Abstract

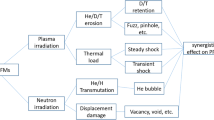

Tungsten (W) as plasma facing material (PFM) needs to face an unprecedented harsh environment in the fusion reactor, which puts forward high requirements for its radiation tolerance. Among the many challenges, the rapid accumulation of helium (He) atoms to form numerous bubbles or even “fuzzy” nanostructure leads to swelling and embrittlement of W matrix and seriously shorten its service life, which is one of the most serious problems faced by PFM-W at present. In this review, we summarize the recent works on the nanochannel W films with high surface-to-volume ratio deposited by magnetron sputtering, and the behaviors of He in the nanochannel W films at different fusion-related irradiation environment. Experimental and simulation results showed that the nanochannel W films have better radiation tolerance performance in managing He behaviors than that of commercial bulk W.

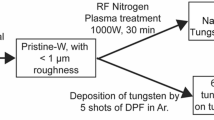

Reproduced with permission from Ref. [27]. Copyright 2018 Elsevier

Reproduced with permission from Ref. [34]. Copyright 2019 Elsevier

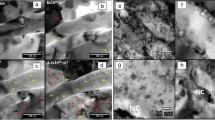

Reproduced with permission from Ref. [34]. Copyright 2019 Elsevier

Reproduced with permission from Ref. [39]. Copyright 2018 Institute of Physics (IOP)

Reproduced from the Ref. [27]. Copyright 2018 Elsevier

Reproduced with permission from Ref. [46]. Copyright 2019 IOP

Reproduced with permission from Ref. [46]. Copyright 2019 IOP

Reproduced with permission from Ref. [47]. Copyright 2020 Elsevier

Reproduced with permission from Ref. [27]. Copyright 2018 Elsevier

Similar content being viewed by others

References

Knaster J, Moeslang A, Muroga T. Materials research for fusion. Nat Phys. 2016;12(5):424.

Abernethy RG. Predicting the performance of tungsten in a fusion environment: a literature review. Mater Sci Technol. 2016;33(4):388.

Hosemann P, Frazer D, Fratoni M, Bolind A, Ashby MF. Materials selection for nuclear applications: Challenges and opportunities. Scri Mater. 2018;143:181.

El-Atwani O, Gigax J, Chancey M, Baldwin JKS, Maloy SA. Nanomechanical properties of pristine and heavy ion irradiated nanocrystalline tungsten. Scr Mater. 2019;166:159.

Zou Y, Maiti S, Steurer W, Spolenak R. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 2014;65:85.

Xin SW, Shen X, Du CC, Zhao J, Sun BR, Xue HX, Yang TT, Cai XC, Shen TD. Bulk nanocrystalline boron-doped VNbMoTaW high entropy alloys with ultrahigh strength, hardness, and resistivity. J Alloy Compd. 2021;853:155995.

Zhang M, Zhou X, Yu X, Li J. Synthesis and characterization of refractory TiZrNbWMo high-entropy alloy coating by laser cladding. Surf Coat Technol. 2017;311:321.

Bai XM, Voter AF, Hoagland RG, Nastasi M, Uberuaga BP. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science. 2010;327(5973):1631.

El-Atwani O, Hattar K, Hinks JA, Greaves G, Harilal SS, Hassanein A. Helium bubble formation in ultrafine and nanocrystalline tungsten under different extreme conditions. J Nucl Mater. 2015;458:216.

El-Atwani O, Hinks JA, Greaves G, Allain JP, Maloy SA. Grain size threshold for enhanced irradiation resistance in nanocrystalline and ultrafine tungsten. Mater Res Lett. 2017;5(5):343.

Chen Z, Niu LL, Wang Z, Tian L, Kecskes L, Zhu K, Wei Q. A comparative study on the in situ helium irradiation behavior of tungsten: coarse grain vs. nanocrystalline grain. Acta Materialia. 2018;147:100.

Wang J, Li C, Yuan Y, Greuner H, Cheng L, Lu GH. Surface modification of W–V alloy exposed to high heat flux helium neutral beams. Nucl Fusion. 2018;58(9):096001.

Huang B, Chen LQ, Qiu WB, Yang XL, Shi K, Lian YY, Liu X, Tang J. Correlation between the microstructure, mechanical/thermal properties, and thermal shock resistance of K-doped tungsten alloys. J Nucl Mater. 2019;520:6.

Xu Q, Ding XY, Luo LM, Miyamoto M, Tokitani M, Zhang J, Wu YC. D-2 retention and microstructural evolution during He irradiation in candidate plasma facing material W-La2O3 alloy. J Nucl Mater. 2017;496:227.

Xu Q, Ding XY, Luo LM, Miyamoto M, Tokitani M, Zhang J, Wu YC. Thermal stability and evolution of microstructures induced by He irradiation in W-TiC alloys. Nucl Mater Energy. 2018;15:76

Dong L, Zhang H, Amekura H, Ren F, Chettah A, Hong M, Qin W, Tang J, Hu L, Wang H, Jiang C. Period-thickness dependent responses of Cu/W multilayered nanofilms to ions irradiation under different ion energies. J Nucl Mater. 2017;497:117.

Wang H, Gao Y, Fu E, Yang T, Xue J, Yan S, Chu PK, Wang Y. Irradiation effects on multilayered W/ZrO2 film under 4MeV Au ions. J Nucl Mater. 2014;455(1–3):86.

Chen F, Tang X, Huang H, Liu J, Li H, Qiu Y, Chen D. Surface damage and mechanical properties degradation of Cr/W multilayer films irradiated by Xe20+. App Surf Sci. 2015;357, Part A:1225.

Beyerlein IJ, Caro A, Demkowicz MJ, Mara NA, Misra A, Uberuaga BP. Radiation damage tolerant nanomaterials. Mater Today. 2013;16(11):443.

Ghalehbandi SM, Malaki M, Gupta M. Accumulative roll bonding—a review. Appl Sci. 2019;9(17):3627.

Zhang X, Hattar K, Chen Y, Shao L, Li J, Sun C, Yu K, Li N, Taheri ML, Wang H, Wang J, Nastasi M. Radiation damage in nanostructured materials. Prog Mater Sci. 2018;96:217.

Bringa EM, Monk JD, Caro A, Misra A, Zepeda-Ruiz L, Duchaineau M, Abraham F, Nastasi M, Picraux ST, Wang YQ, Farkas D. Are nanoporous materials radiation resistant? Nano Lett. 2012;12(7):3351.

Li J, Wang H, Zhang X. A review on the radiation response of nanoporous metallic materials. JOM. 2018;70(11):2753.

Lian Y, Liu X, Cheng Z, Wang J, Song J, Yu Y, Chen J. Thermal shock performance of CVD tungsten coating at elevated temperatures. J Nucl Mater. 2014;455(1–3):371.

Lian Y, Liu X, Wang J, Feng F, Lv Y, Song J, Chen J. Influence of surface morphology and microstructure on performance of CVD tungsten coating under fusion transient thermal loads. Appl Surf Sci. 2016;390:167.

Lian Y, Liu X, Xu ZY, Song JP, Yu Y. Preparation and properties of CVD-W coated W/Cu FGM mock-ups. Fusion Eng Des. 2013;88(9–10):1694.

Qin W, Ren F, Doerner RP, Wei G, Lv Y, Chang S, Tang M, Deng H, Jiang C, Wang Y. Nanochannel structures in W enhance radiation tolerance. Acta Mater. 2018;153:147.

Zhou HB, Li YH, Lu GH. Modeling and simulation of helium behavior in tungsten: a first-principles investigation. Comput Mater Sci. 2016;112:487.

Gibson JSKL, Roberts SG, Armstrong DEJ. High temperature indentation of helium-implanted tungsten. Mater Sci Eng A. 2015;625:380.

De Broglie I, Beck CE, Liu W, Hofmann F. Temperature dependence of helium-implantation-induced lattice swelling in polycrystalline tungsten: X-ray micro-diffraction and Eigenstrain modelling. Scr Mater. 2015;107:96.

Qin W, Wang Y, Tang M, Ren F, Fu Q, Cai G, Dong L, Hu L, Wei G, Jiang C. Microstructure and hardness evolution of nanochannel W films irradiated by helium at high temperature. J Nucl Mater. 2018;502:132.

Perez D, Vogel T, Uberuaga BP. Diffusion and transformation kinetics of small helium clusters in bulk tungsten. Phys Rev B. 2014;90(1):014102.

Hu X, Koyanagi T, Fukuda M, Kumar NAPK, Snead LL, Wirth BD, Katoh Y. Irradiation hardening of pure tungsten exposed to neutron irradiation. J Nucl Mater. 2016;480:235.

Qin W, Jin S, Cao X, Wang Y, Peres P, Choi SY, Jiang C, Ren F. Influence of nanochannel structure on helium-vacancy cluster evolution and helium retention. J Nucl Mater. 2019;527:151822.

Gordo PM, Ferreira Marques MF, Vieira MT. Positron annihilation study on nanocrystalline copper thin films doped with nitrogen. 2017;65:15.

Pentecoste L, Thomann AL, Brault P, Lecas T, Desgardin P, Sauvage T, Barthe MF. Substrate temperature and ion kinetic energy effects on first steps of He+ implantation in tungsten: experiments and simulations. Acta Mater. 2017;141:47.

Li YG, Zhou WH, Huang LF, Zeng Z, Ju X. Cluster dynamics modeling of accumulation and diffusion of helium in neutron irradiated tungsten. J Nucl Mater. 2012;431(1–3):26.

Wang Z. Simulation of radiation effects in structural materials of reactors using high-energy heavy-ion irradiations. Nucl Phys Rev. 2006;23(2):155.

Qin W, Ren F, Zhang J, Dong XN, Feng YJ, Wang H, Tang J, Cai GX, Wang YQ, Jiang CZ. Helium retention in krypton ion pre-irradiated nanochannel W film. Nucl Fusion. 2018;58(2):026021.

Gong YH, Cao XZ, Jin SX, Lu EY, Hu YC, Zhu T, Kuang P, Xu Q, Wang BY. Effect of dislocations on helium retention in deformed pure iron. J Nucl Mater. 2016;482:93.

Zhu T, Cao XZ, Jin SX, Wu JP, Gong YH, Lu EY, Wang BY, Yu RS, Wei L. Helium retention and thermal desorption from defects in Fe9Cr binary alloys. J Nucl Mater. 2015;466:522.

Karl DH. Helium, hydrogen, and fuzz in plasma-facing materials. Mater Res Express. 2017;4(10):104002.

Baldwin MJ, Doerner RP. Helium induced nanoscopic morphology on tungsten under fusion relevant plasma conditions. Nucl Fusion. 2008;48(3):035001.

Petty TJ, Baldwin MJ, Hasan MI, Doerner RP, Bradley JW. Tungsten ‘fuzz’ growth re-examined: the dependence on ion fluence in non-erosive and erosive helium plasma. Nucl Fusion. 2015;55(9):093033.

Ito AM, Takayama A, Oda Y, Tamura T, Kobayashi R, Hattori T, Ogata S, Ohno N, Kajita S, Yajima M, Noiri Y, Yoshimoto Y, Saito S, Takamura S, Murashima T, Miyamoto M, Nakamura H. Molecular dynamics and Monte Carlo hybrid simulation for fuzzy tungsten nanostructure formation. Nucl Fusion. 2015;55(7):073013.

Wei G, Ren F, Fang J, Hu W, Gao F, Qin W, Cheng T, Wang Y, Jiang C, Deng H. Understanding the release of helium atoms from nanochannel tungsten: a molecular dynamics simulation. Nucl Fusion. 2019;59(7):076020.

Wei G, Li J, Li Y, Deng H, Jiang C, Ren F. A better nanochannel tungsten film in releasing helium atoms. J Nucl Mater. 2020;532:152044.

Wang JL, Niu LL, Shu XL, Zhang Y. Stick–slip behavior identified in helium cluster growth in the subsurface of tungsten: effects of cluster depth. J Phys. 2015;27(39):395001.

Wang J, Zhang Y, Zhou HB, Jin S, Lu GH. First-principles investigation of helium dissolution and clustering at a tungsten (110) surface. J Nucl Mater. 2015;461:230.

Pan GY, Li YG, Zhang YS, Zhang CG, Zhao Z, Zeng Z. First-principles investigation of the orientation influenced He dissolution and diffusion behaviors on W surfaces. RSC Adv. 2017;7(41):25789.

Liang L, Ma M, Xiang W, Wang Y, Cheng Y, Tan X. A molecular dynamics simulation study of temperature and depth effect on helium bubble releasing from Ti surface. J Alloy Compd. 2015;645:S166.

Liu S, Dai S, Sang C, Sun J, Stirner T, Wang D. Molecular dynamics simulation of the formation, growth and bursting of bubbles in tungsten exposed to high fluxes of low energy deuterium. J Nucl Mater. 2015;463:363.

Acknowledgements

This work was financially supported by the National Natural Science Fund for Excellent Young Scholars (Grant No. 11522543), the National Natural Science Foundation of China (Grant Nos. 11905058, 11935011 and 11475129), the Natural Science Foundation of Hubei Province, China (Grant Nos. 2020CFA041 and 2016CFA080), and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Contributions

Wen-jing Qin wrote the draft; Wei Guo, Tao Cheng, and Jun Tang collected the data; Chang-Zhong Jiang and Feng Ren contributed to conceived the idea of the study. All authors contributed to the writing and revisions.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Qin, WJ., Guo, W., Cheng, T. et al. Review on helium behaviors in nanochannel tungsten film. Tungsten 3, 369–381 (2021). https://doi.org/10.1007/s42864-021-00097-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-021-00097-3