Abstract

Dyes pollution is a serious environmental problem and heterogeneous catalysis has been proposed as a remediation method. In this study, a set of catalysts of synthetic mordenite with iron oxides was synthesized by a simple chemical co-precipitation method assisted by subsequent thermal treatment with an oxidation process. Physicochemical characterization of prepared materials was performed by a variety of techniques, including XRD, SEM, EDS, SBET, UV–Vis DR, and XPS. Photocatalytic methylene blue (MB) degradation by the synthesized catalyst was evaluated with visible light excitation. From the studied set of catalysts, the sample prepared with a thermal treatment at 100 °C in air atmosphere for 3 h was capable of degrading ~ 90% of MB after 120 min with visible light of λ = 420 nm exposition and a small portion of H2O2 added. The catalyst used three processes to degrade MB: (1) adsorption of organic residues in the mordenite matrix support for electrostatic interactions, (2) photocatalysis heterogeneous reaction with visible light and (3) Fenton reaction catalyst with a small portion to H2O2 by Fe3O4–Fe2O3 presence. The catalytic efficiency to dye degradation was improved by a simple and economical thermal treatment without changing reaction conditions like pH, temperature, dose, or other. Studied mordenite iron oxide catalysts can be retrieved and reused at least five times without noticeable degradation, taking advantage of their magnetic properties. These catalysts could be proposed an economical, simple, and non-toxic alternative for eliminating organic dye pollution using visible light or solar irradiation in wastewater remediation related to textile, food, and pharmaceutical industries.

Highlights

-

The Fe3O4–Fe2O3 supported on mordenite catalyst was synthesized for the first time by a simple and cost-effective chemical method.

-

Elimination of methylene blue using the catalyst synthesized was accomplished with visible light excitation.

-

Reuse of the catalyst for the photodegradation process of dyes from aqueous solution was achieved by magnetic retrieval.

-

It was possible to improve the photocatalytic efficiency by facile and economical thermal treatments without changing the pH, temperature, dose, or other conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

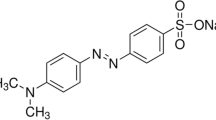

Nowadays, environmental problems due to water pollution have recently drawn much attention from researchers. One of the main pollution sources comes from wastewater containing dyes discharged from textiles, foodstuffs, and leather industries [1]. The presence of colored organic compounds in dye-bearing effluents generally reduces sunlight transmission, affecting photosynthesis and harming aquatic ecosystems [2,3,4,5]. Besides, dyes are complex structures with high molecular weight, which are soluble in water, degradation-resistant, potentially carcinogenic, and mutagenic. Thus, the development of easy, cheap, and green methods for water pollution treatment has been a priority area in the field of environmental sciences [6, 7].

Methylene blue (MB) is an aromatic heterocyclic basic dye. MB is a well-known cationic and primary thiazine dye, having λmax of 664 nm absorbance. It is highly water-soluble and very stable at room temperature. It is a persistent pollution that has many potential applications in the textile, pharmaceutical, paper, dyeing, printing, paint, medicine, and food industries [8]. It is the most common dye in the textile industry. Advanced oxidation processes (AOPs) were developed to treat toxic organic pollutants, such as MB, through strong redox processes with specific radicals generated in this process without generating any additional harmful substances. AOPs approaches employed for the photodegradation of MB are ozonation, ultraviolet/H2O2 oxidation, electrochemical oxidation/degradation, catalytic oxidation, Fenton reaction, photocatalytic degradation, etc. It is desirable to have more than one mechanism that eliminates the presence of methylene blue. Besides, efficiency of the heterogeneous photocatalyst process depends on variables such as irradiation time, light source, dye concentration, pH, oxidant compounds and radical scavengers [9, 10].

Photocatalysis has emerged as a promising technology way to solve pollution problems. Using photocatalytic processes to remove dyes from such effluents might result in decolorization and complete degradation [11]. Semiconductors, due to large band gap and properties, have been used as photocatalytic material with UV/Visible light and, potentially, the practical application of natural solar light [12]. For example, in 2021 Al-Jemeli et al. reported degradation of anti-inflammatory drugs by solar photocatalysis process [13]. Recently, several authors reported photocatalysis as a possible remediation method for the elimination of organic pollution in water and studied different semiconductor hybrid materials for this application, for example in 2023 Bassim et al. reported a green synthesis of CuO/TiO2 nanoparticles were obtained using a natural extract for degrading methylene blue with photocatalysis under ultraviolet light irradiation [14]. In 2023, Xin et al. reported synthesis of nanoflowers of Bi/BiOBr applied for NO removal by photocatalysis using visible light irradiation [15]. In 2023, Dawi et al. reported the synthesis of NiTiO3 by hydrothermal method for eliminating CO2 by photocatalytic reduction to CH4 and water splitting [16]. However, most authors have used materials based on titanium oxide requiring excitation with ultraviolet light, and the difficulty for retrieving the catalyst. Besides, iron oxides are considered favorable semiconductors for photocatalytic reactions due to their band gap of ~ 2.3 eV and good absorbers of visible light with the possibility to take advantage of solar light, they possess excellent stability, can be recyclable, and are highly available [17]. Iron oxides absorb visible light and generate reactive charge carriers, which can promote chemical reactions by activating the adjacent chemical compounds [18,19,20,21,22]. Iron oxides, as reported by several authors [23,24,25,26], are used as catalysts of dye waste degradation through photocatalysis heterogeneous reactions or applying the fenton reaction with hydrogen peroxide and iron cationic species (Fe3+ and Fe2+). Furthermore, since iron oxide compounds can be manipulated by a magnetic field, catalysts based on iron oxides can be retrieved and reutilized.

The performance of catalysts can be improved by loading on porous, large surface area supports, such as alumina, porous carbon, zeolites, or graphene oxide [27]. Zeolites are crystalline hydrated aluminosilicates composed of Si (Si4+) tetrahedral structures binding with four oxygen atoms, where a fraction of Si atoms can be substituted for Al atoms (Al3+), forming ionic exchange sites from compensation charges. Si/Al atomic ratio is an important property in zeolites. Normally, lower values are indicative of natural zeolites with major ion exchange capacity and, higher values, for synthetic zeolites with good adsorption properties to organic substances. They possess ordered structures containing one-, two-, or three-dimensional cavities and channels with sizes up to 2 nm, through which a large number of molecules can pass [28,29,30]. The union and combination of Si, O, and Al atoms form many types of Zeolite structures. An important zeolite is mordenite, with good properties as catalytic support. Mordenite belongs to the pentasil family, which has five membered rings as secondary building units. The mordenite structure is composed of connected 5-membered rings forming a composite building unit “mor” [31]. There are only a few articles related to the photocatalysis of wastewater using mordenite-type Zeolite. Mordenite has high thermal and acid stability and has been used as a catalyst for different reactions. Mordenite has also been used in the adsorptive separation of gas or liquid mixtures and for applications in semiconductors, chemical sensors, and nonlinear optics [32]. Semiconductors supported in zeolites forming hybrid materials could be more efficient for photocatalysis applications, as has been reported recently by authors for different catalytic chemical reactions, like dye pollution degradation. For example, few authors have used hybrid semiconductor materials supported in zeolites. In 2018, Jorfi et al. evaluated the capability of sono-photocatalytic process for real wastewater over MgO supported by zeolite, with 76% efficiency after 4 h [33]. In 2018, Rahmani-Aliabadi et al. informed the synthesis of FeS and Fe2S3 supported onto clinoptilolite nanoparticles via sulfidizing and photocatalytic properties for ciprofloxacin degradation with visible light [34]. In 2020, Padervand et al. reported a photocatalyst based on cerium supported in zeolite used for degrading acetamiprid insecticide with ultraviolet excitation. It was synthesized by coprecipitation method and obtained 82% efficiency of degradation after 180 min under ultraviolet irradiation [35]. In 2022, Torkian et al. reported the synthesis and photocatalytic properties for amoxicillin degradation of silver ion-exchanged natural zeolite/TiO2 photocatalyst nanocomposite with 35% efficiency after 75 min [36]. Also in 2022, Liu et al. reported MoS2 with zeolite photocatalysts synthesized by combining ultrasonic and hydrothermal methods and it was used for degrading tetracycline with 87% efficiency [37]. However, to our best knowledge, there is no report using iron oxides/mordenite as an alternative to the common TiO2 catalyst, applying visible light excitation and taking advantage of magnetic retrieval for reusability of the catalyst.

In this paper, we report the methylene blue photodegradation capabilities under visible light of a catalyst based on Fe3O4–Fe2O3 particles supported on synthetic mordenite (Si/Al = 20), which was synthesized by a facile co-precipitation method. Besides, photocatalytic efficiency was improved by a simple and economical thermal treatment without changing pH, temperature, dose or other conditions. This catalyst seems promising for dye wastewater treatment remediation with solar radiation, applied to textile, food, and pharmaceutical industries.

2 Materials

The following reagent grade materials were acquired and utilized without modification. Na(AlO2)(SiO2)x·yH2O (Mordenite Si/Al ratio = 20, Zeolyst International, USA); Iron (II) chloride tetrahydrate (FeCl2·4H2O 98%, Sigma-Aldrich, USA); Iron (III) chloride hexahydrate (FeCl3·4H2O 97%, Sigma-Aldrich, USA); Sodium hydroxide (NaOH 97% Sigma-Aldrich, USA); and Methylene Blue hydrate (C16H18ClN3S·xH2O > 95% Sigma-Aldrich, USA). Deionized water (pH ~ 7, σ ≤ 5 × 10–6 S/m) was also utilized.

3 Methods

Catalyst of Fe3O4–Fe2O3 supported on mordenite (Fe3O4–Fe2O3/mordenite) was synthesized by co-precipitation. 4 g of synthetic mordenite was added into 60 ml deionized water under magnetic stirring for 10 min to disperse the precipitate. Then, 0.76 g FeCl3 and 0.28 g FeCl2 (2:1) were added to the solution under magnetic stirring for 30 min. After using 20 ml of NaOH 4 M, the solution was precipitated, and the catalyst was collected by centrifugation at 2500 rpm for 15 min and washed with deionized water. The precipitate was dried in an oven at 50 °C for 24 h [38,39,40,41,42,43]. Following, the obtained powder was divided into four parts. One part was separated and used without thermal treatment, while the other three parts were subjected to a partial thermal oxidation process at 100 °C, 200 °C and 300 °C for 3 h in air. Fe3O4–Fe2O3 particles were prepared according to reports [44,45,46].

Structural properties were studied by X-ray diffraction (XRD) and data was collected using a PhilipsTM X´pert MPD diffractometer with a Cu Kα radiation (λ = 1.54056 Å), operating at room temperature. Morphology was analyzed by scanning electron microscopy (SEM) using a JEOL™ model JSM 5300 system with energy dispersive spectroscopy (EDS) detector Kevex SuperDry II for chemical analysis. All samples were placed on carbon tape for analysis. Surface area analysis and textural properties were estimated with a Micromeritics Vacprep 061 equipment assisted by N2 adsorption to 77 K. Diffuse reflectance spectra were obtained with a Cary 5000 UV–Vis-NIR spectrophotometer with a scanned wavelength from 800 to 200 nm. X-ray Photoelectron Spectroscopy (XPS) measurements were carried out in a SPECS system equipped with a hemispherical electron analyzer model PHOIBOS 150 WAL and a monochromatic X-ray source, model XRC 1000, using Al Kα line (1486.6 eV) at 200 W. Also, high-resolution spectra were obtained at a pass energy of 20 eV. For simplicity, samples are labeled as follows: pristine mordenite (M), and prepared catalysts, without thermal treatment (MFe), with thermal treatment at 100 °C for 3 h in air atmosphere (MFe100), with thermal treatment at 200 °C for 3 h in air atmosphere (MFe200), and with thermal treatment at 300 °C for 3 h in air atmosphere (MFe300).

Photocatalytic properties were evaluated in a photochemical reactor Rayonet, model RPR 100, equipped with 16 lamps with a wavelength of 420 nm. Catalyst degradation was carried out at constant stirring and 100 mL/min air flow. 250 mL of the solution to 20 ppm of MB with 125 mg of catalyst were added in a cylindrical quartz cell inside the reactor, and the adsorption process was separated to keep the solution in dark condition for 30 min and subsequently photodegradation reaction with visible light excitation for 2 h. A mechanical stirrer was used to achieve a satisfactory suspension of the photocatalyst and the homogeneity of the reacting mixture. Samples at 15 min intervals were withdrawn. The change of intensity of the absorption peak at 664 nm was monitored by UV–Vis spectroscopy in a Varian Cary® 50 UV–Vis spectrometer. 2.5 ml H2O2 (30%) was added to the solution photodegradation mentioned for evaluating MB elimination by the Fenton reaction catalyzed by the Fe3O4–Fe2O3 supported on mordenite samples.

4 Results and discussion

4.1 X-Ray diffraction

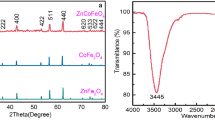

Crystallinity and thermal stability are important properties of supports used in photodegradation applications. Figure 1 shows XRD patterns of M, MFe, MFe100, MFe200 and MFe300 samples. XRD peaks can be indexed to pure mordenite zeolite orthorhombic structure crystallographic XRD pattern JCPDS 43–0171, without peaks of other chemical agents. Peaks are sharp, indicating high crystallinity. Also, they show a tendency to decrease crystallinity as a function of temperature of treatment. There is broadening of peaks as temperature increases, which could be related to dealumination in the mordenite structure. In addition, the insert on the right side of the figure shows the region of the peak corresponding to (202) plane. Although the signal is relatively weak, Fe3O4–Fe2O3 supported on mordenite samples show this peak at higher angles in comparison with the pristine mordenite. It is related to the dealumination process because the Si–O bond (1.60 Å) is shorter than the Al–O bond (1.74 Å) in mordenite. The lattice shrinks when the Al species is leached from the zeolite framework, which means the Al species has successfully escaped [47].

4.2 Scanning electron microscopy and elemental analysis

In Fig. 2, SEM images reveal rough structures with aggregated particles of various sizes, lower than 1000 nm. Figure 2b of prepared catalyst without thermal treatment shows a similar structure than Fig. 2a of pristine mordenite, with more homogeneous and smaller particles. This could be due to the incorporation of Fe3O4–Fe2O3 on mordenite. Images of Figs. 2c–e, corresponding to MFe100, MFe200 and MFe300, show larger size agglomerates, which could be due to sintering and/or dealumination.

To know the chemical composition of the Fe3O4–Fe2O3 supported on mordenite samples, elemental chemical analysis using EDS was performed on the synthesized catalysts. Results presented in Table 1 show the presence of Al, Si, O, Na and Fe for all synthesized samples with an indication of dealumination process as a function of temperature of the thermal treatment.

Following, to know the Fe distribution in the mordenite support in studied samples, an elemental mapping for the sample of MFe100 was obtained, and results are presented in Fig. 3. Al, Si, O, Na and Fe presence is revealed, with Fe atoms well distributed on the mordenite support. This homogeneous distribution of Fe atoms is very convenient since they are used as the catalytic active center for the photodegradation of contaminants.

4.3 UV–Vis optical diffuse reflectance

Optical properties of materials are related to the electronic structure. The calculated results of diffuse reflectance and band gap energy of studied samples are presented in Fig. 4. As shown in Fig. 4a, M sample has high diffuse reflectance for wavelengths > 400 nm, corresponding to visible light. However, mordenite samples with iron oxides present low diffuse reflectance for wavelengths > 400 nm, corresponding to important visible light absorption, from green to violet. Low optical diffuse reflectance for visible light of Fe3O4–Fe2O3 supported on mordenite samples can be used for photodegradation reaction of contaminants excited by visible light. Direct optical band gap energy (Eg) was estimated for M, MFe, MFe100, MFe200 and MFe300 samples using the equation proposed by Kubelka and Munk in 1931:

where S, R, K and F are the scattering, reflectance, absorption coefficients, and Kubelka–Munk function, respectively. Eg and the absorption coefficient are related through the Tauc relation [48]:

where α is the linear absorption coefficient, \(\nu\) is light frequency, h is the Planck constant, and A is the proportionality constant. The power of the parenthesis, n, is taken equal to 2 for direct band gap materials. When incident radiation scatters in a perfectly diffuse manner, the absorption coefficient K becomes equal to 2α. In this case, considering constant the scattering coefficient S, concerning wavelength, the Kubelka–Munk function is proportional to the absorption coefficient α. Applying the last equation, we obtain the relation [49]:

The \({\left[F\left(R\right)h\nu \right]}^{2}\) vs. \(h\nu\) (photon energy) graph is plotted, and the energy band gap of the powder sample can be easily extracted.

The value of Eg for studied samples was obtained by plotting \({\left[F\left(R\right)h\nu \right]}^{2}\) as function of \(h\nu\) (Fig. 4b) and extrapolation of the linear portion of the curve. The obtained results are presented in Fig. 4b. Estimated band gap values for pristine mordenite and Fe3O4–Fe2O3/mordenite samples with different thermal treatments in air atmosphere are ~ 3.4 eV and ~ 2.25 eV, respectively. These results agree with reports of other authors using iron oxide nanoparticles with different organic modifiers [40] or using iron oxide nanoparticles [39, 50]. Moreover, the band gap energy value estimated for the Fe3O4–Fe2O3 supported on mordenite samples shows the possibility of promoting the generation of free charge carriers by using visible light, improving the photodegradation process.

4.4 X-ray photoelectron spectroscopy

Survey XPS was obtained to confirm the chemical composition of Fe3O4–Fe2O3 supported on mordenite samples. Figure 5a shows six signal peaks located at 1072 eV, 103 eV, 532 eV, 75 eV, 285 eV and 712 eV, corresponding to Na 1s, Si 2p, O 1s, Al 2p, C 1s, and Fe 2p3/2, respectively. Also, high-resolution spectra of the Fe 2p region were obtained for MFe, MFe100, MFe200 and MFe300 samples. They were obtained with the purpose of detecting changes in oxidation, according to the chemical equation:

Figures 5b–e show high-resolution spectra and deconvolution into six peaks of MFe, MFe100, MF200 and MFe300 samples. Fe 2p high resolution spectrum is composed of two spectral bands located at 725.3 eV, and 711.9 eV, corresponding to 2p1/2, and 2p3/2 of Fe3+ species, respectively. Also, the other two peaks at a binding energy of 723.8 eV and 710.6 eV are attributed to 2p1/2 and 2p3/2 of the Fe2+ species, respectively. The remaining two weak peaks at 719 eV and 733 eV are satellite peaks. These results and assignments agree with reports of other authors for Fe3O4 and Fe2O3 samples, indicating the successful formation of iron oxide compounds in the mordenite matrix [51,52,53]. Table 2 presents oxidation states of deconvolution estimates of species present in studied samples. They were calculated through the integral of deconvoluted signals in individual XPS peaks. Fe3+ peak signal increases with temperature treatment, from 46 At% to 55 At%, which could be related to an oxidation process. At the same time, the Fe2+ peak signal decreases with temperature treatment, from 54 At% to 45 At%. Then, because of thermal treatment, Fe2+ in Fe3O4 partially becomes Fe3+ in Fe2O3 in studied samples, allowing to obtain Fe2O3 and Fe3O4 in different relative concentrations in the same sample through a simple oxidative thermal process.

4.5 Surface area analysis

Figure 6 shows results of N2 adsorption–desorption isotherms of (a) MFe, (b) MFe100, (c) MFe200, (d) MFe300 samples. They exhibit low adsorption at low relative pressure and hysteresis characteristic of interparticle mesopores of the aggregates present in zeolites [54,55,56]. Table 3 shows textural parameters of the synthesized catalysts. Adsorbed amount of nitrogen, represented by SBET, slowly decreases with thermal treatment temperature, which could be due to sintering and/or dealumination. Volume and diameter of pore show little change within the uncertainty of measurement. A similar effect was observed in previous work with hydrotreated Cu-Ag/mordenite catalysts for NO reduction [57]. The textural properties are related to organic compounds adsorption application and its possible elimination for the remediation process, due to the surface area of the catalyst interacting with organic dye pollution via electrostatic forces. Moreover, the pore of the catalyst is related to the active catalytic centers where dye will be degraded by the photocatalysis and fenton process [58, 59].

4.6 Photocatalytic MB degradation

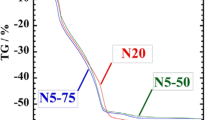

Photocatalytic methylene blue (MB) degradation by the catalysts synthesized was evaluated with visible light excitation. Figure 7 presents the results of UV–visible absorption spectra after photodegradation of MB with visible light for different times of (a) M, (b) MFe, (c) MFe100, (d) MFe200 and (e) MFe300; and (f) MFe100 together with H2O2. Studied catalysts with iron oxides present different decrements in absorbance as function of time, indicating MB degradation with visible light exposition. Absorbance curves show an important contribution from the adsorption effects of MB in the dark (black line, − 30 min) before visible light irradiation exposure on Fe3O4–Fe2O3 supported on mordenite which is the typical behavior in synthetic zeolites with a high Si/Al ratio and could be due to organic residues adsorbed. Figure 8a exhibits results of relative photocatalytic efficiency, represented by C/Co as a function of time of exposure, and Fig. 8b shows kinetics of photocatalytic degradation of MB with visible light of studied catalysts, pristine mordenite and Fe3O4–Fe2O3 supported on mordenite samples. MFe100 shows the best photocatalytic activity with almost 70% MB degradation after 120 min, without adding a co-catalyst (Fig. 8a). The Fenton effect was proved by adding 2.5 ml of H2O2 to MFe100 sample during the MB photocatalytic degradation [60, 61]. Figures 8a and b show how adding H2O2 improves photocatalytic efficiency and kinetics of photocatalytic degradation of MB with visible light, reaching ~ 90% MB degradation after 120 min. On the other hand, M and MFe300 samples do not present considerable photocatalytic activity. Therefore, increasing the temperature of the thermal treatment slightly favored more oxidation in the samples, according to XPS results, increasing Fe2O3 concentration in comparison with Fe3O4, also modification of the surface area, crystallinity and morphology, which could be related with properties for photocatalytic applications.

a The relative photocatalytic efficiency (C/Co) as function of reaction time (t) and b kinetics of photocatalytic degradation of MB with visible light of mordenite pristine and Fe3O4–Fe2O3 supported on mordenite as a function of reaction time (t) in logarithmic scale [−ln(C/Co)], and matched straight lines to first-order reaction kinetics

Curves of relative concentration as a function of time based on the first order kinetic reaction equation [62, 63] was matched to study the kinetics of MB photodegradation, according to the equation:

where C0 and C are respective initial and real-time MB concentrations, and k is the first-order degradation rate constant with visible light. Matched lines are shown in Fig. 8b, and obtained kinetic constants are described in Table 4. Rate constant increases from 0.0043 to 0.0069 min−1 from MFe samples to MFe100 corresponding to ~ 60% increase. Also, rate constant increases about four times from 0.0043 to 0.016 min−1 after MFe100 and a small portion of hydrogen peroxide addition on the Fe3O4–Fe2O3 supported on mordenite catalysts. Considering the rate constant reaction of MB degradation of this catalyst, an extrapolation indicates it could eliminate 99%, approximately, after 180 min of visible irradiation.

Stability of the catalyst was investigated by monitoring the catalytic activity during successive cycles of degradation and results are shown in Fig. 9a, where C0 and C are the initial and real-time MB concentrations, respectively. MFe100 exhibits a very stable photocatalytic performance after five cycles of test without significant loss of activity. Additionally, Fig. 9b shows one of the synthesized catalysts with iron oxides before and after bringing closer a magnet, indicating clearly that thanks to the magnetic properties of the synthesized catalysts it is possible to recover the catalyst through a magnetic field, allowing its reusability in applications of wastewater photodegradation.

4.7 Mechanism of MB degradation

A possible main mechanism for degradation of MB in Fe3O4–Fe2O3/mordenite + H2O2 + Visible light system proposed is: (1) MB is adsorbed in the mordenite support pores through electrostatic interaction, (2) HO• radicals produced by H2O2 activated with photo oxide of Fe2+ and HOO• radicals produced by H2O2 activated with photoreduced of Fe3+ on the surface of Fe3O4–Fe2O3 supported on mordenite samples; and simultaneous process (3) photocatalysis with visible light photons to photogenerated electron–hole pairs that reduces and oxidizes, respectively, O2 and H2O present, generated reactive species OO• and HO•, (4) adsorbed MB in Fe3O4–Fe2O3 supported on mordenite sample is attacked by HO•, OO•, and HOO•, produced by Fenton reaction and photocatalyst. Active centers of MB around the catalyst are provided by the mordenite support with a large surface area. Incorporation of Fe3O4–Fe2O3 particles on mordenite seems to greatly enhance the transformation from Fe3+ to Fe2+ or the recycling of iron species [64, 65]. This possible photocatalytic mechanism of Fe3O4–Fe2O3 supported on mordenite for MB degradation is depicted in Fig. 10.

5 Conclusions

A set of Fe3O4–Fe2O3 supported on mordenite catalysts with different thermal treatments was successfully synthesized by using a simple chemical method and its physicochemical properties were confirmed by DRX, SEM, EDS, XPS, SBET, UV–Vis DR. Crystalline structure and morphology of studied samples are related to thermal treatment. Due to the presence of iron oxides, catalyst samples synthesized with iron oxides have more visible light absorption than pristine mordenite. Samples have a significant temperature dependence with crystallinity, particle agglomeration, surface area, and other textural properties. Sample MFe100 presented the best photodegradation capabilities with visible light excitation. This behavior could be attributed to methylene blue degradation by three processes: adsorption of organic residues in the mordenite matrix support due to electrostatic interactions, photocatalysis heterogeneous reaction with visible light and Fenton reaction catalyst with a small portion of H2O2 by presence of Fe3O4–Fe2O3. Due to the magnetic properties of the Fe3O4–Fe2O3 supported on mordenite samples the catalyst could be retrieved and reused in the photodegradation process. Obtained catalyst MFe100 was able to degrade MB ~ 90% after 120 min. The catalysts synthesized with the presence of Fe3O4–Fe2O3 using visible light for MB degradation were prepared following simple and economical thermal treatments without changing pH, temperature, dose or other conditions. Additionally, catalysts can be retrieved and reused at least five times by using a magnetic field. These catalysts could be proposed for the remediation of wastewater using visible light or solar excitation related to textile, food and pharmaceutical industries.

References

Wang X, Jiang J, Gao W (2022) Reviewing textile wastewater produced by industries: characteristics, environmental impacts, and treatment strategies. Water Sci Technol 85:2076–2096. https://doi.org/10.2166/wst.2022.088

Anwer H, Mahmood A, Lee J et al (2019) Photocatalysts for degradation of dyes in industrial effluents: opportunities and challenges. Nano Res 12:955–972. https://doi.org/10.1007/s12274-019-2287-0

Tkaczyk A, Mitrowska K, Posyniak A (2020) Synthetic organic dyes as contaminants of the aquatic environment and their implications for ecosystems: a review. Sci Total Environ 717:137222. https://doi.org/10.1016/j.scitotenv.2020.137222

Shanker U, Rani M, Jassal V (2017) Degradation of hazardous organic dyes in water by nanomaterials. Environ Chem Lett 15:623–642. https://doi.org/10.1007/s10311-017-0650-2

Rafiq A, Ikram M, Ali S et al (2021) Photocatalytic degradation of dyes using semiconductor photocatalysts to clean industrial water pollution. J Ind Eng Chem 97:111–128. https://doi.org/10.1016/j.jiec.2021.02.017

Viswanathan B (2017) Photocatalytic degradation of dyes: an overview. Curr Catal 7:99–121. https://doi.org/10.2174/2211544707666171219161846

Pirsaheb M, Hossaini H, Raad NK et al (2023) A systematic review on photo-Fenton process as an efficient advanced oxidation for degradation of amoxicillin in aqueous environments. Rev Environ Health 38:313–326. https://doi.org/10.1515/reveh-2021-0155

Din MI, Khalid R, Najeeb J, Hussain Z (2021) Fundamentals and photocatalysis of methylene blue dye using various nanocatalytic assemblies- a critical review. J Clean Prod 298:1236567. https://doi.org/10.1016/j.jclepro.2021.126567

Mussa ZH, Al-Ameer LR, Al-Qaim FF et al (2023) A comprehensive review on adsorption of methylene blue dye using leaf waste as a bio-sorbent: isotherm adsorption, kinetics, and thermodynamics studies. Environ Monit Assess. https://doi.org/10.1007/s10661-023-11432-1

Oladoye PO, Ajiboye TO, Omotola EO, Oyewola OJ (2022) Methylene blue dye: toxicity and potential elimination technology from wastewater. Res Eng 16:100678. https://doi.org/10.1016/j.rineng.2022.100678

Saeed M, Muneer M, Ul Haq A, Akram N (2022) Photocatalysis: an effective tool for photodegradation of dyes-a review. Environ Sci Pollut Res 29:293–311. https://doi.org/10.1007/s11356-021-16389-7/Published

Dong S, Feng J, Fan M et al (2015) Recent developments in heterogeneous photocatalytic water treatment using visible light-responsive photocatalysts: a review. RSC Adv 5:14610–14630. https://doi.org/10.1039/C4RA13734E

Al-Jemeli M, Mahmoud MA, Majdi HS et al (2021) Degradation of anti-inflammatory drugs in synthetic wastewater by solar photocatalysis. Catalysts 11:1330. https://doi.org/10.3390/catal11111330

Bassim S, Mageed AK, AbdulRazak AA, Al-Sheik F (2023) Photodegradation of methylene blue with aid of green synthesis of CuO/TiO2 nanoparticles from extract of citrus aurantium juice. Bullet Chem React Eng Catal 18:1–16. https://doi.org/10.9767/bcrec.16417

Xin Y, Zhu Q, Gao T et al (2023) Photocatalytic NO removal over defective Bi/BiOBr nanoflowers: the inhibition of toxic NO2 intermediate via high humidity. Appl Catal B 324:122238. https://doi.org/10.1016/j.apcatb.2022.122238

Dawi EA, Padervand M, Ghasemi S et al (2023) Multi-functional fluorinated NiTiO3 perovskites for CO2 photocatalytic reduction, electrocatalytic water splitting, and biomedical waste management. J Water Process Eng 54:2214-7144. https://doi.org/10.1016/j.jwpe.2023.103979

Hitam CNC, Jalil AA (2020) A review on exploration of Fe2O3 photocatalyst towards degradation of dyes and organic contaminants. J Environ Manage 258:110050. https://doi.org/10.1016/j.jenvman.2019.110050

Campos EA, Pinto DVBS, de Oliveira JIS et al (2015) Synthesis, characterization and applications of iron oxide nanoparticles—A short review. J Aerosp Technol Manag 7:267–276. https://doi.org/10.5028/jatm.v7i3.471

Bhateria R, Singh R (2019) A review on nanotechnological application of magnetic iron oxides for heavy metal removal. J Water Process Eng 31:100845. https://doi.org/10.1016/j.jwpe.2019.100845

Malhotra N, Lee JS, Liman RAD et al (2020) Potential toxicity of iron oxide magnetic nanoparticles: a review. Molecules 25:3159. https://doi.org/10.3390/molecules25143159

Hasany SF, Ahmed I, Rajan J, Rehman A (2013) Systematic review of the preparation techniques of iron oxide magnetic nanoparticles. Nanosci Nanotechnol 2:148–158. https://doi.org/10.5923/j.nn.20120206.01

Sangaiya P, Jayaprakash R (2018) A review on iron oxide nanoparticles and their biomedical applications. J Supercond Nov Magn 31:3397–3413

Wei X, Xie T, Peng L et al (2011) Effect of heterojunction on the behavior of photogenerated charges in Fe3O4@Fe2O3 nanoparticle photocatalysts. J Phys Chem C 115:8637–8642. https://doi.org/10.1021/jp111250z

Li N, He Y, long, Yi Z zhou, et al (2020) Multiple-metal-doped Fe3O4@Fe2O3 nanoparticles with enhanced photocatalytic performance for methyl orange degradation under UV/solar light irradiation. Ceram Int 46:19038–19045. https://doi.org/10.1016/j.ceramint.2020.04.234

Palanisamy B, Babu CM, Sundaravel B et al (2013) Sol-gel synthesis of mesoporous mixed Fe2O3/TiO2 photocatalyst: Application for degradation of 4-chlorophenol. J Hazard Mater 252–253:233–242. https://doi.org/10.1016/j.jhazmat.2013.02.060

Padervand M, Rhimi B, Wang C (2021) One-pot synthesis of novel ternary Fe3N/Fe2O3/C3N4 photocatalyst for efficient removal of rhodamine B and CO2 reduction. J Alloys Compd 825:156955. https://doi.org/10.1016/j.jallcom.2020.156955

Crini G, Lichtfouse E, Wilson LD, Morin-Crini N (2019) Conventional and non-conventional adsorbents for wastewater treatment. Environ Chem Lett 17:195–213. https://doi.org/10.1007/s10311-018-0786-8

Rangnekar N, Mittal N, Elyassi B et al (2015) Zeolite membranes—a review and comparison with MOFs. Chem Soc Rev 44:7128–7154. https://doi.org/10.1039/C5CS00292C

Van Speybroeck V, Hemelsoet K, Joos L et al (2015) Advances in theory and their application within the field of zeolite chemistry. Chem Soc Rev 44:7044–7111. https://doi.org/10.1039/C5CS00029G

Król M (2020) Natural vs synthetic zeolites. Crystals (Basel) 10:1–8. https://doi.org/10.3390/cryst10070622

Kalvachev Y, Todorova T, Popov C (2021) Recent progress in synthesis and application of nanosized and hierarchical mordenite—a short review. Catalysts 11:1–16. https://doi.org/10.3390/catal11030308

Narayanan S, Tamizhdurai P, Mangesh VL et al (2020) Recent advances in the synthesis and applications of mordenite zeolite - review. RSC Adv 11:250–267. https://doi.org/10.1039/D0RA09434J

Jorfi S, Pourfadakari S, Kakavandi B (2018) A new approach in sono-photocatalytic degradation of recalcitrant textile wastewater using MgO@Zeolite nanostructure under UVA irradiation. Chem Eng J 343:95–107. https://doi.org/10.1016/j.cej.2018.02.067

Rahmani-Aliabadi A, Nezamzadeh-Ejhieh A (2018) A visible light FeS/Fe2S3/zeolite photocatalyst towards photodegradation of ciprofloxacin. J Photochem Photobiol A Chem 357:1–10. https://doi.org/10.1016/j.jphotochem.2018.02.006

Padervand M, Heidarpour H, Bargahi A (2020) A mechanistic study and in-vivo toxicity bioassay on acetamiprid photodegradation over the zeolite supported cerium-based photocatalyst. J Photochem Photobiol A Chem 395:112526. https://doi.org/10.1016/j.jphotochem.2020.112526

Torkian N, Bahrami A, Hosseini-Abari A et al (2022) Synthesis and characterization of Ag-ion-exchanged zeolite/TiO2 nanocomposites for antibacterial applications and photocatalytic degradation of antibiotics. Environ Res 207:112157. https://doi.org/10.1016/j.envres.2021.112157

Liu J, Lin H, Dong Y et al (2022) MoS2 nanosheets loaded on collapsed structure zeolite as a hydrophilic and efficient photocatalyst for tetracycline degradation and synergistic mechanism. Chemosphere 287:132211. https://doi.org/10.1016/j.chemosphere.2021.132211

Besenhard MO, LaGrow AP, Hodzic A et al (2020) Co-precipitation synthesis of stable iron oxide nanoparticles with NaOH: New insights and continuous production via flow chemistry. Chem Eng J 399:125740. https://doi.org/10.1016/j.cej.2020.125740

Hariani PL, Faizal M, Ridwan R et al (2013) Synthesis and properties of Fe3O4 nanoparticles by Co-precipitation method to removal procion dye. Int J Environ Sci Develop 4:336. https://doi.org/10.7763/ijesd.2013.v4.366

Radoń A, Drygała A, Hawełek Ł, Łukowiec D (2017) Structure and optical properties of Fe3O4 nanoparticles synthesized by co-precipitation method with different organic modifiers. Mater Charact 131:148–156. https://doi.org/10.1016/j.matchar.2017.06.034

Anbarasu M, Anandan M, Chinnasamy E et al (2015) Synthesis and characterization of polyethylene glycol (PEG) coated Fe3O4 nanoparticles by chemical co-precipitation method for biomedical applications. Spectrochim Acta A Mol Biomol Spectrosc 135:536–539. https://doi.org/10.1016/j.saa.2014.07.059

Kandpal ND, Sah N, Loshali R, et al. (2014) Co-precipitation method of synthesis and characterization of iron oxide nanoparticles. J Sci Ind Res 73:87-90.

Ahmed FS, AbdulRazak AA, Alsaffar MA (2022) Modelling and optimization of methylene blue adsorption from wastewater utilizing magnetic marble dust adsorbent: a response surface methodology approach. Mater Today Proc 60:1676–1688. https://doi.org/10.1016/j.matpr.2021.12.224

Gao Q, Chen F, Zhang J et al (2009) The study of novel Fe3O4@γ-Fe2O3 core/shell nanomaterials with improved properties. J Magn Magn Mater 321:1052–1057. https://doi.org/10.1016/j.jmmm.2008.10.022

Gallagher KJ, Feitknecht W, Mannweiler U (1968) Mechanism of oxidation of magnetite to y-Fe2O3. Nature 217:1118–1121. https://doi.org/10.1038/2171118a0

Kang YS, Risbud S, Rabolt JF, Stroeve P (1996) Synthesis and characterization of nanometer-size Fe3O4 and γ-Fe2O3 particles. Chem Mater 8:2209–2211. https://doi.org/10.1021/cm960157j

Shao Q, Wei S, Hu X, Dong H, Wen T, Gao L, Long C (2022) Tuning the micro-coordination environment of Al in dealumination Y zeolite to enhance electron transfer at the Cu-Mn oxides interface for highly efficient catalytic ozonation of toluene at low temperatures. Environ Sci Technol 56(22):15449–15459. https://doi.org/10.1021/acs.est.2c05766

Tauc J, Grigorovici R, Vancu A (1966) Optical properties and electronic structure of Ge optical properties and electronic structure of amorphous germanium. Physica Status Solidi (b) 15:627. https://doi.org/10.1002/pssb.19660150224

Aydn C, Abd El-Sadek MS, Zheng K et al (2013) Synthesis, diffused reflectance and electrical properties of nanocrystalline Fe-doped ZnO via sol-gel calcination technique. Opt Laser Technol 48:447–452. https://doi.org/10.1016/j.optlastec.2012.11.004

Kulkarni SA, Sawadh PS, Palei PK, Kokate KK (2014) Effect of synthesis route on the structural, optical and magnetic properties of Fe3O4 nanoparticles. Ceram Int 40:1945–1949. https://doi.org/10.1016/j.ceramint.2013.07.103

Tahir D, Ilyas S, Abdullah B et al (2018) Electronic properties of composite iron (II, III) oxide (Fe3O4) carbonaceous absorber materials by electron spectroscopy. J Electron Spectros Relat Phenomena 229:47–51. https://doi.org/10.1016/j.elspec.2018.09.008

Liu HL, Wu JH, Min JH et al (2009) Monosized core-shell Fe3O4(Fe)/Au multifunctional nanocrystals. J Nanosci Nanotechnol 9(2):754–758. https://doi.org/10.1166/jnn.2009.c018

Wilson D, Langell MA (2014) XPS analysis of oleylamine/oleic acid capped Fe3O4 nanoparticles as a function of temperature. Appl Surf Sci 303:6–13. https://doi.org/10.1016/j.apsusc.2014.02.006

Huang S, Chen P, Yan B et al (2013) Modification of y zeolite with alkaline treatment: textural properties and catalytic activity for diethyl carbonate synthesis. Ind Eng Chem Res 52:6349–6356. https://doi.org/10.1021/ie3032235

Triantafyllidis KS, Karakoulia SA, Gournis D et al (2008) Formation of carbon nanotubes on iron/cobalt oxides supported on zeolite-Y: Effect of zeolite textural properties and particle morphology. Microporous Mesoporous Mater 110:128–140. https://doi.org/10.1016/j.micromeso.2007.10.007

Aguado J, Serrano DP, Escola JM, Peral A (2009) Catalytic cracking of polyethylene over zeolite mordenite with enhanced textural properties. J Anal Appl Pyrolysis 85:352–358. https://doi.org/10.1016/j.jaap.2008.10.009

Ramírez-Garza RE, Rodríguez-Iznaga I, Simakov A, Farías MH, Castillón-Barraza FF (2018) Cu-Ag/mordenite catalysts for NO reduction: effect of silver on catalytic activity and hydrothermal stability. Mater Res Bull 97:369–378. https://doi.org/10.1016/j.materresbull.2017.09.001

Harja M, Buema G, Bucur D (2022) Recent advances in removal of Congo Red dye by adsorption using an industrial waste. Sci Rep 12:6087. https://doi.org/10.1038/s41598-022-10093-3

Afroze S, Sen TK (2018) A review on heavy metal ions and dye adsorption from water by agricultural solid waste adsorbents. Water Air Soil Pollut 229: 225. https://doi.org/10.1007/s11270-018-3869-z

Clarizia L, Russo D, di Somma I et al (2017) Homogeneous photo-Fenton processes at near neutral pH: a review. Appl Catal B 209:358–371. https://doi.org/10.1016/j.apcatb.2017.03.011

Ameta R, Chohadia AK, Jain A, Punjabi PB (2018) Fenton and Photo-Fenton Processes. Advanced Oxidation Processes for Wastewater Treatment: Emerging Green Chemical Technology. Elsevier, Amsterdam, pp 49–87. https://doi.org/10.1016/B978-0-12-810499-6.00003-6

Konstantinou IK, Albanis TA (2004) TiO2-assisted photocatalytic degradation of azo dyes in aqueous solution: Kinetic and mechanistic investigations: a review. Appl Catal B 49:1–14. https://doi.org/10.1016/j.apcatb.2003.11.010

Mahmoodi NM, Arami M, Limaee NY, Tabrizi NS (2006) Kinetics of heterogeneous photocatalytic degradation of reactive dyes in an immobilized TiO2 photocatalytic reactor. J Colloid Interface Sci 295:159–164. https://doi.org/10.1016/j.jcis.2005.08.007

Khan I, Saeed K, Zekker I, Zhang B, Hendi AH, Ahmad A, Ahmad S, Zada N, Ahmad H, Shah LA (2022) Review on Methylene blue: its properties, uses. Toxic Photodegradation. Water 14(2):242. https://doi.org/10.3390/w14020242

Wang Q, Tian S, Ningv P (2014) Degradation mechanism of methylene blue in a heterogeneous fenton-like reaction catalyzed by ferrocene. Ind Eng Chem Res 53(2):643–649. https://doi.org/10.1021/ie403402q

Acknowledgements

This work was supported by DGAPA–UNAM research project PAPIIT IN111622, and CONAHCyT through the FORDECyT project 272894, SENER-CONAHCyT- 117373 and Basic Scientific Research A1-S-26789 and A1-S-17539. RAM thanks CONAHCYT Estancias Postdoctorales por México program, project 3241760, for financial support of this work. The authors would like to thank L. Arce, D. Domínguez, F. Ruiz, J. Mendoza, J. A. Diaz, I. Gradilla, E. Murillo, and E. Aparicio for their valuable technical assistance.

Funding

DGAPA–UNAM, PAPIIT IN111622, Consejo Nacional de Humanidades, Ciencias y Tecnologías, CONAHCYT-FORDECyT project 272894

Author information

Authors and Affiliations

Contributions

RA-M: writing—original draft, visualization, methodology, validation, investigation, formal analysis, data curation, conceptualization. HABN: writing—review & editing, writing—original draft, visualization, validation, methodology, investigation, formal analysis, conceptualization. MHF: writing—review & editing. FC-B: investigation, funding acquisition, formal analysis, conceptualization, methodology, writing—original draft.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability

Data will be made available on request.

Code availability

Not Applicable.

Ethical approval

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Avilés-Monreal, R., Borbón-Nuñez, H.A., Farías, M.H. et al. Photocatalytic activity of Fe3O4–Fe2O3 particles supported on mordenite under visible light exposure for methylene blue degradation. SN Appl. Sci. 5, 389 (2023). https://doi.org/10.1007/s42452-023-05611-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-023-05611-5