Abstract

This paper focused on the effects of the flap with a tiny gap on the flow separation over the NPU-WA-180 airfoil. The effects of the geometric parameters of the flaps, such as the flap gap height, angle, and position, were investigated. The study showed that the flap can significantly improve the stall features of airfoil in a limited phase of angle of attack (AoA), and increase lift and reduce drag at a high AoA. It can increase the lift coefficient and drag coefficient in the case of high AoAs, and the angle range of the lift augmentation and drag reduction can reach more than 9°. Furthermore, an excessively large gap is not conducive to the improvement of the airfoil stall performance. The flap angle plays a key role in the airfoil stall characteristic. As the flap angle decreases, the angle range of improving airfoil stall characteristics becomes larger, the pitching moment increment becomes smaller. However, the maximum lift increment and the effect of the drag reduction will decrease. And the effects of the position of the flap on the airfoil performance were also studied. Considering the maximum lift coefficient and drag coefficients in large AoA, the Type1 installed at the 0.7c position has the best effect; from the perspective of delayed stall, the Type1 installed at the 0.6c position has the best delay effect. These results can provide the data and theoretical support for the flap application in engineering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Biomimetic engineering has stimulated a new area of flow control by combining two different concepts of biology and fluid mechanics. Choi et al. [1] discussed some recent biomimetic flow control results for aerodynamic performance enhancement and skin-friction reduction. Chen et al. [2] proposed a novel biomimetic drag reduction surface, and conducted water tunnel experiments to clarify its efficiency and mechanism combining computational fluid dynamics (CFD) analysis. The researchers [3, 4] conducted a wing reconstruction with reference to free flying birds, and investigated the aerodynamics performance of the wing/airfoil by numerical simulation.

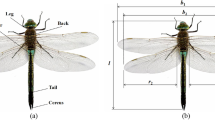

In flight of birds, the feathers on the upper surface of the wings stand up, while birds land (Fig. 1). Meyer et al. [5] and Schatz et al. [6] conducted detailed experimental and numerical investigations on the mechanism of feather movement and its aerodynamic characteristics. The results showed that the flap prevented the development of the reversed flow from the trailing edge to the suction peak position, bringing benefit of the flow separation delay.

There is a body of research focused on the effect of the upper surface flap on flow separation. Johnston et al. [7, 8] designed a lift-enhancing effector device, which was arranged on the upper surface of the airfoil at different angles. The results showed that the device could increase the lift and stall angle of attack (AoA). Kernstine et al. [9] explored the influence of parameters of passive flap on the flow separation, including its size, chord placement, configuration, material, etc. Bramesfeld et al. [10] designed a high-lift device, and investigated the influence of different flap positions and multiple flaps on the pressure distribution of the airfoil. Schlüter [11, 12] placed a passive flap on the different airfoils. The experiments showed that the flap could improve the stall characteristics. Traub et al. [13] studied the effect of several spoiler geometric parameters by water tunnel experiments. The experiments showed that the device could improve the stall characteristics. Wang [14] designed a self-activated flap to place the flap to the wing of the aircraft. The experiments showed that the flap could improve the stall characteristics. Montefort et al. [15] described a thin-wing vibration control method using an array of small flexible flaps attached near the leading edge on the suction surface to manipulate the leading edge vortex structures. Brücker et al. [16] carried out research on the effects of self-adaptive hairy flaps on the stall delay of an airfoil in its ramp-up motion. Liu et al. [17] designed a device to extend the trailing edge of NACA0012 airfoil. The experiments showed that the lift coefficient was significantly increased. Zhuang et al. [18] used morphed trailing-edge flap (MTEF) to control the aerodynamic performance of large wind turbine blades and found that MTEF could significantly change the pressure distribution and air flow.

The above research showed that flap could be used as a viable method of lift enhancement and stall characteristics improvement. Nevertheless, it can still be considered as a relatively novel method, and therefore, it is worthy of further study. Particularly, the flap with gap has not been studied in detail.

Therefore, the effects of flap with gap on the aerodynamic performance of the airfoil were experimentally studied. The influences of key geometry parameters (such as gap height, angle, and position) on the lift, drag, and pitching moment coefficients were explored in detail. This research attempts to explore the flow mechanism of the flap with gap, and at the same time provides theoretical and data basis for the flap with gap in aeronautical engineering application.

2 Equipment and Procedure

The experiments were performed in the NF-3 low-speed wind tunnel, at Northwestern Polytechnical University, China. The turbulence intensity of the wind tunnel was 0.045%, and the test section size was 1.6 m × 3.0 m.

In this work, the study was inspired by the wing shapes of birds during takeoff and landing, and hoped to study the effects of the trailing-edge flap with gap on aerodynamic forces at large AoAs. When birds take off and land, the flow separation will raise the feathers on the trailing edge of the wings, and the raised feathers inhibit the development of the separation flow and play a certain role in flow control. In this condition, bird wings present typical trailing-edge separation characteristics. Therefore, we selected the trailing-edge separation airfoil for this research. The NPU-WA-180 airfoil used in this experiment is a typical trailing-edge separated airfoil. The span length of the airfoil was b = 1.6 m and the chord length was c = 0.6 m. The experimental wind speed was 27.4 m/s, and the corresponding experimental Reynolds number was Re = 1.1 × 106. During the experiments, if the AoA is greater than 8°, the AoA interval is one-degree; otherwise, a two-degree interval is used. Considering the effect of the flow in the corner area of the wind tunnel sidewall on the two-dimensional flow of the model when the flow is separated, the experimental model was designed as three segmentations in this article, as shown in Fig. 2a. The middle section of the model used for force measurement in the balance was made of metal, while the two sides of the model were made of wood. Meanwhile, taking the specific conditions of the experiment into account, that were, the limits of the size and range of the balance, the span length of the middle force measurement section was designed to 400 mm, and the span lengths of the other two sections were all 599 mm with 1 mm gap with the middle section.

In the experimental model designed in this work, the middle metal section is used to measure aerodynamic force, which is divided into upper and lower halves. First, install the lower half, then install the balance, and finally cover the upper half to realize the effect of burying the balance in the metal section. The two sides are wooden models, and its profile shape is consistent with the metal section, which is used to ensure the two-dimensional flow through the metal section. In addition, there is a gap of less than 0.5 mm between the metal section and the wood section model. Through a special structure, it can not only ensure that the flow field is not damaged, but also ensure that the balance can only measure the aerodynamic force felt by the metal section. There was a steel frame inside the model to realize the connection of the three-segment model, that was, the model was a whole and could achieve the same AoA change. Fix the force measuring balance on the middle section of the steel frame, and then fix the metal part model on the balance, so that the balance can only be used to measure the force of the metal model in the middle. The measurement range and calibration results of the balance are shown in Table 1.

In this experiment, the 16-bit A/D acquisition card of NI Company was used to collect the voltage signal output of the balance, the sampling rate was set to 1000 Hz, and the sampling time was 5 s.

Six types of bionic flap were designed, including three gap lengths and three flap angles. The spanwise lengths of the fixed and windward surface are 200 mm, the chord lengths are 120 mm and 180 mm, respectively, as shown in Fig. 3. The thicknesses of the windward surface and the fixed surface are both 1.28 mm. In the wind tunnel experiments, eight small flaps were arranged at the same chord length to ensure that there are small pieces on the middle metal part and the wooden parts on both sides.

In this article, the plane where the flap faced the incoming flow was defined as the windward surface, and the plane fixed to the model was defined as the fixed surface. The small flap was arranged on the suction surface (or upper surface) of the airfoil through its fixed surface.

On the above basis, the included angles between the windward and fixed surfaces are changed to 17° and 7°, forming two flaps. Similarly, the gap heights between the windward and fixed surface are changed to 1.0 mm and 1.5 mm, forming two flaps. The geometric information of the six types of bionic flaps is shown in Table 2.

3 Results and Discussion

The influence of parameters including the gap height, angle, and position of bionic flaps on the static aerodynamic characteristics of airfoil was discussed in this section. The clean airfoil without bionic flap was denoted as "Baseline".

3.1 Effect of Flap Gap

The purpose of this article was to use the flap to improve the aerodynamic characteristics of the stall phase of the airfoil, so it was necessary to obtain the flow separation information of the airfoil. Unfortunately, only the aerodynamic force of the experimental model was collected in this experiment, and the surface pressure information of the model was not obtained. Considering that the trailing-edge separation airfoil was used in this work, the Kirchhoff flow theory [19] was used to analyze trailing-edge separation. A specific case of this theory is to simplify the trailing-edge separation phenomenon into a simple model, as shown in the following equation:

where k is the slope of the normal force line, α0 is the zero-lift AoA, Cn is the normal force coefficient, and f is the position of the separation point. For the reference airfoil (Baseline), the airfoil separation point calculated using Eq. (1) is shown in Fig. 4.

The flow separation point position at stall AoA calculated according to Kirchhoff's theory is x/c≈0.77. To make the flap work near the stall, the flap needs to be installed near x/c = 0.77. In the research of this section, the flap position was placed at 0.7c on the upper surface to study the effects of flap gap on the aerodynamic characteristics of the airfoil.

The aerodynamic coefficients of the airfoil with different flap gap heights are shown in Fig. 5. The gap heights of the flap are 0 mm, 0.5 mm, 1.0 mm, and 1.5 mm, respectively. As can be seen from the figure, the flaps with three different gap heights can increase the pitching moment, and improve airfoil stall characteristics. The maximum lift coefficients of the four gap heights of 0 mm, 0.5 mm, 1.0 mm, and 1.5 mm are increased by 6.1%, 6.0%, 6.0%, and 3.6%, respectively. It can be seen that the lift enhancement abilities of the configurations with gap of 0 mm, 0.5 mm, and 1.0 mm are the same.

The drag reduction effect in large AoA phase is calculated using Eq. (2) in this work, which can be seen in Fig. 6

The circle marked in the figure is the stall AoA for each configuration. In the large AoA range, ideal drag reduction effects can all be obtained using the four flap configurations in this article. In the range of α < 16.5°, the configuration with a gap of 0.5 mm (Type1) has the best drag reduction effect, which can reduce up to 14.53%. While when α > 16.5°, the configuration with a gap of 1.0 mm (Type 4) shows a better drag reduction effect. In the range of α ≥ 16.0°, the configuration with a gap of 0 mm (Type0) has the worst drag reduction effect, due to that the gap at large AoA can leak a part of the separated flow. In terms of Clmax and Cd in the large AoA range, we consider that the configuration with a gap of 0.5 mm (Type1) is the best. Therefore, the flap gap is set to 0.5 mm in Sects. 3.2 and 3.3.

To better analyze the effects of small flaps on the aerodynamic characteristics of the airfoil, the difference of aerodynamic coefficient curves is plotted here for further analysis and discussion. The differences of the aerodynamic coefficient curves of the airfoil with different flap gap heights are shown in Fig. 7.

The change of lift coefficient can be divided into three regions: reduction, transition, and augmentation, and the corresponding cut-off line angles are 8° and 13°, respectively. The cut-off line is the critical point at which a sudden change of the curve trend occurs in the increase or decrease area. Before α = 8°, the air flow through the airfoil surface is attached, and then, when it encounters a small flap, there will be a separation vortex under the flap, resulting in a drop in Cl. The amount of drop in Cl decreases slowly as the AoA increases. When the AoA is between 8° and 13°, the amount of drop in the Cl decreases rapidly as the AoA increases, and then, the Cl continuously increases. This is because there is a formed vortex between the upper surface of the flap and the airfoil, which is conducive to inhibit the further development of the separation vortex over the airfoil [20]. After α = 13°, due to the existence of the flap, two smaller separation vortexes are formed on the upper and lower surfaces of the flap, which plays a good role in weakening the development of stall flow on the airfoil, and the Cl is significantly improved. In the reduction and transition regions, the gap height has no significant effect on Cl.

The change of drag coefficient can be divided into two regions: reduction and augmentation, and the corresponding cut-off line angle is 11°. The amount of increase in Cd gradually decreases with the increase of the AoA, and drops to zero at 8°. It reaches the first extremal value at 11°, and then, it starts to oscillate. This is because 11° is an inflection point of the drag coefficient curve, as shown in Fig. 7b, where significant flow separation occurs on the airfoil surface. In the phase of large AoAs, the gap height has a certain effect on Cd.

The change of Cm can also be divided into two regions: the linear reduction and fluctuation reduction regions, and the corresponding cut-off line angle is 9°. This is because a vortex is formed between the flap upper surface and airfoil at 9°, which causes the pitching moment coefficient to fluctuate.

For the flap with gap, the gap heights of 0.5 mm has the smallest decrease in lift at a small AoA, and the maximum increase in lift and the largest decrease in drag at a high AoA, which is also the best one. The higher the flap gap height is, and the weaker the ability to improve the airfoil stall characteristics becomes. Within the current limited range of gap height variation, the influence of gap height variation on airfoil aerodynamic characteristics is not evident.

3.2 Effect of Flap Angle

The variations of the aerodynamic coefficients of the airfoil with different flap angles are shown in Fig. 8. Here, the flaps with the same gap height (0.5 mm) were located at 70%c on the suction surface of the airfoil trailing edge according to Kirchhoff's flow theory in Sect. 3.1, and the angles of the flap are 7°, 14°, and 17°, respectively. As can be seen, the flaps of three different angles can increase the pitching moment, and improve airfoil stall characteristics. However, the price of both the reduction in lift, and the increase in drag and pithing moment at a small AoA is necessary. The maximum lift coefficients of bionic flap with θ1 = 7.0°, θ2 = 14°, and θ3 = 17° are increased by 4.2%, 6.0%, and 5.9%, respectively, and the drag coefficients are decreased by 3.6%, 11.6%, and 9.4%, respectively.

The differences of the aerodynamic coefficients of the airfoil with different flap angles are shown in Fig. 9. As can be seen from the figure, the change of lift coefficient can be divided into three regions: reduction, transition, and augmentation, and the corresponding cut-off line angles are 8.0° and 13.0°, respectively. In the reduction region, the flap angle is smaller, and the amount of drop in Cl is smaller; in the transition region, the flap angle is smaller, and the initial AoA of improving lift is smaller; in the augmentation region, the flap angle is smaller, the ability to increase lift becomes weaker. The effective AoA range for improving the lift characteristics can reach more than 8°. The flap angle has a significant effect on Cl.

The change of drag coefficient can be divided into two regions: reduction and augmentation, and the corresponding cut-off line angle about is 11°. The flap angle is smaller, the angle at which the amount of increase in the drag coefficient drops to zero is smaller, but the angle at which the change of the drag coefficient reaches the first extreme value is still 11°, and then, the drag coefficient begins to oscillate. The effective AoA range for reducing the drag can reach more than 11°. The flap angle has a significant effect on Cd.

The change of the pitching moment coefficient can also be divided into two regions: the linear reduction and fluctuation reduction regions, and the corresponding cut-off line angle is 9°. The flap angle is smaller, and the amount of increase in the pitching moment coefficient is smaller. The flap angle has a significant effect on the pitching moment coefficient.

The flap angle is smaller, the initial AoA to improve airfoil stall characteristics is smaller, and the initial AoA to reduce the drag is also smaller. At the same time, the angle of the flap is smaller, the range of improving airfoil stall characteristics is larger, and the pitching moment increment is smaller. However, the maximum lift coefficient increment will decrease, and the effect of the drag reduction will also decrease. For the improvement of airfoil stall characteristics, the flap angle is a key factor.

3.3 Effect of Flap Position

It can be seen from Sect. 3.2 that the best control effect can be achieved when the angle of flap is 14°. Therefore, a flap with an angle of 14° was used to study the effects of the flap installation position on the aerodynamic characteristics of the airfoil in this section. As in Sect. 3.2, the gap of flap is 0.5 mm. The flap positions are 60%c, 70%c, and 80%c on the suction surface of the airfoil, called P1, P2, and P3, respectively. The variations of the aerodynamic coefficients of the airfoil with different flap positions are shown in Fig. 10. As can be seen, the flaps of three different positions can increase Cm, reduce Cd, and increase Cl at a large AoA.

The differences of the aerodynamic coefficients of the airfoil with different flap positions are shown in Fig. 11. As can be seen from the figure, the change of lift coefficient can be divided into three regions: reduction, transition, and augmentation, and the corresponding cut-off line angles are 8° and 13°, respectively. In the augmentation region, the flap is too close to the trailing edge, and the effect in the lift increase is significantly weaker, which is not conducive to improve the airfoil stall characteristics. The change of drag coefficient can be divided into two regions: reduction and augmentation. The flap is closer to the trailing edge, and the range of AoA to decrease the drag is larger. The change of the pitching moment coefficient can also be divided into two regions: the linear reduction and fluctuation reduction regions, and the corresponding cut-off line angle is not 9°.

The P2 is the best. This is because the P3 is too close to the trailing edge, which has limited inhibitory effect on the development of vortex separation, and P3 can only increase the lift within the finite AoA. The P1 is too close to the maximum thick of airfoil, which is a blocking effect for airflow over the airfoil. The initial AoA to improve airfoil stall characteristics and initial AoA to reduce the drag are largest. For the improvement of airfoil stall characteristics, the flap position is a key factor.

4 Further Analysis

The effects of the gap, angle, and installation position of the flap on the overall aerodynamic force of the airfoil were analyzed in detail earlier in the article. It is found that the flap can significantly improve the aerodynamic force during the stall and post stall stages. An in-depth analysis of its impact details and reasons were conducted in this section.

It can be seen from Fig. 8 that the flap angle has almost no effect on the slope of the lift line of the linear section, while it moves the linear section of the lift line downward as a whole. The lift coefficient Cl0 at 0° was used to quantitatively evaluate this downward shift. Additionally, the effect of flap angle on the maximum lift coefficient has been discussed in Sect. 3.2. In this section, the maximum lift coefficient is also redrawn to express this effect more clearly, as shown in Fig. 12. The reason for the effect on the overall lift coefficient of the linear segment is that the flap angle changes the camber of the airfoil. In this experiment, flaps are installed on the upper surface of the airfoil, which makes the airfoil bend upward. Therefore, the linear segments of the lift line of all configurations with flaps are moved downward as a whole in this experiment. It can be seen from Sect. 3.2 that the main reason that the flap angle has an effect on the maximum lift coefficient is to change the flow pattern of the reference airfoil in the separation flow stage.

Unlike the effect of flap angle, the installation position of the flap has an effect on the slope of the lift line and the maximum lift coefficient, as shown in Fig. 13. The reason for the effect on the slope of the lift line is that the installation position of the flap changes the thickness distribution of the airfoil, and the thickness of the airfoil will affect the slope of the lift line in turn. It can be seen from Sect. 3.3 that the main reason that the flap installation position affects the maximum lift coefficient is to change the flow pattern of the reference airfoil in the separation flow stage.

The flow separation points in different configurations were calculated using Eq. (1), as shown in Fig. 14. It can be seen that after using the flap, the separation point change curve with the AoA moves significantly to the right, indicating that the flap installed on the suction surface of the airfoil used in this article can significantly delay separation. From the perspective of delayed separation, the Type1 installed at the 0.6c position has the best effect (the separation point curve is at the far right).

The stall AoA and the AoA corresponding the maximum lift coefficient in different configurations are shown in Table 3. The stall AoA of the Type1 configuration installed at the 0.6c position is 18°, which is greater than the stall AoA of other configurations, and the delay effect is the best, which is consistent with the conclusion of Fig. 13.

We conducted a more in-depth study on the influence of flap on typical aerodynamic characteristics (lift line slope, maximum lift coefficient, stall AoA, etc.) in this section. The flap installed on the suction surface changes the camber of the airfoil, resulting that the linear section moves downward as a whole, and also changes the thickness distribution of the airfoil, which changes the slope of the lift line. In terms of the maximum lift coefficient and drag coefficients in large AoA, the Type1 installed at the 0.7c position has the best effect (Sects. 3.1, 3.2, and 3.3); while from the perspective of delayed stall, the Type1 installed at the 0.6c position has the best delay effect.

5 Conclusions

The effects of flap with a tiny gap on airfoil aerodynamic performance were studied by low speed wind tunnel experiments. The conclusions were as follows:

-

(1)

The flaps can improve the maximum lift coefficient of airfoil up to more than 5%, and the effective range of AoA to improve lift characteristics up to more than 9°. The configuration with a gap of 0.5 mm (Type1) is the best. Excessive gap height of flaps is not conducive to the improvement of airfoil stall characteristics.

-

(2)

The flap angle is smaller, the initial AoA to improve airfoil stall characteristics is smaller, and the range of improving airfoil stall characteristics is larger. However, the maximum lift coefficient increment will decrease, and the effect of the drag reduction will also decrease.

-

(3)

The bionic flap position has a significant effect on the airfoil stall characteristics. The flap needs to be installed near the separation point. In terms of the maximum lift coefficient and drag coefficients in large AoA, the Type1 installed at the 0.7c position has the best effect; from the perspective of delayed stall, the Type1 installed at the 0.6c position has the best delay effect.

-

(4)

The gap, angle, and installation position of the flap have a significant effect on the airfoil aerodynamic characteristics. The mechanism is that the flap has the effect of changing the camber and thickness distributions of the basic airfoil, which can affect the maximum lift coefficient, stall AoA, and the slope of the lift line, etc.

The next research plan will be carried out from the following two aspects: on the one hand, for the research on bionic airfoils, the flaps will undergo corresponding deformation or displacement changes with the change of the surface aerodynamic force; on the other hand, we will develop a three-dimensional bionic airfoil wing research to further study the landing configuration of bird wings.

Abbreviations

- C :

-

Chord

- Cl :

-

Lift coefficient

- Cd :

-

Drag coefficient

- Cm :

-

Pitching moment coefficient

- Cn :

-

Normal force coefficient

- α :

-

Angle of attack

- α 0 :

-

Zero-lift angle of attack

- Re :

-

Reynolds number

- k :

-

Slope of the normal force line

- f :

-

Position of the separation point

- θ :

-

Flap angle

References

Choi H, Park H, Sagong W, Lee S (2012) Biomimetic flow control based on morphological features of living creatures. Phys Fluids 24:121302

Chen HW, Rao FG, Shang XP, Zhang DY, Hagiwara I (2013) Biomimetic drag reduction study on herringbone riblets of bird feather. J Bionic Eng 10:341–349

Carruthers AC, Walker SM, Thomas ALR, Taylor GK Aerodynamics of aerofoil sections measured on a free-flying bird. Proc. IMechE, Part G: J. Aerospace Engineering, 224: 855–864, 2009.

Ge CJ, Ren LQ, Liang P, Zhang CC, Zhang ZH (2013) High-lift effect of bionic slat based on owl wing. J Bionic Eng 10:456–463

Meyer R, Hage W, Bechert DW, Schatz M, Knacke T, Thiele F (2007) Separation control by self-activated movable flaps. AIAA J 45(1):191–199

Schatz M, Knacke T, Thilele F, Meyer R, Hage W, Bechert DW (2004) Separation control by self-activated movable flaps. AIAA Paper 2004–1243.

Johnston J, Gopalarathnam A (2012) Investigation of a bio-inspired lift-enhancing effector on a 2d airfoil. Bioinspir Biomim 7:036003

Johnston J, Gopalarathnam A, Edward J Experimental investigation of bio-inspired high lift effectors on a 2-d airfoil. AIAA Paper, 2011–3791, 2011.

Kernstine KH, Moore CJ, Cutler A, Mittal R Initial Characterization of Self- Activated Movable Flaps. AIAA Paper 2008–369, 2008.

Bramesfeld G, Maughmer MD (2002) Experimental investigation of self-actuating, upper- surface, high-lift-enhancing effectors. J Aircr 39(1):120–124

Schlüter JU Lift enhancement at low Reynolds numbers using pop-up feathers. San Antonio, Texas, USA, AIAA Paper, 2009–4195, 2009.

Schlüter JU (2010) Lift enhancement at low Reynolds numbers using self-activated movable flaps. J Aircr 47(1):348–351

Traub LW, Jaybush L (2010) Experimental investigation of separation control using upper-surface spoilers. J Aircr 47(2):714–717

Wang CJ, Schlüter J (2012) Stall control with feathers: self-activated flaps on finite wings at low reynolds numbers. CR Mec 340:57–66

Montefort J, Pohl N, Liu TS, Gregory J, Crafton J (2013) Thin-wing vibration control using flexible fins. AIAA J 51(9):2218–2230

Brücker C, Weidner C (2014) Influence of self-adaptive hairy flaps on the stall delay of an airfoil in ramp-up motion. J Fluids Struct 47:31–40

Liu TS, Montefort J, Liou W, Pantula SR, Shams QA (2007) Lift enhancement by static extended trailing edge. J Aircr 44(6):1939–1947

Chuang Z, Yang G, Zhu YW, Hu D (2020) Effect of morphed trailing-edge flap on aerodynamic load control for a wind turbine blade section. Renewable Energy 148:964–974

Thwaites B, Street RE Incompressible Aerodynamics, Oxford University Clarendon Press, 1960.

Hao LS, Gao YW, Wei BB, Song K, Numerical Simulation of Flow over Bionic Airfoil[J]. International Journal of Aerospace Engineering, article 5556463, 2021.

Acknowledgements

The present work is supported by National Natural Science Foundation of China (11502214) and the Fundamental Research Funds for the Central Universities (D5000200685). The authors would like to express their gratitude to Professor Yuqin Jiao in Northwestern Polytechnical University for his valuable guidance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hao, L., Gao, Y. & Wei, B. Experimental Investigation of Flow Separation Control over Airfoil by Upper Surface Flap with a Gap. Int. J. Aeronaut. Space Sci. 23, 859–869 (2022). https://doi.org/10.1007/s42405-022-00488-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42405-022-00488-x