Abstract

Purpose

The constitutive parameters of viscoelastic materials, such as storage modulus and loss factor, usually have frequency-dependent characteristics. The combination of polymers with different reinforcement and fillers usually exhibits various mechanical characteristics, which makes the identification of the material properties of viscoelastic materials a challenging task. The present study proposes an inverse identification technique based on a neural network optimization (NNO) algorithm to characterize the frequency-dependent material properties of a viscoelastic material.

Methods

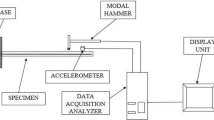

To this end, a symmetric three-layered sandwich plate is considered having face layers of isotropic elastic material and a core layer of viscoelastic material. The experimental free vibration tests are performed using the impact hammer method to determine resonant frequencies and modal loss factors for various eigenmodes. In addition, a numerical model of the sandwich plate is developed to determine vibrational responses utilizing the finite element method. The vibration-based material parameter identification technique is implemented based on the NNO algorithm. The identified material parameters are then compared with the experimental dynamic mechanical analysis (DMA) test results. Furthermore, a numerical parametric study is performed considering the optimized viscoelastic material properties to investigate the influence of various geometrical and structural factors on the free vibration response of the sandwich plate.

Results

The identified results are in excellent agreement with the experimental DMA test results affirming the robustness of the proposed inverse technique. The parametric study not only investigates the effect of various structural and geometric parameters on the dynamic response of the sandwich plate but also verifies that the calibrated properties are both realistic and physically meaningful.

Conclusions

The proposed algorithm is a useful and efficient tool for inverse identification of the constitutive properties, and this approach can be extended for the calibration of other parameters (constitutive or not) for a variety of viscoelastic materials in any field of application. This study is a critical step forward in understanding viscoelastic materials and their frequency-dependent behaviorur.

Similar content being viewed by others

Data availability

The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- NNO:

-

Neural network optimization

- DMA:

-

Dynamic mechanical analysis

- CLD:

-

Constrained layer damping

- FLD:

-

Free layer damping

- FRF:

-

Frequency response function

- FFT:

-

Fast Fourier transform

- ANN:

-

Artificial neural network

- HPB:

-

Half power bandwidth

- FCFF:

-

Clamped-free

- FCFC:

-

Two opposite short sides clamped

- SSSS:

-

All sides simply-supported

- CCCC:

-

All sides clamped

- a :

-

Length of plate

- b :

-

Width of plate

- \(h_{k}\) :

-

Thickness of each layer

- \(u,v,w\) :

-

Linear displacements along x,y, and z directions

- \(\theta\) :

-

Rotational displacement

- \(\varepsilon_{kp}\) :

-

In-plane strain of face layers

- \(\varepsilon_{kb}\) :

-

Bending strain of face layers

- \(\gamma_{ks}\) :

-

Shear strain of face layers

- \(\varepsilon_{2l}\) :

-

Longitudinal strain of core layer

- \(\varepsilon_{2t}\) :

-

Transverse strain of core layer

- \(\gamma_{2s}\) :

-

Shear strain of core layer

- \(U\) :

-

Total strain energy

- \(T\) :

-

Total kinetic energy

- E :

-

Elastic modulus

- G :

-

Shear modulus

- \(K_{{\text{S}}}\) :

-

Shear correction factor

- \(A_{kij}\) :

-

Coefficient matrices due to in-plane membrane deformation of face layers

- \(D_{kij}\) :

-

Coefficient matrices due to bending of face layers

- \(S_{kij}\) :

-

Coefficient matrices due to shear deformation of face layers

- \(Q_{kij}\) :

-

Reduced stiffness matrices of face layers

- \(A_{2ij1} ,A_{2ij2}\) :

-

Coefficient matrices due to in-plane membrane deformation of core layer

- \(S_{2ij1} ,S_{2ij2}\) :

-

Coefficient matrices due to shear deformation of core layer

- \(Q_{2ij}\) :

-

Reduced stiffness matrices of core layer

- \(\left[ K \right]\) :

-

Global stiffness matrix

- \(\left[ M \right]\) :

-

Global mass matrix

- \(G_{{\text{v}}}\) :

-

Shear storage modulus of core material

- \(\beta_{{\text{v}}}\) :

-

Loss factor of core material

- \(\left[ B \right]\) :

-

Strain–displacement matrix

- \(\left[ N \right]\) :

-

Shape function matrix

- \(\delta\) :

-

Generalized displacement vector

- \(\omega\) :

-

Natural frequency

- \(\eta_{{\text{s}}}\) :

-

Modal loss factor

References

Johnson CD (1995) Design of passive damping systems. ASME J Vib Acoust 117(B):171–176. https://doi.org/10.1115/1.2838659

Lall AK, Asnani NT, Nakra BC (1987) Vibration and damping analysis of rectangular plate with partially covered constrained viscoelastic layer. J Vib Acoust Stress Reliab 109(3):241–247. https://doi.org/10.1115/1.3269427

Rao MD (2003) Recent applications of viscoelastic damping for noise control in automobiles and commercial airplanes. J Sound Vib 262(3):457–474. https://doi.org/10.1016/S0022-460X(03)00106-8

Sperling LH (1990) Sound and vibration damping with polymers: basic viscoelastic definitions and concepts. ACS Publ 424:5–22. https://doi.org/10.1021/bk-1990-0424.ch001

Melo JD, Radford DW (2005) Time and temperature dependence of the viscoelastic properties of CFRP by dynamic mechanical analysis. Compos Struct 70(2):240–253. https://doi.org/10.1016/j.compstruct.2004.08.025

Jrad H, Dion JL, Renaud F, Tawfiq I, Haddar M (2013) Experimental characterization, modeling and parametric identification of the non linear dynamic behavior of viscoelastic components. Euro J Mech A/Sol 42:176–187. https://doi.org/10.1016/j.euromechsol.2013.05.004

Rouleau L, Pirk R, Pluymers B, Desmet W (2015) Characterization and modeling of the viscoelastic behavior of a self-adhesive rubber using dynamic mechanical analysis tests. J Aerosp Technol Manag 7(2):200–208. https://doi.org/10.5028/jatm.v7i2.474

Santawisuk W, Kanchanavasita W, Sirisinha C, Harnirattisai C (2010) Dynamic viscoelastic properties of experimental silicone soft lining materials. Dent Mater J 29(4):454–460. https://doi.org/10.4012/dmj.2009-126

Nashif AD, Jones DI, Henderson JP (1991) Vibration damping. Wiley, New York

De Espindola JJ, Da Silva Neto JM, Lopes EM (2005) A generalised fractional derivative approach to viscoelastic material properties measurement. App Math Comput 164(2):493–506. https://doi.org/10.1016/j.amc.2004.06.099

Wojtowicki JL, Jaouen L, Panneton R (2004) New approach for the measurement of damping properties of materials using the Oberst beam. Rev Sci Inst 75(8):2569–2574. https://doi.org/10.1063/1.1777382

Cortes F, Elejabarrieta MJ (2007) Viscoelastic materials characterisation using the seismic response. Mater Design 28(7):2054–2062. https://doi.org/10.1016/j.matdes.2006.05.032

Shi Y, Sol H, Hua H (2006) Material parameter identification of sandwich beams by an inverse method. J Sound Vib 290(3–5):1234–1255. https://doi.org/10.1016/j.jsv.2005.05.026

Barkanov E, Skukis E, Petitjean B (2009) Characterisation of viscoelastic layers in sandwich panels via an inverse technique. J Sound Vib 327(3–5):402–412. https://doi.org/10.1016/j.jsv.2009.07.011

Araujo AL, Mota Soares CM, Herskovits J, Pedersen P (2009) Estimation of piezoelastic and viscoelastic properties in laminated structures. Compos Struct 87(2):168–174. https://doi.org/10.1016/j.compstruct.2008.05.009

Araujo AL, Soares CM, Soares CA (2010) Finite element model for hybrid active-passive damping analysis of anisotropic laminated sandwich structures. J Sandw Struct Mater 12(4):395–515. https://doi.org/10.1177/1099636209104534

Kim SY, Lee DH (2009) Identification of fractional-derivative-model parameters of viscoelastic materials from measured FRFs. J Sound Vib 324(3–5):570–586. https://doi.org/10.1016/j.jsv.2009.02.040

Martinez-Agirre M, Elejabarrieta MJ (2011) Dynamic characterization of high damping viscoelastic materials from vibration test data. J Sound Vib 330(16):3930–3943. https://doi.org/10.1016/j.jsv.2011.03.025

Schwaar M, Gmur T, Frieden J (2012) Modal numerical-experimental identification method for characterising the elastic and damping properties in sandwich structures with a relatively stiff core. Compos Struct 94(7):2227–2236. https://doi.org/10.1016/j.compstruct.2012.02.017

Elkhaldi I, Charpentier I (2012) A gradient method for viscoelastic behaviour identification of damped sandwich structures. Comptes Rendus Mech 340(8):619–623. https://doi.org/10.1016/j.crme.2012.05.001

Allahverdizadeh A, Mahjoob MJ, Maleki M, Nasrollahzadeh N, Naei MH (2013) Structural modeling, vibration analysis and optimal viscoelastic layer characterization of adaptive sandwich beams with electrorheological fluid core. Mech Res Commun 51:15–22. https://doi.org/10.1016/j.mechrescom.2013.04.009

El-Hafidi A, Gning PB, Piezel B, Belaid M, Fontaine S (2017) Determination of dynamic properties of flax fibres reinforced laminate using vibration measurements. Polym Test 57:219–225. https://doi.org/10.1016/j.polymertesting.2016.11.035

Ledi KS, Hamdaoui M, Robin G, Daya EM (2018) An identification method for frequency dependent material properties of viscoelastic sandwich structures. J Sound Vib 428:13–25. https://doi.org/10.1016/j.jsv.2018.04.031

Hamdaoui M, Ledi KS, Robin G, Daya EM (2019) Identification of frequency-dependent viscoelastic damped structures using an adjoint method. J Sound Vib 453:237–252. https://doi.org/10.1016/j.jsv.2019.04.022

Sun W, Wang Z, Yan X, Zhu M (2018) Inverse identification of the frequency-dependent mechanical parameters of viscoelastic materials based on the measured FRFs. Mech Syst Sign Proc 98:816–833. https://doi.org/10.1016/j.ymssp.2017.05.031

Xie X, Zheng H, Jonckheere S, Pluymers B, Desmet W (2019) A parametric model order reduction technique for inverse viscoelastic material identification. Comput Struct 212:188–198. https://doi.org/10.1016/j.compstruc.2018.10.013

Albu-Jasim Q, Papazafeiropoulos G (2021) A neural network inverse optimization procedure for constitutive parameter identification and failure mode estimation of laterally loaded unreinforced masonry walls. CivilEng 2(4):943–968. https://doi.org/10.3390/civileng2040051

Grosso P, De Felice A, Sorrentino S (2021) A method for the experimental identification of equivalent viscoelastic models from vibration of thin plates. Mech Syst Sign Proc 153:107527. https://doi.org/10.1016/j.ymssp.2020.107527

Pierro E, Carbone G (2021) A new technique for the characterization of viscoelastic materials: theory, experiments and comparison with DMA. J Sound Vib 515:116462. https://doi.org/10.1016/j.jsv.2021.116462

Kang L, Sun C, Liu H, Liu B (2022) Determination of frequency-dependent shear modulus of viscoelastic layer via a constrained sandwich beam. Polymers 14(18):3751. https://doi.org/10.3390/polym14183751

Chandra S, Maeder M, Bienert J, Beinersdorf H, Jiang W, Matsagar VA, Marburg S (2023) Identification of temperature-dependent elastic and damping parameters of carbon–epoxy composite plates based on experimental modal data. Mech Syst Sign Proc 187:109945. https://doi.org/10.1016/j.ymssp.2022.109945

Orta AH, Kersemans M, Roozen NB, Van Den Abeele K (2023) Characterization of the full complex-valued stiffness tensor of orthotropic viscoelastic plates using 3D guided wavefield data. Mech Syst Sign Proc 191:110146. https://doi.org/10.1016/j.ymssp.2023.110146

Krzyzak A, Mazur M, Gajewski M, Drozd K, Komorek A, Przybyłek P (2016) Sandwich structured composites for aeronautics: methods of manufacturing affecting some mechanical properties. Int J Aerosp Eng. https://doi.org/10.1155/2016/7816912

Graesser EJ, Wong CR (1992) The relationship of traditional damping measures for materials with high damping capacity: a review mechanics andmechanisms of material damping. ASTM STP 1169:316–343. https://doi.org/10.1520/stp17969s

Joseph SV, Mohanty SC (2019) Free vibration and parametric instability of viscoelastic sandwich plates with functionally graded material constraining layer. Act Mech 230(8):2783–2798. https://doi.org/10.1007/s00707-019-02433-8

Jones DI (2001) Handbook of viscoelastic vibration damping. Wiley, New York

Joseph SV, Mohanty SC (2019) Temperature effects on buckling and vibration characteristics of sandwich plate with viscoelastic core and functionally graded material constraining layer. J Sandw Struct Mater 21(4):1557–1577. https://doi.org/10.1177/1099636217722309

Zienkiewicz OC, Taylor RL, Taylor RL (2000) The finite element method: solid mechanics, vol 2. Butterworth-heinemann, Oxford

Papazafeiropoulos G (2022) Neural network optimization. MATLAB Central File Exchange. https://www.mathworks.com/matlabcentral/fileexchange/102709-neural-network-optimization. Accessed 20 Sept 2022

Papazafeiropoulos G (2022) Neural network optimization (NNO) algorithm. GitHub Repository https://github.com/GeorgePapazafeiropoulos/NNO-Neural-Network-Optimization. Accessed 20 Sept 2022

Yun CB, Bahng EY (2000) Substructural identification using neural networks. Comput Struct 77(1):41–52. https://doi.org/10.1016/S0045-7949(99)00199-6

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prusty, J.K., Papazafeiropoulos, G. & Mohanty, S.C. Experimental Verification of the Neural Network Optimization Algorithm for Identifying Frequency-Dependent Constitutive Parameters of Viscoelastic Materials. J. Vib. Eng. Technol. 12, 2147–2173 (2024). https://doi.org/10.1007/s42417-023-00972-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-023-00972-y