Abstract

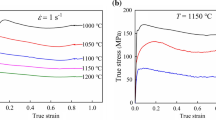

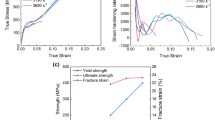

The effect of temperature on the tensile properties and deformation mechanism of GH4169 alloy has been systematically studied over a wide range of room temperature (RT) to 1000 °C. The results indicate that the stress–strain curve of the alloy shows serrations at 200–600 °C, and the character of the serrations changes from type A to type B and then to type C at different temperatures. The ultimate tensile strength of the alloy decreases gradually from RT to 600 °C. The yield strength decreases slowly from RT to 700 °C but decreases rapidly above 800 °C. Transmission electron microscopy analysis relieves that the primary deformation mechanism of the alloy below 500 °C is Orowan bypass mechanism. At temperatures between 600 and 700 °C, the coordinated deformation of twins and cross-slip of dislocations are activated. The transformation of \(\upgamma^{\prime \prime }\) phase to δ phase above 650 °C will decrease the strength. The primary deformation mechanism above 800 °C transforms into the repeated shearing of \(\upgamma^{\prime \prime }\) by dislocations to form multiple stacking faults. Recrystallized grains were observed above 800 °C, and continuous dynamic recrystallization and discontinuous dynamic recrystallization were observed. The stress concentration caused by Nb-rich carbides is the cause of intracrystalline crack nucleation. At 700 °C, grain boundary crack sprouting is caused by the combined effect of slip band impact on grain boundaries and grain boundary dislocation plugging. The relationship between the serrated flow behavior and the deformation mechanism has been discussed based on the experimental results.

Similar content being viewed by others

References

G.Q. Wang, M.S. Chen, H.B. Li, Y.C. Lin, W.D. Zeng, Y.Y. Ma, J. Mater. Sci. Technol. 77 (2021) 47–57.

J. Yang, D. Liu, X. Zhang, M. Liu, W. Zhao, C. Liu, Int. J. Fatigue 133 (2020) 105373.

X. Yang, W. Li, J. Li, B. Xiao, T. Ma, Z. Huang, J. Guo, Mater. Des. 87 (2015) 215–230.

C. Silva, M. Song, M. Wang, K. Holliday, K. Leonard, G. Was, J. Busby, J. Nucl. Mater. 551 (2021) 152954.

J. Luo, W. Yu, C. Xi, C. Zhang, C. Ma, J. Alloy. Compd. 777 (2019) 157–164.

R.B. Bhavsar, A. Collins, S. Silverman, in: Superalloys, Rosharon, USA, 2001, pp. 1–9.

Y. Zhang, N. Liu, Z. Li, G.Q. Zhang, H. Yuan, W.Y. Xu, Z.J. Gao, J.W. Mi, Rare Met. 30 (2011) 401–404.

H. Xue, J.Q. Zhao, Y.K. Liu, C.X. Zhang, J.T. Luo, Trans. Nonferrous Met. Soc. China 30 (2020) 3287–3295.

N.Y. Ye, M. Cheng, S.H. Zhang, H.W. Song, H.W. Zhou, J. Iron Steel Res. Int. 26 (2019) 148–153.

Y.T. Chen, A.C. Yeh, M.Y. Li, S. Kuo, Mater. Des. 119 (2017) 235–243.

H. Lu, X. Jia, K. Zhang, C. Yao, Mater. Sci. Eng. A 326 (2002) 382–385.

X.P. Wei, W.J. Zheng, Z.G. Song, T. Lei, Q.L. Yong, Q.C. Xie, J. Iron Steel Res. Int. 20 (2013) 88–94.

S.H. Zhang, H.Y. Zhang, M. Cheng, Mater. Sci. Eng. A 528 (2011) 6253–6258.

Z. Gao, W. Guo, C. Zhang, J. Tan, Mater. Sci. Eng. A 682 (2017) 156–163.

L. Tan, Y. Li, W. Deng, Y. Liu, F. Liu, Y. Nie, L. Jiang, J. Alloy. Compd. 804 (2019) 322–330.

B. Wilthan, R. Tanzer, W. Schutzenhofer, G. Pottlacher, Rare Met. 25 (2006) 529–531.

Z.L. Tian, S.B. Jiang, Z.Z. Chen, H.S. Bao, Z.D. Liu, J. Iron Steel Res. Int. 24 (2017) 513–519.

T. Peng, Y. Wang, B. Yang, G. Yang, Mater. Sci. Eng. A 828 (2021) 142028.

P. Zhang, Y. Yuan, H. Yin, Y. Gu, J. Wang, M. Yang, G. Yang, X. Song, Metall. Mater. Trans. A 49 (2018) 1571–1578.

X. Liu, J. Fan, P. Zhang, J. Xie, F. Chen, D. Liu, R. Yuan, B. Tang, H. Kou, J. Li, J. Alloy. Compd. 869 (2021) 159342.

P. Maj, J. Zdunek, M. Gizynski, J. Mizera, K.J. Kurzydlowski, Mater. Sci. Eng. A 619 (2014) 158–164.

C. Fressengeas, A.J. Beaudoin, M. Lebyodkin, L.P. Kubin, Y. Estrin, Mater. Sci. Eng. A 400–401 (2005) 226–230.

H. Zhang, C. Li, Q. Guo, Z. Ma, Y. Huang, H. Li, Y. Liu, Mater. Sci. Eng. A 722 (2018) 136–146.

Y. Wang, W.Z. Shao, L. Zhen, C. Yang, X.M. Zhang, J. Alloy. Compd. 471 (2009) 331–335.

K. Kulawik, P.A. Buffat, A. Kruk, A.M. Wusatowska-Sarnek, A. Czyrska-Filemonowicz, Mater. Charact. 100 (2015) 74–80.

E. Pink, A. Grinberg, Mater. Sci. Eng. 51 (1981) 1–8.

T. Liu, X. Cheng, R. Luo, Y. Cao, H. Ding, L. Chen, Q. Wang, B. Zhang, J. Alloy. Compd. 891 (2022) 161992.

B. Reppich, P. Schepp, G. Wehner, Acta Metall. 30 (1982) 95–104.

R.C. Reed, Superalloys Fundam. Appl. (2006) No. 2, 33–120.

Z. Zhong, Y. Gu, Y. Yuan, Z. Shi, Metall. Mater. Trans. A 45 (2014) 343–350.

F. Pettinari, J. Douin, G. Saada, P. Caron, A. Coujou, N. Clément, Mater. Sci. Eng. A 325 (2002) 511–519.

T.L. Achmad, W. Fu, H. Chen, C. Zhang, Z.G. Yang, J. Alloy. Compd. 694 (2017) 1265–1279.

Y. Koizumi, T. Nukaya, S. Suzuki, S. Kurosu, Y. Li, H. Matsumoto, K. Sato, Y. Tanaka, A. Chiba, Acta Mater. 60 (2012) 2901–2915.

Y.J. Xu, D.Q. Qi, K. Du, C.Y. Cui, H.Q. Ye, Scripta Mater. 87 (2014) 37–40.

Y.F. Han, P. Deb, M.C. Chaturvedi, Met. Sci. 16 (1982) 555–562.

J.M. Oblak, D.F. Paulonis, D.S. Duvall, Metall. Trans. 5 (1974) 143–153.

G. Vanderschaeve, B. Escaig, Philos. Mag. A 48 (1983) 265–277.

Y. Gai, R. Zhang, J. Yang, C. Cui, J. Qu, Mater. Sci. Eng. A 842 (2022) 143079.

P. Zhang, Y. Yuan, Y.F. Gu, Y.Y. Dang, J.T. Lu, X.B. Zhao, J.C. Wang, C.Z. Zhu, C.X. Fan, Mater. Charact. 142 (2018) 101–108.

C.L. Hale, W.S. Rollings, M.L. Weaver, Mater. Sci. Eng. A 300 (2001) 153–164.

P. Zhang, Y. Yuan, S.C. Shen, B. Li, R.H. Zhu, G.X. Yang, X.L. Song, J. Alloy. Compd. 694 (2017) 502–509.

M. Daly, T.L. Burnett, E.J. Pickering, O.C.G. Tuck, F. Léonard, R. Kelley, P.J. Withers, A.H. Sherry, Acta Mater. 130 (2017) 56–68.

A. Pineau, A.A. Benzerga, T. Pardoen, Acta Mater. 107 (2016) 424–483.

F.D. León-Cázares, R. Schlütter, T. Jackson, E.I. Galindo-Nava, C.M.F. Rae, Acta Mater. 182 (2020) 47–59.

K. Chen, J. Dong, Z. Yao, T. Ni, M. Wang, Mater. Sci. Eng. A 738 (2018) 308–322.

Y.C. Lin, J. Deng, Y.Q. Jiang, D.X. Wen, G. Liu, Mater. Des. 55 (2014) 949–957.

P. Rodriguez, Bull. Mater. Sci. 6 (1984) 653–663.

G.M. Han, C.G. Tian, C.Y. Cui, Z.Q. Hu, X.F. Sun, Acta Metall. Sin. (Engl. Lett.) 28 (2015) 542–549.

S.A. Nalawade, M. Sundararaman, R. Kishore, J.G. Shah, Scripta Mater. 59 (2008) 991–994.

A. Sarkar, A. Nagesha, P. Parameswaran, R. Sandhya, K. Laha, Mater. Sci. Eng. A 660 (2016) 213–224.

A.H.V. Pavan, R.L. Narayan, S.H. Li, K. Singh, U. Ramamurty, Mater. Sci. Eng. A 832 (2022) 142486.

X. Wang, G. Han, C. Cui, S. Guan, J. Li, G. Hou, Y. Zhou, X. Sun, J. Mater. Sci. Technol. 35 (2019) 84–87.

K.B.S. Rao, V. Seetharaman, S.L. Mannan, P. Rodriguez, High Temp. Mater. Process. 7 (1986) 63–81.

J.W. Christian, S. Mahajan, Prog. Mater. Sci. 39 (1995) 1–157.

C.V. Rao, N.C. Santhi Srinivas, G.V.S. Sastry, V. Singh, Mater. Sci. Eng. A 742 (2019) 44–60.

Acknowledgements

This work was financially supported in part by the State Key Lab of Advanced Metals and Materials in University of Science and Technology Beijing (No. 2022-Z21), China Postdoctoral Science Foundation (No. 2019M661738), Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. SJCX22_1860), and Natural Science Foundation of Jiangsu Province (No. BK20220548).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Rui Luo is a youth editorial board member for Journal of Iron and Steel Research International and was not involved in the editorial review or the decision to publish this article. All authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, Q., Liu, T., Wei, Jb. et al. Temperature dependence in tensile properties and deformation behavior of GH4169 alloy. J. Iron Steel Res. Int. 30, 2566–2581 (2023). https://doi.org/10.1007/s42243-023-01050-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01050-z