Abstract

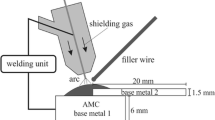

Magnesium- and calcium-aluminosilicate (MAS and CAS, respectively) glass-ceramics containing different amounts of Si3N4 (0, 20, 40, and 60 wt.%) were examined as fillers for alumina joining. After applying filler paste onto the alumina base plate via screen-printing, joining was performed at 1500 °C for 1 h at 12 MPa pressure in a N2 atmosphere. The phase and microstructural evolution in the joint interlayer and the resulting joint strength were analyzed as a function of the Si3N4 content. Both MAS and CAS fillers with up to 40 wt.% Si3N4 wetted the alumina surface after melting, while those with 60 wt.% Si3N4 exhibited incomplete melting. The variation in joint strength was explained by the evolution of phases at the interface and the thermal expansion coefficient mismatch between the filler and alumina base plate. The highest joint strength of 317 ± 39 MPa was obtained for the MAS filler with 40 wt.% Si3N4.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

A.M. Abyzov, N.A. Khristyuk, V.V. Kozlov, F.M. Shakhov, Alumina ceramics doped with manganese titanate via applying Mn–Ti–O coatings to corundum micropowder. J. Korean Ceram. Soc. 57, 692–707 (2020). https://doi.org/10.1007/s43207-020-00076-3

M. Schubert, N. Leupold, J. Exner, J. Kita, R. Moos, High-temperature electrical insulation behavior of alumina films prepared at room temperature by aerosol deposition and influence of annealing process and powder impurities. J. Therm. Spray Technol. 27, 870–879 (2018). https://doi.org/10.1007/s11666-018-0719-x

G. Rani, Photoluminescence characterizations in phase transition alumina with boehmite nanostructures. J. Korean Ceram. Soc. 58, 747–752 (2021). https://doi.org/10.1007/s43207-021-00151-3

H. Miyazaki, M. Hotta, H. Kita, Y. Izutsu, Joining of alumina with a porous alumina interlayer. Ceram. Int. 38, 1149–1155 (2012). https://doi.org/10.1016/j.ceramint.2011.08.043

S. Ghosh, R. Chakraborty, N. Dandapat, K.S. Pal, S. Datta, D. Basu, Characterization of alumina-alumina/graphite/monel superalloy brazed joints. Ceram. Int. 38, 663–670 (2012). https://doi.org/10.1016/j.ceramint.2011.07.054

X. Wang, J. Wang, H. Wang, A heat-resistant organic adhesive for joining Al2O3 ceramics in air and argon atmospheres. J. Manuf. Process. 26, 67–73 (2017). https://doi.org/10.1016/j.jmapro.2017.01.014

W. Zhu, H. Zhang, D. Xue, H. Jiang, X. Ran, Joining alumina ceramic by using glass ceramic filler with high crystallinity for high temperature application. Ceram. Int. 45, 20999–21003 (2019). https://doi.org/10.1016/j.ceramint.2019.06.285

J. Fang, L. Sun, S. Guo, C. Liu, J. Zhang, Study of Li2O addition on crystallization behavior and thermal expansion properties of CaO–Al2O3–SiO2 (CAS) glass-ceramic and its application for joining SiC ceramic. J. Eur. Ceram. Soc. 41, 1817–1827 (2021). https://doi.org/10.1016/j.jeurceramsoc.2020.10.061

M. Herrmann, W. Lippmann, A. Hurtado, Y2O3-Al2O3-SiO2-based glass-ceramic fillers for the laser-supported joining of SiC. J. Eur. Ceram. Soc. 34, 1935–1948 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.01.019

D.H. Yoon, I.E. Reimanis, A review on the joining of SiC for high-temperature applications. J. Korean Ceram. Soc. 57, 246–270 (2020). https://doi.org/10.1007/s43207-020-00021-4

H. Lee, I.G. Kim, T.H. Kim, T.H. Kim, W.J. Chung, Transparent alumino-boro-phosphate glass coating on a thermally tempered soda-lime silicate glass substrate. J. Korean Ceram. Soc. 58, 566–573 (2021). https://doi.org/10.1007/s43207-021-00131-7

K. Geetha, A.M. Umarji, T.R.N. Kutty, Ceramic joining through reactive wetting of alumina with calcium aluminate refractory cements. Bull. Mater. Sci. 23, 243–248 (2000). https://doi.org/10.1007/BF02720077

B. Luo, S. Jiang, W. Zhu, Y. Hu, Y. Qin, X. Tang, Laser joining of Al2O3 liners with Al2O3–MgO–SiO2 glass-ceramic fillers. J. Mater. Process. Technol. 260, 48–56 (2018). https://doi.org/10.1016/j.jmatprotec.2018.05.015

A.P. Tomsia, A.M. Glaeser, J.S. Moya, Interfaces between alumina and refractory glasses for high temperature applications. Key Eng. Mater. 111–112, 191–208 (1995). https://doi.org/10.4028/www.scientific.net/kem.111-112.191

W. Zhu, J. Chen, C. Jiang, C. Hao, J. Zhang, Joining of porous alumina with a CaO-Al2O3-SiO2 glass-ceramic. J. Am. Ceram. Soc. 96, 1738–1744 (2013). https://doi.org/10.1111/jace.12310

L. Esposito, A. Bellosi, Ceramic oxide bonds using calcium aluminosilicate glasses. J. Mater. Sci. 40, 2493–2498 (2005). https://doi.org/10.1007/s10853-005-1981-0

À.R. Garcia, C. Clausell, A. Barba, Oxynitride glasses: a review. Bol. La Soc. Esp. Ceram. Y Vidr. 55, 209–218 (2016). https://doi.org/10.1016/j.bsecv.2016.09.004

S. Hampshire, M.J. Pomeroy, Oxynitride glasses: preparation, properties and implications for mechanical behaviour of silicon nitride. Mater. Sci. Forum. 554, 11–16 (2007). https://doi.org/10.4028/www.scientific.net/msf.554.11

T. Rouxel, Elastic properties and short-to medium-range order in glasses. J. Am. Ceram. Soc. 90, 3019–3039 (2007). https://doi.org/10.1111/j.1551-2916.2007.01945.x

G. Wang, Y. Shan, J. Xu, Y. Chen, J. Xu, J. Li, Joining of AlON ceramics by using β-SiAlON/Y-Si-Al-O-N glass-ceramic as interlayer. J. Non. Cryst. Solids. 503–504, 389–396 (2019). https://doi.org/10.1016/j.jnoncrysol.2018.10.027

H. Liang, H. Guo, J. Yin, K. Zuo, Y. Xia, D. Yao, J. Zhang, Y. Zeng, S. Wang, The application of Lu-Al-Si-O-N oxynitride glass in transparent AlON ceramics joining. Ceram. Int. 45, 2591–2595 (2019). https://doi.org/10.1016/j.ceramint.2018.10.193

H. Liang, K. Zuo, Y. Xia, D. Yao, J. Yin, Y. Zeng, Joining of dense Si3N4 ceramics with tape cast Lu-Al-Si-O-N interlayer. Ceram. Int. 44, 4824–4828 (2018). https://doi.org/10.1016/j.ceramint.2017.12.070

L. Li, C. Liu, L. Sun, H. Yu, X. Wang, X. Wang, J. Zhang, Joining of Si3N4/Si3N4 with in-situ formed Si-Al-Yb oxynitride glasses interlayer. Ceram. Int. 44, 7831–7836 (2018). https://doi.org/10.1016/j.ceramint.2018.01.217

P.A. Walls, M. Ueki, Joining SiAlON ceramics using composite β-SiAlON–glass adhesives. J. Am. Ceram. Soc. 75, 2491–2497 (1992). https://doi.org/10.1111/j.1151-2916.1992.tb05602.x

M. Salman, H.-M. Bae, D.-H. Yoon, Joining of alumina using magnesium- or calcium-aluminosilicate glass–ceramic fillers. Ceram. Int. 48, 21532–21542 (2022). https://doi.org/10.1016/j.ceramint.2022.04.122

T. Ekström, M. Nygren, SiAlON ceramics. J. Am. Ceram. Soc. 75, 259–276 (1992). https://doi.org/10.1111/j.1151-2916.1992.tb08175.x

V.K. Sarin, On the α-to-β phase transformation in silicon nitride. Mater. Sci. Eng. 105–106, 151–159 (1988). https://doi.org/10.1016/0025-5416(88)90491-0

Y. Oyama, O. Kamigaito, Solid solubility of some oxides in Si3N4. Jpn. J. Appl. Phys. 10, 1637 (1971). https://doi.org/10.1143/JJAP.10.1637

X. Liu, D. Qu, X. Luo, Y. Guo, Y. Cui, The effects of β-Si3N4 on the formation and oxidation of β-SiAlON. High Temp. Mater. Process. 39, 247–255 (2020). https://doi.org/10.1515/htmp-2020-0057

S.R. Kushan Akin, C.B. Garcia, T.J. Webster, A comparative study of silicon nitride and SiAlON ceramics against E. coli. Ceram. Int. 47, 1837–1843 (2021). https://doi.org/10.1016/j.ceramint.2020.09.012

M.J. Pomeroy, S. Hampshire, Controlled crystallisation of a Y-Si-Al-O-N glass typical of grain boundary glasses formed in silicon nitride-based ceramics. Key Eng. Mater. 403, 91–94 (2008). https://doi.org/10.4028/www.scientific.net/kem.403.91

A.A.M. El-Amir, A.A. El-Maddah, E.M.M. Ewais, S.M. El-Sheikh, I.M.I. Bayoumi, Y.M.Z. Ahmed, Sialon from synthesis to applications: an overview. J. Asian Ceram. Soc. 9, 1390–1418 (2021). https://doi.org/10.1080/21870764.2021.1987613

T. Hayashi, T.Y. Tien, Formation and crystallization of oxynitride glasses in the system Si, Al, Mg/O. N. J. Ceram. Assoc. Jpn. 94, 54–62 (1986). https://doi.org/10.2109/jcersj1950.94.54

S. Sakka, K. Kamiya, T. Yoko, Preparation and properties of Ca–Al–Si–O–N oxynitride glasses. J. Non. Cryst. Solids 56, 147–152 (1983). https://doi.org/10.1016/0022-3093(83)90460-X

Acknowledgements

This study was supported by the Basic Science Research Program funded by the Korea Ministry of Education (NRF-2018R1D1A1B07043343) and the Technology Innovation Program (20012911) funded by the Korean Ministry of Trade, Industry and Energy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Salman, M., Ryu, SS. & Yoon, DH. Alumina joining using magnesium- or calcium-aluminosilicate glass-ceramic filler comprising Si3N4. J. Korean Ceram. Soc. 60, 560–568 (2023). https://doi.org/10.1007/s43207-023-00285-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-023-00285-6