Abstract

The National Institutes for Quantum and Radiological Science and Technology has the responsibility to develop a cable-in-conduit conductor (CICC) for the ITER central solenoid (CS). Qualification tests of CICCs fabricated in the initial development stage were carried out at the SULTAN test facility; the superconducting performance (Tcs = current-sharing temperature) was found to be degraded by the repeated cyclic loading that simulates realistic ITER operating conditions. From destructive examination and neutron diffraction tests, this degradation appears to result from bending strain on the strands generated by electromagnetic forces. In response, the cabling of the CICC was optimized by shortening the twist pitch to make it stiffer against electromagnetic forces. No Tcs degradation of the optimized CICC was seen in the subsequent SULTAN test; further, a CS insert (CSI) test was performed at the CS model coil test facility, which included hoop strain for a more realistic simulation of ITER conditions. Good performance was also achieved in the CSI test.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

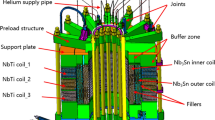

The International Thermonuclear Experimental Reactor (ITER) is an international project undertaken by China (CN), Europe (EU), India (IN), Korea (KO), the Russian Federation (RF), the United States (US), and Japan (JA) [1]; these members are responsible for the design and fabrication of the major components to be assembled into the ITER facility. An overview of ITER is shown in Fig. 1; plasma confinement in the device is based on a superconducting magnet system. All ITER members except IN contribute to the development. The ITER magnet system is the largest unified superconducting magnet system ever built in the world.

The superconducting magnet system [2, 3] consists of four different types of coils. These are 18 toroidal field (TF) coils, 6 poloidal field (PF) coils, 18 correction coils (CC), and 6 central solenoid (CS) modules, as shown in Fig. 2. These coils rely on cable-in-conduit conductors (CICCs) [4], which contain superconducting strands twisted in multiple stages in a stainless steel conduit. The conductors in the TF and CS coils consist of Nb3Sn strands, while the PF and CC conductors consist of Nb-Ti strands. These conductors are cooled by cryogenic fluids and operated below the current-sharing temperature (Tcs).

The National Institutes for Quantum and Radiological Science and Technology (QST), acting as Japan’s domestic agency in ITER, has responsibility to develop the CS conductor [5, 6]. There are 49 conductors, each having the length of several hundred meters, which are to be produced for the CS. The operating scenario for the CS is pulsed operation that induces 15 MA of plasma, with 30,000 repetitions and a burn duration of 400 s [7]; the CS conductor must therefore survive severe repeated cycles of electromagnetic force (EM). A requirement of the CS conductor is no degradation of Tcs from the EM cycles.

In 2010 and 2011, qualification tests of the CS conductor initially developed were performed, showing unexpected degradation of Tcs in the EM cycles. Investigations were undertaken to understand this degradation [8, 9]; one of the most effective techniques was neutron diffraction analysis. This analysis clearly showed strand deformation [10] as the cause of the Tcs degradation; consequently, the authors decided to optimize the conductor design to prevent this deformation. The status of this work is described in this paper.

To re-design the conductor [11,12,13], the twist pitch of the cable was shortened. It was expected that a shorter twist pitch configuration would reduce the strand deformation under EM cycles; however, this optimization produced another problem: dented strands during the cabling process. To overcome this issue, QST improved the cabling process by applying empirical criteria to the dented strand [14]; an overview is presented in this paper.

In 2012, a qualification test of the optimized conductor with a shorter twist pitch was performed and showed no degradation of Tcs with EM cycles [15]. With this success, series production of the CS conductors could begin, and in parallel, to confirm the performance of the optimized short twist pitch conductor under conditions which more precisely duplicate the ITER CS operation, a central solenoid insert (CSI) was tested in 2015. The results satisfied all the CS requirements with a sufficient margin for Tcs [16]. The status is also described in this paper.

2 ITER CS conductor

The CS consists of 6 modules designated CS1U, CS1L, CS2U, CS2L, CS3U, and CS3L, as shown in Fig. 3. Each module has 40 layers of 6 hexa-pancake and 1 quadra-pancake. The hexa-pancake and quadra-pancake consist of 918 m and 613 m CIC conductor, respectively. Thus, a total of 49 CIC conductors are required for six modules plus one spare.

The CS is pulse-operated to produce 15 MA of plasma in the ITER scenario. Details of the scenario are shown in [7]. In this operation, the charge and discharge are repeated up to 30,000 cycles, and thus, the CS conductor is subjected to 60,000 repeated EM cycles. In this scenario, the conductor current is ramped up to 45 kA in a maximum field of 13 T. To accommodate this combination of high current and high magnetic field, the CS conductor consists of 576 Nb3Sn and 288 copper strands, twisted in several stages and contained in a stainless steel conduit [7], as shown in Fig. 4. The conductor is cooled and should be operated below its current-sharing temperature, Tcs. Thus, the value of Tcs should remain above the operating temperature under repeated EM cycles. In the operation, there are two main critical conditions: One is the start-of-discharge (SOD), and the other is the end-of-burn (EOB) [7]. The SOD, with 40 kA of conductor current and 13 T of maximum field, presents the most severe conditions, that is, the smallest temperature margin; in comparison, the maximum EM force is applied during the EOB. Therefore, the constraint on Tcs is defined by the SOD conditions; the limiting value for Tcs is 5.2 K.

3 Initial design of the CS conductor

The major parameters of the initial CS conductor are listed in Table 1; this design was based on previous reports [17, 18]. Nb3Sn and Cu strands were twisted in five stages with 45, 85, 145, 250, and 450 mm pitch, with a center channel, and then inserted into a JK2LB 49 mm square stainless steel conduit. In the initial stage of the development, the qualification test was performed using the SULTAN test facility and will be denoted the SULTAN test. Its purpose was to determine whether the conductor satisfies the required Tcs through a number of EM cycles.

In the SULTAN test, two straight conductor samples of length about 3.5 m are positioned as shown in the test facility, which applies an external magnetic field (Fig. 5) [19]. The SULTAN test facility is the only way to confirm performance of ITER scale conductor. However, the peak external field is limited to 10.85 T, which corresponds to about 11.5 T of maximum field during conductor current flow. Therefore, the current chosen for the Tcs measurements was 45 kA, which reproduces the EM force experienced during the SOD condition (i.e., SOD condition: 40 kA × 13 T ≃ SULTAN condition: 45 kA × 11.5 T), while EM cycle is done by 48.8 kA of sample current (EOB condition) [4]. As the external field in the SULTAN test condition is different from that during SOD, the Tcs criterion was adjusted to 6.5 K for the test.

To measure the current-sharing temperature Tcs, the voltage of the sample was monitored as its temperature was increased, while maintaining the test conditions of 45 kA and 11.5 T. Tcs is defined as the temperature when the voltage reaches 10 μV/m. The Tcs measurement was repeated through the test, allowing the Tcs dependence on number of EM cycles to be determined (Fig. 6). Tcs decreases linearly with the number of EM cycles and is extrapolated to fall below the criterion of 6.5 K at around 12,000 cycles. Thus, the initial conductor design is clearly not appropriate for the CS conductor.

4 Consideration of the degradation

To investigate the SULTAN test results seen in Fig. 6, which shows an unexpected level of Tcs degradation with EM cycles, a destructive examination (DE) was done on the sample tested. A visual inspection of a section of cable surface was carried out to investigate the effects of the large EM forces applied; the observations were specifically directed at the high-load zone (HLZ) and the low-load zone (LLZ). The inspection showed that strands in the LLZ exhibited the most bending (Fig. 7). Because the direction of the bent strand did not correspond to that of the EM loading, another cause was sought; the original assumption had been that strand bending was only caused by EM loading in the HLZ [20, 21]. Thus, the observed phenomenon required a more complex explanation.

Researchers have tried to understand this unexpected strand deformation in the LLZ [9, 22]; one mechanism was assumed: strand buckling. In this mechanism, thermal compressive forces originally acted on strands inside the conduit as a result of differences between the thermal contraction properties of materials in the conductor, operating during the heat treatment and cool-down process. On the other hand, a large void was generated in the LLZ because EM loading pushed strands forward toward the HLZ. Since the large void allows strands to move easily, strands were compressed and then buckled by the thermal compressive forces, and as a result, strand buckling occurs in the LLZ [23].

To study the bent strand condition more quantitatively, various approaches were taken [9, 22, 23]. One of the most sophisticated studies used neutron diffraction analysis [10], which accurately evaluates strains in the strands inside the conductor. Figure 8 shows schematically the response of a neutron diffraction profile for the cases of axial or bending strain. If axial strain occurs, the diffraction peaks are shifted, while if bending strain occurs, the diffraction profile is broadened.

The neutron diffraction analysis was performed for SULTAN test samples from the HLZ, the LLZ, and a low-field zone (LFZ) where the external field is almost zero. Since the LFZ is exposed to a sufficiently small electromagnetic force, it is assumed there is no degradation. The result is shown in Fig. 9. The diffraction profile from the LLZ is much broader than the other profiles. This clearly shows that strands in the LLZ bent the most severely. Since Nb3Sn strands are very sensitive to strain, it was concluded that the main cause of conductor degradation shown in Fig. 6 was strand deformation such as buckling and/or bending in the LLZ.

5 Optimized conductor design

To prevent the strand deformations in the LLZ mentioned in the last section, research and development on the cable configuration was undertaken [11,12,13]. The main approach chosen for optimization was to shorten the twist pitch of the cable to 20, 45, 80, 150, and 450 mm in the stages, as shown in Fig. 10. It was expected that the short twist pitch (STP) configuration would reduce the strand deformation under EM cycles (seen in Fig. 7) because each strand is more tightly fixed inside a cable with a lower void fraction.

However, this optimization approach produced another problem for the cable production process. Destructive examination of the modified (i.e., STP) conductor sample revealed severe strand cross-sectional deformation inside the cable, as shown in Fig. 11 [14]. This deformation occurred during the cable manufacturing process, as a result of each strand being more tightly twisted and compacted. To assess the influence of this deformation on strand performance, critical current (Ic) measurements on dented strands were performed (Fig. 12). From these measurements, Ic can be kept to 95% of its value if the dents are smaller than 0.21 mm; this new result gave the authors an empirical criterion for cable production. Based on this observation, the parameters of the cabling machine can be optimized so that harmful deformation of strands is avoided.

To confirm this effect in the STP-modified conductor, the SULTAN test was performed under the same conditions as in Fig. 6, with the results shown in Fig. 13 [13]. No degradation was observed through the same number of EM cycles, and it is concluded that this STP conductor design is appropriate for the CS conductor. Following the success of this development, series production of CS conductors was started.

6 CS insert test

Following the success of the SULTAN test with the optimized STP conductor, the series production of CS conductors could be started, as mentioned above. In parallel, to finally check the performance of the STP conductor under conditions which are more precisely the same as during CS operation, a central solenoid insert sample (CSI) was tested in the external field of the Central Solenoid Model Coil (CSMC) Facility [17] shown in Fig. 14.

As the CSI is a single-layer solenoid, strain induced by the circular geometry (hoop strain) can be included in the evaluation of the CS conductor performance, which is not possible in the straight-line conductor samples in the SULTAN test. In addition, CSMC can generate an external field up to 13 T. Thus, the purpose of the CSI test is to evaluate Tcs under real CS operation (i.e., SOD conditions: 13 T of external field and 40 kA of current) with hoop strain. An additional objective was to compare the results to the SULTAN tests. Therefore, the CSI tests also included the SULTAN conditions of 11.5 T of external field and 45 kA of current. The requirement criteria for Tcs are 5.2 K and 6.5 K in the SOD and SULTAN conditions, respectively, as discussed above.

The result of the CSI test with SOD conditions is shown in Fig. 15. No degradation of Tcs with increasing EM cycles was observed, and there was a temperature margin of at least 1.5 K above the 5.2 K of the requirement criterion. Thus, it can be assumed that even if 60,000 cycles of EM loading are imposed on the conductor, its performance will be sustained.

The CSI test result under SULTAN conditions is shown in Fig. 16. Again, no degradation of Tcs was observed and there is a sufficient temperature margin above the 6.5 K criterion for SULTAN conditions. In addition, the Tcs was about 0.5 K higher than the SULTAN test; this increase was the result of hoop strain. Thus, correlation between CSI and SULTAN tests was reasonable. This implies that the SULTAN test correctly represents the conductor performance.

7 Conclusion

Development of the CS conductor for ITER has given rise to technical challenges. However, QST overcame these difficulties with novel, accurate, and sophisticated investigation, notable consideration of the mechanisms degrading the current-sharing temperature and development of a short twist pitch design for the CS conductor. Following this successful development stage, the series CS conductor production could be started in 2012. In parallel, a final check to qualify the conductor performance (CSI test) was conducted in 2015. Fabrication of all the CS conductors was successfully completed in 2017; the photograph of completion of the final conductor is presented in Fig. 17. CS conductors were shipped to the USA, which is a coil manufacturer of the CS. The last conductors finally arrived in March 2018.

References

Hotkamp N (2007) An overview of the ITER project. Fusion Eng Des 82:427–434

Sborchia C et al (2014) The ITER magnet systems: progress on construction. IAEA Nucl Fusion 54:013006

Mitchell N et al (2017) The ITER magnet system: configuration and construction status. Fusion Eng Des 123:17–25

Devred A et al (2012) Status of ITER conductor development and production. IEEE Trans Appl Supercond 22:4804909

Nabara Y et al (2013) Examination of Nb3Sn conductors for ITER central solenoids. IEEE Trans Appl Supercond 23(3):4801604

Nabara Y et al (2016) Performance analysis of mass-produced Nb3Sn conductor for central solenoid in ITER. IEEE Trans Appl Supercond 26(3):4200705

Devred A et al (2013) Conductor qualification program for the ITER central solenoid. IEEE Trans Appl Supercond 23:6001208

Bruzzone P et al (2012) Test results of ITER conductors in the SULTAN facility. In: Proceedings of 24th IAEA Fusion Energy Conference IAEA CN-197, p 536

Hemmi T et al (2012) Test results and investigation of Tcs degradation in Japanese ITER CS conductor sample. IEEE Trans Appl Supercond 22:4803305

Hemmi T et al (2013) Neutron diffraction measurement of internal strain in the first Japanese ITER CS conductor sample. Supercond Sci Technol 26:084002

Bessette D (2014) Design of a Nb3Sn cable-in conduit conductor to withstand the 60,000 electromagnetic cycles of the ITER central solenoid. IEEE Trans Appl Supercond 24:4200505

Nijhus A (2011) Optimization of ITER Nb3Sn CICCs for coupling loss, transverse electromagnetic load and axial thermal contraction. Supercond Sci Technol 25:015007

Nabara Y et al (2014) Impact of cable twist pitch on Tcs degradation and AC loss in Nb3Sn conductors for ITER central solenoids. IEEE Trans Appl Supercond 24:4200705

Takahashi Y et al (2014) Cabling technology of Nb3Sn conductor for ITER central solenoid. IEEE Trans Appl Supercond 4:4802404

Devred A et al (2014) Challenges and status of ITER conductor production. Supercond Sci Technol 27:044001

Martovetsky N et al (2016) ITER central solenoid insert test results. IEEE Trans Appl Supercond 26(4):4200605

Tsuji H et al (2001) ITER R&D magnets: central solenoid model coil. Fusion Eng Des 55:153–170

Martovetsky N et al (2002) Test of the ITER central solenoid model coil and CS insert. IEEE Trans Appl Supercond 12:600–605

Bruzzone P et al (2002) Upgrade of operating range for SULTAN test facility. IEEE Trans Appl Supercond 12:520–523

Nunoya Y (2004) Experimental investigation on the effect of transverse electromagnetic force on the V-T Curve of the CIC conductor. IEEE Trans Appl Supercond 14(2):1468–1472

Koizumi N (2006) A new model to simulate critical current degradation of a large CICC by taking into account strand bending. IEEE Trans Appl Supercond 16(2):831–834

Sanabria C et al (2012) Evidence that filament fracture occurs in an ITER toroidal field conductor after cyclic Lorentz force loading in SULTAN. Supercond Sci Technol 25:075007

Kajitani H et al (2013) Analytical study of degradation of CIC conductor performance due to strand bending and buckling. IEEE Trans Appl Supercond 23:2247652

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and animals rights

No human participant and animal were involved in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kajitani, H., Hemmi, T., Suwa, T. et al. Development of cable-in-conduit conductor for ITER CS in Japan. SN Appl. Sci. 1, 182 (2019). https://doi.org/10.1007/s42452-019-0194-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0194-0