Abstract

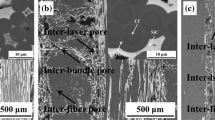

The current study was intended to synthesize and characterize the physical, chemical, and mechanical properties of carbon/carbon (C/C) composites using the chemical vapor infiltration (CVI) process. To that end, carbon fiber felt (CF) was used as a preform, and methane and hydrogen were employed as reactive and carrier gases, respectively. After deciding on the optimum temperature (1050 °C), the composite samples were produced at different times (0–195 h). Then the samples were studied for their phase and microstructure characteristics using XRD, SEM, FESEM, FTIR, and Raman spectroscope. The results showed that by increasing the CVI process time up to 195 h, the density of the produced samples increased from 0.20 to 1.62 g/cm3, and the specific surface area decreased from 58.78 to 0.23 m2/g. Also, by increasing the process duration, the deposition rate decreased due to the reduction of the available surface for carbon deposition. In other words, due to the increase in density, and decrease in both porosity and specific surface area, the thermal conductivity coefficient and the bending strength of the samples increased. The composite specimens' SEM images of the fracture surface indicated a weak interface between the carbon fibers and the carbon layer developed by the CVI process. The structural analyses showed that the morphology of carbon growth during the CVI process was initially laminar, but changed to rough-laminar (RL) with the higher duration of the CVI process.

Similar content being viewed by others

Notes

Open joint stock company.

References

Park SJ, Kim BJ (2015) Carbon fibers and their composites. In: Park S-J (ed) Carbon fibers, vol 210. Springer, New York, pp 275–317

Wu X, Luo R (2011) Mechanical properties investigation of carbon/carbon composites fabricated by a fast densification process. Mater Des 32:2361–2364. https://doi.org/10.1016/j.matdes.2010.11.061

Windhorst T, Blount G (1997) Carbon–carbon composites: a summary of recent developments and applications. Mater Des 18:11–15. https://doi.org/10.1016/S0261-3069(97)00024-1

Park SJ (2018) Novel carbon fibers and their composites. In: Park S-J (ed) Carbon fibers, vol 210. Springer, Singapore. https://doi.org/10.1007/978-981-13-0538-2_9

Morgan P (2005) Carbon fibers and their composites. CRC Press

Lee J, Lee HI, Paik JG (2020) Thermal conductivities of a needle-punched carbon/carbon composite with unbalanced structures. Carbon Lett. https://doi.org/10.1007/s42823-020-00174-6

Kim H, Chung GY, Koo HH, Baek WH (2004) Effects of process parameters for the preparation of C/SiC composites in the F-chemical vapor infiltration reactor. Korean J Chem Eng 21:929–934. https://doi.org/10.1007/BF02705573

Bang KH, Chung GY, Koo HH (2011) Preparation of C/C composites by the chemical vapor infiltration (CVI) of propane pyrolysis. Korean J Chem Eng 28:272–278. https://doi.org/10.1007/s11814-010-0352-y

Hwang DG, Chung GY (2012) Studies on the effects of the concentration in the preparation of C/C composites by the CVI process of propane. J Ind Eng Chem 18:1136–1140. https://doi.org/10.1016/j.jiec.2012.01.016

Ofori JY, Sotirchos SV (1996) Optimal pressures and temperatures for isobaric, isothermal chemical vapor infiltration. AIChE J 42:2828–2840. https://doi.org/10.1002/aic.690421013

Xuefeng L, Jie Z, Kun Q (2019) Densification rate and mechanical properties of carbon/carbon composites with layer-designed preform. Ceram Int 45:4167–4175. https://doi.org/10.1016/j.ceramint.2018.11.085

Dietrich S, Gebert JM, Stasiuk G, Wanner A, Weidenmann KA, Deutschmann O, Tsukrov I, Piat R (2012) Microstructure characterization of CVI-densified carbon/carbon composites with various fiber distributions. Compos Sci Technol 72:1892–1900. https://doi.org/10.1016/j.compscitech.2012.08.009

Delhaes P (2002) Chemical vapor deposition and infiltration processes of carbon materials. Carbon 40:641–657. https://doi.org/10.1016/S0008-6223(01)00195-6

Zhang J, Luo R, Zhang Y, Ni Y, Li J, Yang C (2010) Effect of isotropic interlayers on the mechanical and thermal properties of carbon/carbon composites. Mater Lett 64:1536–1538. https://doi.org/10.1016/j.matlet.2010.04.013

Guo L, Zhang D, Li K, Li H (2009) Fabrication of isotropic pyrocarbon at 1400 °c by thermal gradient chemical vapor deposition apparatus. J Wuhan Univ Technol Mater Sci Ed 24:728–731. https://doi.org/10.1007/s11595-009-5728-7

Benzinger W, Hüttinger KJ (1999) Chemistry and kinetics of chemical vapor infiltration of pyrocarbon-IV. Investigation of methane/hydrogen mixtures. Carbon 37:931–940. https://doi.org/10.1016/S0008-6223(98)00248-6

Zhang SY, Yan XF, Li HJ, Li W, Guo LJ (2009) Deposition of pyrolytic carbon using ethanol as precursor in chemical vapor infiltration. Wuji Cailiao Xuebao [Journal of Inorganic Materials] 24:1073–1076

Yan XF, Zhang SY, Li HJ, Li W, Zhang XM (2008) Carbon/carbon composites prepared by an ethanol pyrolysis. Xinxing Tan Cailiao [New Carbon Materials] 23:314–318

Ren J, Li K, Zhang S, Yao X, Tian S (2015) Preparation of carbon/carbon composite by pyrolysis of ethanol and methane. Mater Des 65:174–178. https://doi.org/10.1016/j.matdes.2014.08.036

Golecki I, Xue, L., Leung, R., Walker, T., Anderson, A., Dewar, D., Duncan, C., Van Horik, J (1998) Properties of high thermal conductivity carbon-carbon composites for thermal management applications. Paper presented at the 1998 High-Temperature Electronic Materials, Devices and Sensors Conference, 1998-February

Luo R, Liu T, Li J, Zhang H, Chen Z, Tian G (2004) Thermophysical properties of carbon/carbon composites and physical mechanism of thermal expansion and thermal conductivity. Carbon 42:2887–2895. https://doi.org/10.1016/j.carbon.2004.06.024

Wang P, Zhang S, Li H, Kong J, Li W, Zaman W (2014) Variation of thermal expansion of carbon/carbon composites from 850 to 2500 °C. Ceram Int 40:1273–1276. https://doi.org/10.1016/j.ceramint.2013.08.038

ASTM Standard C20-00 (2015) Standard test methods for apparent porosity, water absorption, apparent specific gravity, and bulk density of burned refractory brick and shapes by boiling water. American Society for Testing and Materials.https://doi.org/10.1520/C0020-00R10.2

ASTM Standard E290-14 (1998) Standard test methods for bend testing of material for ductility. American Society for Testing and Materials. https://doi.org/10.1520/E0290-14

Coffin IF (1964) Structure–property relations for pyrolytic graphite. J Am Ceram Soc 47(10):473–478. https://doi.org/10.1111/j.1151-2916.1964.tb13793.x

Guellali M, Oberacker R, Hoffmann MJ (2005) Influence of the matrix microstructure on the mechanical properties of CVI-infiltrated carbon fiber felts. Carbon 43:1954–1960. https://doi.org/10.1016/j.carbon.2005.03.006

Zhang M, Su Z, Xie Z, Chen J, Huang Q (2012) Microstructure of pyrocarbon with chemical vapor infiltration. Procedia Eng 27:847–854. https://doi.org/10.1016/j.proeng.2011.12.530

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elahi Davaji, H., Shamoradi, F., Panjepour, M. et al. Preparation and characterization of carbon felt/carbon composites by chemical vapor infiltration process. Carbon Lett. 32, 201–215 (2022). https://doi.org/10.1007/s42823-021-00267-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-021-00267-w