Abstract

Every consumer’s decision has an impact on the environment, and even basic food products such as pasta have an impact due to their high consumption rates. Factors that can be influenced by the consumer include the preparation (cooking), last mile and packaging phases. The last mile has not been considered in most studies but contributes considerably to the environmental impact of pasta. The three phases and their environmental impact on the life cycle of pasta are analyzed in this cradle-to-grave life cycle assessment. The focus of the study lies on the impact categories climate change, agricultural land occupation, fossil depletion, water depletion, freshwater eutrophication and freshwater ecotoxicity. Inventory data were taken from other studies, were collected in cooperation with a zero-packaging organic grocery store in Germany or were gained in test series. Our results show that the preparation of pasta has the greatest environmental impact (over 40% in the impact categories climate change and fossil depletion and over 50% in the impact category freshwater eutrophication), followed by the last mile (over 20% in the impact categories climate change and fossil depletion) and lastly the packaging (nearly 9% in the impact categories freshwater eutrophication and freshwater ecotoxicity). Based on our study´s results, we provide some recommendations for minimizing the environmental impacts of pasta.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Problem statement

Consumers are responsible for a much larger share of CO2-emissions in Germany than previously thought, with a share of about 40% including emissions of energy and transport sectors [1]. Based on the individual consumption sectors of German private households, electricity consumption contributes 7%, mobility currently 19% and nutrition 15% per capita to the climate change burden [2]. At this point it should already be noted that the preparation (electricity consumption), the last mile (mobility) and in general the choice of the product itself including its packaging (nutrition) represent the areas of influence by the consumer. Pasta is one of the standard food products in the German retail trade, as it is consumed by the majority of the population between once and several times a week [3]. Pasta is also one of those products where the consumer has a certain amount of control over the packaging through the choice of alternative packaging options, such as buying food in zero-packaging grocery stores. In order to assess the environmental impact of pasta, it is necessary to consider the entire life cycle, which is divided into various life cycle phases: The life cycle of pasta begins with the primary production (cultivation) of wheat, follows with the semolina and pasta production, packaging production, transports, last mile, packaging end-of-life (EoL), preparation and ends with the consumption of the prepared pasta (and the disposal of waste). The environmental impact of pasta has largely been studied by using Life Cycle Assessment (LCA). In the life cycle of pasta, it is the primary production of durum wheat that contributes most of the environmental impact [4,5,6]. If, on the other hand, the phases of the life cycle of pasta that can be influenced directly by the consumer are brought into focus, they include preparation, last mile (customer’s shopping route) and packaging.

1.2 Current state of research

Several studies have already dealt with the topic of LCA of pasta, including the phases that can be influenced by the consumer. Among them are Bevilacqua et al. [7], De Cecco [4], Barilla [5], Valdigrano [6], Recchia et al. [8] and the Product Environmental Footprint Category Rules (PEFCR) of the Union of organizations of manufactures of pasta products of the E.U. (UN.A.F.O.A) and Life Cycle Engineering [9]. The life cycle stages of different LCA studies on pasta considered and their results vary considerably depending on the study design. According to Bevilacqua et al. [7], the use phase (last mile and cooking with a gas cooktop) contributes about 40% and the packaging production about 15% to the environmental impacts of durum wheat pasta in the impact categories climate change and fossil fuels. The results of the environmental product declaration of De Cecco [4] show that the packaging production and disposal of durum wheat semolina pasta (with the distribution target Italy) accounts for almost 6% of the total climate change burden. The total environmental impact of the above-mentioned De Cecco pasta, excluding the preparation, was 1.5 kg CO2-e for 1 kg of dried pasta. The results of the environmental product declaration for Barilla [5] showed that the packaging production and disposal represented almost 5% of the total climate change burden of pasta (with the distribution target Italy), which was 0.78 kg CO2-e for 1 kg of dried pasta in total. According to the results of the LCA report of Valdigrano [6] on organic durum wheat semolina pasta (variety “Valbio”), the packaging production and disposal accounts for about 10% of the total climate change burden. The environmental impact of organic Valdigrano pasta is slightly lower than that of De Cecco pasta, at 1.3 kg CO2-e for 1 kg of dried pasta. Study results of Recchia et al. [8] showed that the environmental impact of high-quality pasta in the impact category climate change (GWP) with 1.7 kg CO2-e for 1 kg of dried pasta is slightly lower than the environmental impact of conventional pasta with almost 1.8 kg CO2-e for 1 kg of dried pasta. The share of the preparation in the LCA of pasta was about 60% for both pasta variants. In contrast, the preparation according to the PEFCR [9] (characterized benchmark values) contributed only half as much to the environmental impact of pasta with about 30% compared to the results of Recchia et al. [8]. According to all the presented study results, the primary production of wheat causes a considerable proportion of the environmental impact [4,5,6,7,8,9], which is not presented here, however, as this phase cannot be influenced by the consumer. In the studies presented, the preparation contributes 30% to 60% and the packaging 5% to 15% to the overall LCA of pasta. There are no results for the percentage of the last mile on its own in the life cycle of pasta. The results for the environmental impact of the preparation and packaging of pasta alone suggest that it is important to consider the phases that can be directly influenced by the consumer.

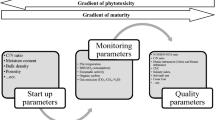

In the following sections, the parameters of these three phases (preparation, last mile and packaging) are considered. The impact of the preparation strongly depends on the choice of hotplate and the amount of water among other factors. The environmental impact of the last mile depends mainly on the purchase distance and the purchase weight and is subject to strong variations, especially due to the allocation of different route purposes [10].

In summary, LCA analyses of pasta have always taken the packaging into consideration, but the research on the preparation is seldom sufficient (as often only one preparation method or one type of stove was considered, cf. Section 4.1) and the last mile has been rarely examined. Only the study of Bevilacqua et al. [7] examined all three phases preparation, last mile and packaging, but in relation to conventional pasta and also only in relation to the private car as a means of transport for the last mile. Of all the studies presented, the study by Bevilacqua et al. [7] corresponds most closely to the study design of the current research project. Hence, some of the study results of Bevilacqua et al. [7] have been adopted for the first phases of the LCA of this project (durum wheat semolina production, pasta production and transport processes).

2 Research question

To this day, it remains unclear whether the consumer can exert major influence over the life cycle of organic durum wheat semolina pasta (DWS-pasta) through the type of preparation, the means of transport over the last mile and the choice of packaging. The current study establishes a connection between previous studies and our own calculations and measurements of the three areas mentioned in relation to organic DWS-pasta. As a basis for the calculation of the LCA within the Umberto LCA + [11] software using the ecoinvent database [12], primary data on packaging was acquired in an organic certified zero-packaging grocery store and an organic grocery store, both are located in Germany. For the calculation of the last mile, data on the shopping distance and the purchase weight was acquired from a study by Mohr [10]. Data for the preparation of pasta were primarily collected within test series performed at the Faculty of Food, Nutrition and Hospitality Services of the Niederrhein University of Applied Sciences. The upstream chain "from cradle to retailer" serves as a foil against which the influence of the consumer stands out.

3 Methods

3.1 Goal and scope definition

The goal of this study is to investigate the environmental impact of the processes that can be influenced by the consumer on the life cycle of organic DWS-pasta. Our focus lies on the preparation process, the last mile and the packaging process. The functional unit (FU) of this study is pasta from Italy, prepared and ready to consume in Germany, made of 1 kg dried, organic DWS-pasta. The scope is from cradle-to-grave. To increase the comparability of pasta bought from an organic zero-packaging grocery store with pasta bought from an organic grocery store, the processes of primary production, semolina production and pasta production including the associated transport processes (excluding last mile) are the same in both scenarios. Accordingly, only those processes differ in which the last mile, preparation, and packaging play a role. The LCA of this study is conducted according to the International Organization for Standardization (ISO) 14,040 and 14,044 standards [13, 14].

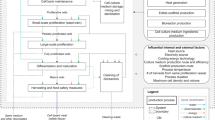

Figure 1 shows a process flow diagram representing the processes in the LCA model. The system includes the phases wheat cultivation, semolina and pasta production, packaging production, wholesale, retail shop, last mile, use phase and all transport processes between different locations. We distinguish between the two scenarios “unpacked” (UP) and “packed” (P). Within the scenario UP, the consumer buys the pasta from an organic zero-packaging grocery store and carries it in a reusable cotton bag. Therefore, two cleaning processes are added, and their effect is calculated: On the one hand, the cleaning of the gravity bin (reusable container in which the pasta is stored and sold) in the zero-packaging grocery store and, on the other hand, the cleaning of the reusable container at the customer. Within the scenario P, the consumer buys pasta traditionally packed in plastic (0.5 kg-LDPE bag). For the scenario P, a further waste removal process is calculated: This involves the disposal of the primary packaging at the customer's premises. Not included in the systems P and UP are the following activities:

-

All kinds of assets like buildings, lorries, etc.,

-

In particular: production, maintenance and cleaning of machines,

-

Forklift truck operation and similar low energy-use processes,

-

Other general and administrative processes within the companies that are not directly attributable to pasta production, like e.g., lighting, heating etc. (cf. overhead costs),

-

Processes regarding recycling of the packaging,

-

In particular: production of gravity bin and reusable cotton bag (only applies to scenario UP)

Process flow diagram and system boundaries of organic durum wheat semolina pasta for both scenarios UP (zero-packaging organic grocery store) and P (organic grocery store). The diagram only shows major inputs and outputs. Please see bullet points at the end of Sect. 2.2 for a list of excluded processes. Inputs and outputs that fall below the cut-off criteria are mostly not shown. For material flows in detail see supplementary file 1. At the end cooked pasta is consumed, therefore leaving the system as virtual flow not shown here. The transport processes between wholesale and retail shop are combined to a single transport process in the sequel

Several material inputs and outputs that are directly connected with the process are mentioned but not calculated due to the cut-off rules. See supplementary file 1 for details. Regarding the data quality, see supplementary file 1 as well.

3.2 Life cycle inventory analysis

3.2.1 Collecting and calculating data

Data used in our model for all phases of the production from cradle up to pasta production were taken from Bevilacqua et al. [7]. Data for the remaining phases were collected by our own measurements, calculated on the basis of other study results. A table showing an overview of the collection and calculation of the individual life cycle phases of the LCA of pasta can be found in the supplementary file 1.

3.2.2 Allocation

Ecoinvent (version 3.6 allocation at the point of substitution [APOS]) [12] was used as the Life Cycle Inventory Database. The ILCD-Handbook [15] cites three different decision contexts, the so-called situations, A ("Micro-level decision support"), B ("Meso/macro-level decision support"), and C ("Accounting"). Situation A is appropriate in our case, i.e., our LCA yields a decision support in the micro-level by identifying key environmental performance indicators that are influenceable by the consumer. In ecoinvent this is a decision for the model Allocation (as opposed to Consequential, which models situation B, the meso-/macroscopic approach) [16]. Ecoinvent/Umberto now comes with two models, Allocation, APOS [17] and Allocation, cut-off [18]. In the cut-off model, the primary production process never obtains credits for reused or recycled waste. Instead, the producer of any good is fully responsible for the disposal of its waste. This, of course, does not correspond to the consumer’s intention and action to reduce environmental impact. The model Allocation, APOS (formerly known as Allocation, ecoinvent default) follows the attributional approach in which burdens are attributed proportionally to specific processes. Therefore, our micro-decision models regarding food products in the consumer’s environment are generally modeled with Allocation, APOS. Within the life cycle of pasta, two allocations occur, which in both cases are calculated by means of the economic value. The allocation between wheat and straw is considered in the ecoinvent dataset: While 93.1% of the environmental impact is attributed to wheat, the allocation factor for straw is 6.9% [19]. In the context of DWS production there is a further allocation between DWS and DW husk, which is mostly used as animal feed. Here, the data of the masses from the study of Lo Giudice [20] and the data of the economic values from current stock exchange prices were used and calculated in the LCA model. The model results in the following allocation: 85% of the environmental impact are attributed to DWS and 15% to DW husks.

3.3 Life cycle impact assessment

Within the impact assessment, the collected data is divided into impact categories, and impact indicators are selected. This study uses the Life Cycle impact assessment (LCIA) method ReCiPe 2008 Midpoint Hierarchist (H) [21]. The impact categories climate change (GWP), agricultural land occupation (ALOP), fossil depletion (FDP), water depletion (WDP), freshwater eutrophication (FEP) and freshwater ecotoxicity (FET) were used for the impact assessment of the packaging (scenario P and UP) and preparation of pasta. In our view, all these impact categories are best for representing the environmental impact of a food product and its packaging. With regard to the environmental impact of the last mile, only the three impact categories GWP, FDP and FET were investigated, since the consideration of the entire life cycle showed that the last mile is particularly relevant in these three impact categories.

3.4 Uncertainty analysis

The consumer has an influence on the last mile, the preparation method and, within the limits of what can be bought, on the packaging (the reason for the study was an investigation of the influence of the final packaging on the LCA, initially limited to zero-packaging grocery stores). According to ISO 14040/14044 standards [13, 14], we perform uncertainty analyses with respect to these processes. The upstream chain is taken as a fixed background. For further details see supplementary file 1.

-

The packaging characteristic is a nominal characteristic. Here, two types of packaging (scenario P and UP) were examined and compared.

-

For the last mile, an average distance (12 km) for the shopping trip and an average weight (5 kg) of the shopping, of which the pasta is a fifth, was selected. The source for this is the work of Mohr [10]. Here we assume that the trip is made by car or afoot solely for the purpose of shopping. Thus, the impact assessment factors for this trip are to be calculated and then proportionally calculated down to the kg of pasta. For the transport distance and the purchase weight of the last mile, a sensitivity analysis was carried out as an uncertainty analysis. The environmental impact of the consumer transport is allocated physically, i.e., by proportion of weight. We do not use the PEFCR guidance ([22], Sect. 7.14.1.3) as modeling guidelines for consumer transport, since this underestimates the influence of the consumer transport.

-

To investigate the environmental impact caused by the preparation of pasta, the three factors water quantity, lid and energy level were investigated according to a full factorial experimental design [23]. A particular electric stove (mobile induction hob) was chosen to perform the preparation. Energy consumption was measured using a mobile measuring device. The preparation of 0.1 kg of pasta was studied with three factors (amount of water 0.5 l and 1 l, with and without lid, variation of the stove setting during the cooking process) on energy consumption. The amount of pasta cooked remained constant in each case. Each cooking experiment was performed three times. For the energy consumptions used for the model, the mean values of the three measurements were used. The variance of the measured values within a preparation method proved to be small compared to the overall effect of the preparation method in this phase. The overall impact of this phase is reported in the evaluation as a range between the lowest and highest impacts.

4 Results

4.1 Contribution of all life cycle phases of pasta

For a complete overview of the environmental impact of all phases, the entire life cycle of pasta is considered here, from initial production to preparation. The scenario P is used for the calculation, and it is assumed that the customer does the shopping route by car. The results for the contribution of life cycle phases of pasta are shown in Fig. 2.

Relative contribution of all life cycle phases, calculated within the six impact categories climate change (GWP), agricultural land occupation (ALOP), fossil depletion (FDP), water depletion (WDP), freshwater eutrophication (FEP) and freshwater ecotoxicity (FET). For the packaging it is assumed that pasta is bought in an organic grocery store (scenario P)

Results displayed in the bar graph (Fig. 2) show that most environmental impact is caused by the life cycle phases primary production, preparation and last mile.

4.2 Environmental impact of primary production, semolina and pasta production, and transports

Primary production accounts for 17% (all percentages are rounded to integers) of the GWP with a value of 620 g CO2-e. With 2.59 m2a for ALOP (89%), 0.18 m3 for WDP (83%) and 5 g 1,4-DCB-e for FET (62%), primary production has the highest share in these three impact categories. In the impact category FEP, the environmental impact of wheat cultivation, at 0.2 g P-e, is 36%. Related to FDP, the cultivation of wheat has a relatively small influence with a proportion of 9% (88.2 g oil-e).

The production processes for semolina and pasta combined cause only a minor environmental impact. In comparison to the other impact categories, the highest impact of both production processes is in the impact category FDP with 81.1 g oil-e (8%). The next highest values are 136 g CO2-e (4%) for GWP and 0.3 g 1,4-DCB-e (4%) for FET. Within the impact categories ALOP, WDP and FEP, the values for the production processes of semolina and pasta are below 3%.

The transport processes (excluding the last mile) account for 9% of the FDP with 89.4 g oil-e and 7% of the GWP with 253 g CO2-e. In the impact category FET, transports account for 0.2 g 1,4-DCB-e (3%) of the environmental impact. Within the remaining impact categories ALOP, WDP, FEP, the environmental impact of the transport processes is less than 1%.

Results for packaging phases (production and EoL), last mile and preparation are considered separately in the following sections due to their high relevance for this study.

4.3 Environmental impact of the life cycle phase packaging

4.3.1 Environmental impact of the packaging in the life cycle of pasta

If the scenario P is calculated within the life cycle of pasta, the packaging (production and EoL of the primary, secondary and tertiary packaging) accounts for a relatively small part of the environmental impact, in contrast to the last mile and the preparation (see Fig. 2). The percentage share of packaging (scenario P) in the life cycle of pasta is below 10% in all impact categories investigated. Packaging has its highest percentage share in the impact categories FEP and FET with 9% each. These are followed by the shares in the impact categories FDP with 7%, GWP with 7%, ALOP with 6% and WDP with 2% (see Fig. 2).

4.3.2 Environmental impact of two different packaging scenarios for pasta

For the next comparison between the two scenarios P and UP, only those phases that are impacted by the packaging are examined. Accordingly, only the packaging production, the transport processes three and four (excluding the last mile), the disposal of the packaging and, in the scenario UP, the cleaning processes of the gravity bin and reusable cotton bag are considered. Of course, the environmental impact of the transport processes refers not only to the packaging, but also to the pasta within the packaging.

Figure 3 and Table 1 show the results of the comparison between the two packaging scenarios within the six impact categories GWP, ALOP, FDP, WDP, FEP and FET in relation to the baseline scenario P for the four phases packaging production, transports, cleaning process, and packaging EoL. Within all impact categories there are considerable differences between the packaging scenarios P and UP: In three impact categories, the environmental impact for scenario UP is less than 50% compared to scenario P in these four phases. In the impact category FEP, scenario UP has the lowest share of 32% compared to scenario P (100%) (93% in relation to the total for the complete FU), followed by 35% for WDP (98% in relation to total) and 39% for FET (93% in relation to total). Compared to scenario P (100%), the scenario UP in these four phases has higher shares in the impact categories GWP with 59% (95% in relation to total), FDP with 61% (94% in relation to total) and ALOP with 63% (94% in relation to total).

Packed (P) vs. unpacked (UP) pasta. The results for the “packed” scenario are set to 100%, including the 4 phases packaging production, transports (excluding last mile), cleaning processes and packaging EoL only. The following impact categories were considered: climate change (GWP), agricultural land occupation (ALOP), fossil depletion (FDP), water depletion (FDP), freshwater eutrophication (FEP), freshwater ecotoxicity (FET)

Packaging production always has a higher environmental impact for scenario P than for UP, especially in the impact category ALOP, as more cardboard packaging materials are used in the scenario P. As there are no major differences between the values for the scenarios P and UP during the transport phase, it can be concluded that the largest share of the environmental impact of transports is attributable to the pasta. The environmental impact of packaging EoL is on average about three times higher for scenario P than for UP due to the larger amount of packaging material. A particularly high proportion of the packaging EoL is within the impact categories WDP, FEP and FET.

Except for WDP, the cleaning processes of the scenario UP account for only a very small proportion of the environmental impact. Since it was assumed that the customer washes the cotton bag only after every tenth use, and because the bag makes up only a small percentage of the total amount of laundry, this cleaning process has such a low environmental impact. If the cotton bag were to be washed after every use, the environmental impact of this cleaning process would increase tenfold, but the UP scenario would still have lower impact in all impact categories except WDP.

4.4 Environmental impact of the life cycle phase last mile

4.4.1 Environmental impact of the last mile in the life cycle of pasta

As already shown in Fig. 2, the last mile phase (customer’s shopping route) accounts for a significant proportion of the environmental impact in the three impact categories GWP, FDP, and FET as soon as the car is chosen as the means of transport. There are three major factors that are decisive here: the distance traveled, the quantity (weight) of the purchase, and the means of transport.

4.4.2 Environmental impact of the last mile transport choice

Comparing the last mile by car and afoot, there are reductions in the environmental impact within the three impact categories GWP, FDP and FET. Figure 4 shows the comparison between the shopping distance traveled by car and the purchase distance traveled afoot related to the total impact of the functional unit. The GWP is 3.63 kg CO2-e for the life cycle of pasta, if the customer covers the shopping distance by car. If, on the other hand, the customer walks to the retail store, the environmental impact is reduced by 21% and the GWP is 2.85 kg CO2-e. Within the impact category FDP, the value is reduced by 25%: the environmental impact is 0.99 kg oil-e for the shopping distance by car and 0.74 kg oil-e for walking. The value for FET is 7.99E-03 kg 1,4-DCB-e if the customer chooses the car as a means of transport and 6.68E-03 kg 1,4-DCB-e if they walk. According to this, the environmental impact is reduced by 16%.

4.4.3 Sensitivity analysis of the purchase distance and purchase weight

To examine the influence of the purchase distance and purchase weight in more detail, sensitivity analyses for the last mile when using a car as a means of transport were conducted. In relation to the GWP, a linear gradient can be observed as the purchasing distance increases (see Fig. 5). The purchase distance of 0 km represents the customer's shopping route afoot, as in effect no environmental impact is attributed to the last mile within this scenario.

Sensitivity analysis of the two influencing factors purchase distance and purchase weight on the environmental impact (climate change [GWP]) of the last mile. Left: Sensitivity analysis of the purchase distance: GWP when traveling the last mile by car with a varying purchase distance (1, 4, 8, 12, 16, 20 and 24 km; phase last mile only) and constant purchase weight (5 kg). Right: Sensitivity analysis of the purchase weight: GWP when traveling the last mile by car with a varying purchase weight (1, 2, 3, 5, 10, 15 and 20 kg) and a constant purchase distance (12 km) (phase last mile only)

Within the baseline scenario (12 km), 0.79 kg CO2-e is attributed to the last mile. If the purchase distance is only 1 km, the environmental impact in the impact category GWP can be reduced by 92% in this phase (by 20% related to the total). With a longer purchase distance of 24 km, the GWP increases by 96% to a value of 1.55 kg CO2-e compared to the baseline scenario in this phase (by 21% related to the total).

The amount of purchasing also plays a decisive role, as the environmental impact of the last mile is attributed proportionally. Accordingly, the GWP decreases with an increasing purchase weight. Figure 5 shows that the GWP for the phase last mile is relatively high, with 3.86 kg CO2-e for a purchasing weight of 1 kg. For a purchasing weight of 5 kg (baseline scenario), the GWP of 0.79 kg CO2-e is already reduced by more than four times. Of course, the GWP here is reciprocally proportional to the distance. At 10, 15 and 20 kg purchase weight, the GWP only decreases slightly in comparison to the baseline scenario (5 kg).

4.5 Environmental impact of the life cycle phase preparation

4.5.1 Environmental impact of the preparation in the life cycle of pasta

The preparation contributes proportionally the most to the environmental impact of three factors that can be influenced by the consumer, as already shown in Fig. 2. All percentages below refer to the corresponding total of the impact category for the functional unit. The preparation has the highest percentage shares in the impact categories GWP with 1.6 kg CO2-e (44%), FDP with 0.41 kg oil-e (41%), and FEP with 2.53E-04 kg P-e (51%) in the context of the entire life cycle of pasta. Preparation has a smaller share in the life cycle of pasta in the impact categories WDP with 0.03 m3 (13%), FET with 5.38E-04 kg 1,4-DCB-e (7%), and ALOP with 0.11 m2a (4%).

4.5.2 Environmental impact of different preparation methods

The results of the impact assessment within the impact categories GWP, ALOP, FDP, WDP, FEP, and FET for the eight preparation methods can be found in Table 2 (cooking phase only). A supplementary bar chart shows the environmental impacts in the impact category GWP (see Fig. 6).

Comparative environmental impact of the preparation of 0.1 kg of pasta in the impact category GWP (cooking phase only). A distinction is made between the three factors water quantity (0.5 l or 1 l), lid (lid or no lid) and power setting (max–min or max-med). The baseline scenario is represented by the factor level combination "1 l; no lid; max-med"

Based on Table 2 and Fig. 6, the set energy level of the induction hotplate has the highest environmental impact compared to the other two factors. The four preparation methods with factor level combination max-med have a higher environmental impact than the preparation methods with factor level max–min combination in all impact categories (see Table 2). The factor with the next highest environmental impact is represented by the amount of water. Preparing 0.1 kg of pasta in 1 l of water always has higher environmental impact than preparing the same amount of pasta in 0.5 l of water. The effect of the factor lid is negligible.

In relation to the entire life cycle of pasta, the preparation (cooking) according to the factor level combination "0.5 l; no lid; max–min" instead of "1 l; no lid; max-med" can reduce the environmental impact in the impact categories FEP by 30%, GWP by 26%, FDP by 25%, WDP by 7%, FET by 4% and ALOP by 2%.

5 Discussion

Consumers have more influence on the life cycle of pasta than previously assumed. The goal of this study was to investigate the (percentage) influence of the three life cycle phases preparation, last mile and packaging. Therefore, the factors within the three scenarios by which the environmental impact can be reduced were examined. Our results show that within the impact categories ALOP, WDP and FET, the primary production of wheat is responsible for the largest part of the environmental impact with more than 60%. In the three sectors that are influenced by the consumer, the preparation of pasta has the greatest environmental impact, followed by the last mile and lastly the packaging. The last mile, which is not considered in most studies, is one of the most important influencing factors according to our results. Our results regarding the preparation and the last mile are thus consistent with the results of Bevilacqua et al. [7], which also showed that the use phase (last mile and cooking) accounts for the largest share in the life cycle of pasta in terms of climate change burden. That the preparation phase accounts for a major share in the life cycle of pasta in terms of the impact category climate change is also consistent with the study results of Recchia et al. [8].

5.1 Influence of the preparation on the LCA of pasta

Preparation–the cooking of pasta–causes the highest environmental impact within the three phases packaging, last mile and preparation (see Fig. 2). If pasta is prepared according to factor level combination "0.5 l; no lid; max–min" instead of "1 l; no lid; max-med", the environmental impact of the preparation can be reduced by 59% in the impact category GWP in this phase (by 26% related to total of functional unit), by 59% in ALOP (2%), by 60% in FDP (24%), by 56% in WDP (7%), by 59% in FEP (30%) and by 58% in FET (4%) (see Table 2).

5.1.1 Cooking technology

With regard to the cooking efficiency and thus the environmental impact of various cooking technologies, we cannot give any conclusions on the basis of our test series, as the cooking tests were carried out using an induction hob only. According to the results of most studies, induction hobs have the lowest environmental impact. For cooking 1 kg of pasta in 10 L of water, the Product Declaration for Barilla calculates a GWP of 607 g CO2-e with gas hob and 1594 g CO2-e with electric hob [5]. Favi et al. [24] compare the environmental impact of an induction and gas hob in the preparation of lunch for a family of four in Italy over a period of 20 years. The results of the midpoint indicators show that the induction hob is responsible for over 60% of GWP and ozone depletion and over 70% of metal depletion [24]. Also, in the end-point categories and cumulative energy demand, gas performs better than induction. The high energy consumption during preparation and therefore the energy sources make the difference here: due to a relatively low share of renewable energy sources, the electrical energy used for induction has a higher environmental impact.

In order to minimize energy consumption, a stove or hob with the highest possible energy efficiency class should be used. When buying a new appliance, the European Commission recommends consumers to consider the EU energy label: appliances with the highest energy efficiency class are marked with an A + + + [25]. Minimum requirements for the energy efficiency of hobs are legally defined since 2014 within the EU Regulation No. 66/2014 [26].

To keep the GWP of the cooking process as low as possible, after Cimini and Moresi [27], the pot should be closed with a lid and the water should first be brought to a boil at the maximum power setting. Once the water has reached boiling point, minimum power should be set for a constant water temperature. Compared to cooking with maximum power setting, the GWP can be reduced by 81% for gas, 73% for electric and 86% for induction hob. It was also found that the choice of a small, medium or large pot size makes little difference compared to the other factors.

When cooking with induction or electric hobs, the choice of energy source should also be considered: Compared to fossil fuels, renewable energies have a lower GWP [28]. Pasta producer Barilla [29] also recommends on their website using the hot cooking water for cleaning (the pot and dishes) after preparation.

5.1.2 Amount of water

The environmental impacts of the preparation can be reduced, among other things, by using less water. Instead of the general recommendation to boil 0.1 kg of pasta in 1 l of water, it could be shown that the amount of water can also be reduced by 50%. In our own tests, a water quantity of 0.5 l per 0.1 kg of pasta achieved just as good a result as with 1 l of water. By reducing the water content, the energy consumption and thus the GWP is lowered. In Barilla's environmental product declaration, it was shown that the carbon footprint can be reduced by 8% if the amount of water used to cook the pasta is reduced by 30% [5]. Our results show a reduction potential of 26% (cooking phase only) with a 50% reduction in water volume (and a lower power setting) related to the impact category GWP.

5.1.3 Lid

The results of this research project showed that the differences between the environmental impacts of the various preparation methods with and without lids is generally very small. This contrasts with the results of Cimini and Moresi [27], who showed that the lid is also a decisive factor in reducing the environmental impact of cooking.

5.2 Influence of the last mile on the LCA of pasta

Regarding the choice of the means of transport, only the car and walking were considered in this study. In the context of LCA of pasta, the last mile has not been sufficiently considered so far. The last mile is not mentioned as part of the life cycle of pasta in the Environmental Product Declarations of Barilla [5] and De Cecco [4] and in the study of Lo Giudice [20]. Other studies, such as the study by Recchia et al. [8], consider the last mile as part of the life cycle of pasta, but they do not sufficiently address the high relevance of this life cycle stage (for example, in the form of sensitivity analyses). Similar observations were also made by Dinkel and Kägi [30], who, among other things, investigated the environmental impact of 1-L mineral water including the last mile. Their results for glass and PET bottles showed that the last mile has about the same environmental impact as all other processes (such as production and disposal processes). Sima et al. [31] showed in their study a Consumer Carbon Footprint (CCF) for the last mile with a range of 124 to 293 g CO2 per kg of food purchased. The lower value is explained by a high number of consumers who made the shopping trip afoot, by bicycle or public transport instead of using the car. Another study examines the comparative environmental impact of the last mile and packaging in clothing purchasing. Hischier [32] showed that the environmental impact of the last mile, especially by car, depends crucially on the number of items of clothing purchased and the frequency of shopping. Comparing the GWP of different means of transport per kilometer driven, a study by Hollingsworth et al. [33] shows that the personal car has the highest value with 257 g CO2-e/ passenger-km (pkm), followed by the e-scooter with 126 g CO2-e/ pkm (−51% compared to the car), the bus ridership with 51 g CO2-e/ pkm (-80% compared to car) and finally the personal bicycle with 5 g CO2-e/ pkm (-98% compared to car). According to the results of the 2007 household passenger transport survey in Germany, daily purchases, such as food, are mainly made by the following means of transport: 45.9% are MIT (motorized individual traffic) drivers, 28.7% walk, 11.5% are MIT passengers, 11% use the bicycle, and 2.9% use public transport [34].

More than half of the daily purchases are made with MIT. Walking is only an option for those who live close enough to a supermarket. Public transport is used by barely 3% of people, which is the lowest share. To reduce the environmental impact, using public transport is better than using MIT. Trains and trams, for example, emit less than half the greenhouse gases of cars [35]. Based on the Paris Agreement, the Federal Environment Agency has summarized the need for action in the transport sector in Germany up to the year 2050. In future, greenhouse gas emissions from transport are to be reduced by increasing electric mobility and more energy-efficient road vehicles, among other things.

5.3 Influence of the packaging (choice of retail store) on the LCA of pasta

Some studies have also shown that packaging contributes relatively little to the environmental impact of pasta. In the product declarations for De Cecco [4] and Barilla [5] and in the Valdigrano study [6], the environmental impact of the packaging (production and EoL) is at most 10%.

Dolci et al. [36] examined the comparative environmental impact of various packaging scenarios for pasta, among other things, in their study. They compared 3 different packaging variations of loose distribution (1-, 3- and 5-kg bags) with 6 different packaging variations of conventional distribution (3 different materials in 500 g and 1 kg packaging each). Comparing different conventional pasta packaging, a 1-kg polypropylene (PP) pillow bag has a lower environmental impact than a 1-kg cartonboard box in all impact categories considered. 1 kg pasta (FU), packed in a 1-kg pillow bag, has a GWP value of 173 g CO2-e. In comparison, our calculations resulted in a value of 500 g CO2-e for a 500-g pillow bag with the same FU. The fact that the value is more than double can be explained by the fact that the transport distance to the retail store is more than twice as long and the proportion of primary packaging is considerably higher (500 g instead of 1 kg). The results of the study show that a loose distribution of pasta has a lower environmental impact compared to pasta in a one-way cartonboard box. Their results also show (contrary to our results) that pasta in a 1-kg PP pillow bag partly has a lower environmental impact than pasta from loose distribution (which is mainly due to the different packaging variations of loose distribution). Since our calculations are based on a 10 kg paper pillow bag instead of 1-, 3- and 5-kg plastic pillow bags as primary packaging, the loose distribution in our study has a lower environmental impact than the conventional packaging in the 500 g pillow bag. Contrary to our assumption that the customer fills the product with a reusable cotton bag, Dolci et al. [36] assumed that the customer fills the pasta into a disposable LDPE or cellulose bag, which also increases the environmental impact of loose distribution.

Currently, the number of zero-packaging grocery stores in Germany is still significantly lower than the number of organic shops and especially of conventional grocery stores [37]. According to Istas [38], a long-term winning of customers for zero-packaging grocery stores requires a standardized store concept with a circular supply chain. For consumers, convenience is one of the most important factors when buying food. Since most zero-packaging grocery stores currently offer very little convenience due to the fact that consumers often bring along mostly heavy reusable food containers, there is still a need for optimization to make shopping faster and easier for the customer. Beitzen-Heineke et al. [39] see the lack of convenience in zero-packaging grocery stores as a result of a small product range and the generally slower purchasing process. The advantages of these stores are above all a resource-saving treatment of food and social advantages for participants in the supply chain. For more far-reaching services, in particular for environmental and social issues, zero-packaging grocery stores would have to adapt to the services of conventional supermarkets.

Recommendations for action to reduce supply barriers on the part of traders as well as knowledge deficits on the part of consumers when buying environmentally friendly food products are given by Weiß [40]. The organic label, for example, has already proven to be helpful for better recognition of environmentally friendly products. Other labels of environmentally friendly products for consumers should be promoted by politicians and the trade, for example to draw attention to the environmental impact of long transport routes and non-seasonal products. Another aspect is the lack of supply of environmentally friendly food products, especially organic and regional ones. These could be improved, for example, by expanding the organic range in supermarkets and by increasing the number of organic shops.

According to Jungbluth [41], the consumer should choose products with the lightest possible weight of packaging material, since the type of packaging contributes significantly less to the environmental impact.

6 Conclusion and outlook

Based on the results of this LCA study, the following recommendations for consumers concerning the packaging, last mile and preparation can be made to reduce the environmental impact of organic DWS-pasta:

The environmental impact of pasta preparation is significantly influenced by the selected power setting and the amount of water. Accordingly, consumers should cook pasta with a low power setting and a small amount of water. The total environmental impact of the LCA of pasta can be reduced by cooking 0.1 kg of pasta according to factor level combination "0.5 l; no lid; heat up with maximal power, then reduce power to minimal setting (max–min)" instead of "1 l; no lid; heat up with maximal power, then reduce power to medium setting (max-med)" in the impact categories FEP by 30%, GWP by 26% and FDP by 25%. There are also lower reduction potentials in the impact categories WDP with 7%, FET with 4% and ALOP with 2%.

To reduce the environmental impact caused by the last mile, the customer should ideally walk to the retail shop or cover the last mile by bicycle or public transport instead of driving there by car. The environmental impact of the LCA of pasta can be reduced by walking instead of driving a car (over a distance of 12 km with a purchase weight of 5 kg) in the impact categories GWP by 21%, FDP by 25% and FET by 16%. Since the last mile accounts for such a large proportion of the environmental impact once the car is used as a means of transport, it is advisable to bundle up purchases and thus drive to the grocery store less frequently. As demonstrated by the results of other studies, public transport, cycling, or walking are alternatives to car travel with a lower environmental impact in descending order. Due to the higher environmental impact of the last mile compared to packaging, shopping (afoot) in a nearby organic grocery store should be preferred to shopping (by car) in a zero-packaging grocery store further away.

The consumer should buy pasta in an organic zero-packaging grocery store instead of an organic grocery store in order to minimize the environmental impact caused by the packaging. Pasta bought in an organic zero-packaging grocery store (purchased in a reusable cotton bag) has a 6% lower environmental impact in each of the impact categories FEP and FET, a 5% lower environmental impact in each of the impact categories GWP and FDP, and finally a 2% lower environmental impact in each of the impact categories ALOP and WDP compared to conventionally packed pasta from an organic grocery store.

The environmental impact of the last mile has often not been considered in LCA product studies. It should be included and researched further in future studies due to its high relevance.

Data availability

Is given by the information in the manuscript.

References

Schlich E (2019) Zur Bedeutung der Privathaushalte für die CO2-Emission Deutschlands [The importance of private households for Germany's CO2 emissions]: Teil 1: Makroökonomische Analyse unter anteiliger Einbeziehung der Sektoren Energiewirtschaft und Verkehr [Part 1: Macroeconomic analysis with proportional inclusion of the energy and transport sectors]. https://doi.org/10.23782/HUW_08_2019

Umweltbundesamt (2020) Konsum und Produkte. https://www.umweltbundesamt.de/daten/private-haushalte-konsum/konsum-produkte. Accessed 15 Oct 2020

Statista (2019) Herstellung von Teigwaren in Deutschland: Statista-Dossier zur Teigwarenherstellung in Deutschland. https://de.statista.com/statistik/studie/id/31258/dokument/herstellung-von-teigwaren-in-deutschland-statista-dossier/. Accessed 31 Mar 2021

De Cecco (2011) Environmental product declaration of De Cecco durum wheat semolina pasta. https://www.environdec.com/Detail/?Epd=8132. Accessed 24 Nov 2020

Barilla (2013) Environmental product declaration of durum wheat semolina pasta in paperboard box. https://www.environdec.com/Detail/?Epd=7699. Accessed 24 Nov 2020

Valdigrano (2014) Pasta di semola di grano duro: Valdigrano di Flavio Pagani Srl. http://www.valdigrano.com/pdf/GER/lca.pdf. Accessed 24 Nov 2020

Bevilacqua M, Braglia M, Carmignani G et al (2007) Life cycle assessment of pasta production in Italy. J Food Qual 30:932–952

Recchia L, Cappelli A, Cini E et al (2019) Environmental sustainability of pasta production chains: an integrated approach for comparing local and global chains. Resources 8(1):1–16

UN.A.F.P.A., Life Cycle Engineering (2018) Product environmental footprint category rules for dry pasta. https://ec.europa.eu/environment/eussd/smgp/pdf/Dry%20pasta%20PEFCR_final.pdf. Accessed 31 Mar 2021

Mohr M (2013) Consumer Carbon Footprint beim Einkauf von Bioprodukten, 1st edn. Shaker Verlag GmbH, Düren

Ifu Institut für Umweltinformatik Hamburg GmbH umberto. https://www.ifu.com/umberto/. Accessed 12 Dec 2020

Ecoinvent ecoinvent - the world's most consistent & transparent life cycle inventory database. https://www.ecoinvent.org/. Accessed 12 Dec 2020

DIN 14040 (2009) Umweltmanagement – Ökobilanz – Grundsätze und Rahmenbedingungen ICS 13.020.10(DIN EN ISO 14040:2009–11)

DIN 14044 (2006) Umweltmanagement – Ökobilanz – Anforderungen und Anleitungen ICS 13.020.60(DIN EN ISO 14044:2006–10)

European Union (2010) International reference life cycle data system (ILCD) Handbook: general guide for life cycle assessment - detailed Guidance. European Commission - Joint Research Centre - Institute for Environment and Sustainability, Luxembourg

Weidema BP, Bauer C, Hischier R et al. (2013) Overview and methology: data quality guideline for the ecoinvent database version 3. Ecoinvent Report 1 (v3). https://www.ecoinvent.org/files/dataqualityguideline_ecoinvent_3_20130506.pdf. Accessed 12 Dec 2020

Ecoinvent Allocation at the Point of Substitution. https://www.ecoinvent.org/database/system-models-in-ecoinvent-3/apos-system-model/allocation-at-the-point-of-substitution.html. Accessed 12 Dec 2020

Ecoinvent Allocation cut-off by classification. https://www.ecoinvent.org/database/system-models-in-ecoinvent-3/cut-off-system-model/allocation-cut-off-by-classification.html. Accessed 12 Dec 2020

Nemecek T, Kägi T (2007) Life Cycle Inventories of Agricultural Production Systems: Data v2.0 (2007). ecoinvent report No. 15, Zürich

Lo Giudice A, Clasadonte MT, Matarazzo A (2011) LCI preliminary results of in the sicilian durum wheat pasta chain production. J Commod Sci Technol Quality 50:65–79

Goedkoop MJ, Heijungs R, Huijbregts M et al. (2013) ReCiPe 2008: A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level. https://www.researchgate.net/publication/302559709_ReCiPE_2008_A_life_cycle_impact_assessment_method_which_comprises_harmonised_category_indicators_at_the_midpoint_and_the_endpoint_level. Accessed 31 Mar 2021

European Commission (2018) PEFCR Guidance document, - Guidance for the 13 development of Product Environmental Footprint Category Rules (PEFCRs), version 6.3. https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_guidance_v6.3.pdf. Accessed 17 Aug 2021

Kleppmann W (2011) Versuchsplanung: Produkte und Prozesse optimieren, 7., aktualisierte u. erw. Aufl. Praxisreihe Qualitätswissen. Hanser, München

Favi C, Germani M, Landi D et al (2018) Comparative life cycle assessment of cooking appliances in Italian kitchens. J Clean Prod 186:430–449. https://doi.org/10.1016/j.jclepro.2018.03.140

European Commission About the energy label and ecodesign. https://ec.europa.eu/info/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/energy-label-and-ecodesign/about_en#relatedlinks. Accessed 28 May 2020

Commission Regulation (EU) (2014) No 66/2014 of 14 January 2014 implementing Directive 2009/125/EC of the European Parliament and of the Council with regard to ecodesign requirements for domestic ovens, hobs and range hoods (Text with EEA relevance), vol 29

Cimini A, Moresi M (2017) Energy efficiency and carbon footprint of home pasta cooking appliances. J Food Eng 204:8–17

Deutscher Bundestag (2007) CO2-Bilanzen verschiedener Energieträger im Vergleich: Klimafreundlichkeit von fossilen Energien, Kernenergie und erneuerbaren Energien im Vergleich [Climate compatibility of fossil energies, nuclear energy and renewable energies in comparison]. Ausarbeitung

Barilla (o. J.) Bio Fusilli [Organic Fusilli]. https://www.barilla.com/de-ch/produkte/pasta/bio/bio-fusilli. Accessed 19 Aug 2020

Dinkel F, Kägi T (2014) CustomLCA: Ökobilanz Getränkeverpackungen [Life cycle assessment of beverage packaging]. Gesamtbericht, Basel

Sima A, Möhrmann I, Thomae D et al (2012) Einkaufswege als Teil des Consumer Carbon Footprints (CCF) - Zum Anteil des Endverbrauchers an der Klimarelevanz von Prozessketten im Lebensmittelbereich [Purchasing channels as part of the Consumer Carbon Footprint (CCF) - The share of the end consumer in the climate relevance of process chains in the food sector]. Ernährungsumschau 59:524–531

Hischier R (2018) Car vs. packaging—a first, simple (environmental) sustainability assessment of our changing shopping behaviour. Sustainability 10:3061. https://doi.org/10.3390/su10093061

Hollingsworth J, Copeland B, Johnson JX (2019) Are e-scooters polluters? The environmental impacts of shared dockless electric scooters. Environ Res Lett 14:84031. https://doi.org/10.1088/1748-9326/ab2da8

BMIV (2019) Verkehr in Zahlen 2019/2020 [Traffic in numbers 2019/2020]: 48. Jahrgang, Flensburg

Umweltbundesamt (2018) Vergleich der durchschnittlichen Emissionen einzelner Verkehrsmittel im Personenverkehr [Comparison of the average emissions of individual means of transport in passenger traffic]. https://www.umweltbundesamt.de/bild/vergleich-der-durchschnittlichen-emissionen-0. Accessed 24 Nov 2020

Dolci G, Nessi S, Rigamonti L et al (2015) Life cycle assessment of waste prevention in the delivery of pasta, breakfast cereals, and rice. Integr Environ Assess Manag 12:445–458

Kröger M, Wittwer A, Pape J (2020) Schlussbericht zum Thema: "Der verpackungsfreie Supermarkt: Stand und Perspektiven. Über die Chancen und Grenzen des Precycling im Lebensmitteleinzelhandel": FKZ: 2814NA0125. Projektnehmer: Hochschule für nachhaltige Entwicklung Eberswalde. Gefördert durch das Bundesministerium für Ernährung und Landwirtschaft auf Grund eines Beschlusses des Deutschen Bundestages im Rahmen des Bundesprogramms Ökologischer Landbau und andere Formen nachhaltiger Landwirtschaft, Eberswalde

Istas D (2019) Expansion of the local, organic and zero-packaging food concept in three contexts: zero-packaging grocerystores, conventional supermarkets, andecostores. Maastricht University, Masterarbeit

Beitzen-Heineke EF, Balta-Ozkan N, Reefke H (2017) The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain. J Clean Prod 140:1528–1541. https://doi.org/10.1016/j.jclepro.2016.09.227

Weiß J (2006) Umweltverhalten beim Lebensmitteleinkauf [Environmental behaviour in food purchasing]: Eine Untersuchung des Einkaufsverhaltens und der Angebotsstrukturen in sechs Berliner Wohngebieten [An investigation of purchasing behavior and supply structures in six Berlin residential areas]. Dissertation, Humboldt-Universität Zu Berlin

Jungbluth N (2000) Umweltfolgen des Nahrungsmittelkonsums [Environmental impacts of food consumption]: Beurteilung von Produktmerkmalen auf Grundlage einer modularen Ökobilanz [Evaluation of product features based on a modular life cycle assessment]. https://doi.org/10.3929/ethz-a-003867192. Accessed 31 Mar 2021

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gnielka, A.E., Menzel, C. The impact of the consumer’s decision on the life cycle assessment of organic pasta. SN Appl. Sci. 3, 839 (2021). https://doi.org/10.1007/s42452-021-04822-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04822-y