Abstract

About 39 million tons of Brewer’s spent grain (BSG), the main by-product of beer manufacturing, are produced annually and is used for low value applications. To valorise this rich bioresource, the present work entails bioprocessing of BSG with various proteases (Novozymes) at two different concentrations (4% and 9%) to solubilise protein, carbohydrate and polyphenols from the grain and evaluate its effect on gut and brain health. The results show the highest (p < 0.05) FRAP (Ferric Reducing Antioxidant Power) based antioxidant activity was obtained for Pro 5 (4%: 108.10 ± 4.17 µmole Trolox Equivalence (TE)/g protein, 18.06 ± 0.70 µmole TE/g d.w., which was 3.6 times higher than untreated control extracts. The highest DPPH (1,1-diphenyl-2-picrylhydrazyl) scavenging activity was obtained for the same extract (Pro 5 at 4%: 0.118 ± 0.006 µg AAE/mg d.w., 9%: 0.110 ± 0.006 µg AAE/mg d.w). Proximate composition showed this extract to contain the highest concentration of proteins at 21.66% ± 2.71, and color analysis showed the same Pro 5 (4%) extract to be the darkest (L*53.73) indicating the possible presence of dark polyphenols. Anticancer screening showed Control and Pro 1 to possess cytotoxic effect against colon cancer cells with IC50 of 3.2 and 13.91 mg/mL, respectively. No significant activity was noted against the brain cancer cell line. Thus anti-colon cancer activity of BSG extracts highlights its potential in gut health. The observed bioactivity resulted from a combination of peptides, carbohydrates and polyphenolic compounds in the extract and warrants further characterisation for targeted nutraceutical applications.

Graphical abstract

Similar content being viewed by others

Introduction

Beer is a popular alcoholic beverage around the world, with 1.86 billion hectoliters produced in 2021 [1]. Over the past few decades consumption has increased [2] and hence multi-branding and mass production have emerged. As a consequence beer holds the third place for the most popular drink in the world after water and tea [1]. Beer is produced by fermentation of four ingredients: water, yeast (starter culture), hops for flavor and bitterness, and malt (germinated starchy grain). The latter can be derived either from barley, the most cultivated cereal in the world or from other cereal grains rich in essential nutrients for human and animals [3]. After steeping the malted barley and separating the wort, brewers spent grains (BSG) are the main solid waste, with an average 20 kg of BSG being produced for every 100 L of beer [4]. BSG is obtained from the outer layer of the grain, which is made up of the seed coat, the pericarp and husk layers, and a small amount of germ and endosperm [5]. About 70% of BSG is used directly in animal feed and its application in human diet is limited [6].

The composition of the BSG is dependent on the malted barley and also on the process and materials used in the production of the beer. The typical composition of BSG is 50% of fibre, 20% of protein and 10–28% of lignin. Fibre fraction is made up of cellulose with xylose, glucose, arabinose and hemicellulose portions that include a maximum of 40% of arabinoxylans. Around 30% of amino acids in BSG could be attributed to [5] storage proteins such as hordein, glutenin, albumin and globulin [7]. In addition, these amino acids have 14.3% of lysine, an essential amino acid usually absent in cereals. This by-product also has a rigid structure and a certain integrity in terms of its lignin composition and its concentration of lipids and minerals. However, BSG has a high water content, which makes it prone to microbial-degradation. The shelf life of BSG can vary from 7 to 10 days in warm climates due to its high water content of up to 70% [8]. This makes BSG unstable and valorisation of it needs to be accompanied with appropriate logistical plans. Biorefinery set up close to breweries can aid extraction and dehydration though these techniques are often expensive.

BSG is being explored for varied applications beyond animal feed [6] such as, energy production through, biogas [9] and bioethanol for fuel [10] via valorisation to reduce industrial waste. In food, BSG is used as an ingredient in baking different doughs, cakes or biscuits [8]. Direct inclusion of BSG in food can negatively impact the techno-functional and sensorial characteristics of the products far outweighing the nutritional benefits. To tailor specific techno-functional properties and enhance bioactivity, enzymatic bioprocessing is essential. This will support the creation of designer food products that can contain functional compounds and provide health benefits and food safety to consumers.The waste from the brewing industry has been reported to have beneficial effects on oxidizing compounds. Phenolic acids found in the husk of barley grain, contribute towards the antioxidant potential of BSG [11]. These types of extracts contain compounds such as ferulic acid and caffeic acid and are known to limit oxidative stress. However, at higher concentrations, they can have the opposite effect by behaving as prooxidants and induce oxidative stress [12], hence their application warrants detailed investigation.

The antioxidant activity of BSG extracts can prevent age-related chronic diseases such as cardiovascular disease, neurogenerative diseases, diabetes (types I and II), and some cancers. BSG is therefore a good solution for the agri-food industry formulations aimed at improving the percentage of fibre, protein and antioxidants while reducing caloric intake. Reserachers have explored utilization of enzymes such as carbohydrases (amylase, cellulase, hemicellulase) and proteases to breakdown complex proteins and carbohydrates into lower molecular weight soluble bioactive compounds [7, 13]. The antioxidant capacity of BSG extracts may, in addition to food applications, also have useful properties for pharmaceutical and nutraceutical application as well as used for food preservation [8]. BSG has been reported as a probiotic due to its high proportion of arabinoxylans and is also being explored to target various metabolic diseases such as hypertension or diabetes through its amino acids and unique peptide composition [5, 14]. For target bioactivity, choice of enzyme plays a critical role as there are several commercial industrially available endo and exopeptidases to choose from.

The objectives of the study are (i) To screen various proteases for their ability to produce soluble, protein enriched extracts from brewers spent grain (ii) To characterise the produced extracts for its biocomposition (iii) To screen the various extracts for antioxidant potential and (iv) To screen anticancer effects for intervention in brain and gut disorders.

Materials and methods

The Brewers’ Spent Grain (BSG) used for the present work was produced in the TU Dublin brewing lab from Hook Head Series Ale Malt from Minch Malt Co. The malted barley has a reported total protein (dry) of 8.5–10.5% w/w. Following lautering, the BSG was freeze dried in Teagasc Ashtown Food Research Centre. The BSG was stored refrigerated at 4 °C in a plastic bag. The enzymes used were acquired from Novozymes. Bovine serum albumin was sourced from the Fisher-Scientific. All other chemicals were obtained from Sigma and were of analytical grade unless otherwise stated.

Proteases for hydrolysis

Proteases 1, 2, and 3 are endoproteases that break peptide bonds at non-terminal amino acids, while Protease 4 is a blend of endo- and exoproteases. Protease 5, is an endoprotease reportedly used in oats and Protease 6 is an exoprotease for vegetable protein. The mixtures of Protease 1 & Protease 4 and Protease 2 and Protease 6 contain an equivalent concentration of each protease.The extracts generated using these enzymes were represented by the name of enzyme as follows; Pro 1, Pro 2, Pro 3, Pro 4, Pro 5, Pro 6, Pro 1 & Pro 4 and Pro 2 & Pro 6.

Proximate composition analysis

Moisture content, protein content, ash content and lipid content of BSG were determined using validated AOAC Official Methods (AOAC Official Method 930.15 Moisture in Animal Feed, AOAC Official Method 2001.11 Protein (Crude) in Animal Feed (Kjeldahl Method), AOAC Official Method 923.03 Ash of Flour Direct Method, AOAC Official Method 963.15 Fat in Cacao Products (Soxhlet Extraction Method) (Association of Official Analytical Chemists, 2000). The carbohydrate + lignin portion was determined by difference. The Jones Factor used for determining the protein content of BSG and its extracts was 5.83 which has been reported for barley.

Moisture content | \(\% Moisture = \frac{Weight\;of\;dish\;before\;drying\;(g) - Weight\;of\;dish\;after\;drying\;(g)}{{Weight\;of\;dish\;before\;drying\;(g) - Weight\;of\;empty\;dish\;(g)}} \times 100\) |

Crude protein content | \(\% Nitrogen = \frac{{\left( {V_{sample} - V_{blank} } \right) \times 1.4007 \times Molarity of acid}}{Sample Weight (g)}\) \(\% \Pr otein = \% Nitrogen \times Jones\;Factor\) |

Crude ash content | \(\% Ash = \frac{Weight\;of\;crucible\;before\;ashing\;(g) - Weight\;of\;crucible\;after\;ashing\;(g)}{{Weight\;of\;crucible\;before\;ashing\;(g) - Weight\;of\;empty\;crucible\;(g)}}\) |

Fat content | \(\% Fat = \frac{Weight\;of\;flask\;with\;extracted\;fat\;(g) - Weight\;of\;empty\;flask\;(g)}{{Weight\;of\;BSG\;in\;thimble\;(g)}} \times 100\) |

Sugar analysis

Monomeric carbohydrates were quantified using calibrated standard curves of arabinose, galactose, glucose, xylose, mannose, fructose ranging from 100 to 0.6 μg mL−1 using a Dionex High Performance Anion-Exchange Chromatography with Pulsed Amperometer Detection (HPAE-PAD) HPLC system. 20 mg of each sample was carefully weighed into an Eppendorf and mixed with 1 mL of ELGA water and vortexed until dissolved. The solution was then filter sterilised through 0.2 μm syringe filter into 0.6 mL vials with pre-cut septum (Thermofisher) with 25 μL of each sample injected onto a CarboPac SA10 column, 250 mm long × 4 mm internal diameter and eluted with an isocratic mobile phase of 1 mM KOH at 1.5 mL min−1. Single dilutions were prepared for all samples, which were then injected in duplicate.

Enzymatic hydrolysis of BSG

10 g of dry BSG was suspended in deionised water (10% T.S.) and solubilised using a New Brunswick Scientific Innova 42 incubator shaker at 55 °C, 125 rpm for 1 h. Then, the pH was adjusted to the optima of the selected enzymes using 2 N NaOH and the proteases were added (4% and 9% per d.w. of protein in BSG for each enzyme preparation) and allowed to incubate for 1 h at 55 °C before heat inactivation at 80 °C for 10 min. The fixed time of incubation was based on preliminary trials while increase in protease concentration (4% and 9%) was based on literature [14]. The resulting suspension was centrifuged at 4000 rpm for 10 min and the supernatant was recovered and freeze dried (Mason Technology LabConCo freeze-dryer) for 72 h. The pellets were then dried in an oven at 65 °C for 48 h. The total yield (g) of the hydrolysate was determined using the freeze dried and oven dried pellets.

Extent of hydrolysis

The extent of hydrolysis is an assay based on the reaction of o-phthalaldehyde (OPA) and 2-mercaptoethanol with amino groups released during proteolysis of a protein substrate. L-serine standards were prepared ranging from 0–500 µg/ml. The assay was set by pipetting 25 µL of the blanks, standards, and samples solutions and reacting it with 175 µL (0.8 mg/ml) of OPA solution (Sigma-Aldrich: P0532) in triplicate onto a 96-well plate. The extent of hydrolysis was determined using the absorbance at 340 nm during 2 min at 24 °C. Due to low extraction of protein in prepared extracts extent of hydrolysis is presented as mg Nitrogen/g of protein and mg Nitrogen/g of d.w.

Antioxidant activity

DPPH

The antioxidant activity was determined via DPPH [11] that gets reduced by receiving a hydrogen atom from antioxidants, losing its purple colour detected spectrophotometrically. 0.0157 g of DPPH was dissolved in 100 ml of methanol to create a 0.4 mM stock solution. This was then diluted to 240 µM working solution. L-ascorbic acid standards were used to create a standard curve. Hydrolysed BSG extract solutions were prepared at 25 mg/ml. The assay was carried out in a 96-well plate, with each sample and standard in triplicate. The plate was incubated at 37 °C for 30 min and absorbance was read at 517 nm. Antioxidant activity was obtained in µg Ascorbic Acid Equivalent (AAE)/mg hydrolysate and % Inhibition, calculated using the following formula:

where Ablank is the absorbance of the control and Asample is the absorbance of the test extract.

FRAP

FRAP reagent was prepared as follows: 1.55 g of sodium acetate trihydrate was dissolved in 8 ml of acetic acid then 450 ml of dH2O was added [13]. The pH of the solution was measured and adjusted to 3.6. The solution was then made up to 500 ml with dH2O. 15.6 mg of TPTZ was dissolved in 5 ml of 40 mM HCl to create a 10 mM TPTZ solution. 27 mg of ferric chloride hexahydrate was weighed and dissolved in 5 ml of dH2O to create 20 mM FeCl3∙6H2O. The solutions were mixed in a ratio of 10:1:1 and heated at 37 °C for 30 min. The initial absorbance of the FRAP reagent was found at 590 nm, then the samples were added to a 96-well plate and incubated at 37 °C for 30 min, following this, the change in absorbance was calculated using the following formula.

Change in absorbance for the samples was interpolated using a Trolox standard curve to find µmole Trolox Equivalent (TE)/g protein for the protease treated extract and as µmole Trolox Equivalent (TE)/g d.w.

Colour analysis

Freeze-dried powder BSG extract was transferred to a transparent glass plate and samples were covered with parafilm to prevent the powder from drawing moisture from the air. Proteases were evaluated using a Chroma meter [15], where L ∗ is lightness, a ∗ is the degree of redness or greenness, and b ∗ is yellowness or blueness. L*a*b readings were taken in triplicate for each extract sample.

Anti-cancer activity against human brain cancer cells

The possibility of anticarcinogenic activity of the BSG’s extracts was calculated, using the methods of Jiang and Sangour [16, 17]. An MTT assay was performed with U-373 cell lines corresponding to human brain tumor cells. U-373 cells were cultured in DMEM mixture F-12 supplemented with L-glutamine, 10% of FBS and 1% of penicillin–streptomycin solution. The colorimetric test allows to know if our different peptide extracts can have a cytotoxic effect. The MTT assay measures the transformation of tetrazolium salt into formazan crystal at a wavelength of 570 nm.

100 µl of U-373 cell line was seed into the wells of a 96 well plate and incubate for 24 h at a density of superior at 1×105 cells/ml. The old medium was then removed and the different concentrations of Blank 7, Pro1 2% and Pro5 2% were added to each well in duplicate for incubation for 24 to 48 h. 10 µL of MTT solution was inserted into each well and the plate was incubated for 4 h before the old solution was removed, followed by adding 100µL of DMSO to solubilise the formazan crystals. The plate was then read using a spectrophotometer at a wavelength of 570 nm and the OD was recorded. The following calculation was used to determine the percentage of viability and to evaluate the anti-cancer activity of BSG extracts.

Anti-cancer activity against human colon cancer cells

The cell line used to test the anti-cancer effect of Control, Pro 1 and Pro 5 was the human colon adenocarcinoma cell line: Caco-2, clone TC7. This cell line is appropriate for our studies because it undergoes spontaneous enterocytic-like differentiation when it is cultured over confluence for 15 days to become polarized cells expressing apical and basolateral surfaces with well-established tight junctions, characteristics of normal epithelial cells [18].For this reason, Caco-2/TC7 allows us to study the antiproliferative effect not only on cancer cells (5 days after seeding) but also on considered normal epithelial cells (15 days after seeding). Cell proliferation was measured using the well-established MTT protocol. Based on a published study we [19] investigated the cellular effects of Control, Pro1 and Pro 5 on undifferentiated (5 days) and differentiated (15 days) Caco-2/TC7 cells, after exposure to the products for 72 h at different concentrations (0−20 mg/mL).

FTIR spectroscopy

The FTIR analysis of the samples were recorded between 4000 and 400 cm−1 using an ATR thermo spectrometer. The BSG enzyme treated extracts was placed on a single reflection diamond and pressed in order to put the crystal and the sample in contact for analysis.

Statistical analysis

Each experiment was conducted in triplicates (unless mentioned otherwise) and the obtained data was used to calculate the mean and the standard deviation. Statistical analysis of the data was carried out using GraphPad Prism 8.0.2. Statistical significance at the 95% confidence interval was determined for data using ANOVA followed by Tukey’s multiple comparison test. Data is reported as mean ± standard deviation of replicates.

Results and discussion

The present work was done to generate bioactive extracts from brewers spent grains’ and to select best functioning enzymes from a portfolio of industrially produced enzymes. Biochemical analysis of protease treated BSG extracts was done to estimate protein & ash content, extent of hydrolysis, yield of extract and carbohydrate composition. Further antioxidant assays such as DPPH and FRAP were used to select potent extracts that can be applied to brain and colon cancer cell lines to investigate anti-cancer effects. Further colour analysis and FTIR spectra was obtained to see changes in composition of different extracts.

Proximate composition analysis

The mean crude protein content of the raw material (BSG) was calculated to be 13.33 ± 0.02 g/100 g, with results ranging from 13.31 to 13.34 g/100 g (Table 1).

These results match values found in literature for BSG, such as 15.2% [4] and 14.2% [7]. In some cases, protein content of BSG can be as high as 31 g/100 g [20], indicating a high degree of variability in the composition of BSG. This discrepancy may be linked to differences in the malted barley used as base material, the conditions of the lautering and brewing process, the use of adjunct materials, and other factors.

The malted barley that was brewed to produce the spent grain used in this project had a reported protein content of 8.5–10.5 g/100 g according to the manufacturer. In this case, the BSG was enriched in protein during the brewing process due to the removal of sugars derived from hydrolysis of starch in the barley endosperm [21] However, as the main interest in this work was the production of peptides from the protein component, it would be worthwhile to seek out a source of BSG that is higher in protein for upscaling studies.

Extent of hydrolysis

The extent of hydrolysis is presented both in mg Nitrogen/g of protein and mg Nitrogen/g of freeze-dried powder extract as shown in Table 2.

The method measures the degree to which a protein component in the substrate is degraded [22]. Enzymatic hydrolysis improves protein extraction and facilitates separation and can also enhance the solubilization of the sample [14]. Typically, degree of hydrolysis is presented as % DH, however, here, the extent of hydrolysis is primarily explained in mg Nitrogen/g extract (d.w.) or mg Nitrogen/g protein as the factor Npb was not estimated in this study.

The 9% Pro 2 & 6 extract demonstrates the highest extent of hydrolysis, followed by the 9% Pro 4 extract as seen in Table 2. The extent of hydrolysis (mg Nitrogen/g d.w.) for the 4% and 9% Pro 2 extracts, the 4% Pro 6, and the 9% Pro 5 extracts are significantly lower than other samples indicating a decreased amount of hydrolysed protein in the extract compared to other protease treated extracts. Amongst 4% protease treated extracts, Pro 5 had the highest extent of hydrolysis. Higher degree of hydrolysis results in products of lower molecular weight often associated with higher bioactivity as reported in other studies [21] As expected, the protease free extracts have significantly lower mg Nitrogen/g d.w. than the rest of the protease treated extracts, proving the release of peptides during enzymatic hydrolysis. The partial hydrolysis in control samples not containing external protease demonstrates autohydrolysis during malting due to endoproteases or exopeptidases found in malted barley [23].

Despite the low mg Nitrogen/g d.w. in the Pro 2 extract, Pro 2 also exhibits the highest mg Nitrogen/g protein. Since the Pro 2 extract had the lowest protein content of all the extracts (2.94% ± 1.17), this implies that while Pro 2 was inefficient at extracting protein from the BSG, but efficient at hydrolysis. A higher enzyme to protein ratio enables higher rate of hydrolysis.

Yield of BSG extracts

The yield of the extract is calculated from 10 g of BSG. Following freeze-drying of the supernatant, the recovered powder was weighed and mean yield in grams and % yield was found for each sample.

The highest recovered yield was for 9% Protease 1 & 4 treated extract at 3.93 ± 0.11 g (~ 40%) as shown in Table 3. This was significantly higher than the sample at the same pH (7.5) without any added enzymes. The sample without enzymes had a yield of 2.54 g. The 9% Proteases 1 & 4 extract was also significantly higher than the same combination of enzymes at 4% concentration. The yield of Pro 1, Pro 2, Pro 3, Pro 6 and Pro 2 1 Pro6 extracts are also significantly higher at 9% enzyme concentration compared to 4%, indicating consistent increase in yield. It is worth noting that Pro 1 had the highest mean yield at 4% concentration and the second highest yield at 9% concentration and both results are significantly higher than the protease free extract at pH 8. Thus the enzymatic treatment leads to higher recovery of soluble fraction.

The lowest mean yield was 4% Pro 6 extract, which had a yield of 2.59 ± 0.17 g, which was significantly lower than the 9% Pro 6 extract. The 9% protease treated extracts tended to be significantly higher than the 4% protease counterparts. The higher the protease concentration, the higher the yield obtained.

Of the extracts produced without protease, the yield of freeze-dried powder decreased as the pH became more alkaline, as the pH 7 extract had a significantly higher yield of 3.33 ± 0.6 g, compared to pH 7.5, or the pH 8 extract. The only case where protease extract yield was lower than its protease free counterpart was 4% Pro 2, an exception to the general observation of enzymes increasing the yield of BSG extract. In the case of 4% Pro 2 extract, combination of factors may account for the lower yield, such as concentration of the enzyme, type of enzyme, pH and loss of material during transfer.

Crude ash content of BSG extracts

Pro 3 9% is the extract with the highest percentage of ash content while the lowest was for Blank pH 7 (Table 4) and these values were significantly different from all other extracts as well as the ash content of the initial BSG material (2.32 ± 0.09). The starting BSG material is similar in ash content to other samples such as Pro3 4%, Pro5 4%, Pro5 9% and Blank 10. Generally higher pH (pH 10) corresponds to addition of higher amount of NaOH which results in higher ash content as observed for blank 10 and Pro 5 extract. For most samples there is no difference in ash content between protease concentration of 9% and 4%; Pro 1 4% and 9%, Pro2 4% and 9%, Pro6 4% and 9%, Pro1 & Pro4 and Pro2 & Pro6 are not significantly different in ash content as are Blank 7.5 and Blank 8. All the aforementioned extracts have been generated at pH 7, 7.5 or 8. This may further indicate the link between the pH used during the hydrolysis and the ash composition of the extracts.

In addition, ash content is known to impact digestibility, taste and quality of finished products, and an unusually high ash value suggests the presence of inorganic adulterants. Determination of ash content is useful to determine the nature and distribution of the mineral constituents' present and more detailed analysis using FTIR will reveal the nature of minerals present [24]. Finally the maximum ash content was found to be 3.449% and is comparable to liertature reports ranging from 3.29% ± 0.06 [25] to 4.77% [26].

Crude protein content of BSG extracts

The results in Table 5 show that for many samples protein extraction was higher at lower enzyme concentration i.e. at 4%. The 4% Pro 5 extract had 4.9 times higher protein content at 21.66% ± 2.71 as compared to the BSG starting material (4.42% ± 0.02). The 4% extracts Pro 1, Pro 3, Pro 1&4 are next in line in terms of high protein content as compared to blank samples. Amongst 9% samples Pro 2, Pro 4, and Pro 2 & 6 gave much lower protein content and are not significantly different from each other while Pro 6 was found to be the most inefficient enzyme in extracting protein from BSG samples. This highlights the issue with attempting to use the protein component of a highly lignocellulosic substrate like BSG, as much of the protein component is bound to or within the carbohydrate portion of the material and extraction can be difficult [27]. In addition, for samples Pro 1, Pro 3, Pro 5, Pro 6, Pro 1&4 and Pro 2&6 there was no significant difference between the protease concentrations at 4% and 9%. This contrasts with Pro 2 and Pro 4, where the higher the protease concentration used during hydrolysis, the higher the protein content of the extract. Until recently, most researchers have reported reduction in protein content after protease treatment while some recent studies indicate doubling of protein in wet fractionated BSG extracts and protease treated BSG extracts [28, 29].

Apart from the choice of enzyme, the pH of hydrolysis also plays a major role in protein content of extracts. Generally, alkaline pH methods are routinely utilized for protein extraction. Hydrolysis of BSG with Pro 2, Pro 4 and Pro 2 & 6 was conducted at pH 7 which corresponded with the lowest protein content, while Pro 6 was conducted at pH 7.5. Pro 1 and Pro 3 were conducted at pH 8 and the mix of Pro 1 & 4 was conducted at pH 7.5. Pro 5, which had the highest protein content was conducted at pH 10. The low solubility of BSG proteins is one of the functional properties that hinder attempts at valorisation [29] and the use of alkaline pH in extraction to improve solubility is commonplace [30, 31].

Antioxidant activity

In the DPPH assay, extracts were assessed against an L-ascorbic acid standard curve and antioxidant activity was expressed as µg AAE/mg d.w. and % Inhibition. The highest results were obtained from the Pro 5 extracts (4%: 0.118 ± 0.006 µg AAE/mg d.w., 39.0% ± 1.9, 9%: 0.110 ± 0.006 µg AAE/mg d.w., 39.0% ± 2.2) followed by 9% Pro 1 (0.073 ± 0.007 µg AAE/mg d.w, 25.8% ± 2.4) and 9% Pro 2 & 6 (0.072 ± 0.012 µg AAE/mg d.w., 25.3% ± 4.4) as shown in Table 6. These values are comparable to those from other plant products such as those obtained for radish seed extracts of 30.26% ± 1.36 and rapeseed extracts of 25.04% ± 2.42 [34]. In agreemetn to our results, other researchers have successfully fractionated antioxidant peptides from BSG [21]. Unfortunately, as the values obtained for the remaining protease treated extracts are low and, in many cases, not significantly different (p < 0.05) from the protease free extracts it may indicate that DPPH antioxidant activity is not necessarily linked to the peptide portion of the extract but maybe multifactorial.

In the FRAP assay, extracts were assessed against a Trolox standard curve to determine antioxidant activity in terms of µmole TE/g protein and µmole TE/g d.w. The highest antioxidant activity was yet again obtained from Pro 5 (4%: 108.10 ± 4.17 µmole TE/g protein, 18.06 ± 0.70 µmole TE/g d.w., 9%: 11.49 ± 0.34 µmole TE/g d.w.), followed by Pro 3 (4%: 52.47 ± 3.02 µmole TE/g protein, 8.77 ± 0.50 µmole TE/g d.w., 9%: 6.74 ± 0.21 µmole TE/g d.w.), and Pro 1 (4%: 59.84 ± 1.68 µmole TE/g protein, 10.00 ± 0.28 µmole TE/g d.w., 9%: 9.37 ± 0.13 µmole TE/g d.w.) extracts. These compare favourably to FRAP results obtained for BSG extracts by other researchers at 0.320 mmol TE/g ± 0.012 and 0.360 mmol TE/g ± 0.006 [13], indicating a good degree of antioxidant activity for the screened samples. Other samples have antioxidant activity lower than the pH 10 protease free extract and not significantly different from other protease free extracts. The increase in µmole TE when converting between g of extract to g of protein may be a sign of the antioxidant activity being linked to the protein component for these samples.

Carbohydrate analysis

For carbohydrate analysis select samples were used based on their % DPPH quenching abilities. The chromatogram showed presence of monosaccharides xylose, arabinose, mannose, glucose, fructose and disaccharide sucrose as shown in Table 7. Most of these sugars can be attributed to cellulose and hemicellulose fractions of BSG. Glucose by far was the most abundant sugar in all extracts. The type of beer influences the extent of wort processing and sugar extraction from malt. High amounts of fermentable sugars in the specific batch could be attributed to inefficient wort processing as well as to breakdown of carbohydrates during the protease treatment. Though proteases seldom act on carbohydrates, water-extractable feruloylated arabinoxylan and starch entrapped by a proteinaceous barrier protein in BSG are broken down during proteolysis as reported by other researchers [32] Released sugar could then react with hydrolysed amino acids to form Maillard reaction products that display antioxidant activity, thus an increase in antioxidant activity post sugar release can be predicted. Maillard reaction product formation has been reported at temperatures as low was 80 ℃ [33] which was enzyme inactivation temperature used in the study. As the water-soluble protease treated BSG extract contains free sugars as well as peptides and amino acids, further studies can be undertaken to exploit the extracts for media supplementation of microbial cultures.

Colour analysis

The colour of the BSG extracts was also evaluated for L* (lightness), a* (degree of red/green), and b* (degree of yellow/blue). The extract colour L* values ranged from 50 to 69, while the a* values ranged from 2.0 to 5.6, and the b* values ranged from 9.3 to 13.6. The darkest extract was Pro 5 while the lightest was Pro 6 as seen in Fig. 1. The other extracts did not differ significantly from each other. This is relevant because darker varieties of BSG have been linked to increased polyphenol content, which may also account for some of the antioxidant activity present in the extracts [25]. Pro 5 has consistently given the greatest bioactivity in antioxidant assays, which may be linked to its high protein content, a polyphenol component or both.

Anti-cancer activity

Most peptide extracts used in food are known for their bioactive properties. A number of these peptides may also have anti-carcinogenic properties depending on the food source from which they are derived [35]. In this study we screened select BSG extracts (Blank7, Pro1 and Pro5) for anti-cancer activity against brain (U-373) and colon (Caco-2) cancer cell lines and tried to correlate it with compositional analysis.

Table 8 shows percentages of the viability of U-373 cells in response to the different concentrations of BSG extracts (5 mg/mL, 10 mg/mL, 25 mg/mL, 35 mg/mL, 50 mg/mL, 70 mg/mL and 100mg/mL). Cell viability percentages for most of the doses remain almost similar against the 7 concentrations studied for Blank7 and Pro1 4% samples. However, Pro5 4% showed a slight decrease in the percentage viability of the glioblastoma brain cells which is visible from 70 mg/mL leading to a significant difference in cell viability at the two maximum concentrations.

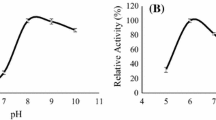

However, the IC50 of Pro5 4% (29.70%) shows that this inhibition is not significant enough to say that this peptide extract has a cytotoxic effect against the U-373 cells (Fig. 2.). For all samples, the results with the MTT assay showed that this natural drug is non-cytotoxic against the glioblastoma brain cell line.

BSG therefore has no anti-cancer activity against glioblastoma since it needs to be at a very high concentration to obtain a decrease in the cell viability. Similar to results seen from fermented bovine colostrum peptides on (Human lymphoblastoid TK6 cells) [36], BSG derived peptides are non-cytotoxic and thereby safe for addition to food products [37] for improved functional properties and applications in human health [36]. Further investigation using tests such as the Alamar Blue Assay or an ATP test would be essential to confirm the results obtained [38].

Figure 3 shows the percentages of the viability of normal (A, B, C) and the cancer (D, E, C) Caco-2 cells in response to the different concentrations of BSG extracts (1 mg/mL, 5 mg/mL, 10 mg/mL, 15 mg/mL and 20 mg/mL). In normal colon cells, cell viability percentages for 1 and 5 mg/mL concentrations were not modified respect to control in Blank 7, Pro 1 and Pro 5 samples. However, the concentrations of 15 and 20 mg/mL of Blank7, Pro 1 and Pro 5 increased the number of live normal colon cells, indicating that treatment with these extracts increases the metabolic function of the cells and thus their viability. The EC50 of Blank 7, Pro 1 and Pro 5 in normal colon cells were 10.19 mg/ml, 17.92 mg/ml and 5.24 mg/mL, respectively. In cancer colon cells, Blank 7 and Pro 1 decreased the viability of these cells at concentrations of 5, 10, 15 and 20 mg/mL. The IC50 of Blank7 and Pro 1 were 3.2 mg/ml and 13.91 mg/mL, respectively, indicating that Blank7 has a higher cytotoxic effect against the colon cancer cells. Pro 5 did not modify the viability of colon cancer cells at any of the tested concentrations. Researchers have demonstrated similar effects of ‘pasta’ incorporated with hydrolysed and fermented BSG on Caco-2 cell lines. Enhanced scavenging activity and increased catalase function was observed in the colon cancer cell lines [39] thereby demonstrating benefit of BSG on gut health.

FTIR spectroscopy

FTIR analysis was used to determine the functional groups in BSG’s extract. The spectrum seen in Fig. 4 shows peaks between 3400 and 900 cm−1.

All three samples have a similar spectral peaks with differences in values of percentage transmittance. As the protein percentage of each sample increases, the transmittance percentage decreases. This value depends on the process used to obtain the dehydrated extract and can also be influenced by the quantity of sample used for FTIR analysis [40]. The large peak at 3300 cm−1 represents the functional hydroxyl group O–H rsulting from presence of water and amine groups. The peak stretches near 2900 cm−1 denotes a C–H function related to the group alkyl. BSG’s samples also contain C=O bond at 1650 cm−1 and saccharide bonds like C–O peak around 1000 cm−1 [41]. C=O bond highlights that the BSG is composed of aromatic acid (fatty and esters acids) and amide I and II characteristic of the presence of proteins in samples [42]. The last stretch at 1000 cm−1 shows the existence of alpha-glycosidic linkage in BSG. This type of linkage is found between glucose in some carbohydrates like cellulose or β-glucan [41].

Biocompositional analysis of the brewers spent grains’ shows that the extracts generated using various endoproteases (Pro1 and Pro5) are composed of molecules of interest such as proteins and carbohydrates that could be profitable in food and nutraceutical applications. It further establishes the superiority of endoproteases in extracting these biomolecules, enhancing bioactivity and enhancing solubility of the hydrolysed samples [43].

Conclusion

In this study, protease treated extracts were successfully produced from BSG and evaluated for their yield, extent of hydrolysis, protein content, antioxidant activity and anticancer activity. Often bioactive peptides and hydrolysates are generated using endoproteases or a combination of both endo and exoproteases. Of all the enzymes screened in this study, maximum antioxidant effect was seen from extracts that were generated using endoproteases. Therefore this study enabled selection of two best performing enzymes out of 8 enzyme combinations. Further consistenly higher extract yields were obtained at higher enzyme concetration though these extracts had lower protein and antioxidant content. This means the protease treatment at higher concentration, enabled higher solubilisation of carbohydrates which is an interesting finding. Future studies may evaluate the antioxidant activity and anti-cancer activity more thoroughly using in vivo studies, as well as investigation into other forms of bioactivity that may be of interest, such as anti-hypertensive activity, anti-diabetic and anti-microbial activity. High protein content with excellent solubility and enhanced bioactive extracts can be used for functional food formulations. BSG extract that demonstrates sufficient antioxidant activity as well as anti-colon cancer effect opens doors for further work in the area of ‘BSG mediated gut health applications’.

Data availability

All data supporting the findings of this study are available within the paper. Should any raw data files be needed they are available from the corresponding author upon reasonable request.

References

Conway J, Global Beer Production. 1998–2021. https://www.statista.com/statistics/270275/worldwide-beer-production/. Accessed 13 Sept 2022.

Colen L, Swinnen J. Economic growth, globalisation and beer consumption. J Agric Econ. 2016;67(1):186–207. https://doi.org/10.1111/1477-9552.12128.

Castro LEN, Colpini LMS. All-around characterization of brewers’ spent grain. Eur Food Res Technol. 2021;247(12):3013–21. https://doi.org/10.1007/s00217-021-03860-5.

Mussatto SI, Dragone G, Roberto IC. Brewers’ spent grain: generation, characteristics and potential applications. J Cereal Sci. 2006;43(1):1–14. https://doi.org/10.1016/j.jcs.2005.06.001.

Lynch KM, Steffen EJ, Arendt EK. Brewers’ spent grain: a review with an emphasis on food and health. J Inst Brewing. 2016;122(4):553–68. https://doi.org/10.1002/jib.363. (John Wiley and Sons Inc).

Bianco A, Budroni M, Zara S, Mannazzu I, Fancello F, Zara G. The role of microorganisms on biotransformation of brewers’ spent grain. Appl Microbiol Biotechnol. 2020;104:8661–78. https://doi.org/10.1007/s00253-020-10843-1/Published.

Xiros C, Christakopoulos P, Xiros C. Biotechnological potential of brewers spent grain and its recent applications. Waste Biomass Valorization. 2012;3:213–32. https://doi.org/10.1007/s12649-012-9108-8.

Ikram S, Huang LY, Zhang H, Wang J, Yin M. Composition and nutrient value proposition of brewers spent Grain. J Food Sci. 2017;82(10):2232–42. https://doi.org/10.1111/1750-3841.13794. (Blackwell Publishing Inc).

Panjičko M, Zupančič GD, Fanedl L, Logar RM, Tišma M, Zelić B. Biogas production from brewery spent grain as a mono-substrate in a two-stage process composed of solid-state anaerobic digestion and granular biomass reactors. J Clean Prod. 2017;166:519–29. https://doi.org/10.1016/j.jclepro.2017.07.197.

Gil-Castell O, Mascia N, Primaz C, Vásqez-Garay F, Baschetti MG, Ribes-Greus A. Brewer’s spent grains as biofuels in combustion-based energy recovery processes: evaluation of thermo-oxidative decomposition. Fuel. 2022;312:122955. https://doi.org/10.1016/j.fuel.2021.122955.

Petrón MJ, Andrés AI, Esteban G, Timón ML. Study of antioxidant activity and phenolic compounds of extracts obtained from different craft beer by-products. J Cereal Sci. 2021. https://doi.org/10.1016/j.jcs.2021.103162.

Nowak M, Tryniszewski W, Sarniak A, Wlodarczyk A, Nowak PJ, Nowak D. Concentration dependence of anti- and pro-oxidant activity of polyphenols as evaluated with a light-emitting Fe2+-Egta-H2O2 system. Molecules. 2022;27(11):3453. https://doi.org/10.3390/molecules27113453.PMID:35684391;PMCID:PMC9182469.

Connolly A, Cermeño M, Alashi AM, Aluko RE, FitzGerald RJ. Generation of phenolic-rich extracts from brewers’ spent grain and characterisation of their in vitro and in vivo activities. Innov Food Sci Emerg Technol. 2021. https://doi.org/10.1016/j.ifset.2021.102617.

He Y, Kuhn DD, O’Keefe SF, Ogejo JA, Fraguas CF, Wang H, Huang H. Protein production from brewer’s spent grain via wet fractionation: process optimization and techno-economic analysis. Food Bioprod Process. 2021;126:234–44. https://doi.org/10.1016/j.fbp.2021.01.005.

Park J, Choi I, Kim Y. Cookies formulated from fresh okara using starch, soy flour and hydroxypropyl methylcellulose have high quality and nutritional value. LWT. 2015;63(1):660–6. https://doi.org/10.1016/j.lwt.2015.03.110.

Jiang H, Li J, Chen A, Li Y, Xia M, Guo P, Chen S. Fucosterol exhibits selective antitumor anticancer activity against HeLa human cervical cell line by inducing mitochondrial mediated apoptosis, cell cycle migration inhibition and downregulation of m-TOR/PI3K/Akt signalling pathway retraction in /10.3892/ol.2022.13618. Oncol Lett. 2018;15:3458–63. https://doi.org/10.3892/ol.2018.7769.

Sangour MH, Ali IM, Atwan ZW, et al. Effect of Ag nanoparticles on viability of MCF-7 and Vero cell lines and gene expression of apoptotic genes. Egypt J Med Hum Genet. 2021. https://doi.org/10.1186/s43042-020-00120-1.

Mesonero J, Mahraoui L, Matosin M, Rodolosse A, Rousset M, Brot-Laroche E. Expression of the hexose transporters GLUT1-GLUT5 and SGLT1 in clones of Caco-2 cells. Biochem Soc Trans. 1994;22(3):681–4. https://doi.org/10.1042/bst0220681. (PMID: 7821663).

Abas E, Espallargas N, Burbello G, Mesonero JE, Rodriguez-Dieguez A, Grasa L, Laguna M. Anticancer activity of alkynylgold(I) with P(NMe2)3 phosphane in mouse colon tumors and human colon carcinoma Caco-2 cell line. Inorg Chem. 2019;58(22):15536–51. https://doi.org/10.1021/acs.inorgchem.9b02528.

Santos M, Jime´nezjime´nez JJ, Bartolome´b BB, Go´mezgo´mez-Cordove´scordove´s C, del Nozal MJ (n.d.). Variability of brewer’s spent grain within a brewery. www.elsevier.com/locate/foodchem

Cermeno M, Connolly A, O’Keeffe MB, Flynn C, Alashi AM, Aluko RE, FitzGerald RJ. Identification of bioactive peptides from brewers’ spent grain and contribution of Leu/Ile to bioactive potency. J Funct Foods. 2019. https://doi.org/10.1016/j.jff.2019.103455. (Article 103455).

Chin YL, Chai KF, Chen WN, Upcycling of brewers’ spent grains via solid-state fermentation for the production of protein hydrolysates with antioxidant and techno-functional properties. Food Chem. 2022; X(13).

Jones BL. Endoproteases of barley and malt. J Cereal Sci. 2005;42(2):139–56. https://doi.org/10.1016/j.jcs.2005.03.007.

Park Y, Determination of moisture and ash contents of foods. Handbook of food analysis. 1996. Marcel Dekker, Inc. https://www.researchgate.net/publication/282135010

Connolly A, Piggott CO, Fitzgerald RJ. Characterisation of protein-rich isolates and antioxidative phenolic extracts from pale and black brewers’ spent grain. Int J Food Sci Technol. 2013;48(8):1670–81. https://doi.org/10.1111/ijfs.12137.

Olszewski MP, Nicolae SA, Arauzo PJ, Titirici MM, Kruse A. Wet and dry? Influence of hydrothermal carbonization on the pyrolysis of spent grains. J Clean Prod. 2020. https://doi.org/10.1016/j.jclepro.2020.121101.

Mitri S, Salameh SJ, Khelfa A, Leonard E, Maroun RG, Louka N, Koubaa M. Valorization of Brewers’ spent grains: pretreatments and fermentation, a review. Fermentation. 2022. https://doi.org/10.3390/fermentation8020050. (MDPI).

Naibaho J, Jonuzi E, Butula N, Korzeniowska M, Yang B. Soy-based yogurt-alternatives enriched with brewers’ spent grain flour and protein hydrolysates: microstructural evaluation and physico-chemical properties during the storage. LWT. 2023. https://doi.org/10.1016/j.lwt.2023.114626.

Celus I, Brijs K, Delcour JA. Enzymatic hydrolysis of Brewers’ spent grain proteins and technofunctional properties of the resulting hydrolysates. J Agric Food Chem. 2007;55(21):8703–10. https://doi.org/10.1021/jf071793c.

Karlsen F, Skov PV. Review – potentials and limitations of utilising brewer’s spent grain as a protein source in aquaculture feeds. J Clean Prod. 2022. https://doi.org/10.1016/j.jclepro.2022.131986. (Elsevier Ltd).

Kaur G, Bhatia S. Radish leaf protein concentrates: optimization of alkaline extraction for production and characterization of an alternative plant protein concentrate. J Food Meas Charact. 2022;16(4):3166–81. https://doi.org/10.1007/s11694-022-01411-4.

Faulds CB, Collins S, Robertson JA, Treimo J, Eijsink VGH, Hinz SWA, Schols HA, Buchert J, Waldron KW. Protease-induced solubilisation of carbohydrates from brewers’ spent grain. J Cereal Sci. 2009;50(3):332–6. https://doi.org/10.1016/j.jcs.2009.01.004.

Viturat S, Thongngam M, Lumdubwong N, Zhou W, Klinkesorn U. Ultrasound-assisted formation of chitosan-glucose Maillard reaction products to fabricate nanoparticles with enhanced antioxidant activity. Ultrason Sonochem. 2023;97:106466. https://doi.org/10.1016/j.ultsonch.2023.106466.

Khatiwada B, Kunwar S, Dhakal A, Joshi A, Miya A, Subedi P. Total phenolic content, antioxidant activity, alpha-amylase inhibitory activity and antibacterial activity of radish seed and rapeseed. Eur J Biotechnol Biosci. 2018;6:21–5.

Chalamaiah M, Yu W, Wu J. Immunomodulatory and anticancer protein hydrolysates (peptides) from food proteins: a review. Food Chem. 2018;245:205–22. https://doi.org/10.1016/j.foodchem.2017.10.087. (Elsevier Ltd).

Gaspar-Pintiliescu A, Oancea A, Cotarlet M, Vasile AM, Bahrim GE, Shaposhnikov S, Craciunescu O, Oprita EI. Angiotensin-converting enzyme inhibition, antioxidant activity and cytotoxicity of bioactive peptides from fermented bovine colostrum. Int J Dairy Technol. 2020;73(1):108–16. https://doi.org/10.1111/1471-0307.12659.

Akmar SL, Ansari M, Berahim Z, Shahidan WNS. Phytochemical compound and non-cytotoxicity effect of sting bee and stingless bee honey against normal human gingival cell lines. Bangladesh J Med Sci. 2022;21(1):158–64. https://doi.org/10.3329/BJMS.V21I1.56343.

Kamiloglu S, Sari G, Ozdal T, Capanoglu E. Guidelines for cell viability assays. Food Front. 2020;1(3):332–49. https://doi.org/10.1002/fft2.44.

Schettino R, Verni M, Acin-Albiac M, Vincentini O, Krona A, Knaapila A, Cagno RD, Gobbetti M, Rizzello CG, Coda R. Bioprocessed Brewers’ spent grain improves nutritional and antioxidant properties of pasta. Antioxidants (Basel). 2021;10(5):742. https://doi.org/10.3390/antiox10050742. (PMID: 34067199; PMCID: PMC8151577).

Szliszka E, Czuba ZP, Domino M, Mazur B, Zydowicz G, Krol W. Ethanolic extract of propolis (EEP) enhances the apoptosis- inducing potential of TRAIL in cancer cells. Molecules. 2009;14(2):738–54. https://doi.org/10.3390/molecules.

Patrignani M, González-Forte del LS. Characterisation of melanoidins derived from Brewers’ spent grain: new insights into their structure and antioxidant activity. Int J Food Sci Technol. 2021;56(1):384–91. https://doi.org/10.1111/ijfs.14653.

Abeynayake R, Zhang S, Yang W, Chen L. Development of antioxidant peptides from brewers’ spent grain proteins. LWT. 2022. https://doi.org/10.1016/j.lwt.2022.113162.

Vogelsang-O’Dwyer M, Sahin AW, Arendt EK, Zannini E. Enzymatic hydrolysis of pulse proteins as a tool to improve techno-functional properties. Foods. 2022;11(9):1307. https://doi.org/10.3390/foods11091307.

Acknowledgements

The Authors would like to acknowledge project ReValue funded by the Welsh Government’s Food Division for providing support in compositional analysis. The work fosters sustainability initiatives undertaken as part of Erasmus+ project NEMOS.

Funding

Open Access funding provided by the IReL Consortium.

Author information

Authors and Affiliations

Contributions

MB, KD and MS: methodology, formal analysis, investigation, data curation, writing—original draft. ASN: conceptualization, investigation, validation, writing—revision and editing, supervision. LG and BG: Cell line assays, data curation and writing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Ethics approval

This study was performed in line with the principles of the Declaration of Helsinki. Approval for cell culture was granted by the Ethics Committee of University of Zaragoza and Technological University Dublin.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Naik, A.S., Brugiere, M., Dunne, K. et al. Protease hydrolysed brewers’ spent grain bioactive extracts for applications in human health. Syst Microbiol and Biomanuf (2024). https://doi.org/10.1007/s43393-024-00241-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43393-024-00241-3