, Kalsar R. Influence of homogenisation time on evolution of eutectic phases, dispersoid behaviour and crystallographic texture for Al–Zn–Mg–Cu–Ag alloy. J Alloys Compd. 2019;802:276–89. https://doi.org/10.1016/j.jallcom.2019.06.091.

Naseri M, Reihanian M, Borhani E. Effect of strain path on microstructure, deformation texture and mechanical properties of nano/ultrafine grained AA1050 processed by accumulative roll bonding (ARB). Mater Sci Eng, A. 2016;673:288–98. https://doi.org/10.1016/j.msea.2016.07.031.

Wang W, Pan Q, Wang X, Sun Y, Long L, Huang Z. Mechanical properties and microstructure evolution of ultra-high strength Al–Zn–Mg–Cu alloy processed by room temperature ECAP with post aging. Mater Sci Eng, A. 2018;731:195–208. https://doi.org/10.1016/j.msea.2018.06.047.

Fritsch S, Wagner MF. On the effect of natural aging prior to low temperature ECAP of a high-strength aluminum alloy. Metals (Basel). 2018;63:1–10. https://doi.org/10.3390/met8010063.

Xu X, Zheng J, Li Z, Luo R, Chen B. Precipitation in an Al–Zn–Mg–Cu alloy during isothermal aging: Atomic- scale HAADF-STEM investigation. Mater Sci Eng, A. 2017;691:60–70. https://doi.org/10.1016/j.msea.2017.03.032.

Tang LEI, Xu G, Deng Y, Gan HAO, Ma A. Mechanical properties and microstructure of an Al–Zn–Mg–Sc–Zr Alloy processed by warm equal channel angular pressing and subsequent aging. JOM. 2018;70:2684–91. https://doi.org/10.1007/s11837-017-2616-z.

Liu S, Li Q, Lin H, Sun L, Long T, Ye L, Deng Y. Effect of quench-induced precipitation on microstructure and mechanical properties of 7085 aluminum alloy. Mater Des. 2017;132:119–28. https://doi.org/10.1016/j.matdes.2017.06.054.

Ghosh A, Ghosh M, Shankar G. On the role of precipitates in controlling microstructure and mechanical properties of Ag and Sn added 7075 alloys during artificial ageing. Mater Sci Eng, A. 2018;738:399–411. https://doi.org/10.1016/j.msea.2018.09.109.

Shaeri MH, Salehi MT, Seyyedein SH, Abutalebi MR, Park JK. Microstructure and mechanical properties of Al-7075 alloy processed by equal channel angular pressing combined with aging treatment. Mater Des. 2014;57:250–7. https://doi.org/10.1016/j.matdes.2014.01.008.

Cerri E, De Marco PP, Leo P. FEM and metallurgical analysis of modified 6082 aluminium alloys processed by multipass ECAP: Influence of material properties and different process settings on induced plastic strain. J Mater Process Technol. 2008;9:1550–64. https://doi.org/10.1016/j.jmatprotec.2008.04.013.

Djavanroodi F, Omranpour B, Ebrahimi M, Sedighi M. Designing of ECAP parameters based on strain distribution uniformity. Prog Nat Sci: Mater Int. 2012;22:452–60. https://doi.org/10.1016/j.pnsc.2012.08.001.

Deng GY, Lu C, Su LH, Tieu AK, Yu HL, Liu XH. Investigation of sample size effect on the deformation heterogeneity and texture development during equal channel angular pressing. Comput Mat Sci. 2013;74:75–85. https://doi.org/10.1016/j.commatsci.2013.03.007.

Kim HS. Finite element analysis of deformation behaviour of metals during equal channel multi-angular pressing. Mater Sci Eng, A. 2002;328:317–23.

Xu S, Zhao G, Ma X, Ren G. Finite element analysis and optimization of equal channel angular pressing for producing ultra-fine grained materials. J Mater Process Technol. 2007;184:209–16. https://doi.org/10.1016/j.jmatprotec.2006.11.025.

Elhefnawey M, Shuai GL, Li Z, Zhang DT, Li L. On achieving superior strength for Al–Mg–Zn alloy adopting cold ECAP. Vacuum. 2020. https://doi.org/10.1016/j.vacuum.2020.109191.

Shaeri MH, Shaeri M, Ebrahimi M, Salehi MT, Seyyedein SH. Effect of ECAP temperature on microstructure and mechanical properties of Al–Zn–Mg–Cu alloy. Prog Nat Sci: Mater Int. 2016;26:182–91. https://doi.org/10.1016/j.pnsc.2016.03.003.

Funding

This study has not been funded by Govt. of India.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest in this work.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghosh, A., Das, K., Eivani, A.R. et al. Development of mechanical properties and microstructure for Al–Zn–Mg–Cu alloys through ECAP after optimizing the outer corner angles through FE modeling. Archiv.Civ.Mech.Eng 23, 78 (2023). https://doi.org/10.1007/s43452-023-00609-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00609-7