Abstract

COMSOL Multiphysics simulation software has been used to create a hexagonal photonic crystal fiber (H-PCF) with hexagonal cladding and a rotating hexa elliptical shape core. The hexagonal photonic crystal fiber (H-PCF) fiber is built on five layers of circular air holes, and it is suitable for telecommunication applications especially optical fiber communication in the terahertz (THz) frequency range. The hexagonal photonic crystal fiber (H-PCF) is designed to have an ultra-low effective material loss (EML), a higher core power fraction, a bigger effective area, and reduced confinement loss. The smallest effective material loss from the proposed hexagonal photonic crystal fiber (H-PCF) is 0.00689 cm−1, with a better core power fraction of 82%, less confinement loss of 3.45 × 10–14 cm−1 and a better effective area of 3.65 × 10–4 m2 is achieved at one terahertz (THz) waveguide region. Furthermore, using the features of the V-Parameter, our developed hexagonal photonic crystal fiber (H-PCF) fiber reveals an optical waveguide with one mode throughout a frequency range of terahertz (THz) wave area. So, it has been said that our hexagonal photonic crystal fiber (H-PCF) structure will be highly beneficial for optical fiber communications applications in the THz frequency range.

Article Highlights

-

Analytical approach for modeling and simulation-based photonic crystal fiber based on low effective material loss (0.00689 cm−1)

-

Provide 82 percent core power fraction and confinement loss with 3.45x10-14 cm−1

-

Competent transmission of broadband hexagonal photonic crystal fiber (H-PCF) THz signals for communication purposes

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Photonic Crystal fibers (PCF) are noble type optical fibers where in a microstructure arrangement of different background materials that have different refractive index is present and that microstructure arrangement is periodic. Also, photonic crystal fibers are composed of an air-filled core, capillaries, decided to create several lattice structures. In recent time, the usage of photonic crystal fibers exceedingly because of its unprecedented and unparalleled noble qualities that is not possible with traditional fibers. Although the conventional optical fibers can useful in case various applications, including telecommunication and non-telecommunication, they are not suitable for other significant applications due to its structural and cut-off wavelength limitations and also the materials choice for conventional optical fibers are limited. Therefore, the conventional optical fibers are not so much applicable for wide range of applications. On the contrary, photonic crystal fibers (PCFs) can able to guide light through the fiber using total internal reflection as well as photonic bandgap (PBG) effect [1]. Therefore, photonic crystal fibers are using in various diversified applications both in telecommunication sectors and non-telecommunication sectors.

Researchers have discovered that photonic crystal fibers (PCFs) perform far better than conventional fibers in the terahertz (THz) frequency range. Terahertz (THz) frequency waveguides have been utilized in a variety of applications in recent years, including communication and chemical detection [2], medical imaging [3], spectroscopy [4], astronomy [5], sensors [6], data transmission [7], security screening [8], radio [9] and other diversified applications.

Previously many researchers designed various types of photonic crystal fibers (PCFs) [10] based on different core structures which are designed for terahertz wave regions [11, 12]. Many researchers have used bulk materials for optical waveguides such as ZEONEX [13] and TOPAS [14]. Researchers are drawn to photonic crystal fibers (PCFs) because they produce reduced confinement loss, larger effective area, lower effective material loss (EML) and a greater core power fraction, lower scattering loss, and lower dispersion loss.

Many researchers around the world designed and developed photonic crystal fibers (PCFs) of various structures using terahertz (THz) waveguides. A simple designed of circular photonic crystal fibers is designed by S. Kumar et al. [15] which shows a very lower confinement loss and a negative dispersion rate. Porous core octagonal photonic crystal fibers (POPCFs) for low loss THz frequency region are proposed by S. Kaijage [16]. In their proposed PO-PCF the TOPAS was considered as the background material. Although in their proposed porous core octagonal photonic crystal fibers they found the effective material loss (EML) of 0.07 cm−1 but in their proposed PO-PCF they didn’t consider two important characteristics parameters such as core dispersion rate and core power fractions. Bao et al. [17] found a higher effective material loss of 0.31 cm−1 from their proposed honeycomb bandgap fibers (BGF). Islam et al. [18] presented a hybrid-core circular cladding photonic crystal fiber with ultra-low effective material loss (EML) and ultra-flattened dispersion rate of 0.035 cm−1 and 0.07 ps/THz/cm, respectively, for the THz frequency. Hasanujjaman et al. [19] developed and evaluated a porous-core kagome lattice photonic crystal fiber (PCF) that may be used in the Terahertz waveguide. TOPAS was utilized as the background material in their suggested created PCF, and the developed technique of PCF was done using the finite element method (FEM). From their designed PCF the observed an effective material loss (EML) of 0.035 cm−1, lowers confinement loss, and a more stable dispersion loss at 1 terahertz (THz) frequency region.

In our research work, a design of a hexagonal photonic crystal fiber (H-PCF) fiber based on a unique hexagonal from exterior and a core with a rotating hexagonal shape is done where the five layers circular air hole-based hexagonal photonic crystal fiber (H-PCF) fiber is perfect for telecommunication related application specially in optical fiber, laser injection in the terahertz (THz) frequency region. The designed hexagonal photonic crystal fiber (H-PCF) presents an ultra-low effective material loss (EML), It is possible to achieve a higher core power fraction, a lower confinement loss, and a larger effective area. Form the designed hexagonal photonic crystal fiber (H-PCF), the minimum effective material loss (EML) is 0.00689 cm−1, a better core power fraction of 82%, a lower confinement loss of 3.45 × 10–14 cm−1 and a better effective area of 3.65 × 10–4 m2 is achieved at 1 terahertz (THz) waveguide region. The characteristics value that we found with our designed hexagonal photonic crystal fiber (H-PCF) shows much better results than the PCF structure that was previously constructed and described in the articles presented in Table 1.

The article is organized as follows: Sect. 2 describes the design approach of the H-PCF fiber. The mathematical equations and formula that are used in the article is described in Sect. 3. In Sect. 4, the simulation results and outcomes of the model are presented. Finally, the conclusions are outlined in Sect. 5.

2 Approach of design methodology

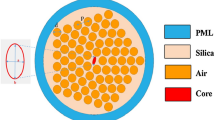

The hexagonal 5 layers cladding areas with a core region that is rotated hexagonally are shown in Fig. 1. The backdrop material is ZEONEX (n = 1.509), and the rotated-hexa core features elliptical-shaped air holes. This fiber is designed for use in the terahertz (THz) frequency range. The Λ1 and d1 parameters specify the cladding area is round air holes pitch and diameter. Furthermore, the initial layer of 6 circular air holes in the elliptical form of the rotated-hexa in core areas. Furthermore, the da (width), db (height) parameters represent the elliptical form is diameter and pitch Hexagons in rotation are indicated by the Λc consistently. ZEONEX (n = 1.509) is utilized as background material to decrease material loss, CL, and SL in terahertz (THz) frequency. Moreover, the thickness of the Perfectly Matched Layer (PML) is calculated by the 8% of the maximum fiber diameter and the optimum parameters are cladding diameter d1 = d2 = d3 = d4 = d5 = 284 μm, cladding pitch Λ1 = Λ2 = Λ3 = Λ4 = Λ5 = 375 μm, core diameter da = 62 μm, db = 192 μm, and core pitch Λc = 100 μm and PML1 = 2260 μm and PML2 = 2460 μm.

3 Mathematical data analysis

A general goal Advanced numerical methods are used in COMSOL Multiphysics simulation software. We utilized COMSOL software to build our H-PCF and to numerically analyze it using the Perfectly Matched Layer and Finite Element Method (FEM), calculating all the data the for the numerical study of photo-sensitive comportment.

The calculation of Scattering Loss of H-PCF fiber is done utilizing the following equation [20]:

Here, \({\mathrm{\alpha }}_{\mathrm{R}}\) represents scattering loss, \({\mathrm{C}}_{\mathrm{R}}\) indicates scattering coefficient and a constant value of \({\mathrm{C}}_{\mathrm{R}}=1\), f is the frequency and c are the speed of light in m/s.

The confinement loss is calculated with the help of the following equation [21]:

Here, \({\mathrm{L}}_{\mathrm{c}}\) indicates confinement loss, \(\mathrm{Im }\left[{\mathrm{n}}_{\mathrm{eff}}\right]\) indicates imaginary part of the effective refractive index, f is the functional frequency, c is the speed of light.

Our H-PCF was created with ZEONEX (n = 1.509) as the backdrop material, which absorbed frequencies from our H-PCF. The use of ZEONEX (n = 1.509) material as a backdrop material results in extremely low effective material loss (EML). In order to determine the effective material loss (EML) of our H-PCF design, use the following equation [22]:

Here, \({\alpha }_{\mathrm{eff}}\) represents the EML of H-PCF, \({\mu }_{0}\) is the permeability in comparison, \({\upvarepsilon }_{{0}}\) represents the relative permittivity, \({n}_{mat}\) is the refractive index, \({S}_{z}\) indicates the pointing vector, \({\mathrm{\alpha }}_{\mathrm{mat }}=1\) is the absorption loss. A pointing vector is shown by the following relation:

Using the following equation as a guide the effective area can be calculated [23]:

where, Aeff is the effective area, I (r) is the cross-sectional electric field intensity and I(rd) =|Et|2.

Calculation of the fiber core power percent by the following equation [24]:

Here, η represents the fiber core power fraction, the area of the core, cladding, or air hole can be computed using the intermigration of the numerator and denominator, where \({S}_{z}\) denotes the pointing vector.

The following equation is used to find the V- parameters of H-PCF [25]:

where, neff represents the effective refractive index (RI) which is found form the COMSOL Multiphysics software with the frequency ranges from 0.08 to 3 terahertz (THz) and ncl = 1.509, indicates the refractive index of the cladding that is V = 2.93216 × sqrt(neff × neff - ncl × ncl) and r indicates the fiber core radius.

4 Outcomes analysis and deliberations

H-PCF was created using COMSOL Multiphysics simulation software with a frequency range of 0.80–3.0 THz according to Fig. 2. The mode field distributions of X-polarization at 1 THz, whereas waveguide Y-polarization at 1 THz is indicated by Fig. 2a and b, respectively of H-PCF fiber. Our suggested structure features ultra-low effective material loss (EML), decreased scattering loss and confinement loss, all of which are highly beneficial for communications since the total power is tightly constrained to the core region.

Figure 3 depicts the variation of effective area with the increase of frequency in THz region at 62%, 72% and 82% porosity level. It is clear from the characteristics curve that the effective area of H-PCF almost exponentially declines with the rise in frequency at THz region. At 1.0 THz it is found that the value of effective area is around 3.65 × 10–4 m2, 3.70 × 10–4 m2 and 4.55 × 10–4 m2 for 82%, 72% and 62% correspondingly. Here, the ideal parameters are cladding diameter d1 = d2 = d3 = d4 = d5 = 284 μm, cladding pitch Λ1 = Λ2 = Λ3 = Λ4 = Λ5 = 375 μm, core diameter da = 62 μm, db = 192 μm, and core pitch Λc = 100 μm.

In the Fig. 4, the characteristics of effective area contrasted with core diameter is shown for three porosity level such as 82%, 72% and 62%. As we seen from the characteristics curve it is found that core diameter region (approximately 240 μm to 360 μm) the effective area is not changing the effective area began to grow as core diameter increased to decline at a level up to 440 μm approximately and it shows constant characteristics. At core diameter Dcore = 420 μm, the effective areas are approximately found 4.72 × 10–8, 4.55 × 10–8 and 4.38 × 10–8 m2 for 62%, 72% and 82% porosities respectively at 1terahartz (THz) operating frequency.

In the following Fig. 5, depicts the behavior graph of accordance with the fluctuation in effective material loss with the change in frequency in terahertz region for three different porosity levels such as 82%, 72% and 62%. After the simulation procedure form the COMSOL Multiphysics software, we have found that the total amount of lights (data values) transmits within the core area. As a result, this structure shows better graphical results of low effective material loss with the frequency ranges from 0.08 to 3 terahertz (THz) for 82%, 72% and 62% porosity. Moreover, the attributes graph also shows that is found the EML deteriorations with the rise in frequency at THz region for better communications applications at the three-porosity levels of 82%, 72% and 62%. At 1 THz frequency, the EML are 0.00689 cm−1, 0.00699 cm−1 and 0.0149 cm−1 for 82%, 72% and 62% porosity correspondingly.

Figure 6 shows the characteristics curve of the effective material loss versus core diameters at micrometer range of the designed H-PCF for the three different porosity levels of 82%, 72% and 62%. It may be shown from the typical graph that with the increase of core diameter the effective material losses decreases for all the defined three different porosity levels. In our proposed H-PCF Dcore = 420 μm, the EML is about 0.00689 cm−1 for 82% core porosity fabricating it in a way that maximizes value while minimizing complexity.

As illustrated in Fig. 7, the power fractions of the core, cladding, and material vary with frequency in the terahertz range. According to the figure, at the cladding area, the power percentage is nearly flat as the frequency increases. In the core region, the power fraction increases with frequency, but after a certain frequency, it remains constant. For material power fraction, As frequency rises, the power fraction declines in terahertz region but after a certain value of frequency the power fraction shows a flat characteristic considering the continued rise in frequency. For 1 THz frequency the power fractions are 0.25%, 20%, 82% for cladding, material and core respectively.

Figure 8 shows a graph of qualities of scattering loss varies with frequency in terahertz region at optimum parameters. It is seen from the characteristics graph that scattering region in dB/km increases with the increase of the frequency in THz. It is also shown that the slope of increasing curve is low that means the scattering loss increasing but slowly with the increase in frequency. This indicates the fact that light was significantly reflected from the core. This H-PCF has achieved a minimal scattering loss of 1.24 × 10–10 dB/km at 1 THz.

Figure 9 shows the variation of Confinement Loss with the increase of the frequency at terahertz region at optimum constraints of the designed H-PCF. Form the graph it is examined that at the starting the confinement loss started decreasing but from 1 to 1.7 THz the confinement loss stayed constant and then again decreased but this time the decrease found more gradual than from the starting point. The value of Confinement Loss is found 3.46 × 10–14 cm−1 for 1 terahertz in frequency.

The variation of V-parameter with respect to the increase of frequency in the THz range for the intended H-PCF under the ideal design conditions (Single mode fiber) is shown on Fig. 10. From the graph, it is examined that the V-parameter is increasing in proportional to the increase of the frequency at terahertz region up to around 2.10 THz. After 2.10 THz the V-parameter increases a little slowly than before and at after around 3 THz the V-parameters remains constant with the increase in frequency. Due to this, the H-PCF may be used for optical fiber communications applications.

The effective area, EML, confinement loss, scattering loss, Power Fraction, V-parameter characteristics shows a better result by our designed H-PCF at the terahertz region than the previously designed PCF. The comparison results of different parameters that are proposed previously and our proposed H-PCF results are shown in the following Table 1.

We examined different results values of different features from the research of previously suggested PCF and out designed H-PCF in the above comparison table. We discovered that our H-PCF, as intended, produces outstanding results. The comparison table shows that we get the lowest effective material loss (EML) per centimeter from our designed H-PCF, the highest core porosity of 82 percent, a higher core power fraction than previously found core power percentage, larger effective area and less confinement loss from our designed H-PCF. Because our developed H-PCF achieves excellent results in all characteristics areas, it may be used in a variety of important applications, such as broad band transmission. Fabrication method is a significant consideration in the design of H-PCF. PCF may be made in a variety of ways, including jacketing, stacking, collapsing, stretching, and sketching on a traditional drawing tower. However, in recent years, a manufacturing process known as the sol–gel method has become popular for fabricating PCF [35, 38, 39]. As a result, sol–gel will be used as the method to produce our proposed H-PCF in order to obtain a higher-quality PCF fiber.

5 Conclusion

PCF with an elliptical core is designed to achieve ultra-low effective material loss in the THz frequency range. From the hexagonal photonic crystal fiber (H-PCF) design, remarkable outcomes are obtained. At the 1 terahertz waveguide region, the hexagonal photonic crystal fiber (H-PCF) achieves a superior core power fraction of 82 percent, a lower confinement loss of 3.46 × 10–14 cm−1, smallest effective material loss of 0.00689 cm−1 and a better effective area of 3.65 × 10–4 m2. Therefore, we believe that the hexagonal photonic crystal fiber (H-PCF) will be more appropriate and pleasant for optical fiber communication system in the terahertz (THz) range.

Data availability

Data sharing is not applicable to this article.

References

Saitoh K, Koshiba M (2003) Leakage loss and group velocity dispersion in air-core photonic bandgap fibers. Opt Express 11(23):3100–3109. https://doi.org/10.1364/OE.11.003100

Arif, M. F. H., Asaduzzaman, S., Ahmed, K., & Morshed, M. (2016, May). High sensitive PCF based chemical sensor for ethanol detection. In 2016 5th International Conference on Informatics, Electronics and Vision (ICIEV) (pp. 6–9). IEEE. https://doi.org/10.1109/ICIEV.2016.7760031

Sun Q, He Y, Liu K, Fan S, Parrott EP, Pickwell-MacPherson E (2017) Recent advances in terahertz technology for biomedical applications. Quant Imaging Med Surg. https://doi.org/10.21037/qims.2017.06.02

Zhang J, Grischkowsky D (2004) Waveguide terahertz time-domain spectroscopy of nanometer water layers. Opt Lett 29(14):1617–1619. https://doi.org/10.1364/OL.29.001617

Chen Q, Jiang Z, Xu GX, Zhang XC (2000) Near-field terahertz imaging with a dynamic aperture. Opt Lett 25(15):1122–1124. https://doi.org/10.1364/OL.25.001122

Nagel M, Haring Bolivar P, Brucherseifer M, Kurz H, Bosserhoff A, Büttner R (2002) Integrated THz technology for label-free genetic diagnostics. Appl Phys Lett 80(1):154–156. https://doi.org/10.1063/1.1428619

Yang, Y., & Roy, S. (2015, December). PCF scheme for periodic data transmission in smart metering network with cognitive radio. In 2015 IEEE Global Communications Conference (GLOBECOM) (pp. 1–6). IEEE. https://doi.org/10.1109/GLOCOM.2015.7416969

Ishigaki K, Shiraishi M, Suzuki S, Asada M, Nishiyama N, Arai S (2012) Direct intensity modulation and wireless data transmission characteristics of terahertz-oscillating resonant tunnelling diodes. Electron Lett 48(10):582. https://doi.org/10.1049/el.2012.0849

Chaudhary S, Amphawan A (2018) Solid core PCF-based mode selector for MDM-Ro-FSO transmission systems. Photon Netw Commun 36(2):263–271. https://doi.org/10.1007/s11107-018-0778-4

Hasan MR, Akter S, Khatun T, Rifat AA, Anower MS (2017) Dual-hole unit-based kagome lattice microstructure fiber for low-loss and highly birefringent terahertz guidance. Optical Eng. https://doi.org/10.1117/1.OE.56.4.043108

Suhaimi NANB, Maidi AMI, Abas PE, Kaijage S, Begum F (2022) Design and simulation of heptagonal porous core photonic crystal fiber for terahertz wave transmission. Optik. https://doi.org/10.1016/j.ijleo.2022.169142

Yakasai IK, Abas PE, Suhaimi H, Begum F (2020) Low loss and highly birefringent photonic crystal fibre for terahertz applications. Optik. https://doi.org/10.1016/j.ijleo.2020.164321

Tang X, Jiang Y, Sun B, Chen J, Zhu X, Zhou P, Wu D, Shi Y (2013) Elliptical hollow fiber with inner silver coating for linearly polarized terahertz transmission. IEEE Photonics Technol Lett 25(4):331–334. https://doi.org/10.1109/LPT.2013.2238525

Nielsen K, Rasmussen HK, Adam AJ, Planken PC, Bang O, Jepsen PU (2009) Bendable, low-loss Topas fibers for the terahertz frequency range. Opt Express 17(10):8592–8601. https://doi.org/10.1364/OE.17.008592

Pandey SK, Prajapati YK, Maurya JB (2020) Design of simple circular photonic crystal fiber having high negative dispersion and ultra-low confinement loss. Result Optics. https://doi.org/10.1016/j.rio.2020.100024

Kaijage SF, Ouyang Z, Jin X (2013) Porous-core photonic crystal fiber for low loss terahertz wave guiding. IEEE Photonics Technol Lett 25(15):1454–1457. https://doi.org/10.1109/LPT.2013.2266412

Islam MS, Sultana J, Dorraki M, Atai J, Islam MR, Dinovitser A, Ng BWH, Abbott D (2018) Low loss and low dispersion hybrid core photonic crystal fiber for terahertz propagation. Photonic Netw Commun 35(3):364–373. https://doi.org/10.1007/s11107-017-0751-7

Bao H, Nielsen K, Rasmussen HK, Jepsen PU, Bang O (2012) Fabrication and characterization of porous-core honeycomb bandgap THz fibers. Opt Express 20(28):29507–29517. https://doi.org/10.1364/OE.20.029507

Hasanuzzaman GKM, Habib MS, Razzak SA, Hossain MA, Namihira Y (2015) Low loss single-mode porous-core kagome photonic crystal fiber for THz wave guidance. J Lightwave Technol 33(19):4027–4031. https://doi.org/10.1109/JLT.2015.2459232

Shova R I, Sunny S M A S, Badrudduza A S M, Hossain S and Ahmed T .2020. Externally gold coated photonic crystal fiber biosensor based on surface plasmon resonance. IEEE Int. Women in Engineering (WIE) Conf. on Electrical and Computer Engineering (WIECON-ECE) pp 336–9

Arif M, Huq F, Hossain MM, Islam N, Khaled SM (2019) A nonlinear photonic crystal fiber for liquid sensing application with high birefringence and low confinement loss. Sens Bio-Sens Res 22:100252

Ponseca CS Jr, Pobre R, Estacio E, Sarukura N, Argyros A, Large MC, Van Eijkelenborg MA (2008) Transmission of terahertz radiation using a microstructured polymer optical fiber. Opt Lett 33(9):902–904. https://doi.org/10.1364/OL.33.000902

Rahman M M, Mou F A, Mahmud A A, Bhuiyan M I H and Islam M R. 2019. Photonic crystal Fiber based terahertz sensor for alcohol detection in beverages: design and analysis. IEEE Int. Conf. on Telecommunications and Photonics (ICTP), December

Bulbul AAM, Imam F, Awal MA, Mahmud MA (2020) A novel ultra-low loss rectangle based porous-core PCF for efficient THz Wave guidance: design and numerical analysis. Sensors 20:6500

Goto M, Quema A, Takahashi H, Ono S, Sarukura N (2004) Teflon photonic crystal fiber as terahertz waveguide. Jpn J Appl Phys 43(2B):L317. https://doi.org/10.1143/JJAP.43.L317

Islam R, Rana S, Ahmad R, Kaijage SF (2015) Bend-insensitive and low-loss porous core spiral terahertz fiber. IEEE Photon Technol Lett 27(21):2242–2245. https://doi.org/10.1109/LPT.2015.2457941

Hasan MR, Islam MA, Anower MS, Razzak SM (2016) Low-loss and bend-insensitive terahertz fiber using a rhombic-shaped core. Appl Opt 55(30):8441–8447. https://doi.org/10.1364/AO.55.008441

Hasan MR, Islam MA, Rifat AA (2016) A single mode porous-core square lattice photonic crystal fiber for THz wave propagation. Eur Opt Soc Rapid Publ. https://doi.org/10.1186/s41476-016-0017-5

El Hamzaoui H, Ouerdane Y, Bigot L, Bouwmans G, Capoen B, Boukenter A, Bouazaoui M (2019) Sol-gel derived ionic copper-doped microstructured optical fiber: a potential selective ultraviolet radiation dosimeter. Opt Express 20:29751–29760

Rahman MM, Mou FA, Mahmud AA, Bhuiyan MIH, Islam MR (2019) Photonic crystal Fiber based terahertz sensor for alcohol detection in beverages: design and analysis”. IEEE Int Conf Telecommun Photonics (ICTP). https://doi.org/10.1109/ICTP48844.2019.9041767

Cordeiro CM, Dos Santos EM, Cruz CB, de Matos CJ, Ferreira DS (2019) Lateral access to the holes of photonic crystal fibers–selective filling and sensing applications. Opt Express 14:8403–8412

Wu Z, Shi Z, Xia H, Zhou X, Deng Q, Huang J, Jiang X, Wu W (2016) Design of highly birefringent and low-loss oligoporous-core THz photonic crystal fiber with single circular air-hole unit. IEEE Photonics J 8:1–11

Rana S, Hasanuzzaman GK, Habib S, Kaijage SF, Islam R (2014) Proposal for a low loss porous core octagonal photonic crystal fiber for T-ray wave guiding. Opt Eng 53(11):115107–115107. https://doi.org/10.1117/1.OE.53.11.115107

Ahasan Habib M, ShamimAnower M, Rabiul Hasan M (2018) Highly birefringent and low effective material loss microstructure fiber for THz wave guidance. Optics Commun 423(1):140–144. https://doi.org/10.1016/j.optcom.2018.04.022

Sultana J, Islam MS, Ahmed K, Dinovitser A, Ng BW-H, Abbott D (2018) Terahertz detection of alcohol using a photonic crystal fiber sensor. Appl Opt 57(10):2426. https://doi.org/10.1364/ao.57.002426

Sultana J, Islam MS, Islam MR, Abbott D (2018) High numerical aperture, highly birefringent novel photonic crystal fibre for medical imaging applications. Electron Lett 54(2):61–62. https://doi.org/10.1049/el.2017.3694

Islam MS, Sultana J, Rana S, Islam MR, Faisal M, Kaijage SF, Abbott D (2017) Extremely low material loss and dispersion flattened TOPAS based circular porous fiber for long distance terahertz wave transmission. Opt Fiber Technol 34(1):6–11. https://doi.org/10.1016/j.yofte.2016.11.014

Paul BK, Bhuiyan T, Abdulrazak LF, Sarker K, Hassan MM, Shariful S, Ahmed K (2019) Extremely low loss optical waveguide for terahertz pulse guidance. Result Phys. https://doi.org/10.1016/j.rinp.2019.102666

Ahmed K, Chowdhury S, Paul BK, Islam MS, Sen S, Islam MI, Asaduzzaman S (2017) Ultrahigh birefringence, ultralow material loss porous core single-mode fiber for terahertz wave guidance. Appl Opt 56(12):3477–3483. https://doi.org/10.1364/AO.56.003477

Funding

The authors have not received any funding for this research.

Author information

Authors and Affiliations

Contributions

All authors contributed equally in this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

No unethical work has been performed in this research work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rahman, M.H., Rana, M.M., Hossain, M.S. et al. Analytical approach for modeling and simulation of photonic crystal fiber based on low effective material loss. SN Appl. Sci. 5, 71 (2023). https://doi.org/10.1007/s42452-023-05295-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-023-05295-x