Abstract

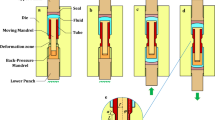

In this study, severe plastic deformation (SPD) process of hydrostatic tube cyclic extrusion–compression (HTCEC) was performed through two passes on the commercially pure copper tubes with the purpose of fabricating relatively long ultrafine-grained (UFG) tubes. In HTCEC process, the presence of pressurized hydraulic fluid around the piece plays a key role in the reduction of the friction load and, consequently, in the reduction of required pressing load. In principle, this facilitates the production of long and large tubes. After processing by HTCEC, the mechanical characteristics and microstructure evolution were examined. Microstructure analysis revealed that after the first pass of HTCEC process, an ultrafine cell microstructure with an average size of ~ 993 nm was attained. After two passes of HTCEC, the average size of cells/subgrains was reduced to ~ 340 nm. This was while the average grain size of the annealed sample was 41 μm. Also, after two passes of HTCEC process, a remarkable increase in the yield strength from 154 to 336 MPa, and the ultimate strength from 223 to 414 MPa was observed. Furthermore, the mean value of microhardness increased from 74 to 149 HV, and a more uniform distribution of microhardness along the thickness was seen, compared to the first pass of HTCEC. Meanwhile, unlike most conventional SPD methods, the value of elongation to failure was slightly lessened from 59.5 to 41.6%. SEM fractography analysis denoted that mostly ductile fracture occurred in the HTCEC-processed samples. In general, two main advantages of HTCEC process can be the production of relatively long ultrafine-grained tubes and the significant increase in the strength and hardness besides a low loss of ductility.

Similar content being viewed by others

References

Pardis N, et al. Development of new routes of severe plastic deformation through cyclic expansion–extrusion process. Mater Sci Eng A. 2014;613:357–64.

Pardis N, et al. Cyclic expansion-extrusion (CEE): a modified counterpart of cyclic extrusion-compression (CEC). Mater Sci Eng A. 2011;528(25):7537–40.

Ensafi M, Faraji G, Abdolvand H. Cyclic extrusion compression angular pressing (CECAP) as a novel severe plastic deformation method for producing bulk ultrafine grained metals. Mater Lett. 2017;197:12–6.

Eftekhari M, et al. Processing and characterization of nanostructured Grade 2 Ti processed by combination of warm isothermal ECAP and extrusion. Mater Sci Eng A. 2017;703:551–8.

Fattah-alhosseini A, et al. An Investigation of mechanical properties in accumulative roll bonded nano-grained pure titanium. Mater Sci Eng A. 2017;688:218–24.

Edalati K, Horita Z. A review on high-pressure torsion (HPT) from 1935 to 1988. Mater Sci Eng A. 2016;652:325–52.

Chen Y, et al. Fabrication of bulk UFG magnesium alloys by cyclic extrusion compression. J Mater Sci. 2007;42(17):7601–3.

Pardis N, et al. Microstructure, texture and mechanical properties of cyclic expansion–extrusion deformed pure copper. Mater Sci Eng A. 2015;628:423–32.

Mesbah M, Faraji G, Bushroa AR. Characterization of nanostructured pure aluminum tubes produced by tubular channel angular pressing (TCAP). Mater Sci Eng A. 2014;590:289–94.

Eftekhari M, et al. Hot tensile deformation behavior of Mg-Zn-Al magnesium alloy tubes processed by severe plastic deformation. J Alloy Compd. 2018;742:442–53.

Farshidi MH, Kazeminezhad M, Miyamoto H. Microstructrual evolution of aluminum 6061 alloy through tube channel pressing. Mater Sci Eng A. 2014;615:139–47.

Babaei A, Mashhadi M, Jafarzadeh H. Tube cyclic expansion-extrusion (TCEE) as a novel severe plastic deformation method for cylindrical tubes. J Mater Sci. 2014;49(8):3158–65.

Tóth L, et al. Severe plastic deformation of metals by high-pressure tube twisting. Scripta Mater. 2009;60(3):175–7.

Mohebbi M, Akbarzadeh A. Accumulative spin-bonding (ASB) as a novel SPD process for fabrication of nanostructured tubes. Mater Sci Eng A. 2010;528(1):180–8.

Babaei A, Mashhadi M. Tubular pure copper grain refining by tube cyclic extrusion–compression (TCEC) as a severe plastic deformation technique. Prog Nat Sci Mater Int. 2014;24(6):623–30.

Samadpour F, et al. Hydrostatic cyclic expansion extrusion (HCEE) as a novel severe plastic deformation process for producing long nanostructured metals. Mater Sci Eng A. 2018;718:412–7.

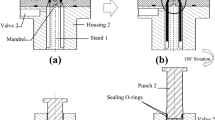

Savarabadi MM, Faraji G, Zalnezhad E. Hydrostatic tube cyclic expansion extrusion (HTCEE) as a new severe plastic deformation method for producing long nanostructured tubes. J Alloy Compd. 2019;785:163–8.

Jamali S, Faraji G, Abrinia K. Hydrostatic radial forward tube extrusion as a new plastic deformation method for producing seamless tubes. Int J Adv Manuf Technol. 2017;88(1–4):291–301.

Song Y, et al. Mechanical properties of copper after compression stage of high-pressure torsion. Mater Sci Eng A. 2011;528(13–14):4840–4.

An X, et al. Enhanced cyclic deformation responses of ultrafine-grained Cu and nanocrystalline Cu–Al alloys. Acta Mater. 2014;74:200–14.

Savarabadi MM, Faraji G, Eftekhari M. Microstructure and mechanical properties of the commercially pure copper tube after processing by hydrostatic tube cyclic expansion extrusion (HTCEE). Metals Mater Int. 2019;2019:1–15.

Fata A, et al. Enhanced hot tensile ductility of Mg-3Al-1Zn alloy thin-walled tubes processed via a combined severe plastic deformation. J Mater Eng Perform. 2018;27(5):2330–7.

Purcek G, et al. Microstructure and mechanical behavior of UFG copper processed by ECAP following different processing regimes. Phil Mag. 2012;92(6):690–704.

Faraji G, et al. TEM analysis and determination of dislocation densities in nanostructured copper tube produced via parallel tubular channel angular pressing process. Mater Sci Eng A. 2013;563:193–8.

Chengpeng W, Fuguo L, Jinghui L. Producing thin-walled tube of pure copper by severe plastic deformation of shear extrusion. Rare Metal Mater Eng. 2015;44(10):2391–5.

Bagherpour E, et al. Nanostructured pure copper fabricated by simple shear extrusion (SSE): a correlation between microstructure and tensile properties. Mater Sci Eng A. 2017;679:465–75.

Wei KX, et al. Effect of deep cryogenic treatment on microstructure and properties of pure copper processed by equal channel angular pressing. Adv Eng Mater. 2019;21(7):1801372.

Li J, et al. Experimental study on pure copper subjected to different severe plastic deformation modes. Mater Sci Eng A. 2016;656:142–50.

Edalati K, et al. Equal-channel angular pressing and high-pressure torsion of pure copper: evolution of electrical conductivity and hardness with strain. Mater Trans. 2012;53(1):123–7.

Alawadhi MY, et al. Direct influence of recovery behaviour on mechanical properties in oxygen-free copper processed using different SPD techniques: HPT and ECAP. J Market Res. 2017;6(4):369–77.

Kashi HT, et al. Microstructure and mechanical properties of the ultrafine-grained copper tube produced by severe plastic deformation. Iran J Mater Sci Eng. 2017;14(2):32–40.

Bagherpour E, et al. Microstructure quantification of ultrafine grained pure copper fabricated by simple shear extrusion (SSE) technique. Mater Sci Eng A. 2016;674:221–31.

Miyajima Y, et al. Dislocation density of pure copper processed by accumulative roll bonding and equal-channel angular pressing. Mater Charact. 2015;104:101–6.

Zhu C, et al. Microstructure and strength of pure Cu with large grains processed by equal channel angular pressing. Mater Des (1980–2015). 2013;52:23–9.

Shaarbaf M, Toroghinejad MR. Nano-grained copper strip produced by accumulative roll bonding process. Mater Sci Eng A. 2008;473(1–2):28–33.

Tavakkoli V, et al. Severe mechanical anisotropy of high-strength ultrafine grained Cu–Zn tubes processed by parallel tubular channel angular pressing (PTCAP). Mater Sci Eng A. 2015;625:50–5.

Huang X, Kamikawa N, Hansen N. Strengthening mechanisms in nanostructured aluminum. Mater Sci Eng A. 2008;483:102–4.

Hosseini SA, Manesh HD. High-strength, high-conductivity ultra-fine grains commercial pure copper produced by ARB process. Mater Des. 2009;30(8):2911–8.

Brown TL, et al. A study of the interactive effects of strain, strain rate and temperature in severe plastic deformation of copper. Acta Mater. 2009;57(18):5491–500.

Fattah-Alhosseini A, et al. Microstructural evolution, mechanical properties, and strain hardening behavior of ultrafine grained commercial pure copper during the accumulative roll bonding process. Mater Sci Eng A. 2016;650:8–14.

Lanjewar H, et al. Severe plastically deformed commercially pure aluminum: Substructure, micro-texture and associated mechanical response during uniaxial tension. Mater Sci Eng A. 2019;764:138195.

Moradpour M, et al. Finite element modeling and experimental validation of CGP classical and new cross routes for severe plastic deformation of an Al-Mg alloy. J Manuf Process. 2019;37:348–61.

Bahadori SR, Dehghani K, Bakhshandeh F. Microstructure, texture and mechanical properties of pure copper processed by ECAP and subsequent cold rolling. Mater Sci Eng A. 2013;583:36–42.

Lugo N, et al. Microstructures and mechanical properties of pure copper deformed severely by equal-channel angular pressing and high pressure torsion. Mater Sci Eng A. 2008;477(1–2):366–71.

Edalati K, Fujioka T, Horita Z. Microstructure and mechanical properties of pure Cu processed by high-pressure torsion. Mater Sci Eng A. 2008;497(1–2):168–73.

Salimyanfard F, et al. EBSD analysis of nano-structured copper processed by ECAP. Mater Sci Eng A. 2011;528(16–17):5348–55.

Ebrahimi M, Djavanroodi F. Experimental and numerical analyses of pure copper during ECFE process as a novel severe plastic deformation method. Prog Nat Sci Mater Int. 2014;24(1):68–74.

Babaei A, et al. Repetitive forging (RF) using inclined punches as a new bulk severe plastic deformation method. Mater Sci Eng A. 2012;558:150–7.

Kocich R, et al. Twist channel angular pressing (TCAP) as a method for increasing the efficiency of SPD. Mater Sci Eng A. 2010;527(23):6386–92.

Shamsborhan M, Ebrahimi M. Production of nanostructure copper by planar twist channel angular extrusion process. J Alloy Compd. 2016;682:552–6.

Faraji G, Kim H. Review of principles and methods of severe plastic deformation for producing ultrafine-grained tubes. Mater Sci Technol. 2017;33(8):905–23.

Azimi A, et al. Mechanical properties and microstructural evolution during multi-pass ECAR of Al 1100–O alloy. Mater Des. 2012;42:388–94.

Hansen N. Hall-Petch relation and boundary strengthening. Scripta Mater. 2004;51(8):801–6.

Jamaati R, Toroghinejad MR. Effect of stacking fault energy on mechanical properties of nanostructured FCC materials processed by the ARB process. Mater Sci Eng A. 2014;606:443–50.

Jafarzadeh H, Abrinia K. Fabrication of ultra-fine grained aluminium tubes by RTES technique. Mater Charact. 2015;102:1–8.

Deng J, et al. Hot tensile deformation and fracture behaviors of AZ31 magnesium alloy. Mater Des. 2013;49:209–19.

Acknowledgements

This work was supported by Iran National Science Foundation (INSF).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Eftekhari, M., Faraji, G. & Bahrami, M. Processing of commercially pure copper tubes by hydrostatic tube cyclic extrusion–compression (HTCEC) as a new SPD method. Archiv.Civ.Mech.Eng 21, 120 (2021). https://doi.org/10.1007/s43452-021-00272-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00272-w