Abstract

This study investigated a road failure on an erosion prone highway of Sagamu-Papalanto southwestern Nigeria. The mineralogical and chemical composition of the soils were analyzed using X-ray diffraction and X-ray fluorescence methods. The geotechnical properties of the soil such as grain size distribution, consistency limits test, specific gravity, compaction, California bearing ratio (CBR), porosity, permeability, shear strength test and cone penetrometer test were also conducted on the soil samples. The results of the investigation showed that the moisture content, specific gravity, liquid limit, plastic limits and plasticity index ranged from 9.4–18.2%; 2.54–2.58; 26.8–42.6%; 18.2–25.2% to 7.1–21.6%, respectively. Grain size distribution showed the fine and coarser fractions range from 12–32.5% to 49.4–80.5%, respectively. The maximum dry density and its optimum moisture content ranged from 1.64–1.74 g/cm3 to 12–17%, respectively. CBR results ranged from 3 to 12%. The class of subsoils namely A-26, A-7, A-2–7 (clayey soils), were identified and rendered unsuitable as road construction materials. The results from this investigation revealed that the subsoils are poor road construction materials due to its fines and plasticties. This should be put into consideration during the reconstruction and rehabilitation of the road.

Similar content being viewed by others

1 Introduction

Transportation has proven to be a vital tool in the socio-economic development of any nations; as its serves as a vehicle that propels other infrastructural development. Every nation’s economic status relies on how well it has been able to develop its roads, airports, ports, shipping pipelines and railways [1, 2]. Transportation helps to link up all markets, driving trades and wealth distribution. Road transportation directs the spread and distribution of economic practices across the world [3]. It has been shown from past records that loss several lives and properties abound resulting from road accidents. [4]. Highway pavements and foundation soils are inseparable duo toward the development of any country [5]. Diverse road failure components are observable within a short period of time after commissioning. Roads are literally constructed on geologic materials and these materials’ properties impact their functioning as transport medium [6]. The major components of several typical flexible highway pavements from the base to the top include the subgrade, sub-base, base course and riding surfaces [7, 8]. However, loss of lives and properties has been linked to the poor design and substandard construction activities arising from non- compliance with the recommended standards. However, road failures are usually followed by the following signs such as rutting, potholes, differential heave, deformation, peeling and cracking [9,10,11]. Several factors have been linked to the increasing recorded road failures include geomorphological, geological and geotechnical factors, design and construction inadequacies, maintenances and road usage [12,13,14]. Climatic factors in particular temperature alterations and attacks by acid rain have been reported to reduce the performance of the road base materials. Gidigasu [15] and Graham and Shields [16] reported insufficient width and the makeup of the road shoulders as other contributing factors that give rise to road failure. Specifically, several pavement failures in the Southern region and Niger Delta region of Nigeria have been traced to hydrogeological and geological conditions linked with swampy, textural properties of the subsoils and poor drainage measures. [17, 18]. The prevalence of pavement failures have also been attributed to the engineering characteristics of the underlying geology and the subgrade materials. The engineering characteristics of the underlying geology have been reported to have been controlled by their mineralogical compositions [19, 20]. Poor geotechnical characteristics of the soils such as poor bearing capacity, low maximum dry density, high liquid limit, plasticity index, optimum moisture content, California bearing ratio and high compressibility are typically responsible for road failures [19, 21]. These states often result to pavement failures in the shape of cracked pavements and surface deformation. However, the appropriateness of soils as base course or subbase course and the subgrade are in cogent connection to the conveyance and bearing of axle load which determine the strength, durability and life of roads [22, 23]. Geotechnical assessment of subsoils helps in comprehending the behaviour of the soils that can cause remarkable impairment to road construction and also propose solutions in problems connected with both expansive and unexpansive soils [24,25,26]. Past investigations have also emphasized the role of geophysical investigations and integrated geotechnical and geophysical investigations in the investigation of the significant factors responsible for ceaseless highway pavement failures in parts of southern Nigeria [27,28,29].

The study under investigation is focused on a major highway along Sagamu-Papalanto in Ogun state southwestern Nigeria. The highway has been in a state of total deterioration despite serving as accessible road to industries like dangote cement factory at Ibese Ogun state and Lafarge cement industry at Ewekoro. The road has been in a precarious state and left abandoned to be hiding place for criminals. Loss of lives and properties through frequent road accidents has also been reported on the highway. The highway is located on a sedimentary terrain, during the field inspection; excessive weathering and flooding was noticed on the surface of the road. The flooding has eroded the bituminous layer off the surface of the road. The state of the road has resulted to a decline in economic activities in the area. The investigation was undertaken to ascertain the cause of road failure along Sagamu-Papalanto highway. The study under investigation is aimed at determining the cause of road failure on the highway pavement of Sagamu-Papalanto in Ogun state southwestern Nigeria using integrated methods and also proffer the needed recommendation for the reconstruction and rehabilitation of the existing road.

2 Location, geomorphology and geology of the study area.

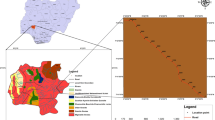

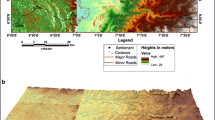

The study area lies within Longitude 3°11´35.627´´E to 3°34´42.25´´E and Latitude 6°51´1.217´´N to 6°54´16.457´´N on the Sagamu–Papalanto Expressway in Ogun State Southwestern Nigeria (Fig. 1).The road extends up to 60 km long, it serves as route to other connecting cities like Ewekoro, Ibese, Ifo and Lagos -Ibadan Express and other part of the country. Sagamu-Papalanto highway is enclosed in the north by Oyo and Osun States, in the south by Lagos State, in the east by Ondo State and in the west by Benin Republic. It transverses between Papalanto Junction through several villages and settlement to Sagamu Interchange. The geology of the area comprises of sedimentary units which consists of argillaceous sediment that is soft, friable and some siliceous and ferruginous materials (Fig. 1). The Geology and stratigraphy of the Dahomey basin has been grouped into six lithostratigraphic Formations namely, from oldest to youngest namely: Abeokuta, Ewekoro, Akinbo, Oshosun, Ilaro, and Benin Formations [30, 31] The Abeokuta Formation represents an irregularity and lay directly above the basement complex, Ewekoro, Oshosun and Ilaro Formations overlie these in turn and all are overlain by the coastal plain sands of the Benin Formation. The studied area is located on sedimentary Formation of the south western Nigeria and underlain by the basement complex [32].It belongs to the Ewekoro Formation which is Tertiary formed during the Paleocene and Eocene period. It also forms a greater depression of artesian basin for groundwater formation which is mostly made up of shale/clay.The area has a wide spread humid tropical climate pronounced by the presence of wet and dry seasons. The wet seasons starts in April and terminates in October whereas the dry seasons run from October to March. The mean annual rainfall is approximately 1375 mm. The style and pattern of rainfall is dual mode in nature, in addition to an annual peak in the month of June and a secondary maximum in the month of September [33].The mean yearly temperature also differ from 22 °C in wet season to 30 °C in dry season mean. The humidity range from 40% December to 80% July. The whole of the study has area has moist air that comes from the Atlantic Ocean throughout the year. The relief is of moderately uneven and undulating; the area is predominated by dendritic drainage pattern which implies quite similar resistance of the underlying rocks to weathering.

3 Materials and methods

The adopted methodology in this study includes reconnaissance survey, field work (collection of samples), laboratory tests and interpretation of results. Visual inspection and reconnaissance survey which involved a detailed geological field mapping was undertaken in the course of the fieldwork to identify the failed sections of the road under investigation. Ten disturbed soil sample was collected using an auger from a burrow pits at a depth of 2.5–3 m. The samples collected were kept inside an air tight bag and then labeled for easily identification of the sampling points in the laboratory. The collected samples were sent to Lagos state material testing laboratory before been apportioned for mineralogical, chemical and geotechnical characterization.

The samples were spread on a tray for air drying; the lumps in the samples were reduced to fine particles through the use of a pellet. The selected samples were divided and apportioned for elemental and mineralogical analysis respectively using the X-Ray Diffraction (XRD) and X-Ray Fluorescence (XRF) machines.

The X-Ray Diffraction (XRD) was carried out in accordance with the procedures of [34]. The X- Ray Diffraction (XRD) analyses were carried out on the soil samples through the use of the 6000XRD model machine with CuKα radiation called the empyrean PANalyticalschimadzu. However, the elemental composition of the samples were conducted by using the PANAnalytical’s minipal 4 model of the XRF which is also known as the Energy Dispersive X-ray Fluorescence (EDXRF) spectrometer.The machine is a light weight portable bench top which can easily be lifted for use. The soil samples before been used for the chemical and mineralogical analysis were crushed to remove all lumps with the aid of an arget pulverizing machine. The crushed soil samples were made to pass through 150 micro mesh sieves. This was necessary to ensure uniformity of the samples. About 5 g of the crushed sample were weighed into a beaker thereafter 1 g of starch soluble (binding aid) were added. The mixture were carefully mixed to ensure homogeneity and thereafter compressed under an increased pressure that will give rise to bolus that will be used for the analysis. The bolus mass was carefully placed in their respective measuring positions that has been marked out on the sample changer of the measuring equipment. The sample changer of the equipment servers as point of measuring the element composition in the analyzed samples. The current of is set at 12–14 kV when measuring the major oxides using a chosen filter temperature for the major oxides. The medium used for analyzing the samples was air and by using a time measurement of 100 s.The equipment used was calibrated by using the gain control of the machines; thereafter the separate samples were measured by tapping the corresponding spots of the sample changer.

The XRD analysis was carried out by gently mixing a powder with a dispersant solution (ethanol). These were later rolled out equally over the slide, thereafter glass plate was used to carefully press the samples into an XRD sample holder. The machine operation was set at a current of 40 mA, a voltage of 40 kV, a step size of 0.016, a timer per step of 50.165 s, a separation slit fixed at the angle of 0.6°and a range of 4–80 deg 2θ. The X’Pert High Score Plus incorporated in the PDF-4 Minerals 2013 ICDD database were used in identifying the crystalline mineral phases and was in accordance with the stated procedures of [35, 36].A sample of 15 kg of fresh rocks were collected near the basement area along the study area for a detailed petrographic studies using the petrographic microscope so as to order to determine the parent material of the studied soil samples.

The geotechnical tests such as sieve analysis, Atterberg consistency limit tests, specific gravity, compaction, shear strength, permeability, porosity and california bearing ratio (CBR) were conducted on the soil samples. These analyses were carried out in accordance with [37,38,39,40,41,42,43]. The detailed methods of the geotechnical analysis conducted on the soil samples are highlighted in [44].

The CPT machine used has a peak angle of 60º and a hinge area of 10cm2.It consist of a steel frame and a driving head which accommodate hydraulic pressure capsule. The driving head is lifted or let down by manually controlling the winch. The Dutch cone penetrometer test was carried out by driving a hardened steel cone uninterruptedly into the ground before taken its measurement of its resistance to penetration. The cone body is forced into the ground by using the steel rods that is fastened to the driving head. These rods are shielded from friction by an empty outer rod. The cone driving rods and outer rods were forced at the same time into the ground for an interval of 200 mm. The operated pressure is then exerted on the inner rods, the cone is moved forward separately of the outer rods for an interval of about 40 mm at the standard of nearly 100 mm/sec. The force required to progress the cone is transferred across the capsule in the driving head to a gauge and the penetration resistance indicated on the gauge is recorded. The outer tube is then advanced and.

the whole assembly is driven further by 250 mm where the operation is repeated.Four cone penetration test (CPT)) were carried out along the studied area in accordance with [43].

4 Results and discussion

4.1 Chemical and Mineralogical investigation of the selected soils

The results of the mineralogy tests on the soil are summarized in Table 1. The prominent clay mineral types identified are quartz, kaolinite and illites whereas muscovite, iron sulphate and dickite were detected in their minor proportions. The spare number of minerals detected and measure was as result of the detection limit of the equipment. More and Reynolds [45] reported that the low concentration of mineral phases detected was due to the equipment used and also as a result of the predominance of the indentified mineral phases in the soil samples which are mostly clay. The results in Table 1 showed that illite was identified in L3; kaolinites were identified in the L2, L3, L4, L9 and L10. Muscovite was also detected in samples L1, L8 and L9. There was no presence of montmorillonite and smectite which is accordance with was reported by [46] that montmorillonite is not present in the south western Nigerian soils studied. The results of the mineralogical investigation are in confirmation to the index properties of the soil in (Table 4) that shows that the index properties of the soils are of low to medium plasticity. The presence of detection of kaolinite as a major minerals (Table 1) shows that the soils of the study area is well drained and the detection of muscovite in some sample locations may result to field compaction problem [47,48,49]. The results show that all the identified minerals (Table 1) belong to the phyllosicate family of the silicate mineral group (Fig. 2). The predominant amount of quartz and kaolinite with minor amounts of illite and muscovite shows that these minerals were derived from felsic sources which are derivatives of the granitoids basement rocks.

The results of the geochemical analysis are summarized in Table 2. The total amount of chemical elements in there decreasing order includes; SiO2, Al2O3, and Fe2O3, with averages of 45.77%, 22.9% and 22.60% respectively. The studied soil samples are characterized by high amounts of silica from 40.54 to 53.98%, appreciable amount of sesquioxides (Al2O3 and Fe2O3) which varied from 17.10 to 29.5% for Al2O3, 2.87 to 29.41% for Fe2O3 and reasonable amount of bases (K2O and CaO). The other chemical element concentrations were all lower than 5% (Table 2).The silica(S)/sesquioxides ratios(R) in Table 2 varied from 0.81 to 1.67.

BIS [43] and Onana et al. [49] classified soils based on the silica/sesquioxides ratio as laterite if the is less than 1.33; lateritic if ratio ranges from 1.33 to 2 and non-lateritic if it is greater than 2. According to this classification, 5% of the studied soils are classified as non-lateritic soils while the rest 95% are lateritic.

A triangular diagram of (Na2O + CaO)-Al2O3-K2O after [50] was plotted using the major oxides from the XRF analysis data in Table 2. The triangular diagram was plotted in order to show the trend of weathering. The triangular diagram shows the degree of the conversion of feldspars to clay and the trend of weathering in an average granitic rock.

Figure 3 shows the trend of weathering on the samples plotted using the Nesbitt and Young triangular diagram. It was revealed from the (Na2O + CaO)-Al2O3-K2O diagram that all the samples exhibit an intense weathering history. The Nesbitt and Young triangular diagram shows a relative contrast in elemental composition of Al2O3, CaO, Na2O, and K2O which plot closer to higher contents of Al2O3. The results shows a relatively high intensity of weathering that has advanced to a phase at which appreciable amounts of the alkali and alkali earth elements have been detached from the soil samples. The weathering process for the samples has moved from K-feldspars to muscovite, illite through to kaolinite and a deficiency in the percentage proportion of CaO + Na2O. This result shows that there is a progressive weathering that has taken place within the plagioclase phase. The pattern of enrichment of the mineral phases is from Al2O3 > K2O > CaO + Na2O. The soil samples are grouped in (Fig. 3) as plagioclase at 50–50% CaO + Na2O vs Al2O3, at 50–60% concentrations along the K2O–Al2O3 trend as K-feldspars whereas at 75–80% Al2O3 concentration as illite and at 75% Al2O3 as muscovite.

The (Na2O + CaO)-Al2O3-K2O diagram of all samples from the study area after [50]

4.2 Petrographic characteristics of the selected rock

The rock studied under the microscope is made of quartz, biotite, muscovite, garnet chlorite, K- feldspar (orthoclase and microcline), and plagioclase (Fig. 4). Supplementary minerals are apatite and zircon. It is mesocratic, medium to coarse grained (1–5 mm) micaceous igneous rock with an alignment of dark and light colored minerals in a preferred direction showing gneissose foliation. The vitreous luster of micaceous was also observed from the sample. The minerals observed in the hand specimen include; quartz, feldspars and mica (mostly muscovite). The thin section of this rock sample (Fig. 4) showed quartz, plagioclase, biotite, microcline, orthoclase, muscovite and pyroxene. Quartz occupy up to 30% of the rock minerals. It appeared as colorless polycrystalline mineral with no pleochroism and twinning. It displayed an undoluse extinction with an anhedral to subhedral shape. Biotite occurrence is 22% in the rock. It is pale to brownish colour with characteristics perfect cleavage and prismatic habit. Microcline is made up of 11% of the rock minerals. It is colourless but cloudy in plane polarized light with low relief. It showed cross hatch twinning and oblique extinction. Orthoclase appears as colourless cloudy crystal with low relief and undergoes an oblique extinction. Orthoclase is made up of 12% of the rock minerals. Plagioclase is colourless with low relief. It displayed polysynthetic twinning and undergoes oblique extinction. It occupies 22% of the rock minerals. Opaque minerals of about 3% were observed in the rock thin section.

The second rock sample studied is a boulder of leucocratic (pinkish) fine grained with random orientation of light and few dark coloured minerals (Fig. 5). It consists of alkali feldspars, quartz and biotite in the hand specimen. The thickness of the rock is about 2.2 m and the rock is suspected to be rhyolite with no evidence of migmatization. The thin section study (Fig. 5) shows the occurrence of quartz, microcline, orthoclase, plagioclase, biotite and iron oxide. Biotite occurs as rounded pale brown mineral but did not show the characteristic pleiochrosim. Quatrz occur as an andedral crystals which gives grey interference colour with complete extinction. Microcline shows a cross hatched twining while orthoclase shows carsbad twining. The occurrence of plagioclase is lesser than those of orthoclase and microcline.

4.3 Geotechnical characteristics of the studied soil.

4.3.1 Index properties

The results of the index tests on the soil samples are summarized in Table 3.The grain size analysis is important in determining the strength of the soil and also determine the particle size distribution of the studied soils [51]. The results shows the percentage amount of clays, silts, fines, sand and gravel ranged from 12.1–27.5%, 6.1–15.8%, 12–38.5%, 49.4–80.1% and 4.7–20.2% (Table 3 and Fig. 6). The Federal Ministry of Works and Housing [52] recommends subgrade soils to possess less than 35% amount of fines. The results obtained in comparison with FMWH [52] shows that four soil samples did not meet up the specification. It can be inferred from the result that the soils are susceptible to frequent shrinkage and swelling potentials during the various wet and dry seasons which are usually the characteristics of the environmental and climatic condition of the study location. The high percentage of fines had been linked to the predominance of clay which feasibly exerts a dominant control on the mass behaviour of soil which makes it mechanical unfit.

AASHTO [53] classification system is based on the particle sizes, liquid limit and plasticity index. According to the grouping, soils with less than 35% pass through the No.200 sieve are classified under A-1 to A-3, typically clayey soils. While soils with more than 35% pass through the No. 200 sieve are classified under A-4 to A-7, typically granular soils. The group index is the parameter that gives an indication of the load bearing capacity within the AASHTO soil group. The resulting increase in the group index will cause decrease in the load carrying capacity. The results on the studied samples (Table 3) revealed that the soils are classified as A-26, A-24, A-2 and A-7 according to [53]. The soils in these groups are considered as clayey soils. The soils are grouped as fair to poor materials for road construction. The soils classified as A-2–7 soil on AASHTO soil classification is regarded as poorly graded and poor graded(GP) on USCS soil classification with group index of 0 [54]. Therefore, they are unfit for use as subgrade, subbase and base road construction materials. The clayey soils are classified as fair to poor road materials, while the granular soils are classified as excellent or good road materials.

The values of the specific gravity ranges 2.54–2.58 (Table 3).The specific gravity is often used as a criteria in the selection an appropriate materials for highway pavement construction.The value is low when compared with the residual soils with the basement complex of Nigeria [55] It has been revealed by [56] that specific gravity has strong correlation between the chemical composition and the mineralogy of a soil. Gidigasu [15] reported that the greater the specific gravity; the greater the degree laterization. The more the percentage of clay fraction and alumina concentration the less the specific gravity. The studied soils have been grouped as inorganic soils.

The natural moisture content of the analyzed soil samples varied from 9.4 to 18.2% (Table 3). It was revealed that three sample locations values are higher than the specified value of (5–15%) recommended by the FMWH [52] for road construction. This shows high water adsorption potential of the soil materials. The results revealed that the values obtained will lead to reduction in shear strength of these road construction materials [21]. Thus, they are unfit as subgrade, subbase and base materials. High fluctuation in moisture content often results to a large volume changes in the clayey soils [27]. The results obtained for the moisture content ranges from favorable, marginal favorable to unfavorable in accordance to the work of [57].

The consistency limits is used in determining the settlement and strength characteristics of soils for road construction [58, 59]. The liquid, plastic limit and plasticity index results of the studied soils ranged from 26.8–46.2%, 18.2–25.2% to7.1–21.6%, respectively. All the studied soils have the potentials of causing a major deformation under load due to their plastic natures. Thus, all the studied the studied soils are within FMWH [52] recommended specification of 50% for liquid limit making them fit as used for subgrade, sub-base and base road construction materials. However, only eight samples are within FMWH [52] specified maximum plasticity index of 20% for highway subgrade materials, while other soil samples are above the maximum recommended standard value making them unfit for subgrade materials. The Casagrande’s plasticity chart (Fig. 7) containing the A-line plays an important role in the classification [60]. The studied soil samples are then classified into CI, CL and CH on the basis of particle size distribution, liquid limit and plasticity index. Two samples falls within the low plasticity (CL) and eight samples falls within the medium plasticity (CI) categories in the Casagrande’s chart.

Plasticity chart of the samples [60]

Clay activity of soils is obtained by integrating Atterberg limits and clay content into an exclusive parameter [61]. The results of the percentage clay sized fraction and plasticity index were used to calculate the activity in order to determine the measure and the degree of likelihood of exhibiting colloidal behaviour (Table 3). This is linked to the geologic history and mineralogy of clays presents in the soils. The characteristics of clay soils are known by the physicochemical characteristics of the different constituents’ minerals and by the relative proportions in which the minerals are present [4]. Underwood [57] proposed three classes of clay based on their activity which includes; the normal clays, active clays and inactive clays which ranges from 0.75 to 1.25, value greater than 1.25 and value less than 0.75 Table 4. The activity less than 1 corresponds to kaolinite, while activity between 1 and 2 corresponds to illite and greater than 2 corresponds to montmorillonite [61]. The clay activity of the soils under investigation ranged from 0.29–2.17 (Fig. 8). The results indicate that the predominant clay mineral present in the soil is kaolinite as eight sample location has clay activity values of less than one, which is inactivity and low moisture affinity.

The linear shrinkage of the soils varied from 3.86 to 14.4% (Table 3). It was revealed from the results that seven samples have values greater than [9, 61] recommendation, which states that the maximum values of linear shrinkage require for sub grade materials should be 8%. This results show that the soils would be subjected to shrinkage and swelling during the seasonal wet and dry seasons which is typical of the tropical climatic condition of the study area. The linear shrinkage results correlates with results obtained from grain size analysis; thus, the soil samples are not suitable for both highway subbase and subgrade materials. Only three fulfils the specification as subsoil materials that are fit for road construction. The soils that are prone to swelling and shrinkage can be modified by stabilization processes to establish the desired properties for road construction.

The free swell of the soils varied from 5.17–31 (Table 3). The results show that the soils in the study area ranged from kaolinite and illite which possesses low to medium swelling potential (Table 5).

4.3.2 Soil strength properties.

The strength of subsoils for road construction are govern by the soil’s resistance to distress under the application of load as determined by compaction, CBR, cohesion, permeability, and porosity tests, and their results are summarized in Table 6.The compaction of soils for road construction required the attainment of a high degree of densification in order to prevent detriment consolidation that will arise from traffic load [4]. The compaction curves for the studied soils are shown in Fig. 9. The maximum dry density (MDD) of the soils in the study area ranged from 1.50 to 1.78 g/cm3 at optimum moisture content (OMC) of 12–17% (Table 6). Five samples have MDD values above the maximum 1.70 g/cm3 as specified by FMWH [52]. However, from the results of the tests it was revealed that the residual soils have low bearing capacities and cannot ultimately serve as construction barriers due to the poor MMD and low OMC except if well compacted and stabilized to reduce voids, to increase the strength and reduce its permeability. It is worthy to note that the best soil for foundation of pavement structures must always be compacted above the MDD and the OMC values to yield the maximum strength prevent inflow of water and distribute wheel loads uniformly into the pavement structures. It was also inferred from the results of the MDD and OMC that the soils have poor to fair foundation attribute, and are loose materials that require minimal force for it’s to dissociate. This is potentially responsible for the incidence of road failure in the study area.

California bearing ratio is a test that is often employed in the evaluation of soil strength in subgrade, subbase and base course materials for road, footpath and airfield pavement design [4, 63]. The results of the CBR ranged from 3–12% (Table 6, Fig. 10). Only four of the analyzed soil samples have the required > /5% CBR value recommended for highway subgrade soil materials [52, 63]. The CBR values of the study area are generally low, requiring that the soils should be subjected to soil improvement strategies in order to acquire the required strength for road construction materials.

The coefficient of permeability for the soils ranged from 1.85 × 10–5 to 8.86 × 10–5 m/s (Table 6). It is classified into practically impermeable, medium permeable to low permeable which makes the soil to be fit for road construction purposes [4, 64]. Igwe et al. [65] reported that permeability coefficients (k) in the range of 10–7–10–5 m/s are categorized as moderately to highly permeable materials. However, when these soils come in contact with water, the soils will retain water and lead to the rapid weakening due to poor drainage and exposure to the surface [4, 8].

The porosity of the soils ranged from 34–53% (Table 6). The extent and amount of rainfall are the agents that control the infiltration potential of a soil [66]. The results revealed that the studied soils are loose and porous which was observed from the high percentage of fines that are predominant in the particle size distribution (Table 3).

The angle of internal friction ranged from 22–30 φ° and the cohesion ranged from 1–7 kPa (Table 6). The shear strength plays an important role in determining the compactive effort of materials for road construction. The results from the investigation revealed the soil samples have low angle of internal friction and cohesion. This implies that the soils will be vulnerable to erosion and abruptly collapse under an imposed load.

4.3.3 Cone penetrometer test

The cone penetration test (CPT) data collected are presented in Table 7. This was carried out to determine the strength of near surface materials and also access the in situ strength of the subsoil tested. The graphs of the cone penetrometer tests which shows the rate of penetration against depth Figs. 11, 12, 13 and 14. The results revealed a low cone resistance value which indicates clayey sand material for sample point1, 2, 3 and 4. The linear nature of the graphs of sample 3 and 4 shows that the subsurface materials offer no resistance to the driven cone when compared to sample point 1. The results of the CPT tests for sample points 1 to 4 revealed a depth range of 2–16 m. The CPT termination points at this penetrated depth show that the soils are unfit for erecting the foundation. The low shear strength values obtained for the sampling points also revealed that the subsurface materials are undesirable as road pavement materials. The increase depth in relation to the cone resistance is as a result of the intercalation of clay (Table 8).

Using the established standard used by Lagos State Material Laboratory test for CPTs in foundation engineering, “Simplified Description of the use and Design Methods stated in [68, 69].

Undrained shear strength (Cu)

where qc = cone end resistance value.Nk = Point of refusal or termination point

However, the easy penetration of the cone rod to a depth of 10 m at the sampling points could be as a result of heavy flooding which was as a result of the ingress of water into the intercalation of the soil layers thereby making it to be loose and less cohesive. Erosion control is therefore necessary in the study area as abrupt erosion may result to heavy saturation of the pavement, drainage failure and blockage of the culvert. In addition, drainage system should be put in place in order to allow for easy passage of surface and ground water through seepages.

5 Conclusion

The subsoil investigation of Sagamu-Papalanto road has been carried out. The results revealed that the soil samples are majorly clayey and granular soils, easily compacted with poor drainage. The soil samples indicatSe a cohesive nature with variable moisture content due to the climatic and hydrological conditions of the study area. The geotechnical investigations showed that the soils are poor road construction materials, but the strength can be improved when subjected to stabilization measures as indicated from the strength tests(compaction, California bearing ratios tests) This should be out into consideration during the reconstruction and the rehabilitation of the Sagamu-Papalanto highway. In forestalling the incidence of road deterioration and failure in Nigeria, checks should be put in place to ensure every materials that will be used during construction works is tested and treated in order to avoid pre and post failure of road during construction activity. It is expected that period maintenance should be encourage in order to avoid roads dilapidating before their design life span.

Availability of data and materials

The data sets used and analyzed during the current study are available from the corresponding author on request.

References.

Paul HN, Radnor JP (1976) Highway Engineering. John Willey and Sons, New York

Oglesby CH, Garry HR (1978) Highway Engineering, 4th edn. John Willey and sons, New York, p 691

Kadyali LR, Lal NB (2008) Highway Engineering. Khanna Publishers Delhi-6, Fifth Edition, 858pp.

Olofinyo OO, Fatoyinbo OOF, IO, (2019) Engineering properties of residual soilsin part of Southwestern Nigeria: implication for road foundation. SN Appl. Sci. 1:507. https://doi.org/10.1007/s42452-019-0515-3

Gupta BL, Gupta A (2003) Roads, railways, bridges, tunnel and harbor dock engineering, 5th edn. Standard Publishers Distributors, NaiSarak, New Delhi

Meshida EA (2006) Highway failure over talc–tremolite schist terrain: a case study of the Ife to Ilesha Highway, Southwestern Nigeria. Bull EngGeol Environ 65:457–461. https://doi.org/10.1007/s10064-005-0037-7

Adlinge SS, Gupta AK (2010) Pavementdeteriorationanditscause. J MechCivEng 2(4):9–15

Adeyemi GO (2013) Engineering geology: the Big Heart for structures and their environment. An Inaugural Lecture 2012/2013 University of Ibadan 21 February (2013) Ibadan University Press. Publishing House University of Ibadan, Ibadan, p 91

Jegede OG (2004) Highway pavement failure induced by poor geotechnical properties at a section along the F209 Okitipupa-Igbokoda highway. Southwest Nigeria Ife J Sci 6(1):41–44

Osadebe CC, Omange GN (2005) Soil properties and pavement performance in the Nigerian rainforest; a case study of Shagamu-Benin road. Southwestern Nigeria Ife J Sci 7(1):119–122

Nwankwoala HO, Amadi AN, Ushie FA, Warmate T (2014) Determination of subsurface geotechnical properties for foundation design and construction in Akenfa Community, Bayelsa. Nigeria Am J CivEngArchit 2(4):130–135

Adegoke–Anthony WC, Agada OA (1980) Geotechnical characteristics of some residual soils and their implications on road design in Nigeria. Technical Lecture. Lagos, Nigeria pp 1–16

Mesida EA (1981) Laterite on the highways—understanding soil behaviour. West Afr Tech Rev 13:112–118

Ajayi LA (1987) Thought on road failures in Nigeria. Niger Eng 22(1):10–17

Gidigasu MD (1983) Development of acceptance specifications for tropical gravel paving materials. EngGeol 19:213–240

Graham J, Shields DH (1984) Influence of geology and geological processes on the geotechnical properties of a plastic clay. J EngGeol 22(2):109–126

James AN, Edworthy KJ (1985) The effect of water interaction on engineering structures. HydrolSci J 30(3):395–406

Jegede G (1997) Highway pavement failure induced by soil properties along the F209 highway at Omuoke, southwestern Nigeria. Niger J, Sci

Akpan O (2005) Relationship between road pavement failures, engineering indices and underlying geology in a tropical environment. Glob J GeolSci 3(2):99–108

Amadi AN, Eze CJ, Igwe CO, Okunlola IA, Okoye NO (2012) Architect’s and Geologist’s view on the causes of building failures in Nigeria. Mod ApplSci 6(6):31–38

Ademilua O (2018) Geotechnical characterization of subgrade soils in Southwestern Part of Nigeria. Proceedings of first and second international conferences of the Nigerian Association of Engineering Geology and the Environment, Lagos, Nigeria 1:42–48

Jegede OG, Olaleye BM (2013) Evaluation of engineering geologic and geotechnical properties of subgrade soils along re-allignedIgbara-Ikogosi Highway. South-west Nigeria Int J EngSci 2(5):18–21

Nwankwoala HO, Amadi AN (2013) Geotechnical investigation of sub-soil and rock characteristics in parts of Shiroro–Muya–Chanchaga Area of Niger State. Nigeria Int J Earth SciEng 6(1):8–17

Amadi AN, Akande WG, Okunlola IA, Jimoh MO, Francis-Deborah G (2015) Assessment of the geotechnical properties of lateritic soils in Minna, North Central Nigeria for road design and construction. Am J Min Metall 3(1):15–20. https://doi.org/10.1269/ajmm-3-1-

Owoyemi OO, Adeyemi GO (2017) Variability in the highway geotechnical properties of two residual lateritic soils from Central Nigeria. J GeolGeophys 6:290. https://doi.org/10.4172/2381-8719.1000290

Daramola SO, Malomo S, Asiwaju-Bello YA (2018) Premature failure of a major highway in Southwestern Nigeria. The case of Ipele-Isua highway. Int J Geo-Eng 9:1–12

Adiat KAN, Adelusi AO, Ayuk MA (2009) Relevance of geophysics in road failures investigation in a typical basement complex of South Western Nigeria. Pac J SciTechnol 5(1):528–539

Salami BM, Falebita DE, Fatoba OJ, Ajala MO (2012) Integrated geophysical and geotechnical investigation of a bridge site—a case study of swamp/creek environment in SE Lagos. Nigeria Ife J Sci 14(1):75–82

Akinlalu AA (2017) Integrated geophysical investigation for pavement failure along a dual carriageway, Southwestern Nigeria a case study. Kuwait J Sci 44(4):135–149

Okosun EA (1990) Review of the Cretaceous Stratigraphy of the Dahomey Embayment, West Africa. Cretac Res 11:17–27

Nton ME (2001) Sedimentological and geochemical studies of sock units in the Eastern Dahomey Basin, Southwestern Nigeria Unpublished PhD thesis, University of Ibadan. p. 315, 2001

Adegoke OS, Ogbe FGA, Jan Du Chene RE (1976). Excursion to the Ewekoro quarry (Paleocene-Eocene). Geol. Guide Nigerian Cretaceous-Recent Loc. pp. 1–17.

Balogun O (2003) Senior secondary atlas. Longman, Lagos

Thomas IL, Haukka MT (1978) XRF determination of trace and major elements using a single-fused disc. ChemGeol 21(1):39–50

Carrol D (1971) Clay minerals: a guide to their X-ray identification of soils. In: Geological society of America special paper 126, USA

International Joint Committee Properties on Mineral Powder Diffraction Standard (1980) Mineral powder diffraction file data book. IJCPS, Pennsylvania

ASTM D6913–04 (2009) Standard Test Methods for Particle Size Distribution (Gradation) ASTM International, West Conshohocken

ASTM D4318–10(2015) Standard Test Methods for Laboratory Consistency Limits Test

ASTM D854–14 (2015) Standard Test Methods for Specific Gravity of Soil .West Conshohocken, www.astm.org

ASTM D698–12. (2015)Standard Test Methods for Laboratory Compaction Test for Road Bases 70.

ASTM D3080)-15 (2015) Standard Test Methods for Laboratory Shear strength Test for Road Bases

ASTM D854)-10 (2015) Standard Test Methods for Laboratory Porosity and Permeability Test for Road Base

Standard B, (BS), (1990) Methods of testing soils for civil engineering purposes. British Standards Institution, London

Arora KR (2009) Soil mechanics and foundation engineering. Standard Publishers Distributors, Delhi

Moore DM, Reynolds RC Jr (1997) X-ray Diffraction and the Identification and Analysis of Clay Minerals. Oxford University Press, Oxford, p 378

Okogbue CO (1988) The physical and mechanical properties of laterite gravels from south eastern Nigeria relative 36 to their engineering performance. J Afr Earth Sci 5(6):659–664

Gidigasu MD (1976) Laterite soil engineering. Elsevier, Amsterdam, p 554

Ogunsanwo O (1988) Basic geotechnical properties, chemistry and mineralogy of some laterite soils from southwestern Nigeria. Bull IntAssocEngGeol 37:131–135

Onana VL, Ngooze A, MedjoEko R, Ntouala RFD, NangaBineli MT, Owoudou BN, Ekodeck GE (2017) Geological identification, geotechnical and mechanical characterization of charnokite-derived lateritic gravels from southern Cameroon for road construction purposes. Transport Geotech 10:35–46

Nesbitt HW, Young GM (1984) Prediction of some weathering trends of plutonic and Volcanic rocks based on thermodynamic and kinetic considerations. Geochimica et CosmochimicaActaz 48(7):1523–1534

Naresh CS, Nowatzki PE (2006) Soils and foundations. Ref Man Fed Highway Adm 2:8–75

Federal Ministry of Works and Housing (FMWH) (1997) General specification for roads and bridges, vol II. Abuja, Federal Highway Department Lagos, p 317

AASHTO (1993) Standard specification for transportation materials and methods of sampling and testing, 14th edn. American Association of State Highway and Transportation Officials, Washington, DC

Gopal R, Rao ASR (2011) Basic and Applied Soil Mechanics, 2nd edn. New Age Int’l, New Delhi, p 84

Jegede G (1998) Effects of some engineering and geological factors on highway failures in parts of Southwestern Nigeria. Unpublished Ph.D. thesis, Federal University of Technology, Akure, p 251

Kabir MH, Taha MR (2004) Assessment of physical properties of a granite residual soil as an isolation barrier. Electron J GeotechEng 92:13

Underwood LB (1967) Classification and identification of shales. J Soil Mech Found 93(11):97–116

Sowers GM, Sowers GE (1970) Introductory soil mechanics and foundations. Macmillan, New York, p 556

Adeyemi GO (1995) The influence of parent rock factor on some engineering index properties of three residual lateritic soils in southwestern Nigeria. Bull EngGeol Environ 52:3–8

Casagrande A (1947) Classification and identification of soils. American Society of Engineers, Reston, pp 783–811

Skempton AW (1953) The colloidal “activity” of clays. In: Proceedings of 3rd international conference of soil mechanics, Zurich, pp 57–61

IS:, (1970) reaffirmed 1987. Indian standard classification and identification of soils for general engineering purposes, BIS, New Delhi

Wignall A, Kendrick PS, Ancil R, Capson M (1999) Roadwork; theory and practice, 4th edn.Butterworth-Heinemann, Oxford, p 309

Lambe TW (1951) Soil testing for engineers. Wiley, New York, p 165

Igwe O, Mode W, Nnebedum O, Okonkwo I, Oha I (2013) The analysis of rainfall induced slope failure at Iva Valley area of EnuguState. Environ Earth Sci. https://doi.org/10.1007/s12665-013-2647-x

Emeh C, Igwe O (2017) Variations in soils derived from an erodible sandstone formation and factors controlling their susceptibility to erosion and landslide. J GeolSoc India 90(3):259–384

Das BM (2000) Fundamentals of geotechnical engineering, 4th Ed., USA

Ubido EO, Igwe O, Ukah BU, Idris IG (2017) The implication of subsoil geology in foundation failure using geotechnical methods: A case study of Lagos Southwestern Nigeria. International J Advan Res and Pub 1(5):165–174

Ubido OE, Igwe O, Ukah BU (2018) Integrated Geological, Geophysical and Geotechnical Assessment of Building Failure in Lagos; Case Study of Ogudu Lagos South Western Nigeria Inter j bas& app sciijbas-ijensvol: 17 no:06

Funding

Funding of the entire work was personal.

Author information

Authors and Affiliations

Contributions

Ubido Oyem Emmanuel carried out the field and Laboratory work drafted the manuscript. Igwe Ogbonnaya and Ukah Bernadette Uche: Conceived the study participated in its design, coordination and gave academic guidance. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ubido, O.E., Ogbonnaya, I. & Ukah, B.U. Evauation of road failure along an erosion prone highway in ogun state southwestern nigeria using integrated methods. SN Appl. Sci. 2, 2094 (2020). https://doi.org/10.1007/s42452-020-03849-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03849-x