Abstract

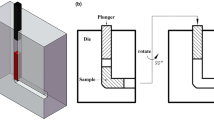

The microstructure, mechanical properties, and strengthening mechanisms of an Al-Mg-Si alloy (AA6060) subjected to severe plastic deformation using equal channel angular pressing (ECAP) were investigated. Samples were passed through a die with an inner angle of Φ = 90° and outer arc of curvature of ψ = 37° at room temperature up to 12 passes via route Bc. Electron backscatter diffraction (EBSD) was used to evaluate the microstructure and misorientation boundaries. The microstructure showed a large fraction of low-angle boundaries associated with subgrain formation in the first ECAP pass, while after eight and 12 passes, a heterogeneous ultrafine grain structure with an average grain size around 0.57 and 0.47 μm, respectively, was obtained. In order to characterize the mechanical properties, microhardness and tensile tests were carried out. Results of mechanical property tests show that microhardness, yield stress, and ultimate tensile strength increase as ECAP pass number increases up to a maximum value of 120 HV, 344 MPa, and 355 MPa, respectively, after five passes. The Hall–Petch effect, dislocation, solid solution, and precipitation strengthening were evaluated to determine the dependence of the yield stress on the ECAP pass number. The results show that the strength effect arises from the subgrain microstructure rather than from the high-angle grain boundaries developed.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev K, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45:103–189

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981

Segal VM, Reznikov VI, Drobyshevski AE, Kopylov VI (1981) Plastic working of metals by simple shear. Russ Metall 1:99–105

Valiev RZ, Krasilnikov NA, Tsenev NK (1991) Plastic deformation of alloys with submicron-grained structure. Mater Sci Eng A 137:35–40

Valiev RZ, Korznikov AV, Mulyukov RR (1993) Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater Sci Eng A 168:141–148

Valiev RZ (2003) Paradoxes of severe plastic deformation. Adv Eng Mater 5:296–300

Sheppard T (1999) Extrusion of aluminium alloys. Springer, US

Association TEA (2015) European aluminium. http://www.eaa.net. Accessed 14 Dec 2015

Birol Y (2013) Precipitation during homogenization cooling in AlMgSi alloys. Trans Nonferrous Met Soc Chin 23:1875–1881

Gleiter H (1989) Nanocrystalline materials. Prog Mater Sci 33:223–231

Claves SR, Elias DL, Misiolek WZ (2002) Analysis of the intermetallic phase transformation occurring during homogenization of 6XXX aluminum alloys. Mater Sci Forum 396-402:667–674

Zajac S, Hutchinson B, Johansson A, Gullman LO (1994) Microstructure control and extrudability of Al-Mg-Si alloys microalloyed with manganese. Mat Sci Technol 10:323–333

Langerweger J (1986) Influence of heat treatment practice on extrudability and properties of AlMgSi alloy sections. Proc Conf Alum Technol 216–222

Karhausen K, Dons AL, Aukrust T (1996) Microstructure control during extrusion with respect to surface quality. Mater Sci Forum 217-222:403–408

Kuijpers NCW, Kool WH, Zwaag S (2002) DSC study on Mg-Si phases in as-cast 6XXX. Mater Sci Forum 396-402:675–680

Tanihata H, Sugawara T, Matsuda K, Ikeno S (1999) Effect of casting and homogenizing treatment conditions on the formation of Al-Fe-Si intermetallic compounds in 6063 Al-Mg-Si alloys. J Mater Sci 34:1205–1210

Ghassemali E, Tan MJ, Wah CB, Lim SCV, Jarfors AEW (2015) Effect of cold-work on the Hall-Petch breakdown in copper based micro-components. Mech Mater 80:124–135

Luo P, McDonald DT, Xu W, Palanisamy S, Dargusch MS, Xia K (2012) A modified Hall-Petch relationship in ultrafine-grained titanium recycled from chips by equal channel angular pressing. Scr Mater 66:785–788

Hansen N (2004) Hall-Petch relation and boundary strengthening. Scr Mater 51:801–806

Qiao XG, Gao N, Starink MJ (2012) A model of grain refinement and strengthening of Al alloys due to cold severe plastic deformation. Philos Mag 92:446–470

Apps PJ, Bowen JR, Prangnell PB (2003) The effect of coarse second-phase particles on the rate of grain refinement during severe deformation processing. Acta Mater 51:2811–2822

Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1997) An investigation of microstructural evolution during equal-channel angular pressing. Acta Mater 45:4733–4741

Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) The process of grain refinement in equal-channel angular pressing. Acta Mater 46:3317–3331

Furukawa M, Horita Z, Nemoto N, Langdon TG (2001) Review: processing of metals by equal-channel angular pressing. J Mater Sci 36:2835–2843

Xu C, Horita Z, Langdon TG (2011) Microstructural evolution in an aluminum solid solution alloy processed by ECAP. Mater Sci Eng A 528:6059–6065

Terhune SD, Swisher DL, Oh-ishi K, Horita Z, Langdon TG, McNelley TR (2002) An investigation of microstructure and grain-boundary evolution during ECA pressing of pure aluminum. Metall Mater Trans A 33:2173–2184

Kim WJ, Sa YK, Kim HK, Yoon US (2008) Plastic forming of the equal-channel angular pressing processed 6061 aluminum alloy. Mater Sci Eng A 487:360–368

Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) Factors influencing the equilibrium grain size in equal-channel angular pressing: role of Mg additions to aluminum. Metall Mater Trans A 29:2503–2510

Vinogradov A, Ishida T, Kitagawa K, Kopylo VI (2005) Effect of strain path on structure and mechanical behavior of ultra-fine grain Cu–Cr alloy produced by equal-channel angular pressing. Acta Mater 53:2181–2192

Ko YG, Shin DH, Park KT, Lee CS (2006) An analysis of the strain hardening behavior of ultra-fine grain pure titanium. Scr Mater 54:1785–1789

Fang DR, Duan QQ, Zhao NQ, Li JJ, SD W, Zhang ZF (2007) Tensile properties and fracture mechanism of al-mg alloy subjected to equal channel angular pressing. Mater Sci Eng A 459:137–144

Chang JY, Shan A (2003) Microstructure and mechanical properties of AlMgSi alloys after equal channel angular pressing at room temperature. Mater Sci Eng A 347:165–170

Kim WJ, Chung CS, Ma DS, Hong SI, Kim HK (2003) Optimization of strength and ductility of 2024 Al by equal channel angular pressing (ECAP) and post-ECAP aging. Scr Mater 49:333–338

Koch CC (2003) Optimization of strength and ductility in nanocrystalline and ultrafine grained metals. Scr Mater 49:657–662

Morris DG (1998) Mechanical behaviour of nanostructured materials. Trans Tech, Uetikon-Zurich

Horita Z, Fujinami T, Nemoto M, Langdon TG (2000) Equal-channel angular pressing of commercial aluminum alloys: grain refinement, thermal stability and tensile properties. Metall Mater Trans A 31:691–701

Hansen N, Huang X, Hughes DA (2001) Microstructural evolution and hardening parameters. Mater Sci Eng A 317:3–11

Hansen N, Huang X (1998) Microstructure and flow stress of polycrystals and single crystals. Acta Mater 46:1827–1836

Totten GE, MacKenzie DS (2003) Handbook of aluminium. Marcel Dekker, New York

Reihanian M, Ebrahimi R, Tsuji N, Moshksar MM (2008) Analysis of the mechanical properties and deformation behavior of nanostructured commercially pure Al processed by equal channel angular pressing (ECAP). Mater Sci Eng A 473:189–194

Gubicza J, Chinh NQ, Krállics G, Schiller I, Ungár T (2006) Microstructure of ultrafine-grained fcc metals produced by severe plastic deformation. Curr Appl Phys 6:194–199

Tsuji N (2006) In: Zhu YT, Varyukhin V (eds) Nanostructured materials by high-pressure severe plastic deformation. Springer, Dordrecht, pp 227–234

Furukawa M, Horita Z, Nemoto M, Valiev RZ, Langdon TG (1998) Factors influencing the flow and hardness of materials with ultrafine grain sizes. Philos Mag A 78:203–216

Torre FD, Lapovok R, Sandlin J, Thomson PF, Davies CHJ, Pereloma EV (2004) Microstructures and properties of copper processed by equal channel angular extrusion for 1-16 passes. Acta Mater 52:4819–4832

Valiev RZ, Enikeev NA, Muraskin M, Kazykhanov VU, Sauvage X (2010) On the origin of the extremely high strength of ultrafine-grained Al alloys produced by severe plastic deformation. Scr Mater 63:949–952

Valiev RZ, Enikeev NA, Murashkin M, Aleksandrov SE, Goldshtein RV (2010) Superstrength of ultrafine-grained aluminum alloys produced by severe plastic deformation. Dokl Phys 55:267–270

Hughes DA, Hansen N (2000) Microstructure and strength of nickel at large strains. Acta Mater 48:2985–3004

Hansen N (2005) Boundary strengthening in undeformed and deformed polycrystals. Mater Sci Eng A 409:39–45

Luo P, McDonald DT, Zhu SM, Palanisamy S, Dargusch MS, Xia K (2012) Analysis of microstructure and strengthening in pure titanium recycled from machining chips by equal channel angular pressing using electron backscatter diffraction. Mater Sci Eng A 538:252–258

Rodríguez-Calvillo P, Ferrer N, Cabrera JM (2015) Analysis of microstructure and strengthening in CuMg alloys deformed by equal channel angular pressing. J Alloys Compd 626:340–348

Mishra A, Kad BK, Gregori F, Meyers MA (2007) Microstructural evolution in copper subjected to severe plastic deformation: experiments and analysis. Acta Mater 55:13–28

Kamikawa N, Huang X, Tsuji N, Hansen N (2009) Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed. Acta Mater 57:4198–4208

Asgharzadeh H, Simchi A, Kim HS (2011) Microstructural features, texture and strengthening mechanisms of nanostructured AA6063 alloy processed by powder metallurgy. Mater Sci Eng A 528:3981–3989

Asgharzadeh H, Simchi A, Kim HS (2011) Microstructure and mechanical properties of oxide-dispersion strengthened Al6063 alloy with ultra-fine grain structure. Metall Mater Trans A 42:816–824

Topping TD, Ahn B, Li Y, Nutt SR, Lavernia EJ (2012) Influence of process parameters on the mechanical behavior of an ultrafine-grained Al alloy. Metall Mater Trans A 43:505–519

Friedel J (1964) Dislocations. Pergamon, Oxford

Nabarro FRN (1967) Theory of crystal dislocations. Oxford University Press, Oxford

Cayron C, Buffat P (2000) Transmission electron microscopy study of the β′ phase (Al–Mg–Si alloys) and QC phase (Al–Cu–Mg–Si alloys): ordering mechanism and crystallographic structure. Acta Mater 48:2639–2653

Myhr OR, Grong Ø, Andersen SJ (2001) Modelling of the age hardening behaviour of Al-Mg-Si alloys. Acta Mater 49:65–75

Gouttebroze S, Mo A, Grong Ø, Pedersen KO, Fjaer HG (2008) A new constitutive model for the finite element simulation of local hot forming of aluminum 6xxx alloys. Metall Mater Trans A 39:522–534

Gubicza J, Chinh NQ, Labar JL, Dobatkin S, Hegedus Z, Langdon TG (2009) Correlation between microstructure and mechanical properties of severely deformed metals. J Alloys Compd 483:271–274

Valiev RZ, Kozlov EV, Ivanov YF, Lian J, Nazarov AA, Baudelet B (1994) Deformation behaviour of ultra-fine-grained copper. Acta Metall Mater 42:2467–2475

Acknowledgements

The authors would like to thank the CTM (Centro Tecnológico de Manresa) Foundation for their support with the microstructural and mechanical characterization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Khelfa, T., Rekik, M.A., Muñoz-Bolaños, J.A. et al. Microstructure and strengthening mechanisms in an Al-Mg-Si alloy processed by equal channel angular pressing (ECAP). Int J Adv Manuf Technol 95, 1165–1177 (2018). https://doi.org/10.1007/s00170-017-1310-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1310-1