Abstract

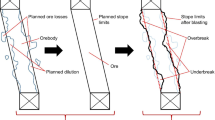

Effective management of ore loss and dilution is essential for successful grade control and short-term mine planning due to their significant impact on the economic, environmental, and technical aspects of open-pit mining operations. Factors influencing ore loss and dilution fall into two categories: (i) controllable factors like mine equipment selectivity and blast design and (ii) uncontrollable factors such as spatial heterogeneity of ore and waste blocks on a bench. This paper focuses on the second category by applying spatial entropy concept to capture heterogeneity at the scale of selective mining units. In this paper, global spatial entropy is used to assess the impact of spatial heterogeneity between ore and waste blocks on the magnitude of ore loss and dilution, while the local spatial entropy can guide the allocation of blast movement monitoring balls pre-blast. High values of the global spatial entropy indicate increasing potential of ore loss and dilution, which reduce profit. Furthermore, the study investigates the relationship between spatial entropy, cut-off grades, blast movement, dig-limits optimization model running time, and profit through a number of case studies. The results show that changes in cut-off grade and blast movement can significantly affect spatial entropy post-blasting and increase ore loss, dilution, and profit reduction, revealing the need for controlled blasting at specific bench sections. Additionally, the results demonstrate an exponential increase in profit reduction due to ore loss and dilution with a rising global spatial entropy.

Similar content being viewed by others

Code Availability

There is no public code available.

References

Zarshenas Y, Saeedi G (2016) Risk assessment of dilution in open pit mines. Arab J Geosci 9(3):1–11

Zarshenas Y, Saeedi G (2017) Determination of optimum cutoff grade with considering dilution. Arab J Geosci 10:1–7

Dowd PA, Dare-Bryan PC (2018) Planning, designing and optimising production using geostatistical simulation. In: Dimitrakopoulos, R. (eds) Advances in applied strategic mine planning. Springer, Cham. https://doi.org/10.1007/978-3-319-69320-0_26

Marinin M, Marinina O, Wolniak R (2021) Assessing of losses and dilution impact on the cost chain: Case study of gold ore deposits. Sustainability 13(7):3830

Pakalnis R, Poulin R, Hadjigeorgiou J (1996) Quantifying the cost of dilution in underground mines. Int J Rock Mech Min Sci Geomech Abstr 33(3):291–308

Hmoud S, Kumral M (2022) Effect of blast movement uncertainty on dig-limits optimization in open-pit mines. Nat Resour Res 31(1):163–178. https://doi.org/10.1007/s11053-021-09998-z

Kumral M (2015) Grade control in multi-variable ore deposits as a quality management problem under uncertainty. Int J Qual Reliab Manag 32(4):334–345

Nelis G, Meunier F, Morales N (2022) Column gneration for mining cut definition with geometallurgical interactions. Nat Resour Res 31(1):131–148

Nelis G, Morales N (2022) A mathematical model for the scheduling and definition of mining cuts in short-term mine planning. Optim Eng 23(1):233–257

Sari YA, Kumral M (2017) Dig-limits optimization through mixed-integer linear programming in open-pit mines. J Oper Res Soc 69(2):171–182. https://doi.org/10.1057/s41274-017-0201-z

Richmond A, Beasley J (2004) Financially efficient dig-line delineation incorporating equipment constraints and grade uncertainty. Int J Surf Min Environ Reclam 18(2):99–121. https://doi.org/10.1080/13895260412331295376

Vasylchuk YV, Deutsch CV (2019) Optimization of surface mining dig limits with a practical heuristic algorithm. Min Metall Explor 36(4):773–784. https://doi.org/10.1007/s42461-019-0072-8

Wilde B, Deutsch CV (2015) A short note comparing feasibility grade control with dig limit grade control. Report of Center for Computational Geostatistics. The University of Alberta. pp. 302.1 302.10

Isaaks E, Barr R, Handayani O (2014) Modeling blast movement for grade control. In Proceedings of the 9th International Mining Geology Conference. Adelaide, Australia, p 433–440

Isaaks E, Treloar I, Elenbaas T (2014) Optimum dig lines for open pit grade control. In Proceedings of the 9th International Mining Geology Conference. Adelaide, Australia, p 425–432

Norrena K, Deutsch C (2000) Automatic determination of dig limits subject to geostatistical, economical and equipment constraints. Center for Computational Geostatistics (CCG), University of Alberta, Edmonton, Alberta, Canada

van Duijvenbode J, Shishvan M (2022) Stochastic analysis of dig limit optimization using simulated annealing. J South Afr Inst Min Metall 122(2):715–724

Ruiseco JR (2016) Dig-limit optimization in open pit mines through genetic algorithms. (Master thesis, McGill University, Quebec, Canada)

Ruiseco JR, Kumral M (2017) A practical approach to mine equipment sizing in relation to dig-limit optimization in complex orebodies: multi-rock type, multi-process, and multi-metal case. Nat Resour Res 26(1):23–35. https://doi.org/10.1007/s11053-016-9301-8

Ruiseco JR, Williams J, Kumral M (2016) Optimizing ore–waste dig-limits as part of operational mine planning through genetic algorithms. Nat Resour Res 25(4):473–485. https://doi.org/10.1007/s11053-016-9296-1

Williams J, Singh J, Kumral M, Ruiseco JR (2021) Exploring deep learning for dig-limit optimization in open-pit mines. Nat Resour Res 30(3):2085–2101. https://doi.org/10.1007/s11053-021-09864-y

Deutsch M (2017) A branch and bound algorithm for open pit grade control polygon optimization. In Proceedings of the 38th International Symposium on the Applications of Computers and Operations Research in the mineral industry (APCOM), Golden, Colorado USA, Ed. Dagdelen, K. 14–18.

Salman S, Muhammad K, Khan A, Glass HJ (2021) A block aggregation method for short-term planning of open pit mining with multiple processing destinations. Minerals 11(3):288. https://doi.org/10.3390/min11030288

Tabesh M, Askari-Nasab H (2011) Two-stage clustering algorithm for block aggregation in open pit mines. Min Technol 120(3):158–169

Tabesh M, Askari-Nasab H (2013) Automatic creation of mining polygons using hierarchical clustering techniques. J Min Sci 49(3):426–440

Tabesh M, Askari-Nasab H (2019) Clustering mining blocks in presence of geological uncertainty. Min Technol 49:426–440

Engmann E, Ako S, Bisiaux B, Rogers W, Kanchibotla S (2013) Measurement and modelling of blast movement to reduce ore losses and dilution at Ahafo Gold Mine in Ghana. Ghana Min J 14:27–36

Thornton D, Sprott D, Brunton I (2005) Measuring blast movement to reduce loss and dilution. In Proceedings of the International Society of Explosives Engineers Annual Conference, Ed. Jerry Wallace. Orlando, Florida, Feb 6–9, 2005. Cleveland, Ohio, USA.

Zhang S (1994) Rock movement due to blasting and its impact on ore grade control in Nevada open pit gold mines (Doctoral dissertation, University of Nevada, Reno). p 155

Yennamani AL (2010) Blast induced rock movement measurement for grade control at the Phoenix mine. (Master thesis, University of Nevada, Reno). p 233

Gilbride LJ (1995) Blast-induced rock movement modelling for bench blasting in Nevada open-pit mines. (Doctoral dissertation, University of Nevada, Reno). p 295

Harris GW (1997) Measurement of blast-induced rock movement in surface mines using magnetic geophysics. (Master thesis, University of Nevada, Reno)

Taylor D, Firth I (2003) Utilization of blast movement measurements in grade control. In Proceedings of the 31st APCOM Symposium, Ed. Camisani-Calzolari, South Africa, p 243–247

Yu Z, Shi X, Zhang Z, Gou Y, Miao X, Kalipi I (2022) Numerical investigation of blast-induced rock movement characteristics in open-pit bench blasting using bonded-particle method. Rock Mech Rock Eng 55(6):3599–3619. https://doi.org/10.1007/s00603-022-02831-w

Zou Z, Jun Y (2020) Modelling blast movement and muckpile formation with the position-based dynamics method. Int J Min Reclam Environ 1–12. https://doi.org/10.1080/17480930.2020.1835210

Vasylchuk YV, Deutsch CV (2019) Approximate blast movement modelling for improved grade control. Min Technol 128(3):152–161. https://doi.org/10.1080/25726668.2019.1583843

Yu Z, Shi X, Zhou J, Chen X, Miao X, Teng B, Ipangelwa T (2020) Prediction of blast-induced rock movement during bench blasting: use of gray wolf optimizer and support vector regression. Nat Resour Res 29(2):843–865

Yu Z, Shi X, Zhou J, Rao D, Chen X, Dong W, Miao X, Ipangelwa T (2019) Feasibility of the indirect determination of blast-induced rock movement based on three new hybrid intelligent models. Engineering with Computers, p 1–16

La Rosa D, Thornton D (2011) Blast movement modelling and measurement. In Proceedings of the 35th APCOM Symposium. Baafi, Kininhmonth, and Baafi (eds). Wollongong, NSW, pp 297–310

Shannon CE (1948) A mathematical theory of communication. Bell System Tech J 27(3):379–423

Hoeting JA, Leecaster M, Bowden D (2000) An improved model for spatially correlated binary responses. J Agric Biol Environ Stat 5:102–114

Patil G, Taillie C (1982) Diversity as a concept and its measurement. J Am Stat Assoc 77(379):548–561

Aghakouchak A (2014) Entropy–copula in hydrology and climatology. J Hydrometeorol 15(6):2176–2189

Butera I, Vallivero L, Ridolfi L (2018) Mutual information analysis to approach nonlinearity in groundwater stochastic fields. Stoch Env Res Risk Assess 32(10):2933–2942

Manchuk JG, Birks JS, McClain CN, Bayegnak G, Gibson JJ, Deutsch CV (2021) Estimating stable measured values and detecting anomalies in groundwater geochemistry time series data across the Athabasca Oil Sands Area. Canada Nat Resour Res 30(2):1755–1779

Singh V (1997) The use of entropy in hydrology and water resources. Hydrol Process 11(6):587–626

Feizi F, Karbalaei-Ramezanali A, Tusi H (2017) Mineral potential mapping via TOPSIS with hybrid AHP–Shannon entropy weighting of evidence: a case study for porphyry-cu, Farmahin area, Markazi Province. Iran Nat Resour Res 26(4):553–570

Liu Z, Chen J, Mao X, Tang L, Yu S, Deng H, Wang J, Liu Y, Li S, Bayless RC (2021) Spatial association between orogenic gold mineralization and structures revealed by 3D prospectivity modeling: a case study of the Xiadian gold deposit, Jiaodong Peninsula. China Nat Resour Res 30(6):3987–4007

Zhang S, Carranza E, Wei H, Xiao K, Yang F, Xiang J, Zhang S, Xu Y (2021) Data-driven mineral prospectivity mapping by joint application of unsupervised convolutional auto-encoder network and supervised convolutional neural network. Nat Resour Res 30(2):1011–1031

Theil H (1972) Statistical decomposition analysis: with applications in the social and administrative sciences. North-Holland Publishing Company.

Batty M (1974) Spatial entropy. Geographical analysis 6(1) 1-31

Batty M (1976) Entropy in spatial aggregation. Geographical analysis 8(1) 1-21. https://doi.org/10.1111/j.1538-4632.1976.tb00525.x

Batty M (2010) Space, scale, and scaling in entropy maximizing. Geogr Anal 42(4):395–421. https://doi.org/10.1111/j.1538-4632.2010.00800.x

Karlström A, Ceccato V (2000) A new information theoretical measure of global and local spatial association. Rev Reg Res (Jahrb für Reg) 22:13–40

Anselin L (1995) Local indicators of spatial association—LISA. Geogr Anal 27(2):93–115

O'Neill RV, Krummel J, Gardner R, Sugihara G, Jackson B, DeAngelis D, Milne B, Turner MG, Zygmunt B, Christensen S (1988) Indices of landscape pattern. Landscape ecology 1(3) 153-162

Claramunt C (2005) A spatial form of diversity. In Proceedings of Spatial Information Theory: International Conference, COSIT 2005, Ellicottville, NY, USA, September 14–18, 2005. Proceedings 7 (218–231). Springer Berlin Heidelberg.

Li X, Claramunt C (2006) A spatial entropy-based decision tree for classification of geographical information. Trans GIS 10(3):451–467. https://doi.org/10.1111/j.1467-9671.2006.01006.x

Leibovici DG (2009) Defining spatial entropy from multivariate distributions of co-occurrences. In Proceedings of Spatial Information Theory: 9th International Conference, COSIT 2009 Aber Wrac’h, France, September 21–25, K. Stewart Hornsby et al. (eds) 2009 Proceedings 9. Springer Berlin Heidelberg, p 392–404

Leibovici DG, Claramunt C, Le Guyader D, Brosset D (2014) Local and global spatio-temporal entropy indices based on distance-ratios and co-occurrences distributions. Int J Geogr Inf Sci 28(5):1061–1084

Li H, Reynolds JF (1993) A new contagion index to quantify spatial patterns of landscapes. Landscape Ecol 8(3):155–162. https://doi.org/10.1007/BF00125347

Parresol BR, Edwards LA (2014) An entropy-based contagion index and its sampling properties for landscape analysis. Entropy 16(4):1842–1859

Riitters KH, O’Neill RV, Wickham JD, Jones KB (1996) A note on contagion indices for landscape analysis. Landscape Ecol 11(4):197–202

Zhang F, Yao L, Zhou W, You Q, Zhang H (2020) Using Shannon entropy and contagion index to interpret pattern self-organization in a dynamic vegetation-sand model. IEEE Access 8:17221–17230

Altieri L, Cocchi D, Roli G (2017) The use of spatial information in entropy measures. arXiv preprint arXiv:1703.06001. https://arxiv.org/abs/1703.06001

Altieri L, Cocchi D, Roli G (2018) A new approach to spatial entropy measures. Environ Ecol Stat 25:95–110

Altieri L, Cocchi D, Roli G (2019) Measuring heterogeneity in urban expansion via spatial entropy. Environmetrics 30(2):e2548. https://doi.org/10.1002/env.2548

Altieri L, Cocchi D, Roli G (2021) Spatial entropy for biodiversity and environmental data: the R-package SpatEntropy. Environ Model Softw 144:105149

Journel AG, Deutsch CV (1993) Entropy and spatial disorder. Math Geol 25(3):329–355

Cover TM, Thomas JA (2006) Elements of information theory. Wiley series in telecommunications and signal processing. Wiley-Interscience, USA

IBM (2021) IBM ILOG CPLEX Optimization Studio 20.1.0 documentation. https://www.ibm.com/products/ilog-cplex-optimization-studio/cplex-optimizer. Accessed 7 Apr 2023

Deutsch CV, Journel AG (1998) GSLIB: geostatistical software library and user’s guide, 2nd edn. Oxford University Press, New York

Loeb J, Thornton D (2014) A cost benefit analysis to explore the optimal number of blast movement monitoring locations. In Proceedings of the Ninth International Mining Geology Conference. Melbourne, Australia, p 441–450

Funding

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) (Fund number: NSERC RGPIN-2019–04763). The authors thank the NSERC for this support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Article highlights

• Ore loss and dilution management are crucial for open-pit mining operations.

• Ore loss and dilution can be significantly influenced by the spatial heterogeneity of ore and waste blocks, cut-off grade, and blast movement.

• This paper utilizes the concept of spatial entropy to quantify the heterogeneity of ore and waste at the selective mining unit scale.

• Spatial entropy shows clear impact on ore loss, dilution, and mine profitability, and can improve blast designs in open-pit operations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hmoud, S., Kumral, M. Spatial Entropy for Quantifying Ore Loss and Dilution in Open-Pit Mines. Mining, Metallurgy & Exploration 40, 2227–2242 (2023). https://doi.org/10.1007/s42461-023-00881-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-023-00881-4