Abstract

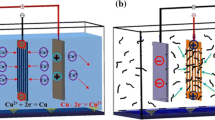

Using 2.5-dimensional carbon fiber fabrics as the reinforcement, porous carbon/carbon(C/C) substrates were firstly fabricated by impregnation/carbonization (I/C) technique with furan resin and then treated at 2000, 2300 and 3000 °C, respectively. Finally, carbon fiber reinforced carbon and copper(C/C–Cu) composites were prepared by infiltrating melt copper alloy into C/C substrates under pressure. The effects of treating temperatures on microstructures and thermal conductivities of the composites were investigated. The results show that heat treatment plays an important role in the microstructure and thermal conductivity of C/C–Cu composites. It is conducive not only to rearrange the carbon crystallite of resin-based carbon in oriented layer structure, but also to improve the content and connectivity of copper alloy. The thermal conductivity increases with the increase in heat treatment temperature in both parallel and perpendicular direction; the thermal conductivity in parallel direction is evidently superior to that in perpendicular direction.

Similar content being viewed by others

References

J. Yin, H.B. Zhang, C. Tan, X. Xiong, Effect of heat treatment temperature on sliding wear behavior of C/C-Cu composites under electric current. Wear 312, 91–95 (2014)

L. Yang, L. Ran, M. Yi, Carbon fiber knitted fabric reinforced copper composite for sliding contact material. Mater. Des. 32, 2365–2369 (2011)

G.X. Chen, H.J. Yang, W.H. Zhang, X. Wang, S.D. Zhang, Z.R. Zhou, Experimental study on arc ablation occurring in a contact strip rubbing against a contact wire with electrical current. Tribol. Int. 61, 88–94 (2013)

Y. Kubota, S. Nagasaka, T. Miyauchi, C. Yamashita, H. Kakishima, Sliding wear behavior of copper alloy impregnated C/C composites under an electrical current. Wear 302, 1492–1498 (2013)

G. Bucca, A. Collina, A procedure for the wear prediction of collector strip and contact wire in pantograph–catenary system. Wear 266, 46–59 (2009)

T. Ding, G.X. Chen, J. Bu, W.H. Zhang, Effect of temperature and arc discharge on friction and wear behaviours of carbon strip/copper contact wire in pantograph–catenary systems. Wear 271, 1629–1636 (2011)

D.L. McDanels, K.W. Baker, D.L. Ellis, In graphite fiber/copper matrix composites for space power heat pipe fin applications. Proceedings of the eighth symposium on space nuclear power system. AIP Publishing 2008: 313–319

H.M. Zhang, X.B. He, X.H. Qu, Q. Liu, X.Y. Shen, Microstructure and thermal properties of copper matrix composites reinforced with titanium-coated graphite fibers. Rare Met. 32, 75–80 (2013)

J. Chen, X. Xiong, P. Xiao, Thermal conductivity of unidirectional carbon/carbon composites with different carbon matrixes. Mater. Des. 30, 1413–1416 (2009)

W. Li, H.J. Li, S.Y. Zhang, J.F. Wei, J. Wang, Z.Q. Li, Effect of high temperature treatment on the microstructure and mechanical properties of binary layer textured 2D C/C composites. New Carbon Mater. 26, 328–334 (2011)

Y. Tanabe, J. Yamanaka, K. Hoshi, H. Migita, E. Yasuda, Surface graphitization of furan-resin-derived carbon. Carbon 39, 2347–2353 (2001)

A. Sadezky, H. Muckenhuber, H. Grothe, R. Niessner, U. Pöschl, Raman microspectroscopy of soot and related carbonaceous materials: spectral analysis and structural information. Carbon 43, 1731–1742 (2005)

F.Q. Zhang, B.Y. Huang, Q.Z. Huang, X. Xiong, T.F. Cheng, Effects of the interface on the graphitization of a carbon fiber/pyrolytic carbon composite. Carbon 41, 610–612 (2003)

M. Keitaro, J.L. Leslie, T. Yasuhiro, Y. Eiichi, E. Morinobu, Stress graphitization of C/C composite reinforced by carbon nanofiber. Carbon 43, 1577–1579 (2005)

Z.D. Guan, Z.T. Zhang, J.S. Jiao, Physical Performances of Inorganic Materials (Tsinghua University Press, Beijing, 1992), pp. 131–150

J. Chen, X. Xiong, P. Xiao, The effect of MWNTs on the microstructure of resin carbon and thermal conductivity of C/C composites. Solid State Sci. 11, 1890–1893 (2009)

G. Savage, Carbon Carbon Composites (Chapman & Hall, London, 1993), p. 309

L. Manocha, A. Warrier, S. Manocha, D. Sathiyamoorthy, S. Banerjee, Thermophysical properties of densified pitch based carbon/carbon materials—I. Unidirectional composites. Carbon 44, 480–487 (2006)

Acknowledgments

This work is supported by the National Natural Science Foundation of China (No. 51302322).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, P., Yin, J., Zhang, H. et al. Effect of heat treatment on microstructure and thermal conductivity of carbon/carbon–copper composites. Appl. Phys. A 122, 207 (2016). https://doi.org/10.1007/s00339-016-9748-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9748-9