Abstract

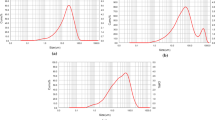

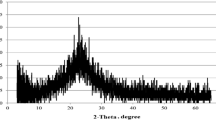

Fly ash is a well-known supplementary cementitious material that is the by-product of coal-fired thermal power plants. The contribution of fly ash to the enhancement of the mechanical and durability properties of cementitious materials has been documented in concrete technology for many years. In this study, to allow superior mechanical and durability properties, fly ash-based mixtures have been produced after optimization of particle size distribution (PSD) of Class F and Class C fly ash according to the formula of Fuller–Thompson. Different distribution modulus values ranging from 0.3 to 0.6 were used to achieve ideal PSD in accordance with the Fuller–Thompson equation. 30% of F- and C-class fly ash by weight of cement were used to replace with cement in cementitious composites by optimizing PSD with help of air jet sieve. The recommended optimization technique improved the 7-, 28- and 90-day compressive and flexural strength results of mortars. Compressive and flexural strength tests and rapid chloride permeability test of cement-based systems incorporating fly ash up to 15% replacement ratio with optimized PSD at 90-days exhibited better results than those of plain samples owing to the filler effect.

Similar content being viewed by others

References

Kim T, Davis JM, Ley MT, Kang S, Amrollahi P. Fly ash particle characterization for predicting concrete compressive strength. Constr Build Mater. 2018;165:560–71.

Yao ZT, Ji XS, Sarker PK, Tang JH, Ge LQ, Xia MS, Xi YQ. A comprehensive review on the applications of coal fly ash. Earth Sci Rev. 2015;141:105–21.

Demir İ, Güzelküçük S, Sevim Ö. Effects of sulfate on cement mortar with hybrid pozzolan substitution. Eng Sci Technol Int J. 2018;21(3):275–83.

Neville AM. Properties of concrete. New York: Longman Scientific and Technical; 1981.

Lanzerstorfer C. Fly ash from coal combustion: dependence of the concentration of various elements on the particle size. Fuel. 2018;228:263–71.

Lea FM. The chemistry of cement and concrete. New York: Chemical Publishing Co; 1956.

Li S, Cooke RA, Wang L, Ma F, Bhattarai R. Characterization of fly ash ceramic pellet for phosphorus removal. J Environ Manag. 2017;189:67–74.

Bernal SA, Juenger MC, Ke X, Matthes W, Lothenbach B, De Belie N, Provis JL. Characterization of supplementary cementitious materials by thermal analysis. Mater Struct. 2017;50(1):26.

ASTM C618-19. Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. West Conshohocken, PA: ASTM International; 2019.

Lane RO, Best JF. Properties and use of fly ash in cement concrete. Concr Int. 1982;4(7):81–92.

Shaikh FU. Effect of ultrafine fly ash on the properties of concretes containing construction and demolition wastes as coarse aggregates. Struct Concr. 2016;17(1):116–22.

Shaikh FU, Supit SW. Compressive strength and durability properties of high-volume fly ash (HVFA) concretes containing ultrafine fly ash (UFFA). Constr Build Mater. 2015;82:192–205.

Zhao J, Wang D, Wang X, Liao S, Lin H. Ultrafine grinding of fly ash with grinding aids: impact on particle characteristics of ultrafine fly ash and properties of blended cement containing ultrafine fly ash. Constr Build Mater. 2015;78:250–9.

Ma BG, Cai LX, Jian SW, Su L. Influence of fly ash fineness on autoclaved energy conservation block’s performance and hydration products. Key Eng Mater. 2014;599:302–9.

Bagheri A, Zanganeh H, Alizadeh H, Shakerinia M, Marian MAS. Comparing the performance of fine fly ash and silica fume in enhancing the properties of concretes containing fly ash. Constr Build Mater. 2013;47:1402–8.

Feret R. Sur la compacité des mortiers hydrauliques. Ann Ponts Chaussees. 1892;4:5–16.

Fuller WB, Thompson SE. The laws of proportioning concrete. ASCE J Transp. 1907;59:67–143.

Hunger M. An integral design concept for ecological self-compacting concrete. Eindhoven, the Netherlands: PhD thesis Eindhoven University of Technology; 2010.

Mueller FV, Wallevik OH, Khayat KH. Linking solid particle packing of Eco-SCC to material performance. Cem Concr Compos. 2014;54:117–25.

Wang X, Wang K, Taylor P, Morcous G. Assessing particle packing based self-consolidating concrete mix design method. Constr Build Mater. 2014;70:439–52.

Yu R, Spiesz P, Brouwers HJH. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem Concr Res. 2014;56:29–39.

Yu R, Spiesz P, Brouwers HJH. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem Concr Compos. 2015;55:383–94.

Yu R, Spiesz P, Brouwers HJH. Development of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC): towards an efficient utilization of binders and fibres. Constr Build Mater. 2015;79:273–82.

Sevim Ö, Demir İ. Optimization of fly ash particle size distribution for cementitious systems with high compactness. Constr Build Mater. 2019;195:104–14.

Sevim Ö, Demir İ. Physical and permeability properties of cementitious mortars having fly ash with optimized particle size distribution. Cem Concr Compos. 2019;96:266–73.

TS EN 197-1. Cement—part 1: composition, specification sand conformity criteria for common cements. Ankara: Turkish Standard Institution; 2012.

TS EN 196-1. Methods of testing cement—part 1: determination of strength. Ankara: Turkish Standard Institution; 2016.

TS EN 933-10. Tests for geometrical properties of aggregates—part 10: assessment of fines-grading of filler aggregates (air jet sieving). Ankara: Turkish Standard Institution; 2009.

ASTM C1202-19. Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration. West Conshohocken, PA: ASTM International; 2019.

Erdoğdu K, Türker P. Effects of fly ash particle size on strength of Portland cement fly ash mortars. Cem Concr Res. 1998;28(9):1217–22.

Bentz DP, Jensen OM, Hansen KK, Olesen JF, Stang H, Haecker CJ. Influence of cement particle-size distribution on early age autogenous strains and stresses in cement-based materials. J Am Ceram Soc. 2001;84(1):129–35.

Bentz DP, Hansen AS, Guynn JM. Optimization of cement and fly ash particle sizes to produce sustainable concretes. Cem Concr Compos. 2011;33(8):824–31.

Al-Najjar Y, Yesilmen S, Al-Dahawi AM, Sahmaran M, Yıldırım G, Lachemi M, Amleh L. Physical and chemical actions of nano-mineral additives on properties of high-volume fly ash engineered cementitious composites. ACI Mater J. 2016;113(06):791–801.

Yeşilmen S, Al-Najjar Y, Balav MH, Şahmaran M, Yıldırım G, Lachemi M. Nano-modification to improve the ductility of cementitious composites. Cem Concr Res. 2015;76:170–9.

Sahmaran M, Yıldırım G, Aras GH, Keskin SB, Keskin OK, Lachemi M. Self-healing of cementitious composites to reduce high CO2 emissions. ACI Mater J. 2017;114(01):93–104.

Yıldırım G, Khiavi AH, Yeşilmen S, Şahmaran M. Self-healing performance of aged cementitious composites. Cem Concr Compos. 2018;87:172–86.

Acknowledgements

The authors wish to thank the Scientific and Technical Research Council of Turkey (TUBITAK) for financial support (Project: 115M325).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This manuscript has not been published by another journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Filazi, A., Demir, İ. & Sevim, O. Enhancement on mechanical and durability performances of binary cementitious systems by optimizing particle size distribution of fly ash. Archiv.Civ.Mech.Eng 20, 58 (2020). https://doi.org/10.1007/s43452-020-00061-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00061-x