Abstract

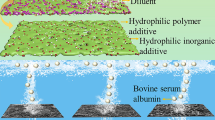

Ultra-high molecular weight polyethylene (UHMWPE) membranes were prepared by 5 wt% UHMWPE/paraffin oil gels via thermally induced phase separation method and dried in air without significant collapse. The UHMWPE membranes were annealed at 110 °C for increasing the pores size in order to decrease the capillary forces. Furthermore, a new multiple stage extractant exchange drying (MSEED) technique was adopted to decrease the shrinkage of the UHMWPE membranes. Specifically, the paraffin oil was extracted by dichloromethane, then dichloromethane was replaced by ethanol, next ethanol could be exchanged to other liquid which is non-affinity with UHMWPE, for example water. UHMWPE membranes (annealing for 25 min) dried by dichloromethane-ethanol–water-air process have the lowest volume shrinkage of 16.5% and the porosity is as high as 88.29%. Moreover, compared with supercritical CO2 (SC-CO2) drying, atmospheric drying UHMWPE membranes have a lower pure water permeance, but a higher carbon particles rejection.

Similar content being viewed by others

References

Liu S, Yu W, Zhou C. Tuning the water permeability of ultra-high molecular weight polyethylene microporous membrane by molecular self-assembly and flow field. Polymer. 2014;55:2113–24. https://doi.org/10.1016/j.polymer.2014.02.068.

Fan L-L, Quan J-Y, Zhang H, Yu J-R, Hu Z-M, Wang Y. Preparation of hydrophilic UHMWPE hollow fiber membranes by chemically bounding silica nanoparticles. Chin J Polym Sci. 2020;39:189–200. https://doi.org/10.1007/s10118-021-2507-1.

Li N, Lu Q, Yin W, Xiao C, Li J. The structure and properties of poly(vinylidene fluoride)/ultrahigh-molecular -weight polyethylene blend hollow fiber membranes via TIPS with mixed diluents. J Membrane Sci. 2020;595:117527. https://doi.org/10.1016/j.memsci.2019.117527.

Matsuyama H, Okafuji H, Maki T, Teramoto M, Kubota N. Preparation of polyethylene hollow fiber membrane via thermally induced phase separation. J Membrane Sci. 2003;223:119–26. https://doi.org/10.1016/S0376-7388(03)00314-4.

Lloyd DR, Kinzer KE, Tseng HS. Microporous membrane formation via thermally induced phase separation I Solid-liquid phase separation. J Membrane Sci. 1990;52:239–61. https://doi.org/10.1016/S0376-7388(00)85130-3.

Liu R, Wang X, Yu J, Wang Y, Zhu J, Hu Z. Development and evaluation of UHMWPE/woven fabric composite microfiltration membranes via thermally induced phase separation. RSC Adv. 2016;6:90701–10. https://doi.org/10.1039/C6RA11456C.

Liu R, Wang X, Yu J, Wang Y, Zhu J, Hu Z. Surface modification of UHMWPE/fabric composite membrane via self-polymerized polydopamine followed by mPEG-NH2 immobilization. J Appl Polym Sci. 2018;135:46428. https://doi.org/10.1002/app.46428.

Matsuyama H, Kim M-M, Lloyd DR. Effect of extraction and drying on the structure of microporous polyethylene membranes prepared via thermally induced phase separation. J Membrane Sci. 2002;204:413–9. https://doi.org/10.1016/S0376-7388(02)00052-2.

Aydinli B, Tincer T. The preparation and characterization of hydrophilic macroporous foams from water soluble polymers grafted ultra-high molecular weight polyethylene. J Appl Polym Sci. 2013;127:1077–83. https://doi.org/10.1002/app.37939.

Liu S, Zhou C, Yu W. Phase separation and structure control in ultra-high molecular weight polyethylene microporous membrane. J Membrane Sci. 2011;379:268–78. https://doi.org/10.1016/j.memsci.2011.05.073.

Li N, Xiao C, Zhang Z. Effect of polyethylene glycol on the performance of ultrahigh-molecular-weight polyethylene membranes. J Appl Polym Sci. 2010;117:720–8. https://doi.org/10.1002/app.30500.

Cai L, Song AY, Li W, Hsu P-C, Lin D, Catrysse PB, Liu Y, Peng Y, Chen J, Wang H, Xu J, Yang A, Fan S, Cui Y. Spectrally selective nanocomposite textile for outdoor personal cooling. Adv Mater. 2018;30:1802152. https://doi.org/10.1002/adma.201802152.

Shi X, Bin Y, Hou D, Men Y, Matsuo M. Gelation/crystallization mechanisms of UHMWPE solutions and structures of ultradrawn gel films. Polym J. 2013;46:21–35. https://doi.org/10.1038/pj.2013.66.

Guo Y, Zhang T, Chen M, Li C, Wu H, Guo S. Constructing tunable bimodal porous structure in ultrahigh molecular weight polyethylene membranes with enhanced water permeance and retained rejection performance. J Membrane Sci. 2021;619:118778. https://doi.org/10.1016/j.memsci.2020.118778.

Lermontov SA, Malkova AN, Sipyagina NA, Straumal EA, Maksimkin AV, Kolesnikov EA, Senatov FS. Properties of highly porous aerogels prepared from ultra-high molecular weight polyethylene. Polymer. 2019;182:121824. https://doi.org/10.1016/j.polymer.2019.121824.

Aravind PR, Shajesh P, Soraru GD, Warrier KGK. Ambient pressure drying: a successful approach for the preparation of silica and silica based mixed oxide aerogels. J Sol-Gel Sci Technol. 2010;54:105–17. https://doi.org/10.1007/s10971-010-2164-2.

Venkateswara RA, Nilsen E, Einarsrud MA. Effect of precursors, methylation agents and solvents on the physicochemical properties of silica aerogels prepared by atmospheric pressure drying method. J Non-Cryst Solids. 2001;296:165–71.

Li Y, Grishkewich N, Liu L, Wang C, Tam KC, Liu S, Mao Z, Sui X. Construction of functional cellulose aerogels via atmospheric drying chemically cross-linked and solvent exchanged cellulose nanofibrils. Chem Eng J. 2019;366:531–8. https://doi.org/10.1016/S0022-3093(01)00907-3.

Jie X, Cao Y, Qin J-J, Liu J, Yuan Q. Influence of drying method on morphology and properties of asymmetric cellulose hollow fiber membrane. J Membrane Sci. 2005;246:157–65. https://doi.org/10.1016/j.memsci.2004.08.007.

Wang B, Zhang W, Zhang W, Mujumdar AS, Huang L. Progress in drying technology for nanomaterials. Dry Technol. 2005;23:7–32. https://doi.org/10.1081/DRT-200047900.

Minhas BS, Matsuura T, Sourirajan S, Solvent-Exchange Drying of Cellulose Acetate Membranes for Separation of Hydrogen-Methane Gas Mixtures. In: Reverse Osmosis and Ultrafiltration, American Chemical Society; 1985, pp. 451–466. https://doi.org/10.1021/bk-1985-0281.ch033.

Lui A, Talbot FDF, Fouda A, Matsuura T, Sourirajan S. Studies on the solvent exchange technique for making dry cellulose acetate membranes for the separation of gaseous mixtures. J Appl Polym Sci. 1988;36:1809–20. https://doi.org/10.1002/app.1988.070360808.

Lui A, Talbot FDF, Sourlrajan S, Fouda A, Matsuura T. Studies on gas transport through dry cellulose acetate membranes prepared by solvent exchange technique. Sep Sci Technol. 1988;23:1839–52. https://doi.org/10.1080/01496398808075667.

Quan J, Wang H, Li T, Fan L, Yu J, Wang Y, Zhu J, Hu Z. Air and water vapor permeable UHMWPE composite membranes for X-ray shielding. Ind Eng Chem Res. 2020;59:9136–42. https://doi.org/10.1021/acs.iecr.0c01162.

Laird ED, Wang W, Cheng S, Li B, Presser V, Dyatkin B, Gogotsi Y, Li CY. Polymer single crystal-decorated superhydrophobic buckypaper with controlled wetting and conductivity. ACS Nano. 2012;6:1204–13. https://doi.org/10.1021/nn203861s.

Gao S, Liu H, Capillary mechanics, 1st ed. Beijing: Science Press; 2010. p 48 (In Chinese).

Rastogi S, Spoelstra AB, Goossens JGP, Lemstra PJ. Chain mobility in polymer systems: on the borderline between solid and melt. 1. Lamellar doubling during annealing of polyethylene. Macromolecules. 1997;30:7880–9. https://doi.org/10.1021/ma970519o.

Xue YQ, Tervoort TA, Rastogi S, Lemstra PJ. Welding behavior of semicrystalline polymers. 2. Effect of cocrystallization on autoadhesion. Macromolecules. 2000;33:7084–7. https://doi.org/10.1021/ma000754y.

Lechner M, Wohlfarth C, Wohlfarth B. Surface tension of pure liquids and binary liquid mixtures. NewYork: Springer; 2015.

Acknowledgements

This research is supported by Shanghai International S&T Cooperation Fund (No. 16160731302) and the Natural Science Foundation of China (No. 51473031).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Quan, J., Song, Q., Yu, J. et al. Atmospheric Drying UHMWPE Membranes via Multiple Stage Extractant Exchange Drying Technique. Adv. Fiber Mater. 4, 235–245 (2022). https://doi.org/10.1007/s42765-021-00102-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-021-00102-x