Abstract

Waste and recyled materials have been introduced in asphalt concrete mixtures as substitute for raw aggregates along with the efforts towards constructing sustainable pavements. Municipal solid waste incinerated (MSWI) fly ash is among the alternative materials that can be be used as substitute for the natural mineral filler. However, the effect of using (MSWI) fly ash on the mechanical properties of bituminous mixtures is fragmented and not thoroughly evluated. Additionally, various studies assessed the performance of asphalt mixtures with (MSWI) fly ash as filler replacement in terms of indirect tensile strength, moisture susceptibility, frost resistance and Marshall stability. Therefore, there is a need for the evaluation and realistic prediction of the performance of asphalt concrete mixtures with (MSWI) fly ash used as filler substitution. The objective of this research study is characterising asphalt concrete mixtures with (MSWI) fly ash used as subtitute for the limestone filler, notably 0%, 25%, 50%, 75% and 100% by weight of aggregates and evaluating their performance in comparison with the control mix. This is conducted mechanistically through linear viscoelastic characterisation. Linear viscoelastic characterisation comprises measurement of the stiffness of the mixture expressed in terms of dynamic modulus and the extent of elastic and viscous response expressed in terms of phase angle. The findings revealed that the use of (MSWI) fly ash in asphalt concrete mixtures as filler substitution increased the rutting resistance up to 50% of incorporation and the resistance to low temperature cracking when incorporated in percentages higher than 25%.

Similar content being viewed by others

References

Oshone, M., Dave, E., Daniel, J. S., & Rowe, G. M. (2017). Prediction of phase angles from dynamic modulus data and implications for cracking performance evaluation. Road Materials and Pavement Design, 18(sup4), 491–513. https://doi.org/10.1080/14680629.2017.1389086

Heukelom, W., & Klomp, A. J. G. (1964). Road design and dynamic loading. Journal of Association of Asphalt Paving Technologists, 33, 92–125.

Van der Poel, C. (1955). Time and temperature effects on the deformation of asphaltic bitumens and bitumen-mineral mixtures. Society of Petroleum Engineers Journal, 11, 47–53.

Nemati, R., & Dave, E. V. (2018). Nominal property based predictive models for asphalt mixture complex modulus (dynamic modulus and phase angle). Construction and Building Materials, 158, 308–319. https://doi.org/10.1016/j.conbuildmat.2017.09.144

Naik, A. K., & Biligiri, K. P. (2015). Predictive models to estimate phase angle of asphalt mixtures. Journal of Materials in Civil Engineering, 27(8), 04014235. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001197

Loulizi, A., Flintsch, G. W., Al-Qadi, I. L., & Mokarem, D. (2006). Comparing resilient modulus and dynamic modulus of hot-mix asphalt as material properties for flexible pavement design. Transportation Research Record, 1970(1), 161–170. https://doi.org/10.1177/0361198106197000117

Witczak, M. W. (2005). Simple performance tests: Summary of recommended methods and database. Transportation Research Board. https://doi.org/10.17226/13949

Chehab, G. R. (2002). Characterization of asphalt concrete in tension using a viscoelastoplastic model. In Asphalt paving technology: Association of asphalt paving technologists—Proceedings of the technical sessions (Vol. 72, pp. 315–355)

Mensching, D. J., Rowe, G. M., & Sias Daniel, J. (2017). A mixture-based black space parameter for low-temperature performance of hot mix asphalt. Road Materials and Pavement Design, 18(sup1), 404–425. https://doi.org/10.1080/14680629.2016.1266770

Bi, Y., Guo, F., Zhang, J., Pei, J., & Li, R. (2021). Correlation analysis between asphalt binder/asphalt mastic properties and dynamic modulus of asphalt mixture. Construction and Building Materials, 276, 122256. https://doi.org/10.1016/j.conbuildmat.2021.122256

Amirkhanian, A. N., Xiao, F., & Amirkhanian, S. N. (2011). Evaluation of high temperature rheological characteristics of asphalt binder with carbon nano particles. Journal of Testing and Evaluation, 39(4), 1. https://doi.org/10.1520/JTE103133

Ghuzlan, K. A., & Al Assi, M. O. (2017). Sasobit-modified asphalt binder rheology. Journal of Materials in Civil Engineering, 29(9), 04017142. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001996

Ghuzlan, K. A., Al-Khateeb, G. G., & Qasem, Y. (2013). Rheological properties of polyethylene-modified asphalt binder. Athens Journal of Technology and Engineering, 10, 1–14.

Migliori, F., Pastor, M., & Ramond, G. (1993). Etude statistique de quelques cas de fissurations thermiques. In Proceedings of the fifth eurobitumen congress, Stockholm, Sweden (pp. 16–18)

Button, J. W., Hastings, C. P., Little, D. N. (1996). Effects of asphalt additives on pavement performance. Report no. FHWA/TX-97/187-26, Texas Transportation Institute

Luo, R., & Lytton, R. L. (2010). Characterization of the tensile viscoelastic properties of an undamaged asphalt mixture. Journal of Transportation Engineering, 136(3), 173–180. https://doi.org/10.1061/(ASCE)TE.1943-5436.0000083

Zhang, Y., Luo, R., & Lytton, R. L. (2012). Anisotropic viscoelastic properties of undamaged asphalt mixtures. Journal of Transportation Engineering, 138(1), 75–89. https://doi.org/10.1061/(ASCE)TE.1943-5436.0000302

Pouranian, M. R., Rahbar-Rastegar, R., & Haddock, J. E. (2019). Development of a soybean-based rejuvenator for asphalt mixtures containing high reclaimed asphalt pavement content. In International symposium on asphalt pavement & environment (pp. 264–273). Springer, Cham. https://doi.org/10.1007/978-3-030-29779-4_26

Weldegiorgis, M. T., & Tarefder, R. A. (2015). Towards a mechanistic understanding of moisture damage in asphalt concrete. Journal of Materials in Civil Engineering, 27(3), 04014128. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001062

Modarres, A., & Rahmanzadeh, M. (2014). Application of coal waste powder as filler in hot mix asphalt. Construction and Building Materials, 66, 476–483. https://doi.org/10.1016/j.conbuildmat.2014.06.002

ASTM D242. (2019). Standard specification for mineral filler for asphalt mixtures.

European Standard EN 12620. (2013). Aggregates for concrete. European Committee for Standardization, ICS 91.100.15; 91.100.30.

Tenza-Abril, A. J., Saval, J. M., & Cuenca, A. (2015). Using sewage-sludge ash as filler in bituminous mixes. Journal of Materials in Civil Engineering, 27(4), 04014141. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001087

Muniandy, R., Aburkaba, E., & Taha, R. (2013). Effect of mineral filler type and particle size on the engineering properties of stone mastic asphalt pavements. The Journal of Engineering Research, 10(2), 13–32. https://doi.org/10.24200/tjer.vol10iss2pp13-32

Diab, A., & Enieb, M. (2018). Investigating influence of mineral filler at asphalt mixture and mastic scales. International Journal of Pavement Research and Technology, 11(3), 213–224.

Woszuk, A., Wróbel, M., Bandura, L., & Franus, W. (2020). Brick debris dust as an ecological filler and its effect on the durability of asphalt mix. Materials, 13(21), 5023. https://doi.org/10.3390/ma13215023

Yan, K., Li, L., & Ge, D. (2019). Research on properties of bitumen mortar containing municipal solid waste incineration fly ash. Construction and Building Materials, 218, 657–666. https://doi.org/10.1016/j.conbuildmat.2019.05.151〹

Woszuk, A., Wróbel, M., & Franus, W. (2019). Application of zeolite tuffs as mineral filler in warm mix asphalt. Materials, 13(1), 19. https://doi.org/10.3390/ma13010019

Nciri, N., Shin, T., Lee, H., & Cho, N. (2018). Potential of waste oyster shells as a novel biofiller for hot-mix asphalt. Applied Sciences, 8(3), 415. https://doi.org/10.3390/app8030415

Buttlar, W. G., Bozkurt, D., Al-Khateeb, G. G., & Waldhoff, A. S. (1999). Understanding asphalt mastic behavior through micromechanics. Transportation Research Record, 1681(1), 157–169. https://doi.org/10.3141/1681-19

Bahia, H. U., Faheem, A., Hintz, C., Al-Qadi, I., Reinke, G., Dukatz, E. (2011). Test methods and specification criteria for mineral filler used in HMA. NCHRP Research Results Digest, 357, Transportation Research Board, Washington, DC. https://doi.org/10.17226/22871

Likitlersuang, S., & Chompoorat, T. (2016). Laboratory investigation of the performances of cement and fly ash modified asphalt concrete mixtures. International Journal of Pavement Research and Technology, 9(5), 337–344.

Zulkati, A., Diew, W. Y., & Delai, D. S. (2012). Effects of fillers on properties of asphalt-concrete mixture. Journal of transportation engineering, 138(7), 902–910. https://doi.org/10.1061/(ASCE)TE.1943-5436.0000395

Lesueur, D. (2009). The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Advances in colloid and interface science, 145(1–2), 42–82. https://doi.org/10.1016/j.cis.2008.08.011

Khedaywi, T., Al Kofahi, N., & Al-Zoubi, M. (2020). Effect of olive waste ash on properties of asphalt cement and asphalt concrete mixtures. International Journal of Pavement Research and Technology, 13(3), 276–285.

Khedaywi, T., & Khaled, F. (2021). Effect of waste oil shale ash on properties of asphalt cement and asphalt concrete mixtures: State of the art. International Journal of Pavement Research and Technology, 15, 111–123. https://doi.org/10.1007/s42947-021-00002-8.

Woszuk, A., Bandura, L., & Franus, W. (2019). Fly ash as low cost and environmentally friendly filler and its effect on the properties of mix asphalt. Journal of Cleaner Production, 235, 493–502. https://doi.org/10.1016/j.jclepro.2019.06.353

Hassanieh, D. Z. A., Chehab, G. R., Srour, I., & Kassem, H. A. (2016). Recycling cementitious constituents of construction demolition waste in asphalt mixes: The case of Lebanon. International Journal of Sustainable Society, 8(2), 109–125. https://doi.org/10.1504/IJSSOC.2016.077513

Kadhim, M. A., Al-Busaltan, S., & Almuhanna, R. R. (2019). An evaluation of the effect of crushed waste glass on the performance of cold bituminous emulsion mixtures. International Journal of Pavement Research and Technology, 12(4), 396–406.

Eisa, M. S., Basiouny, M. E., & Daloob, M. I. (2021). Effect of adding glass fiber on the properties of asphalt mix. International Journal of Pavement Research and Technology, 14(4), 403–409.

Al-Hdabi, A. (2016). Laboratory investigation on the properties of asphalt concrete mixture with Rice Husk Ash as filler. Construction and Building Materials, 126, 544–551. https://doi.org/10.1016/j.conbuildmat.2016.09.070

Ahsan, M. B., & Hossain, Z. (2018). Effect of particle size of rice husk ash (RHA) in mitigating alkali silica reaction (ASR) in concrete pavement. International Journal of Pavement Research and Technology, 11, 861–866.

Arabani, M., & Mirabdolazimi, S. M. (2011). Experimental investigation of the fatigue behaviour of asphalt concrete mixtures containing waste iron powder. Materials Science and Engineering: A, 528(10–11), 3866–3870. https://doi.org/10.1016/j.msea.2011.01.099

Yilmaz, M., Kök, B. V., & Kuloğlu, N. (2011). Effects of using asphaltite as filler on mechanical properties of hot mix asphalt. Construction and Building Materials, 25(11), 4279–4286. https://doi.org/10.1016/j.conbuildmat.2011.04.072

Saad, M., Baalbaki, O., Khatib, J., El Kordi, A., & Masri, A. (2019). Manufacturing of lightweight aggregates from municipal solid waste incineration bottom ash and their impacts on concrete properties. In Proceedings of the 2nd international congress on engineering and architecture, Marmaris, Turkey (pp. 22–24)

Xu, G., & Shi, X. (2018). Characteristics and applications of fly ash as a sustainable construction material: A state-of-the-art review. Resources, Conservation and Recycling, 136, 95–109. https://doi.org/10.1016/j.resconrec.2018.04.010

Abukhettala, M. (2016). Use of recycled materials in road construction. In Proceedings of the 2nd international conference on civil, structural and transportation engineering, Ottawa, Canada (pp. 138-1)

De Rezende, L. R., Marques, M. O., & da Cunha, N. L. (2015). The use of non-conventional materials in asphalt pavements base. Road Materials and Pavement Design, 16(4), 799–814. https://doi.org/10.1080/14680629.2015.1055334

El-Assaly, A., & Ellis, R. (2001). Evaluation of recycling waste materials and by-products in highway construction. The International Journal of Sustainable Development & World Ecology, 8(4), 299–308. https://doi.org/10.1080/13504500109470088

Saride, S., Puppala, A. J., & Williammee, R. (2010). Civil engineers ground improvement 163 February 2010 Issue GI1. sta, 717(715), 00

Lee, S. T. (2009). Influence of recycled fine aggregates on the resistance of mortars to magnesium sulfate attack. Waste Management, 29(8), 2385–2391. https://doi.org/10.1016/j.wasman.2009.04.002

Li, X. (2008). Recycling and reuse of waste concrete in China: Part I. Material behaviour of recycled aggregate concrete. Resources, Conservation and Recycling, 53(1–2), 36–44. https://doi.org/10.1016/j.resconrec.2008.09.006

Sargın, Ş, Saltan, M., Morova, N., Serin, S., & Terzi, S. (2013). Evaluation of rice husk ash as filler in hot mix asphalt concrete. Construction and Building Materials, 48, 390–397. https://doi.org/10.1016/j.conbuildmat.2013.06.029

Simone, A., Mazzotta, F., Eskandarsefat, S., Sangiorgi, C., Vignali, V., Lantieri, C., & Dondi, G. (2019). Experimental application of waste glass powder filler in recycled dense-graded asphalt mixtures. Road Materials and Pavement Design, 20(3), 592–607. https://doi.org/10.1080/14680629.2017.1407818

Arabani, M., Tahami, S. A., & Taghipoor, M. (2016). Laboratory investigation of hot mix asphalt containing waste materials. Road Materials and Pavement Design, 18(3), 713–729. https://doi.org/10.1080/14680629.2016.1189349

Tuncan, M., Tuncan, A., & Cetin, A. (2003). The use of waste materials in asphalt concrete mixtures. Waste Management & Research, 21(2), 83–92. https://doi.org/10.1177/0734242X0302100202

Mistry, R., & Roy, T. K. (2016). Effect of using fly ash as alternative filler in hot mix asphalt. Perspectives in Science, 8, 307–309. https://doi.org/10.1016/j.pisc.2016.04.061

Asi, I., & Assa’ad, A. (2005). Effect of Jordanian oil shale fly ash on asphalt mixes. Journal of Materials in Civil Engineering, 17(5), 553–559. https://doi.org/10.1061/(ASCE)0899-1561(2005)17:5(553)

Tapkın, S. (2008). Mechanical evaluation of asphalt–aggregate mixtures prepared with fly ash as a filler replacement. Canadian Journal of Civil Engineering, 35(1), 27–40. https://doi.org/10.1139/L07-082

Gedafa, B., & Suleiman. N. (2018). Investigating the use of fly ash for sustainable asphalt pavements. Project proposal. University of North Dakota. Bismarck, India

Romeo, E., Mantovani, L., Tribaudino, M., & Montepara, A. (2018). Reuse of stabilized municipal solid waste incinerator fly ash in asphalt mixtures. Journal of Materials in Civil Engineering, 30(8), 04018157. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002347

Churchill, E. V., & Amirkhanian, S. N. (1999). Coal ash utilization in asphalt concrete mixtures. Journal of Materials in Civil Engineering, 11(4), 295–301. https://doi.org/10.1061/%28ASCE%290899-1561%281999%2911%3A4%28295%29

Ali, N., Chan, J. S., Simms, S., Bushman, R., & Bergan, A. T. (1996). Mechanistic evaluation of fly ash asphalt concrete mixtures. Journal of Materials in Civil Engineering, 8(1), 19–25. https://doi.org/10.1061/(asce)0899-1561(1996)8:1(19)

AASHTO M 323. (2017). Standard specification for superpave volumetric mix design

Superpave. (1996). "Superpave mix design." Asphalt Institute, Lexington, KY Superpave Series No. 2 (SP-2)

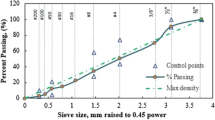

Vavrik, W. R., Huber G., Pine, W. J., Carpenter, S. H., & Bailey, R. (2002). Bailey method for gradation selection in hot-mix asphalt mixture design. Transportation Research E-Circular, Transportation Research Board, Washington D.C., No. E-C044.

Baalbaki, O., Elkordi, A., Ghanem, H., Machaka, M., & Khatib, J. M. (2019). Properties of concrete made of fine aggregates partially replaced by incinerated municipal solid waste bottom ash. Academic Journal of Civil Engineering, 37(2), 532–538. https://doi.org/10.26168/icbbm2019.77

Charbaji, M., Baalbaki, O., Elkordi, A., & Khatib, J. (2018). Processing of incinerated municipal solid waste fly ash for use in concrete. International Journal of Civil Engineering and Technology (IJCIET), 9(13), 1853–1864.

Charbaji, M., Baalbaki, O., Khatib, J. M., & Elkordi, A. (2018). Characterization of fly ash originated from lebanese municipal solid waste plant. In International congress on engineering and architecture, Turkey (pp. 1565–1576).

Benassi, L., Pasquali, M., Zanoletti, A., Dalipi, R., Borgese, L., Depero, L. E., Vassura, I., Quina, M. J., & Bontempi, E. (2016). Chemical stabilization of municipal solid waste incineration fly ash without any commercial chemicals: First pilot-plant scaling up. ACS Sustainable Chemistry & Engineering, 4(10), 5561–5569. https://doi.org/10.1021/acssuschemeng.6b01294

Huang, W. J., & Lo, J. S. (2004). Synthesis and efficiency of a new chemical fixation agent for stabilizing MSWI fly ash. Journal of Hazardous Materials, 112(1–2), 79–86. https://doi.org/10.1016/j.jhazmat.2004.04.006

Lu, Y., Tian, A., Zhang, J., Tang, Y., Shi, P., Tang, Q., & Huang, Y. (2020). Physical and Chemical properties, pretreatment, and recycling of municipal solid waste incineration fly ash and bottom ash for highway engineering: A literature review. Advances in Civil Engineering. https://doi.org/10.1155/2020/8886134

Zhu, Y., Zhao, Y., Zhao, C., & Gupta, R. (2020). Physicochemical characterization and heavy metals leaching potential of municipal solid waste incinerated bottom ash (MSWI-BA) when utilized in road construction. Environmental Science and Pollution Research, 27(12), 14184–14197. https://doi.org/10.1007/s11356-020-08007-9

Ren, X., & Sancaktar, E. (2019). Use of fly ash as eco-friendly filler in synthetic rubber for tire applications. Journal of cleaner production, 206, 374–382. https://doi.org/10.1016/j.jclepro.2018.09.202

Mirković, K., Tošić, N., & Mladenović, G. (2019). Effect of different types of fly ash on properties of asphalt mixtures. Advances in Civil Engineering. https://doi.org/10.1155/2019/8107264

ASTM C618. (2015). Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. West Conshohocken: Author

Rao, C., Stehly, R. D., & Ardani, A. (2011). Proportioning fly ash as cementitious material in airfield pavement concrete mixtures. Mix Optimization Catalog for Project IPRF-01-G-002-06-2. https://doi.org/10.13140/RG.2.1.2776.3363

Lesueur, D., Teixeira, A., Lázaro, M. M., Andaluz, D., & Ruiz, A. (2016). A simple test method in order to assess the effect of mineral fillers on bitumen ageing. Construction and Building Materials, 117, 182–189. https://doi.org/10.1016/j.conbuildmat.2016.05.003

Bautista, E. G., Flickinger, J., Saha, R., Flores-Vivian, I., Faheem, A. F., & Sobolev, K. (2015). Effect of coal combustion products on high temperature performance of asphalt mastics. Construction and Building Materials, 94, 572–578. https://doi.org/10.1016/j.conbuildmat.2015.07.022

Sharma, V., Chandra, S., & Choudhary, R. (2010). Characterization of fly ash bituminous concrete mixes. Journal of Materials in Civil Engineering, 22(12), 1209–1216. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000125

Dulaimi, A., Nageim, H. A., Ruddock, F., & Seton, L. (2017). Performance analysis of a cold asphalt concrete binder course containing high-calcium fly ash utilizing waste material. Journal of Materials in Civil Engineering, 29(7), 04017048. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001883

Bonaquist, R. (2011). Mix design practices for warm mix asphalt. NCHRP report 691.

Woszuk, A., & Franus, W. (2016). Properties of the warm mix asphalt involving clinoptilolite and Na-P1 zeolite additives. Construction and Building Materials, 114, 556–563. https://doi.org/10.1016/j.conbuildmat.2016.03.188

Airey, G. D., & Collop, A. C. (2016). Mechanical and structural assessment of laboratory-and field-compacted asphalt mixtures. International Journal of Pavement Engineering, 17(1), 50–63. https://doi.org/10.1080/10298436.2014.925551

Mallick, R. B. (1999). Use of superpave gyratory compactor to characterize hot-mix asphalt. Transportation Research Record, 1681(1), 86–96. https://doi.org/10.3141/1681-11

Tao, M., & Mallick, R. B. (2009). Effects of warm-mix asphalt additives on workability and mechanical properties of reclaimed asphalt pavement material. Transportation Research Record, 2126(1), 151–160. https://doi.org/10.3141/2126-18

Chomicz-Kowalska, A., Gardziejczyk, W., & Iwański, M. M. (2016). Moisture resistance and compactibility of asphalt concrete produced in half-warm mix asphalt technology with foamed bitumen. Construction and Building Materials, 126, 108–118. https://doi.org/10.1016/j.conbuildmat.2016.09.004

Flores, G., Gallego, J., Miranda, L., & Marcobal, J. R. (2021). Influence of the compaction method in the volumetric design of cold recycled mixtures with emulsion. Materials, 14(5), 1309. https://doi.org/10.3390/ma14051309

Wróbel, M., Woszuk, A., & Franus, W. (2020). Laboratory methods for assessing the influence of improper asphalt mix compaction on its performance. Materials, 13(11), 2476. https://doi.org/10.3390/ma13112476

Tapkın, S., & Keskin, M. (2013). Rutting analysis of 100 mm diameter polypropylene modified asphalt specimens using gyratory and Marshall compactors. Materials Research, 16(2), 546–564. https://doi.org/10.1590/S1516-14392013005000016

Carlberg, M., Eng, P., & Richardson, N. (2003). Comparison of Marshall and Superpave gyratory volumetric properties of saskatchewan asphalt concrete mixes. Superpave Implementation and Experience in Canada, 5

AASHTO T 342. (2019). Standard method of test for determining the dynamic modulus of hot mix asphalt (HMA).

Bonaquist, R. F., Christensen, D. W., & Stump, W. (2003). Simple performance tester for Superpave mix design: First-article development and evaluation. Transportation Research Board, 513. https://doi.org/10.17226/21954

Rahman, A. S. M. A., & Tarefder, R. A. (2016). Dynamic modulus and phase angle of warm-mix versus hot-mix asphalt concrete. Construction and Building Materials, 126, 434–441. https://doi.org/10.1016/j.conbuildmat.2016.09.068

Booij, H. C., & Thoone, G. P. J. M. (1982). Generalization of Kramers-Kronig transforms and some approximations of relations between viscoelastic quantities. Rheologica Acta, 21(1), 15–24.

Yang, X., & You, Z. (2015). New predictive equations for dynamic modulus and phase angle using a nonlinear least-squares regression model. Journal of Materials in Civil Engineering, 27(3), 04014131. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001070

Hassan, H. F., & Al-Shamsi, K. (2010). Characterisation of asphalt mixes containing MSW ash using the dynamic modulus |E*| test. International Journal of Pavement Engineering, 11(6), 575–582. https://doi.org/10.1080/10298436.2010.501865

Yinfei, D., Ling, X., Haibin, D., Deyi, D., Hao, W., & Weidong, L. (2020). Evaluation of thermal behavior and high-temperature performances of asphalt mixture containing fly ash cenosphere. Construction and Building Materials, 245, 118429. https://doi.org/10.1016/j.conbuildmat.2020.118429

Wang, H., Al-Qadi, I. L., Faheem, A. F., Bahia, H. U., Yang, S. H., & Reinke, G. H. (2011). Effect of mineral filler characteristics on asphalt mastic and mixture rutting potential. Transportation Research Record, 2208(1), 33–39. https://doi.org/10.3141/2208-05

Williams, M. L., Landel, R. F., & Ferry, J. D. (1955). The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. Journal of the American Chemical society, 77(14), 3701–3707. https://doi.org/10.1021/ja01619a008

Pellinen, T. K., & Matthew, W. W. (2002). Use of stiffness of hot-mix asphalt as a simple performance test. Transportation Research Record: Journal of the Transportation Research Board, 1789, 80–90. https://doi.org/10.3141/1789-09

Kassem, H. A., Najjar, S. S., & Chehab, G. R. (2016). Probabilistic modeling of the inherent variability in the dynamic modulus master curve of asphalt concrete. Transportation Research Record, 2576(1), 60–71. https://doi.org/10.3141/2576-07

Wu, S. P., Li, B., Qiu, J., & Li, N. (2007). Effects of conductive fillers on the dynamic response and fatigue life of conductive asphalt concrete. In J. Alfaiate, M. H. Aliabadi, M. Guagliano, L. Susmel (Eds.), Key engineering materials (Vol. 348, pp. 145–148). Trans Tech Publications Ltd.

Acknowledgements

The statements made herein are solely the responsibility of the authors.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

About this article

Cite this article

Joumblat, R., Al Basiouni Al Masri, Z. & Elkordi, A. Dynamic Modulus and Phase Angle of Asphalt Concrete Mixtures Containing Municipal Solid Waste Incinerated Fly Ash as Mineral Filler Substitution. Int. J. Pavement Res. Technol. 16, 1196–1216 (2023). https://doi.org/10.1007/s42947-022-00190-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-022-00190-x